Equipment for extracting skin-moisturizing and wrinkle-resistant cosmetic

An anti-wrinkle cosmetic and extraction equipment technology, applied in grain processing and other directions, can solve problems such as inability to discharge residues, plant juices that cannot be completely squeezed out, and plants that are easily mashed and not thoroughly enough to achieve a high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

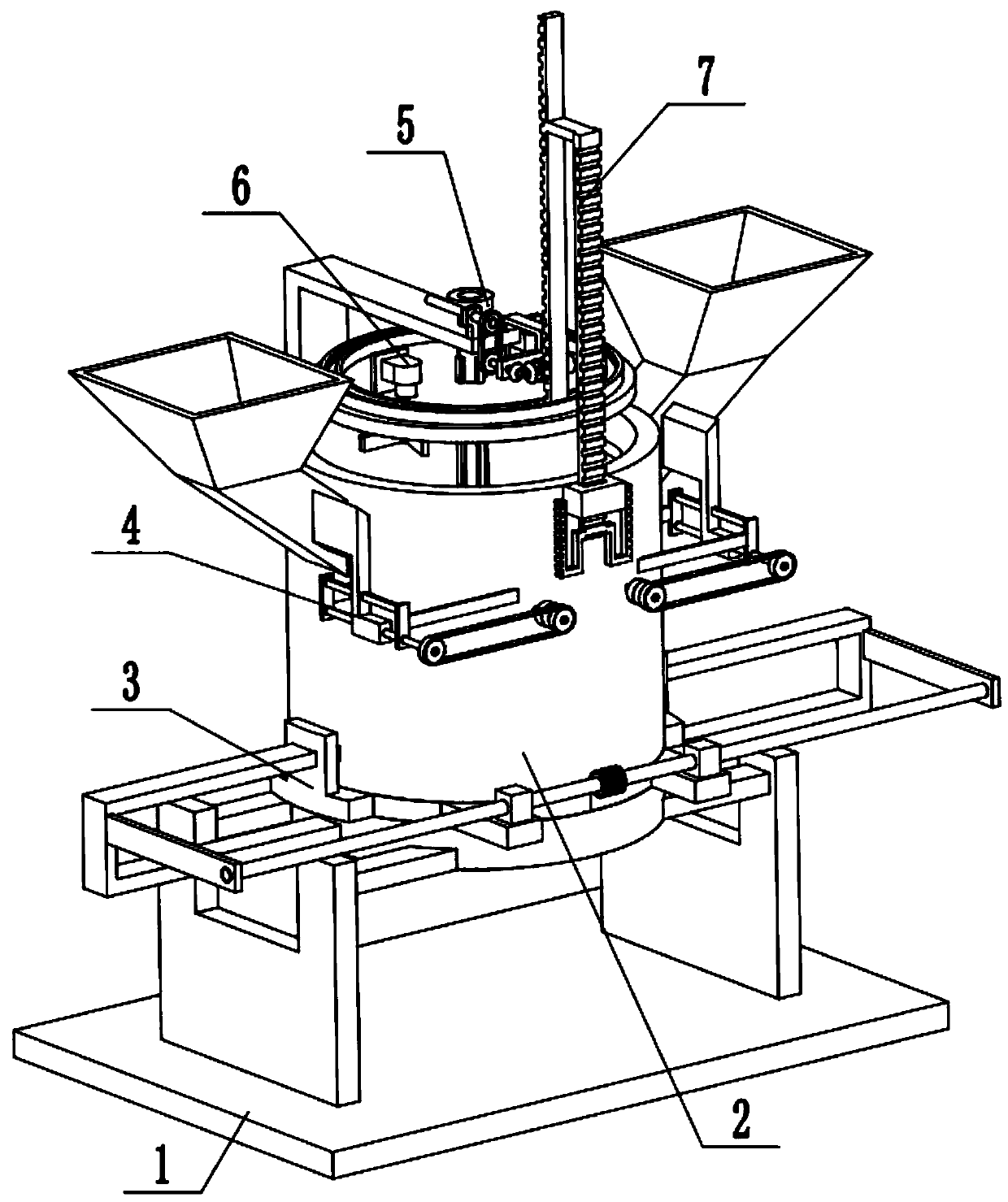

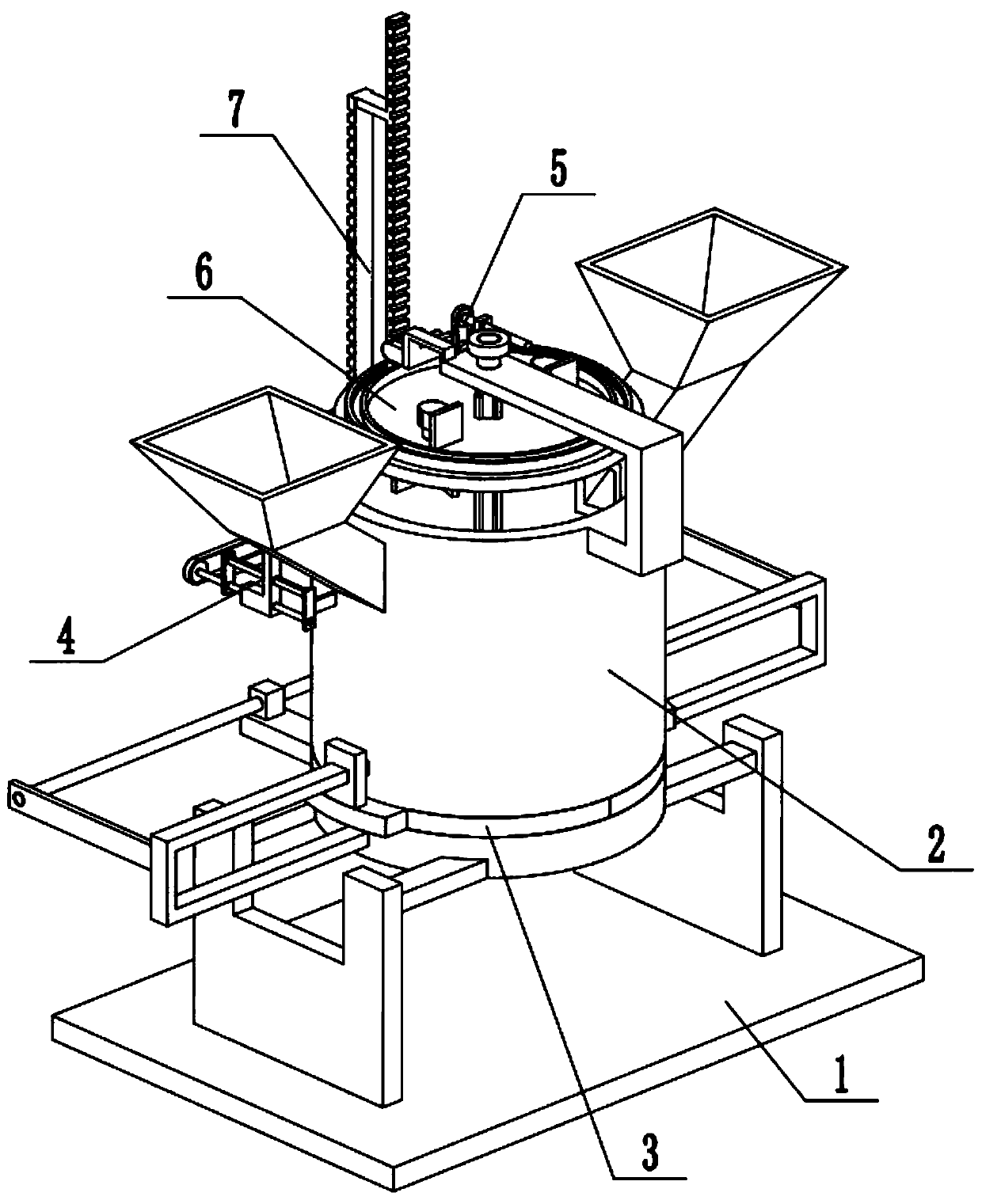

[0028] Combine below Figure 1-9Describe this embodiment, an extracting device for moisturizing and anti-wrinkle cosmetics, including a base frame 1, an extracting cylinder assembly 2, a movable floor mechanism 3, an intermittent feeding control mechanism 4, a power output mechanism 5, an extrusion crushing mechanism 6 and a reciprocating control mechanism. Mechanism 7, the extraction cylinder assembly 2 is fixedly connected to the chassis 1, the movable floor mechanism 3 is arranged at the lower end of the extraction cylinder assembly 2, two intermittent feed control mechanisms 4 are provided, and two intermittent feed control mechanisms 4 It is symmetrically arranged on both sides of the extraction cylinder assembly 2, the power take-off mechanism 5 is fixedly connected to the upper end of the extraction cylinder assembly 2, the extrusion crushing mechanism 6 is connected to the power output mechanism 5 with a sliding fit, and the reciprocating control mechanism 7 is connecte...

specific Embodiment approach 2

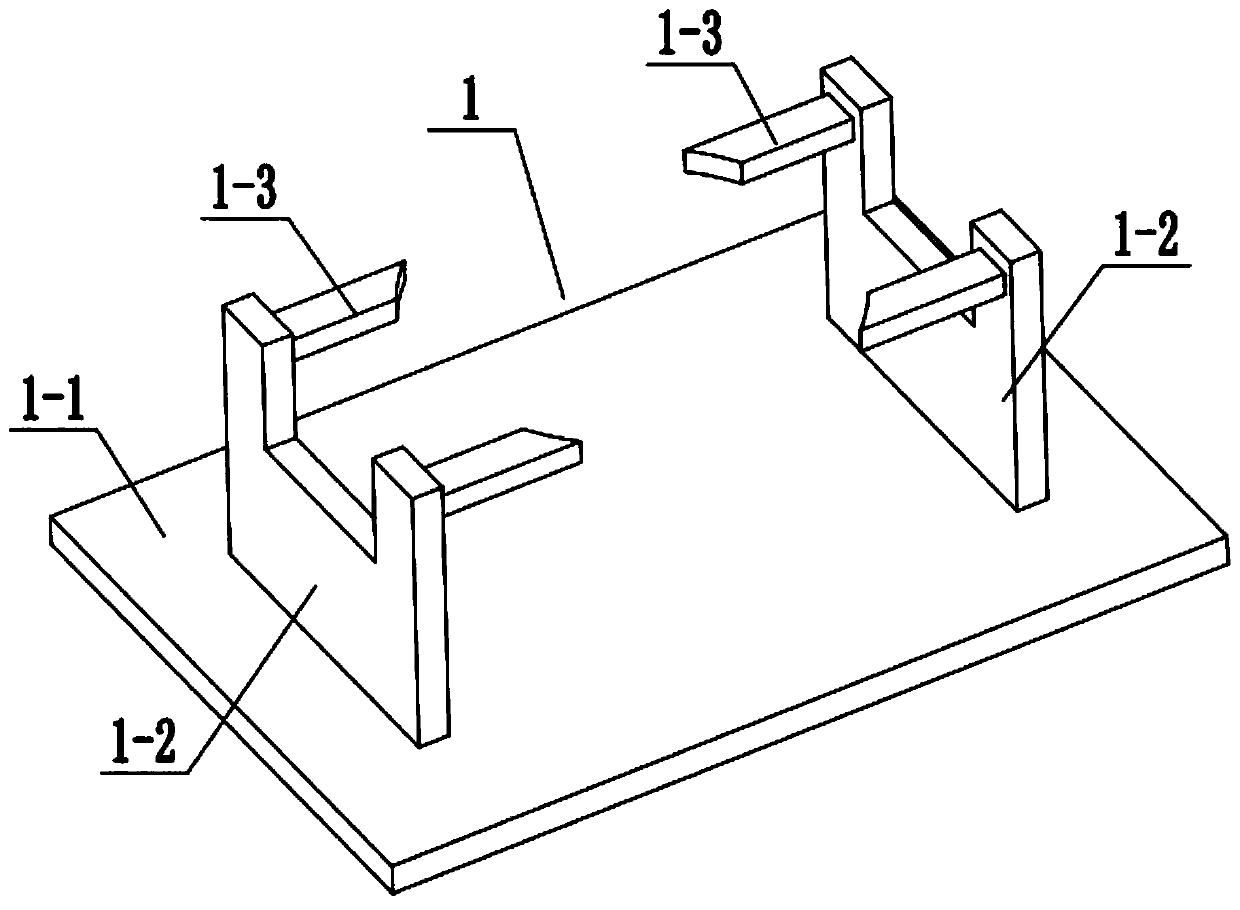

[0030] Combine below Figure 1-9 To illustrate this embodiment, the underframe 1 includes a bottom plate 1-1, a side frame plate 1-2, and a support plate 1-3; two side frame plates 1-2 are fixedly connected to the bottom plate 1-1, and the two side frame plates The inner sides of the plates 1-2 are fixedly connected to two support plates 1-3, and the extraction cylinder assembly 2 is fixedly connected between the four support plates 1-3.

specific Embodiment approach 3

[0032] Combine below Figure 1-9 To illustrate this embodiment, the extraction cylinder assembly 2 includes an extraction cylinder body 2-1, a C-shaped frame 2-2, a ring seat 2-3, a bottom plate chute 2-4, a fixed sliding sleeve 2-5, a feeding Seat 2-6 and feeding baffle chute 2-7; the lower end of the extraction cylinder body 2-1 is fixedly connected to two C-shaped frames 2-2, and the ring seat 2-3 is fixedly connected to two C-shaped frames 2-2. 2, the ring seat 2-3 is coaxial with the extraction cylinder body 2-1 and has the same diameter, and the bottom plate chute 2-4 is formed between the ring seat 2-3 and the extraction cylinder body 2-1, and the extraction cylinder body 2 The upper end of -1 is fixedly connected to the fixed sliding sleeve 2-5, and the two feed seats 2-6 are symmetrically fixedly connected and connected to both sides of the upper end of the extraction cylinder body 2-1, and the front ends of the two feed seats 2-6 are all set A feeding baffle chute 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com