Combined reinforced anti-pull anchor rod device and construction method thereof

A construction method and anti-pull anchor technology, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the waste of steel, increase the amount of reinforcement for uplift piles and anti-floating anchors, and the strength of steel bars cannot be fully utilized To achieve the effect of avoiding the compactness of the construction surface, overcoming the lack of durability and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

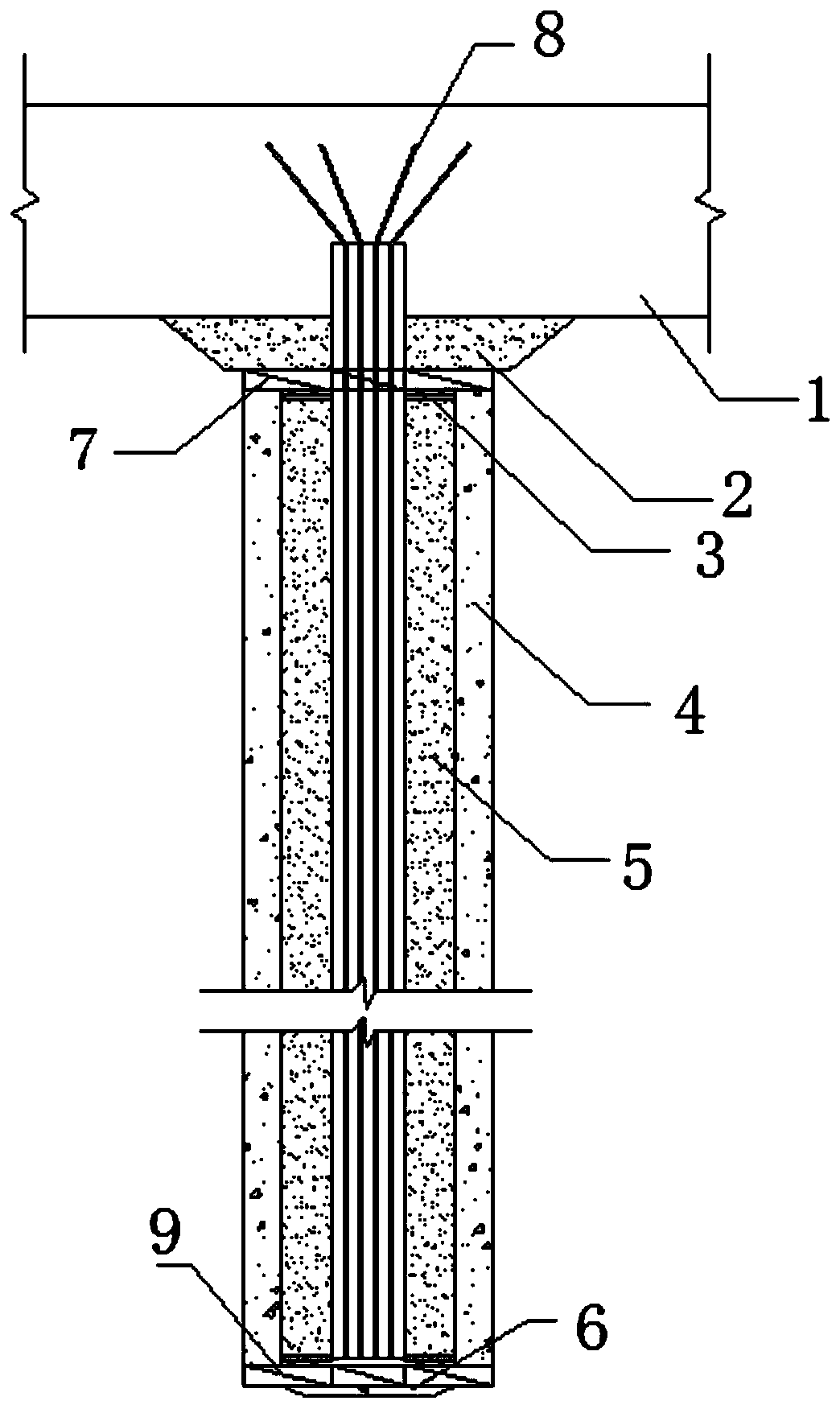

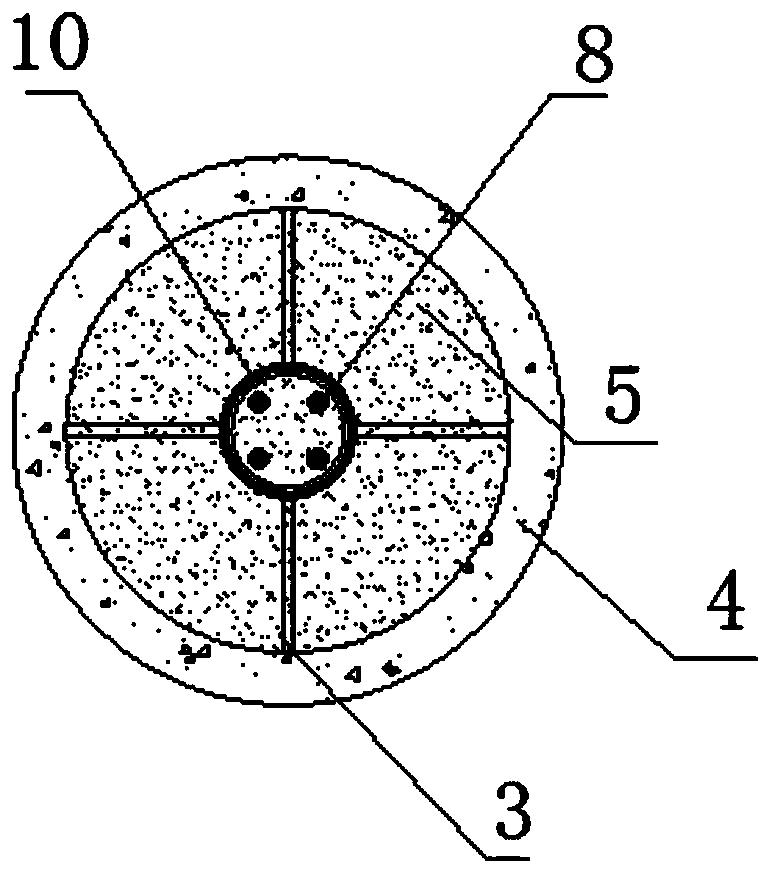

[0041] combine Figure 1 to Figure 2 As shown, the first embodiment provides a combined reinforced uplift anchor device, which includes: a concrete prefabricated pile body 4, a positioning bracket 3, a core tube 10 and several bars 8; the concrete prefabricated pile body 4 is provided with an upper end Plate 7 and lower end plate 9; the positioning bracket 3 is a cross centering bracket, a positioning hole (for installing the core pipe 10) is formed in the center of the positioning bracket 3, one of the positioning brackets 3 is fixed to the upper end plate 7 of the concrete prefabricated pile 4 The lower surface of the concrete prefabricated pile body 4 (inside the concrete prefabricated pile body 4), another positioning bracket 3 is fixed on the upper surface of the lower end plate 9 of the concrete prefabricated pile body 4 (located inside the concrete prefabricated pile body 4); Installed in the positioning hole of the positioning bracket 3 at the lower end plate 9, the up...

Embodiment 2

[0050] The second embodiment also provides a construction method for the combined reinforced anti-pull anchor device according to the first embodiment, which includes the following steps:

[0051] S1. Reasonably configure the length of the precast concrete piles according to the calculated bearing capacity, preferably single-section precast piles, and fix the positioning brackets 3 (precast concrete piles 4) on the upper end plate 7 and the lower end plate 9 of each section of the concrete precast pile The upper end plate 7 and the lower end plate 9 are respectively welded or bonded to the positioning bracket 3), and the core tube 10 is placed in the positioning hole of the positioning bracket 3 (the core tube 10 is a rigid plastic tube or a welded steel pipe for low-pressure fluid transportation), The bottom of the concrete prefabricated pile body 4 is sealed with cement mortar or bean stone concrete (to form a pile bottom seal 6), and waterproof and anti-corrosion treatment i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com