Light balancing conductor material and preparation method thereof

A technology of light conductor and luminescent powder, applied in the field of polymer materials, can solve the problems of affecting the color rendering of light sources, poor dispersion of light diffusing agents, agglomeration and other problems, achieve good color temperature and color rendering index, effectively control luminous flux, increase Effects of Scattering and Transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

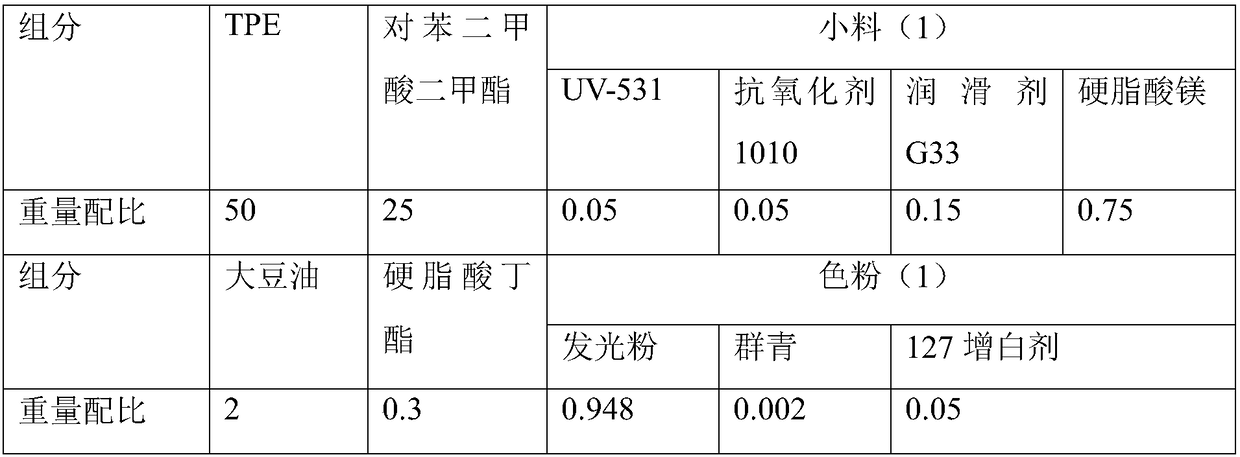

[0054] Embodiment 1: the transparent resin adopts TPE, the plasticizer adopts dimethyl terephthalate; the ultraviolet absorber selects UV-531, antioxidant 1010, lubricant G33, zinc stearate;

[0055]

Embodiment 2

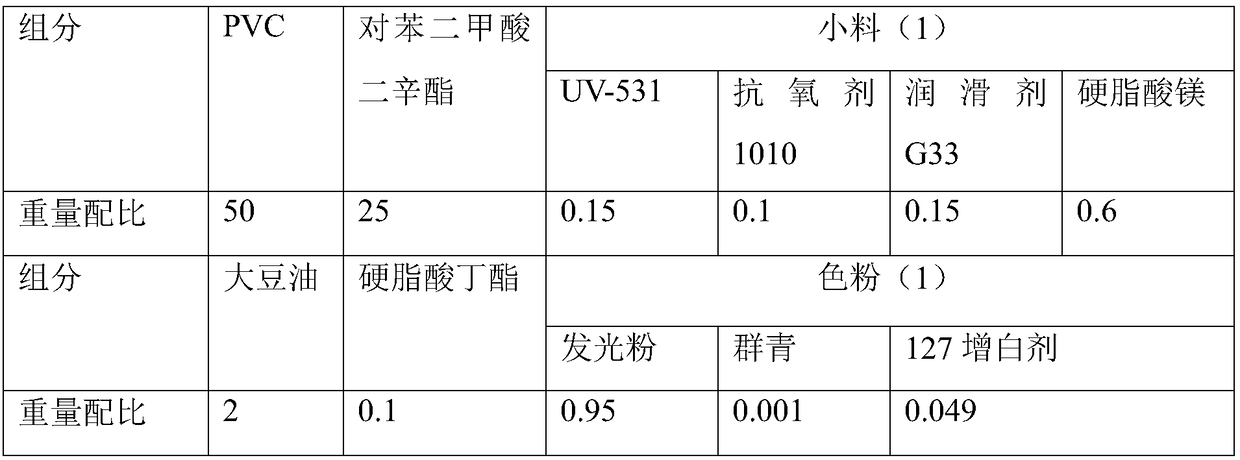

[0056] Embodiment two: transparent resin adopts PVC, plasticizer adopts dioctyl terephthalate, ultraviolet absorber selects UV-531, antioxidant 1010, lubricant G33, magnesium stearate;

[0057]

[0058] In the table, (1) after small material means 1 part by mass of small material, and similarly, after (1) after toner means 1 part by mass of toner, and the following explanations are the same.

Embodiment 3

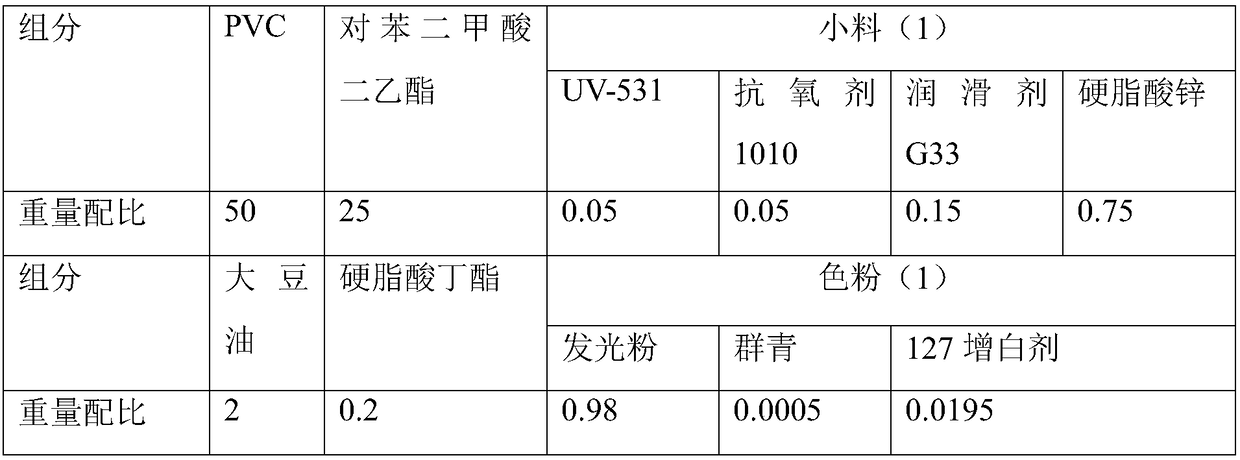

[0059] Embodiment three: transparent resin adopts PVC, plasticizer adopts diethyl terephthalate, ultraviolet absorber selects UV-531 for use, antioxidant 1010, lubricant G33, zinc stearate;

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com