Liquid medicine extraction device capable of automatically controlling deslagging according to amount of extruded liquid medicine

An extraction device and liquid medicine technology, applied in the field of biomedicine, can solve the problems of low degree of automation, waste of medicine, heavy workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

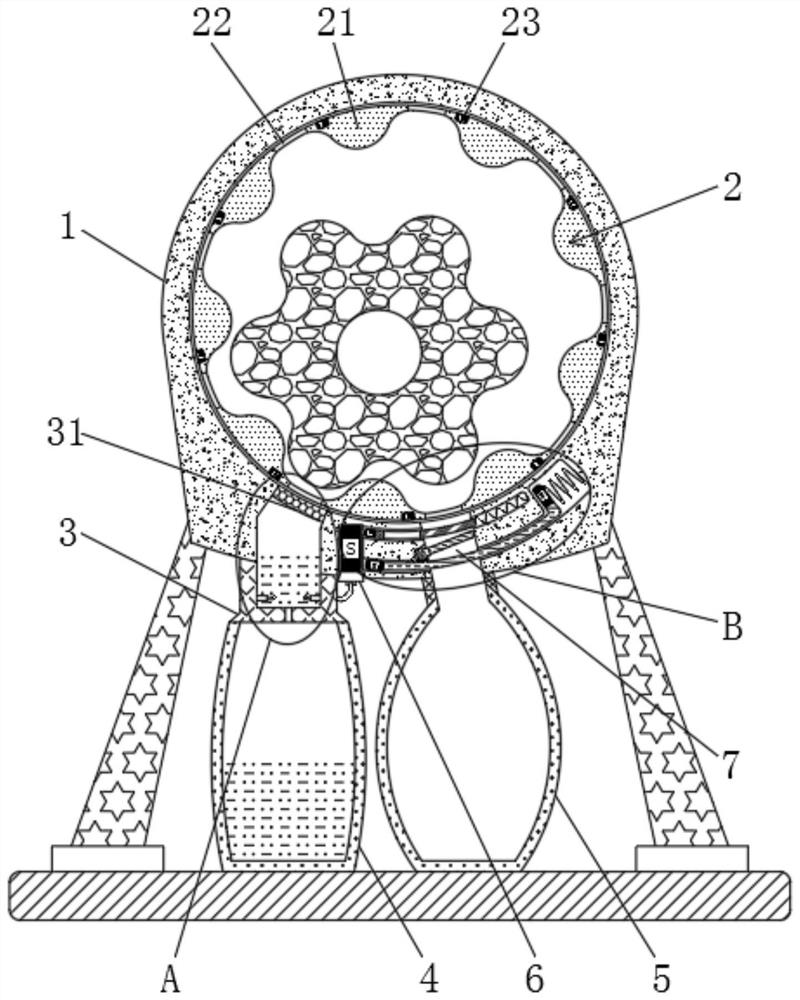

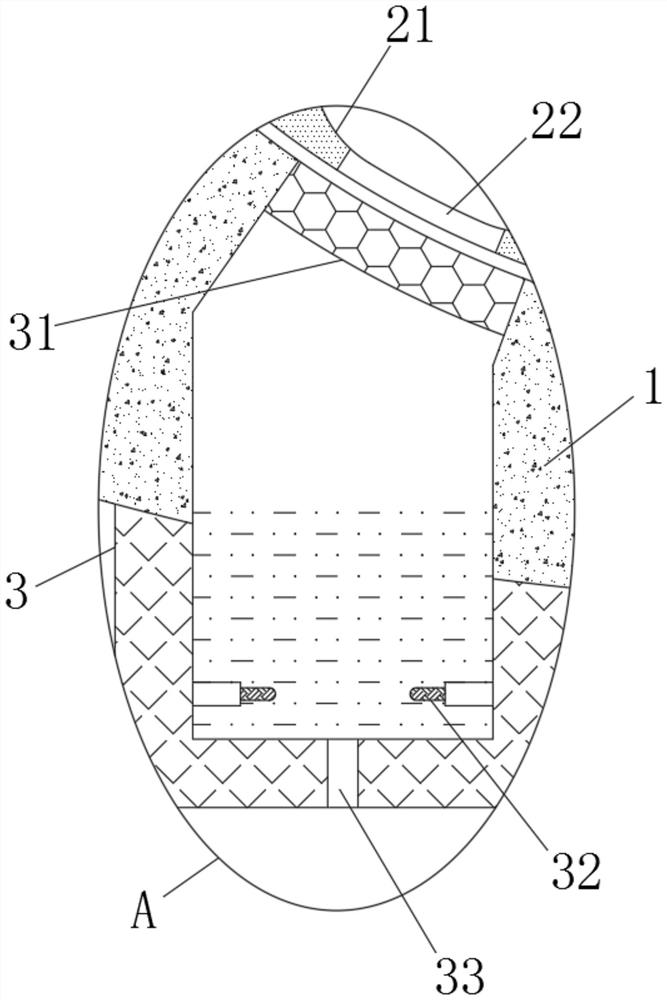

[0022] see Figure 1-3 , a medicinal liquid extraction device that automatically controls slag discharge according to the amount of extruded medicinal liquid, comprising a fixed cylinder 1, the inner rear wall of the fixed cylinder 1 is rotatably connected with a grinding mechanism 2, and the left side of the bottom of the fixed cylinder 1 is welded with blanking Pipe 3, drug residue collection box 5 and electromagnet 6, the bottom of the drop pipe 3 is welded with a liquid medicine collection box 4, and a slag removal hole 7 is opened between the fixed cylinder 1 and the drug residue collection box 5, and the slag removal hole 7 The inner left wall is plugged with an arc-shaped baffle 71 and a material guide mechanism 8 .

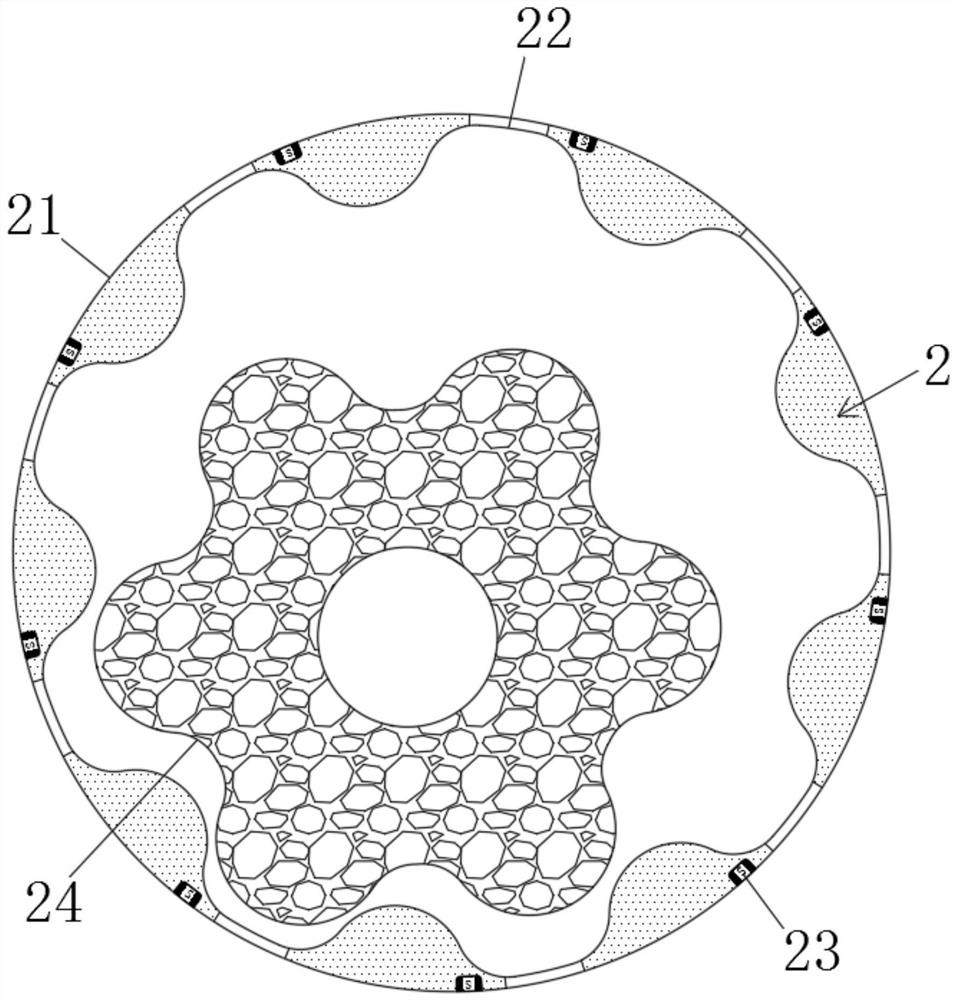

[0023] The grinding mechanism 2 includes a rotating cylinder 21. The outer side of the rotating cylinder 21 is provided with an annular array of blanking openings 22. The outer side of the rotating cylinder 21 is welded with annularly arranged magnetic blo...

Embodiment 2

[0026] see Figure 1-4 , a medicinal liquid extraction device that automatically controls slag discharge according to the amount of extruded medicinal liquid, comprising a fixed cylinder 1, the inner rear wall of the fixed cylinder 1 is rotatably connected with a grinding mechanism 2, and the left side of the bottom of the fixed cylinder 1 is welded with blanking Pipe 3, drug residue collection box 5 and electromagnet 6, the bottom of the drop pipe 3 is welded with a liquid medicine collection box 4, and a slag removal hole 7 is opened between the fixed cylinder 1 and the drug residue collection box 5, and the slag removal hole 7 The inner left wall is plugged with an arc-shaped baffle 71 and a material guide mechanism 8 .

[0027]The grinding mechanism 2 includes a rotating cylinder 21. The outer side of the rotating cylinder 21 is provided with an annular array of blanking openings 22. The outer side of the rotating cylinder 21 is welded with annularly arranged magnetic bloc...

Embodiment 3

[0030] see Figure 1-4 , a medicinal liquid extraction device that automatically controls slag discharge according to the amount of extruded medicinal liquid, comprising a fixed cylinder 1, the inner rear wall of the fixed cylinder 1 is rotatably connected with a grinding mechanism 2, and the left side of the bottom of the fixed cylinder 1 is welded with blanking Pipe 3, drug residue collection box 5 and electromagnet 6, the bottom of the drop pipe 3 is welded with a liquid medicine collection box 4, and a slag removal hole 7 is opened between the fixed cylinder 1 and the drug residue collection box 5, and the slag removal hole 7 The inner left wall is plugged with an arc-shaped baffle 71 and a material guide mechanism 8 .

[0031] The grinding mechanism 2 includes a rotating cylinder 21. The outer side of the rotating cylinder 21 is provided with an annular array of blanking openings 22. The outer side of the rotating cylinder 21 is welded with annularly arranged magnetic blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com