Combined multifunctional vermicelli machine

A multi-functional, vermicelli machine technology, applied in the fields of food forming, food science, application, etc., can solve the problems of poor control of vermicelli heating temperature, insufficient vermicelli maturity, more energy waste, etc., to improve temperature detection efficiency and The effect of heating efficiency, reducing bodily injury and improving extrusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

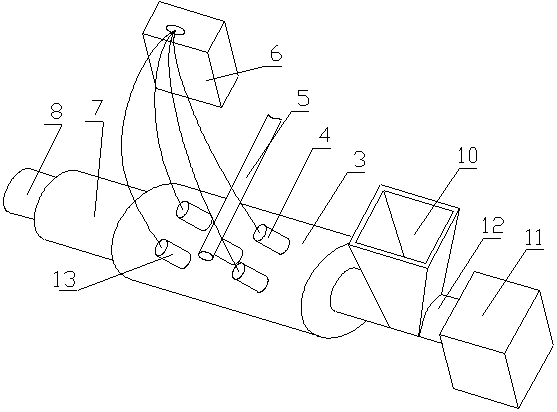

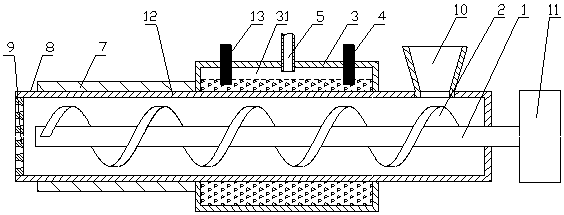

[0029]A combined multifunctional vermicelli machine aims at providing a constant and more suitable temperature range for ripening vermicelli. This vermicelli machine comprises frame and powder material sleeve 12, and this powder material sleeve 12 is directly fixed on the frame. A screw rod 1 is set inside the powder sleeve 12, and the screw rod 1 can freely rotate around the axis of the screw rod 1 in the powder sleeve 12 under the action of the driving force. The screw rod 1 is provided with a screw-in blade 2 , and the fans can move along the axial direction of the screw rod 1 under the action of the screw-in blade 2 . Preferably, the screw-in blade 2 includes an inner helical blade 22, an outer helical blade 21 connected to the inner helical blade 22, the cross-sectional width of the inner helical blade 22 is 50 mm to 70 mm, and the cross-sectional thickness of the inner helical blade 22 is 8 mm to 15 mm. . The section width of the outer helical blade 21 is 30 mm to 50 m...

Embodiment 2

[0036] On the basis of Embodiment 1, the tail heater 7 is composed of an electromagnetic generator, a power control cabinet, a temperature detector, and several electromagnetic induction heating coils arranged on the outer surface of the discharge end, and several electromagnetic induction heating coils are set The outer surface of the discharge end is filled with thermal insulation materials; the electromagnetic generators are in one-to-one correspondence with the electromagnetic induction heating ring and are electrically connected; the several electromagnetic generators are electrically connected to the power control cabinet; The barrel is equipped with a temperature detector connected electromechanically to the meter or PC, the meter or PC is electrically connected to the power control cabinet, and the temperature detector is fixedly connected to the outer wall of the barrel.

[0037] When the tail heater 7 is working: the power control cabinet converts the connected 220V A...

Embodiment 3

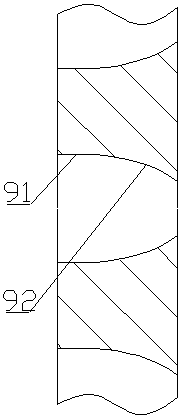

[0039] On the basis of the above embodiments, the discharge hole of the discharge die 9 is set such that the diameter of the discharge hole increases gradually along the flow direction of the material. The cross section of the discharge hole is composed of a straight section 91 and a curved section 92, and the curved section 92 and the straight section 91 are sequentially arranged along the flow direction of the material.

[0040] The cross-section of the discharge hole of the discharge die 9 is made up of a straight section 91 and a curved section 92, so that the aperture of the discharge hole increases gradually along the flow direction of the material, so that the fans will not be subjected to resistance or pressure in the discharge hole. The resistance is small, so that the vermicelli can be smoothly discharged through the discharge hole, reducing the possibility of the discharge hole being blocked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com