Stirring extrusion type hair dyeing comb

An extrusion type, stirring shaft technology, applied in the direction of hair brushes, hairdressing equipment, devices for washing hair or scalp, etc., can solve the problems of the effect of hair dyeing, inconvenient use, etc., and achieve the effect of less residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

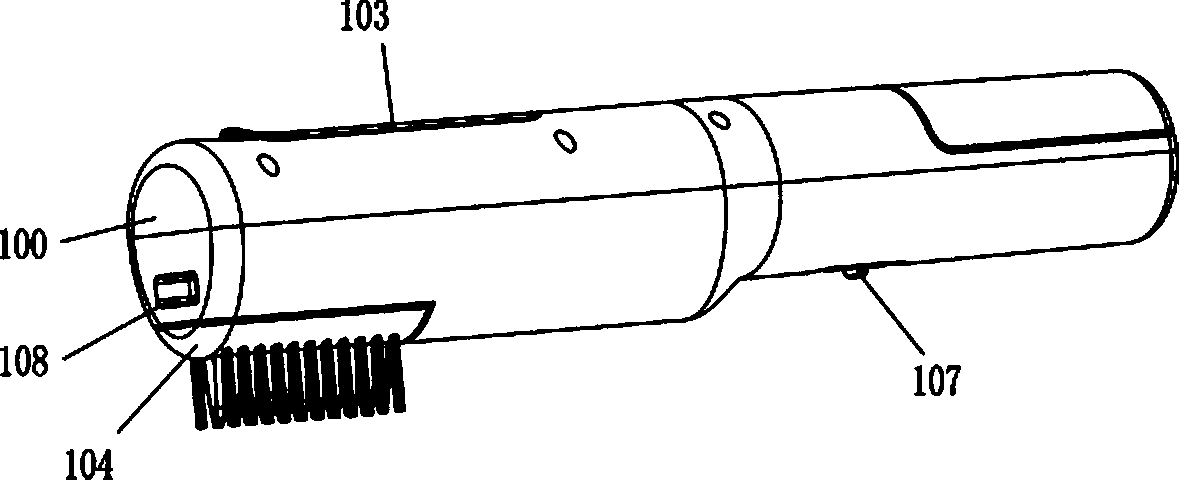

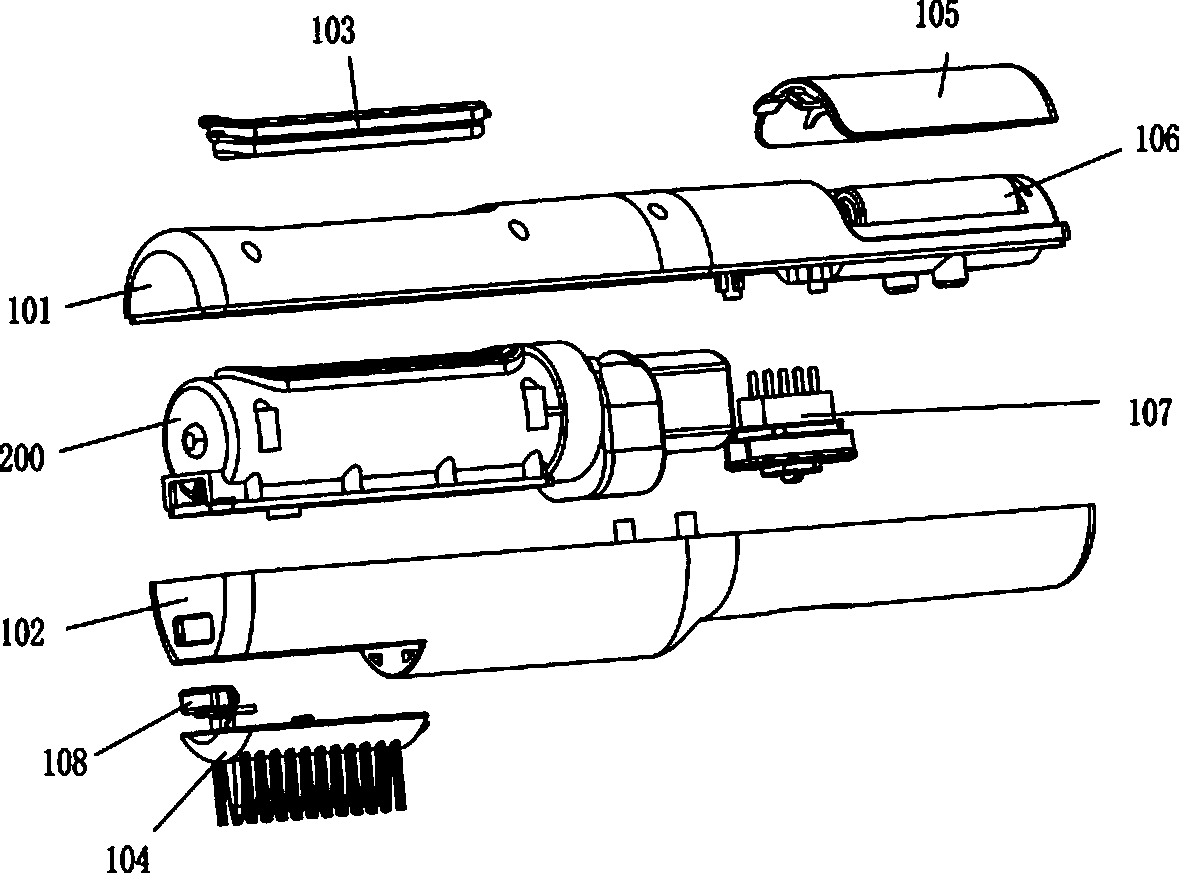

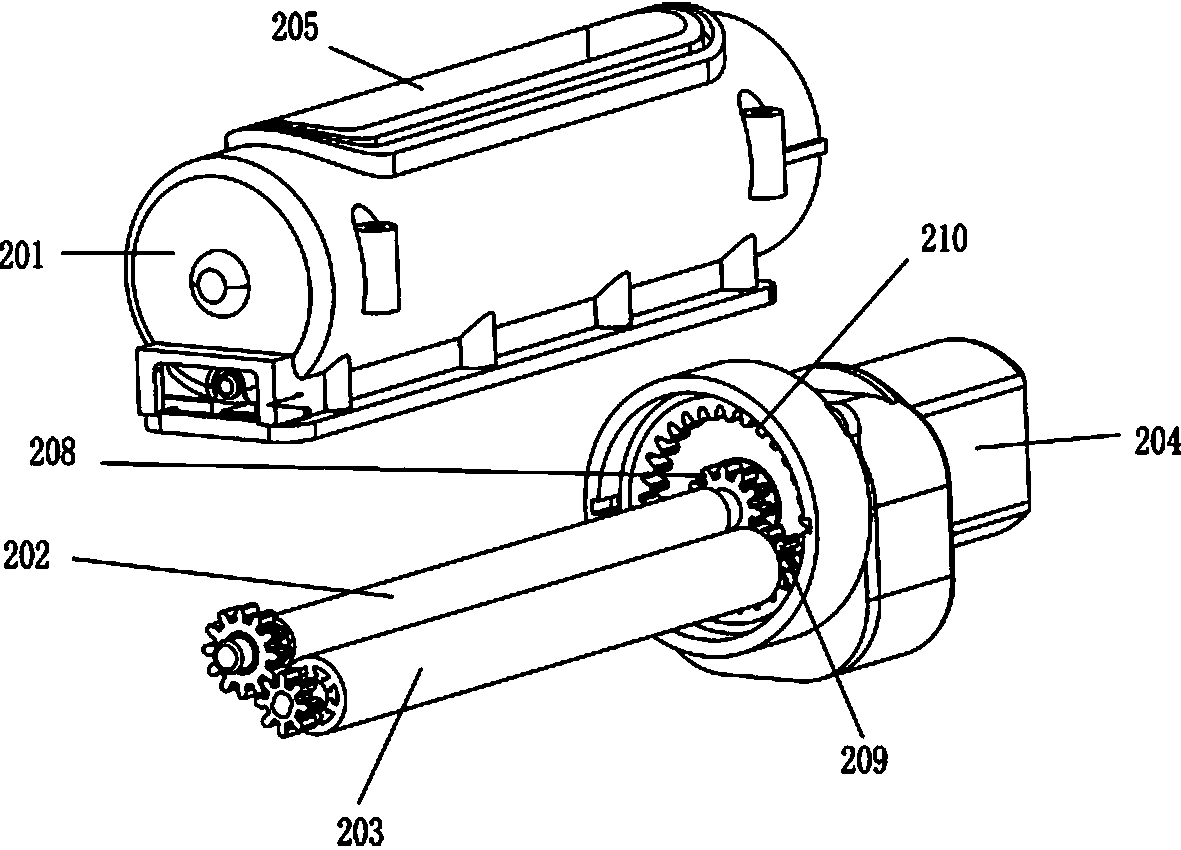

[0024] Such as Figure 1-2 As shown, it is a stirring extrusion type hair dyeing comb, its main body is a hair dyeing comb housing 100, the hair dyeing comb housing 100 is divided into an upper housing 101 and a lower housing 102, and the upper housing 101 and the lower housing 102 are interlocked Together, the upper end of the upper housing 101 is provided with a cylinder cover 103, the lower end of the lower housing 102 is provided with a comb head 104, a stirring mechanism 200 is provided between the upper housing 101 and the lower housing 102, and the upper housing 101 is also provided with Battery chamber, battery 106 is placed in the battery chamber, the battery chamber is covered with battery cover 105, the stirring mechanism 200 is powered by battery 106, and a start switch 107 is connected between the stirring mechanism 200 and the battery 106 to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com