Drying system for sludge treatment

A sludge drying technology, applied in energy wastewater treatment, dehydration/drying/thickened sludge treatment, loading/unloading, etc., can solve the problems of slow drying speed, slow drying efficiency, uneven heating, etc., to achieve Reduce stickiness, improve efficiency, and prevent wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

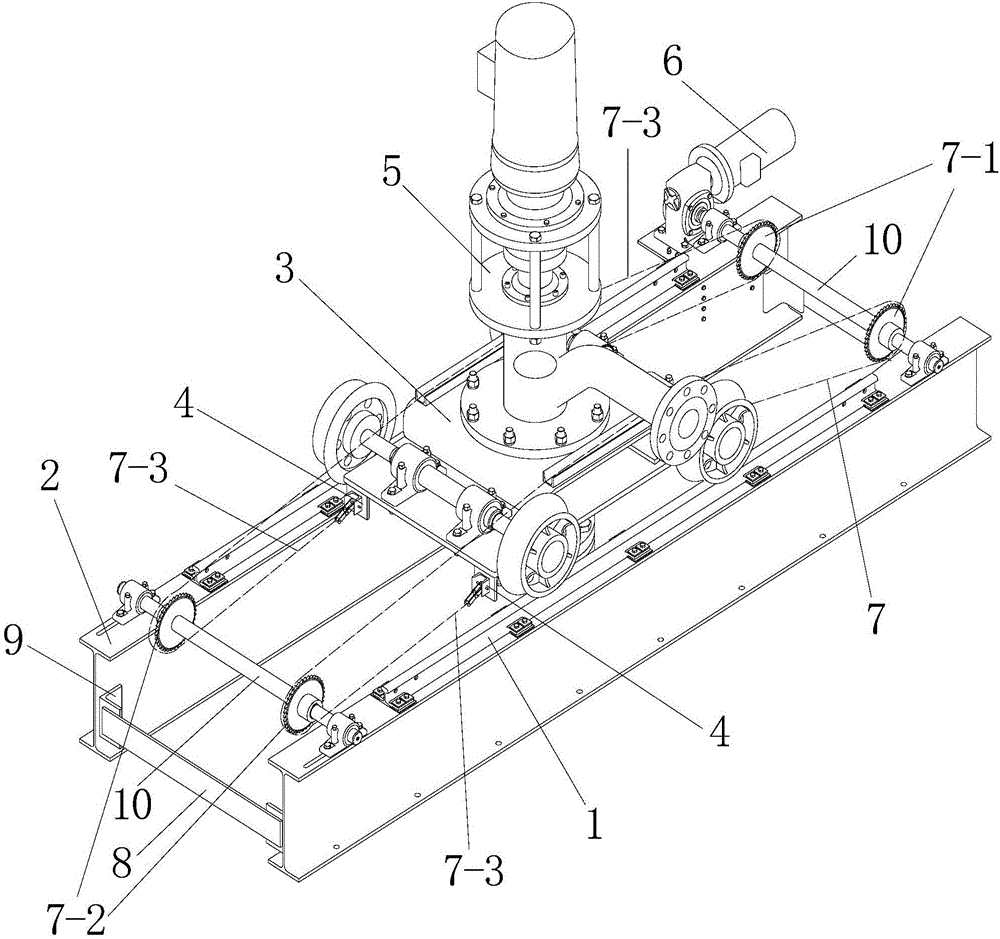

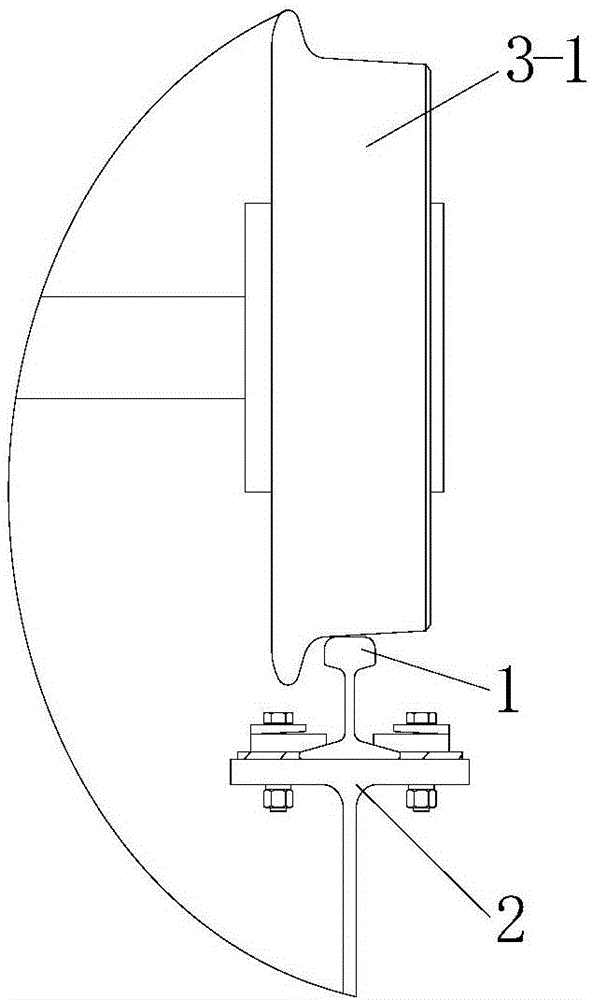

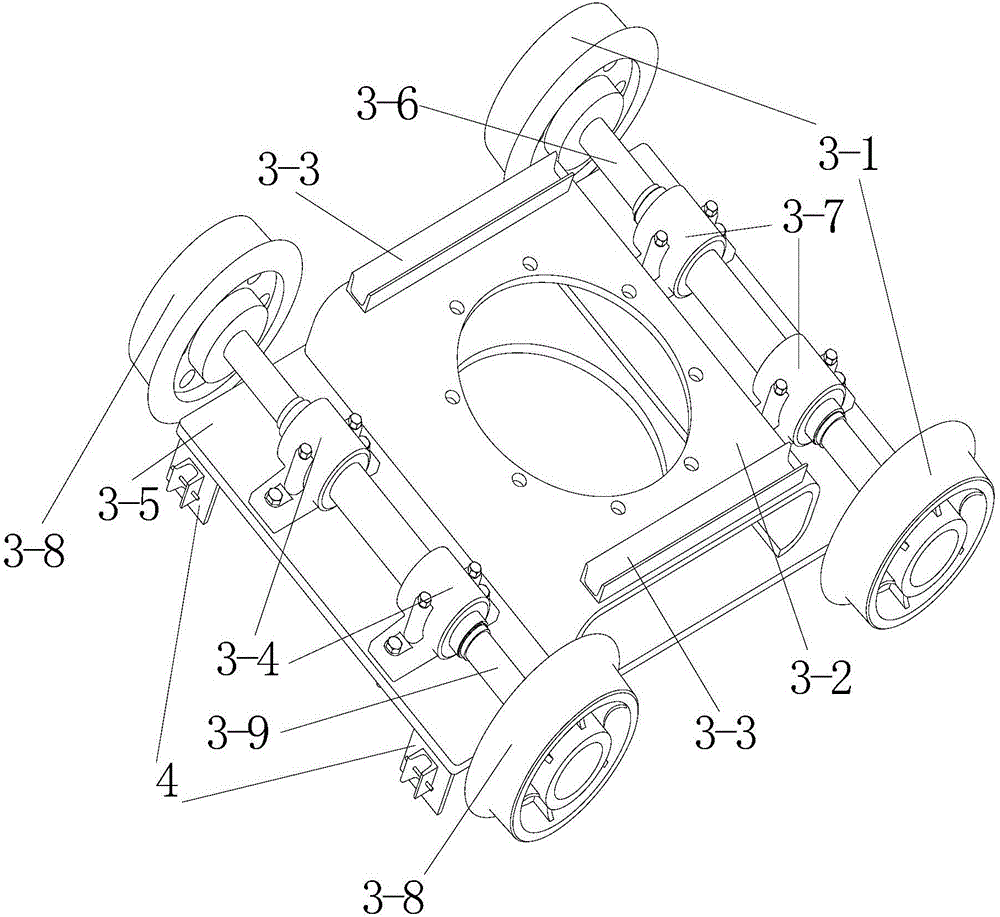

[0047] see Figure 8 , the up, down, left, and right directions mentioned in this paragraph are the same as Figure 8 The up and down and left and right are the same. The sludge drying system of the present invention includes a shell, a sludge feeding device, a plurality of chain plate conveying devices, a heat preservation device, a diversion device, a heat insulation device, and a sludge output device. A sludge inlet for sludge entry is provided above the housing, and a sludge outlet for sludge falling is provided below the housing. The sludge feeding device is located above the sludge inlet of the shell. After the sludge comes out of the sludge feeding device, it falls directly into the shell through the sludge inlet of the shell. The outlet of the feeding device (that is, below the two H-shaped steels mentioned below) is connected, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com