Negative electrode sheet module and preparation method thereof, method for manufacturing battery and battery

A technology for negative electrode sheets and components, which is applied in the field of negative electrode sheet components and their preparation, can solve the problems of battery safety impact, battery needs to be improved, prone to dislocation, etc., to improve product quality, safety and other performance improvements, and improve stacking efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

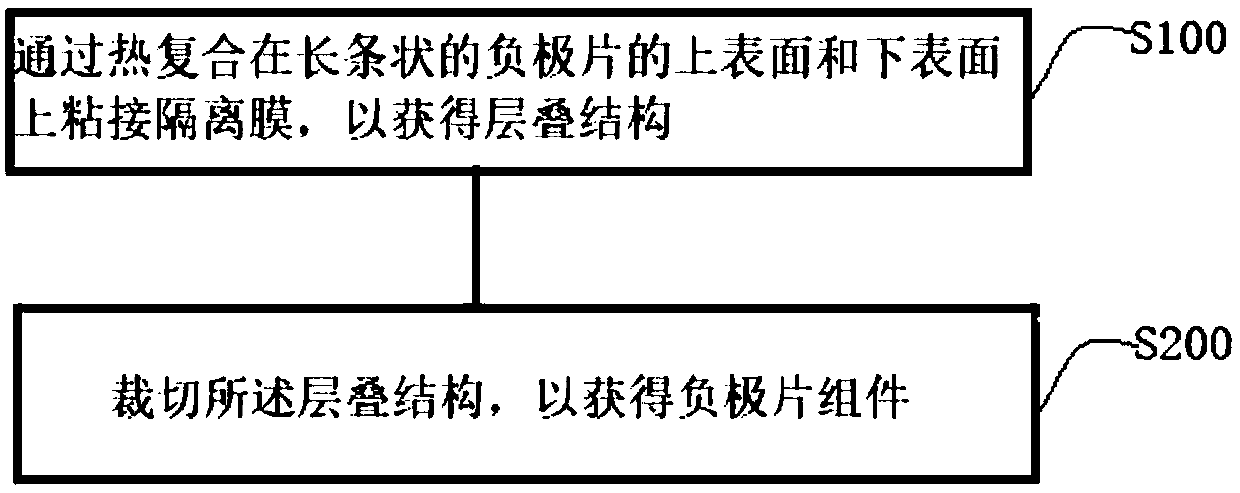

[0052] Preparation steps:

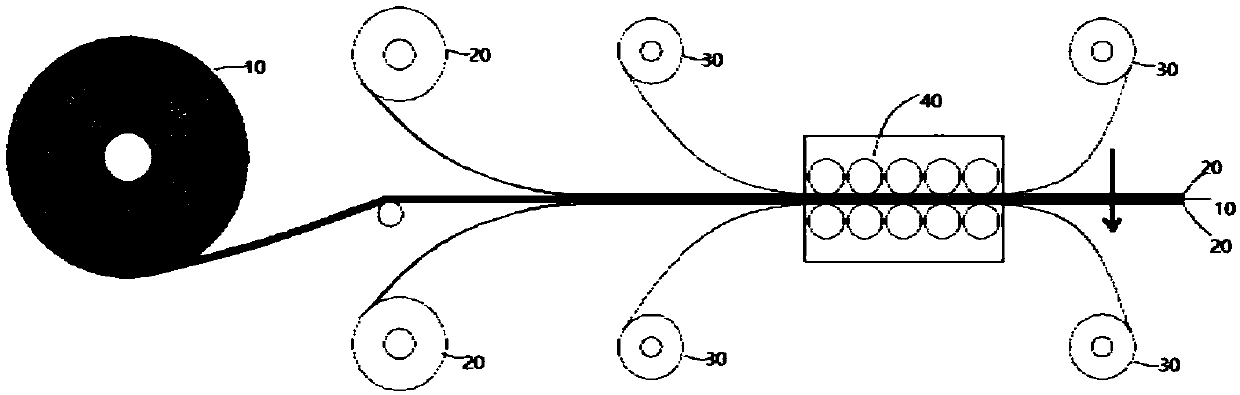

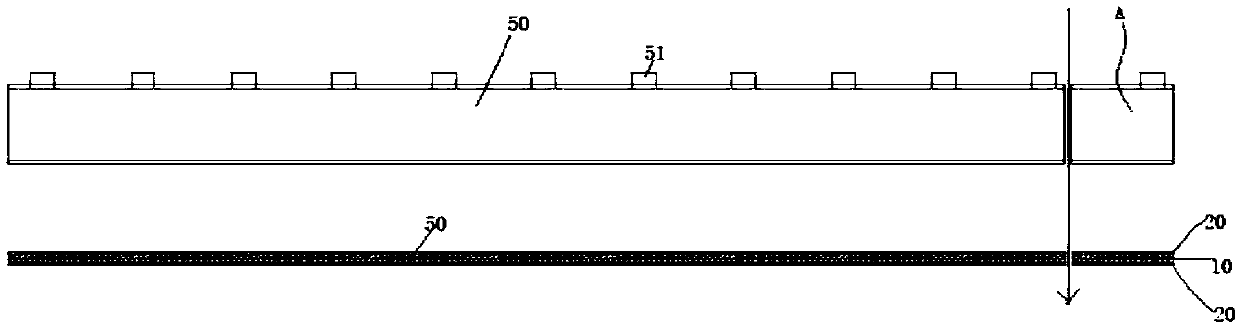

[0053] 1. Reference figure 2 In the process flow shown, the negative electrode sheet 10, the separator 20 and the protective film 30 are all provided in the form of rolls, and there is a hollow cup in the middle, and the negative electrode sheet 10, the separator 20 and the protective film 30 are directly assembled on the thermal compound machine. On the hanging shaft, the middle is the negative electrode sheet 10, and the two sides of the negative electrode sheet 10 are the separator 20 and the protective film 30 respectively. Position 40 (such as hot rolling furnace), after hot rolling, the separator is adsorbed on the surface of the negative electrode sheet, and the protective film will be wound and recycled by the reel for reuse. Among them, the load of the hot roll pressing was 2000 kgf, the temperature was 90° C., and the speed was 30 m / min. Then, the obtained stacked structure is cut according to a predetermined size to obtain a negative e...

Embodiment 2- Embodiment 10

[0059] The specific preparation steps and testing methods are the same as those in Example 1, except that the hot rolling parameters for preparing the negative electrode sheet assembly and the hot pressing parameters for stacked products are shown in Table 1.

[0060] Table 1

[0061]

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com