Bearing system with oil film pressure detection function

A technology of oil film pressure and function, applied in the direction of rotating bearings, bearings, bearing assembly, etc., can solve the problems of inapplicability and inability to measure oil film pressure, and achieve the effects of convenient layout, reduced friction and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

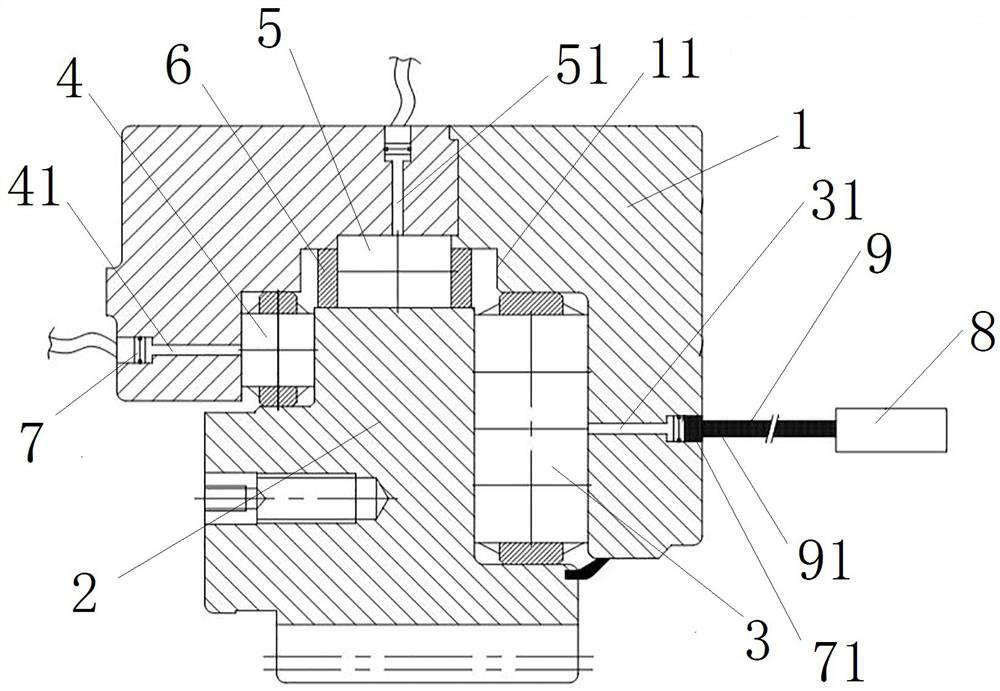

[0043] Such as Figure 1 to Figure 5 As shown, the bearing system with the oil film pressure detection function includes the outer ring 1 and the inner ring 2, the inner ring 2 and the outer ring 1 are rotatably assembled together, and the main thrust roller is installed between the inner ring 2 and the outer ring 1 through the cage 6 3. Auxiliary thrust roller 4 and radial roller 5.

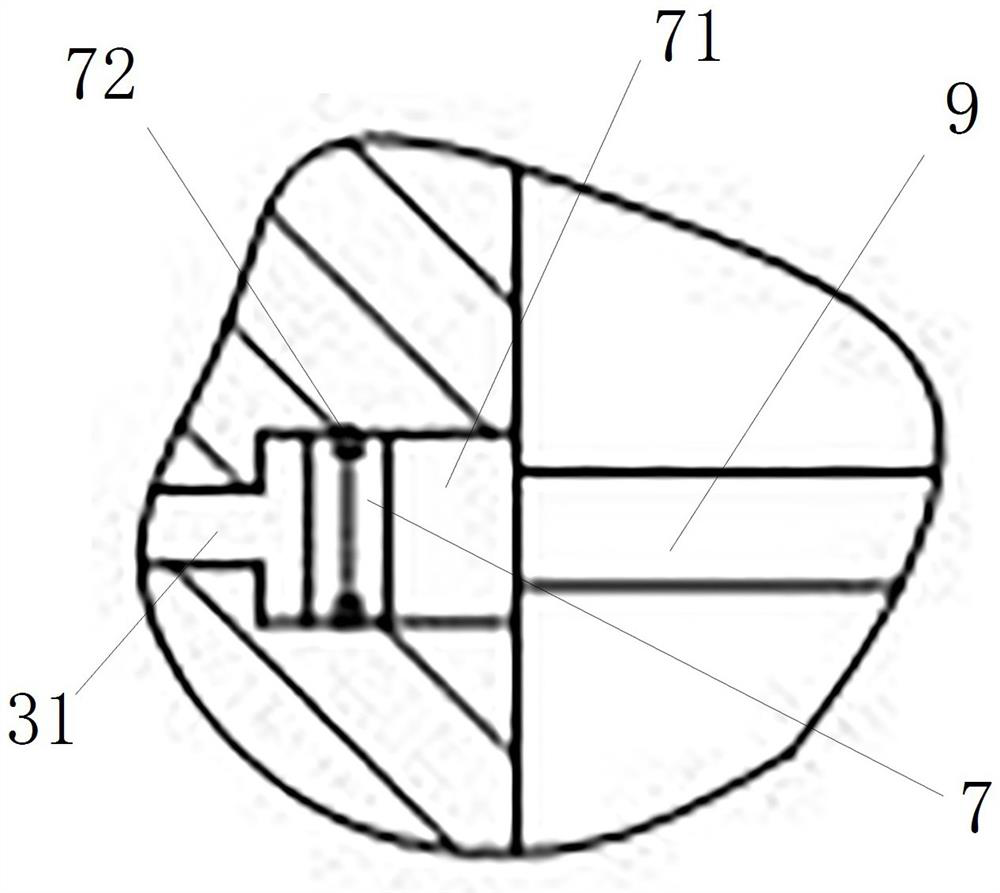

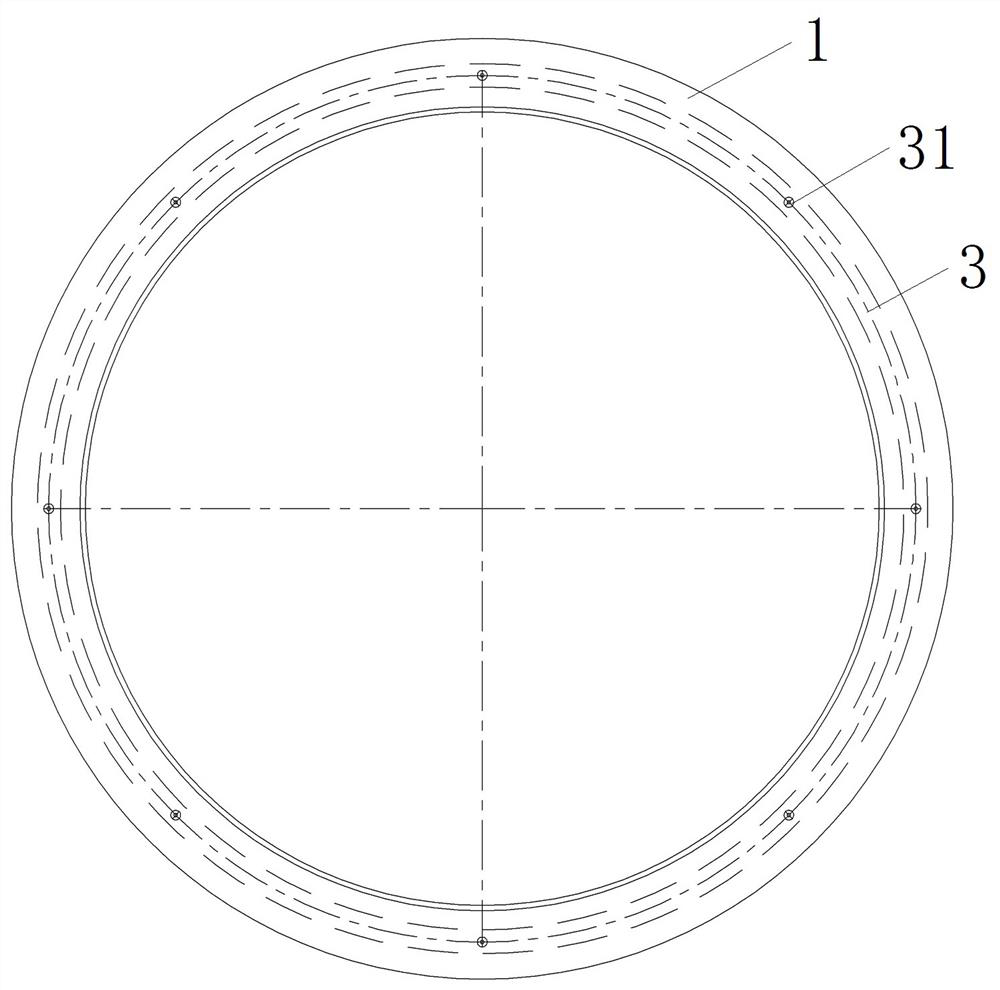

[0044]The outer ring 1 is circular as a whole, the outer side of the outer ring 1 is used for fixed assembly with the corresponding structure of the shield machine, and the inner side of the outer ring 1 is provided with a raceway 11 for the inner ring 2 to rotate and assemble. The outer ring 1 is provided with a main thrust capillary hole 31 , an auxiliary thrust capillary hole 41 and a radial capillary hole 51 , and there are multiple main thrust capillary holes 31 , auxiliary thrust capillary holes 41 and radial capillary holes 51 . The main pushing capillary holes 31 are evenly distributed ...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the oil film pressure between the corresponding roller and the outer ring 1 is transmitted to the piston 7 through the lubricating oil in the corresponding capillary hole, and the piston 7 flows to the hydraulic oil pipe 9 The hydraulic oil 91 in the hydraulic oil pipe 9 exerts an outward force to convert the oil film pressure between the corresponding roller and the outer ring 1 into the oil pressure of the hydraulic oil 91 in the hydraulic oil pipe 9 . However, in this embodiment, the hydraulic oil pipe adopts a flexible pipe that can expand and contract. In actual work, when the corresponding roller moves to the position of the corresponding capillary hole, due to the existence of oil film pressure, the distance between the corresponding roller and the outer ring The lubricating oil will enter the corresponding capillary holes, and the lubricating oil in the capillary holes will push the ...

Embodiment 3

[0055] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, a piston cavity 71 is provided at the outer end of each capillary hole for guiding and assembling the piston 7 . In this embodiment, each capillary hole is a straight hole with a constant inner diameter, and the end of the hydraulic oil pipe close to the outer ring is provided with a rigid connecting pipe section. The rigid connecting pipe section extends along the axial direction of the outer ring and is connected to the flange of the outer ring. The guides are fitted in rigidly connected pipe sections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com