Impact-resistant reinforced mildew-proof acrylonitrile-butadiene-styrene copolymer material and preparation method thereof

A technology of styrene copolymer and acrylonitrile, which is applied in the field of polymers, can solve problems such as easy mold generation, easy carbonization and decomposition, and increased consumption of antibacterial agents, and achieves short-term high-efficiency sterilization and long-term sterilization. Processability, the effect of improving the anti-mold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

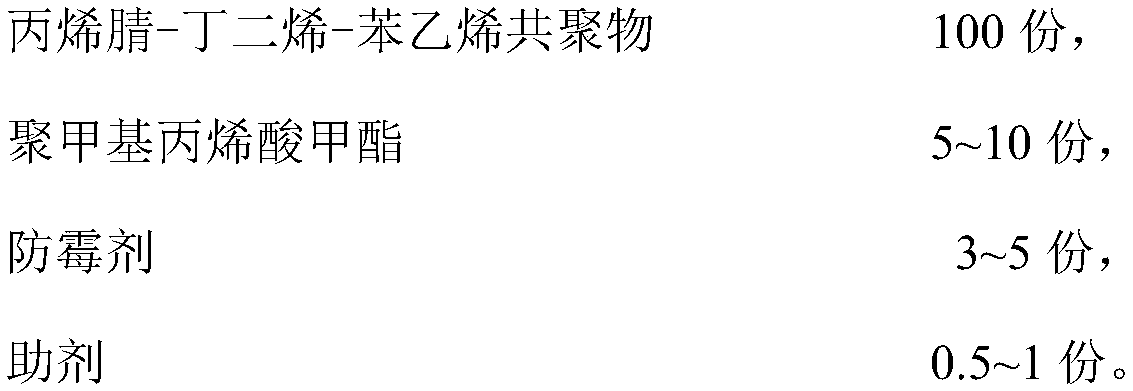

Method used

Image

Examples

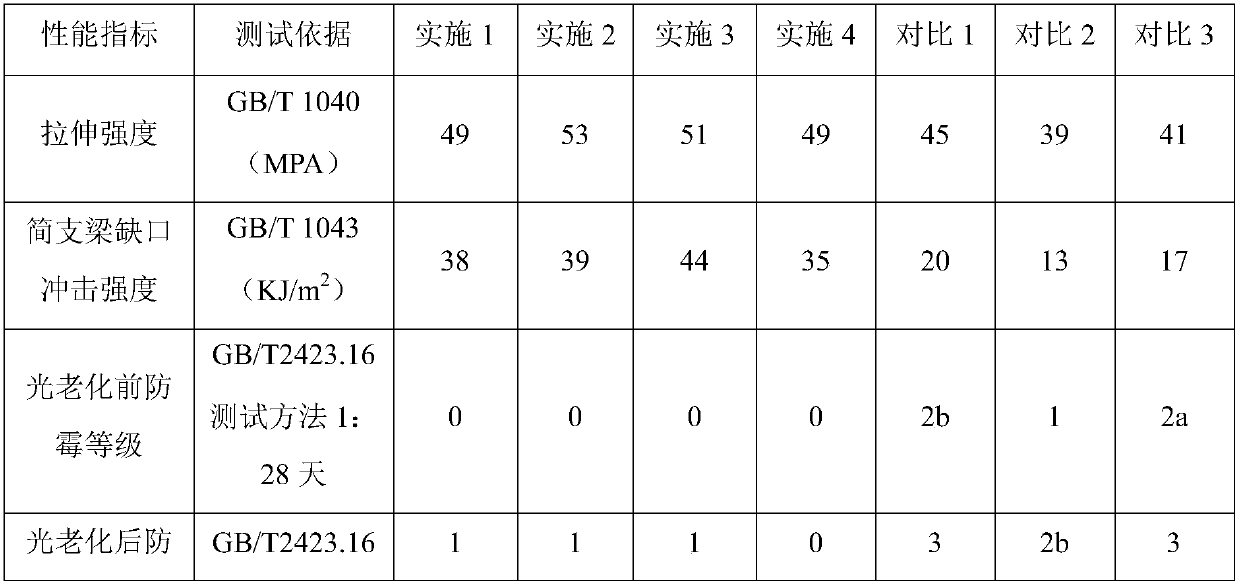

Embodiment 1

[0024] Weigh 100 parts of acrylonitrile-butadiene-styrene copolymer, 10 parts of polymethyl methacrylate, 3 parts of antifungal agent and 0.1 part of tetrakis[β-(3,5-di-tert-butyl-4-hydroxy Phenyl) propionic acid] pentaerythritol ester, 0.1 part of tris (2,4-di-tert-butylphenyl) phosphite, 0.3 part of montan wax, after high-speed mixing, a uniformly mixed material was obtained; the uniformly mixed material was Extrusion and granulation in a twin-screw extruder produces an impact-resistant reinforced anti-mold acrylonitrile-butadiene-styrene copolymer material, wherein the temperature of each zone of the twin-screw extruder is: 190 °C in zone I, 220 °C in zone II ℃, 230℃ in zone III, 230℃ in zone IV, 230℃ in zone V, 230℃ in zone VI, and 230℃ in the machine head.

Embodiment 2

[0026] Weigh 100 parts of acrylonitrile-butadiene-styrene copolymer, 8 parts of polymethyl methacrylate, 4 parts of antifungal agent and 0.15 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxy Phenyl) propionic acid] pentaerythritol ester, 0.15 part of tris (2,4-di-tert-butylphenyl) phosphite, 0.45 part of montan wax, after high-speed mixing, a uniformly mixed material was obtained; the uniformly mixed material was Extrusion and granulation in a twin-screw extruder produces an impact-resistant reinforced anti-mold acrylonitrile-butadiene-styrene copolymer material, wherein the temperature of each zone of the twin-screw extruder is: 190 °C in zone I, 220 °C in zone II ℃, 230℃ in zone III, 230℃ in zone IV, 230℃ in zone V, 230℃ in zone VI, and 230℃ in the machine head.

Embodiment 3

[0028] Weigh 100 parts of acrylonitrile-butadiene-styrene copolymer, 6 parts of polymethyl methacrylate, 5 parts of antifungal agent and 0.15 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxy Phenyl) propionic acid] pentaerythritol ester, 0.15 part of tris (2,4-di-tert-butylphenyl) phosphite, 0.45 part of montan wax, after high-speed mixing, a uniformly mixed material was obtained; the uniformly mixed material was Extrusion and granulation in a twin-screw extruder produces an impact-resistant reinforced anti-mold acrylonitrile-butadiene-styrene copolymer material, wherein the temperature of each zone of the twin-screw extruder is: 190 °C in zone I, 220 °C in zone II ℃, 230℃ in zone III, 230℃ in zone IV, 230℃ in zone V, 230℃ in zone VI, and 230℃ in the machine head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com