Soft and hard roller continuous cyclic bending method and device

A soft and hard rolling and bending technology, applied in the field of preparation of micro-nano space structure, can solve the problems of difficult production control, poor effect, low efficiency, etc., and achieve the effect of smooth processing, ensuring process quality, and efficient and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

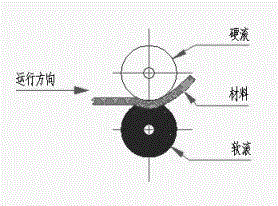

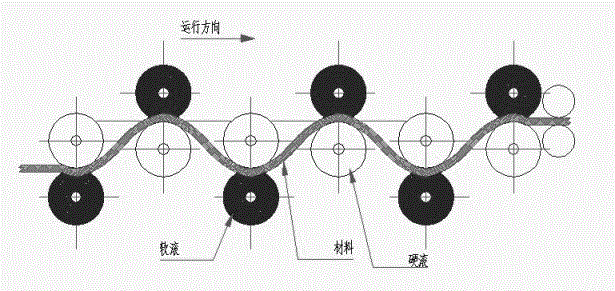

Method used

Image

Examples

Embodiment 1

[0026] The hard rollers are made of carbon steel or other high-hardness alloy materials, and the surface is subjected to heat treatment such as quenching; the soft rollers are made of heat-resistant silicone rubber with a Shore hardness of 60A; AZ31 magnesium alloy materials are continuously passed through 10 groups of units at 130°C~350°C Two-way bending combined rolls composed of rolls, adjust the axial distance between the soft and hard rolls, so that the rolling deformation of the magnesium alloy material passing through the unit is 0.12, and the distance between the rolling shafts of each group of units is equal, after being straightened by the straightening roll, annealed at 300 ° C After recrystallization for 30 minutes, the surface grain size is refined, which can reach about 1 / 3~1 / 4, and the grain size is distributed in a gradient along the thickness direction, and the surface texture strength is also weakened compared with the neutral layer, which can be improved Mate...

Embodiment 2

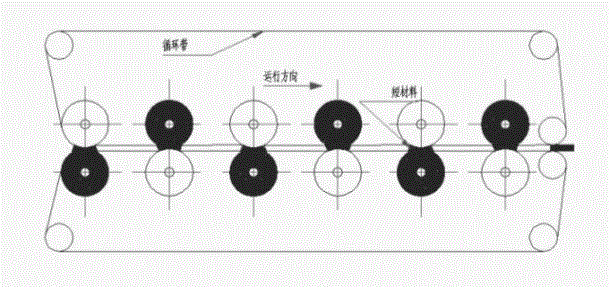

[0028] In Example 1, if the material to be processed is a short material. Such as image 3 As shown, add the circulation belt to the mechanism, the circulation belt is made of Teflon or steel belt, and graphite or other additive materials are coated between them, and other processing parameters are the same as in Example 1, and the short material and the long material can be processed.

[0029] Replace AZ31 in examples 1 and 2 with gold Au, silver Ag, copper Cu, aluminum Al, iron Fe, magnesium Mg, nickel Ni, lead Pb or their respective alloys; hard rolling adopts various carbon steels, alloy materials, ceramics Material, hard plastic, stone and other hard materials, the soft roller adopts various heat-resistant silicone, fluorine rubber, perfluororubber and other heat-resistant rubber or other heat-resistant materials, by choosing a reasonable combination of soft and hard rollers; cycle The belt can be made of steel Fe, copper Cu and other metals or their alloy belts; it can ...

Embodiment 3

[0031] The pole plate of the storage battery is a porous material. The positive electrode material of the lead storage battery is 68mm long, 45mm wide, and 2.5mm thick, and the negative electrode material is 68mm long, 45mm wide, and 1.9mm thick. Or other soft materials, hardness 30~60A, diameter 60mm. The material is passed through a two-way bending combination roll composed of 20 sets of unit rolls. Adjust the roller clearance 0.2mm ~ 1.5mm. Wrap the processed positive electrode sample with ultra-fine glass fiber AGM material with a thickness of 1 mm, clamp the processed negative electrode material on both sides, pack it into a sandwich-structured battery sample, use three-stage charging and discharge, and record the discharge capacity. At the same time, make a group of comparison specimens with the same structure composed of unprocessed materials, and use the same charging and discharging method. Such as Figure 4 , 5 , the experiment proves that the capacity of the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com