Intelligent dispersed material suction and conveying system

A bulk material and intelligent technology, applied in the field of intelligent bulk material suction and transportation system, can solve the problems of long loading and unloading time, short distance, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

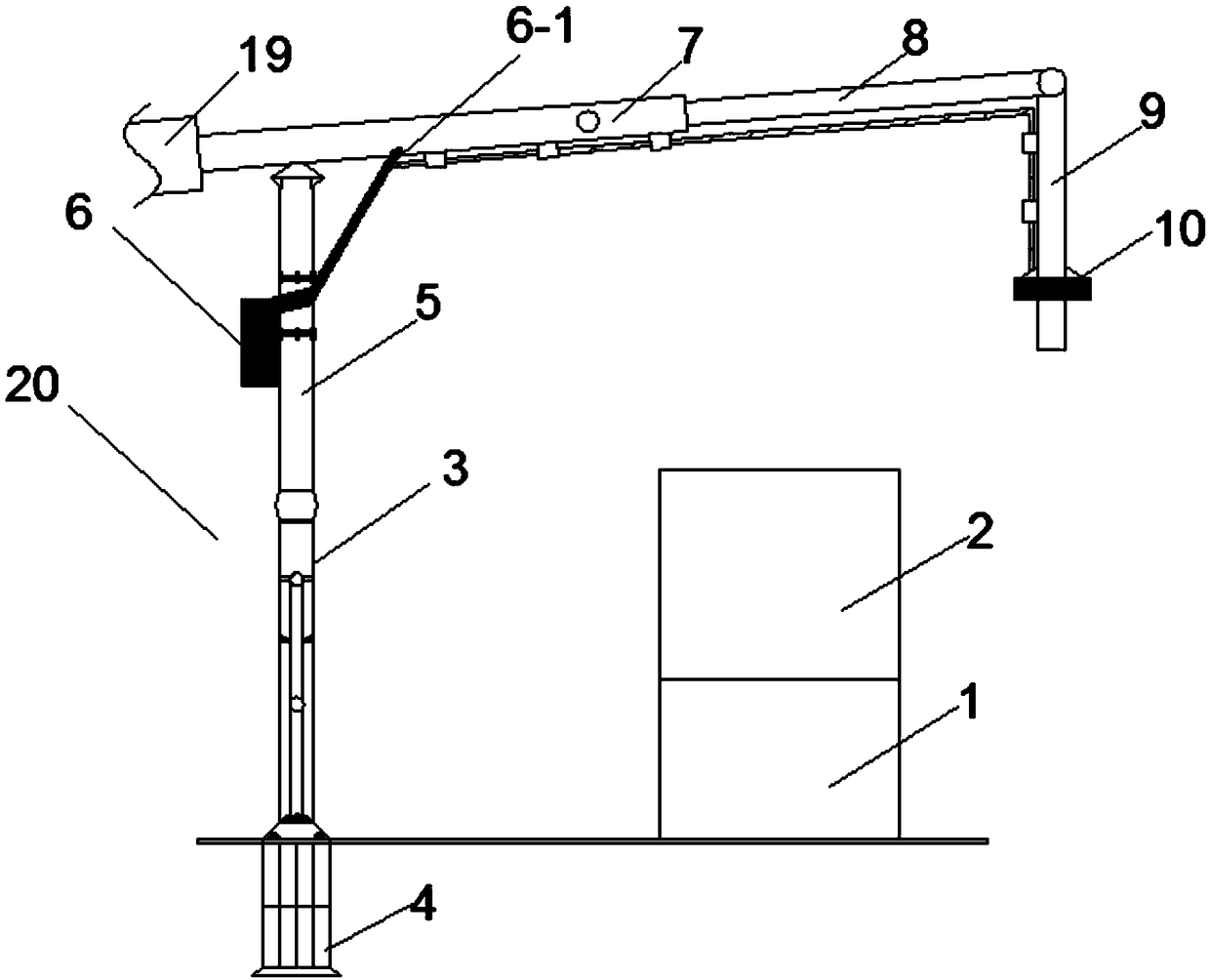

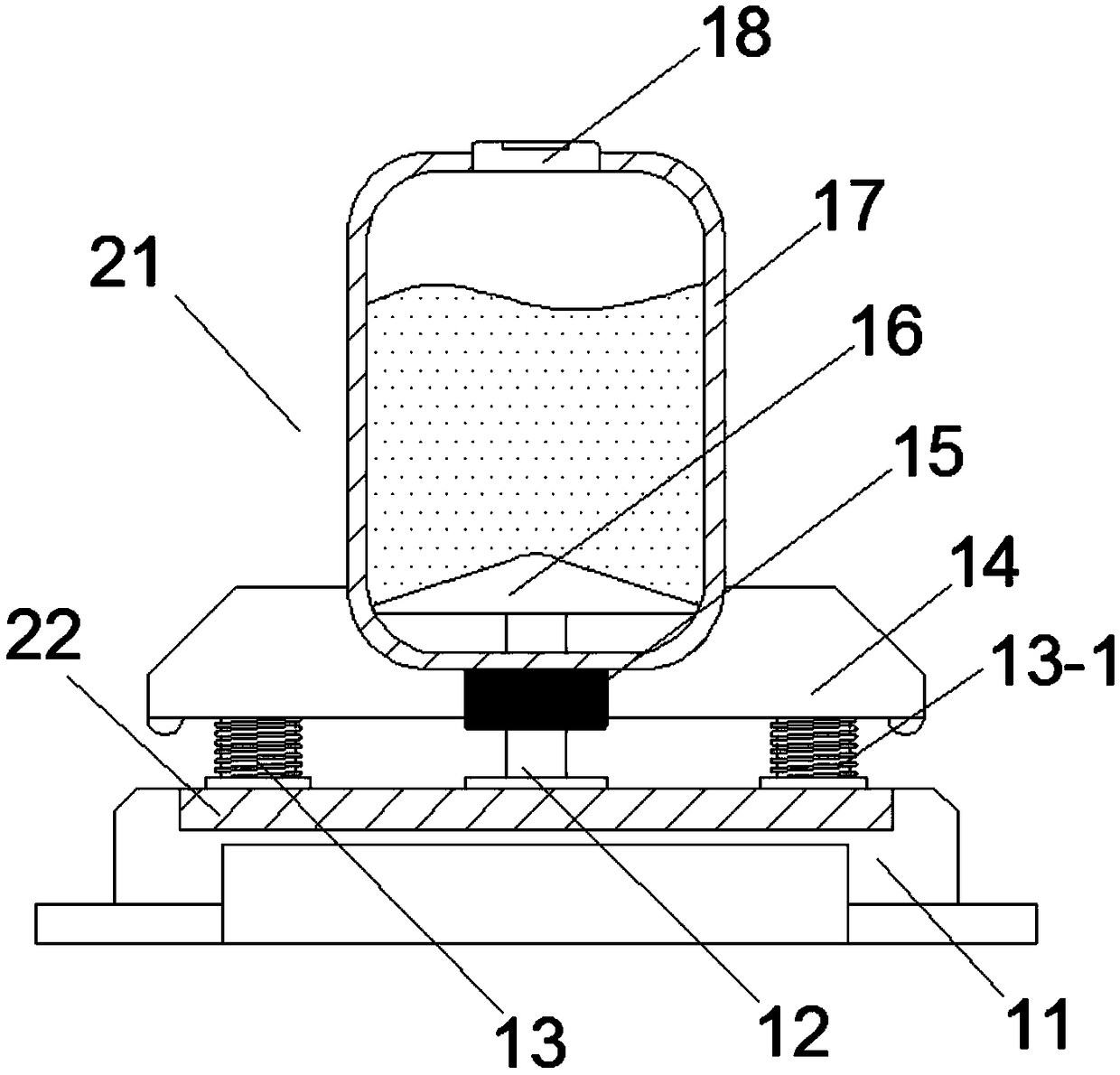

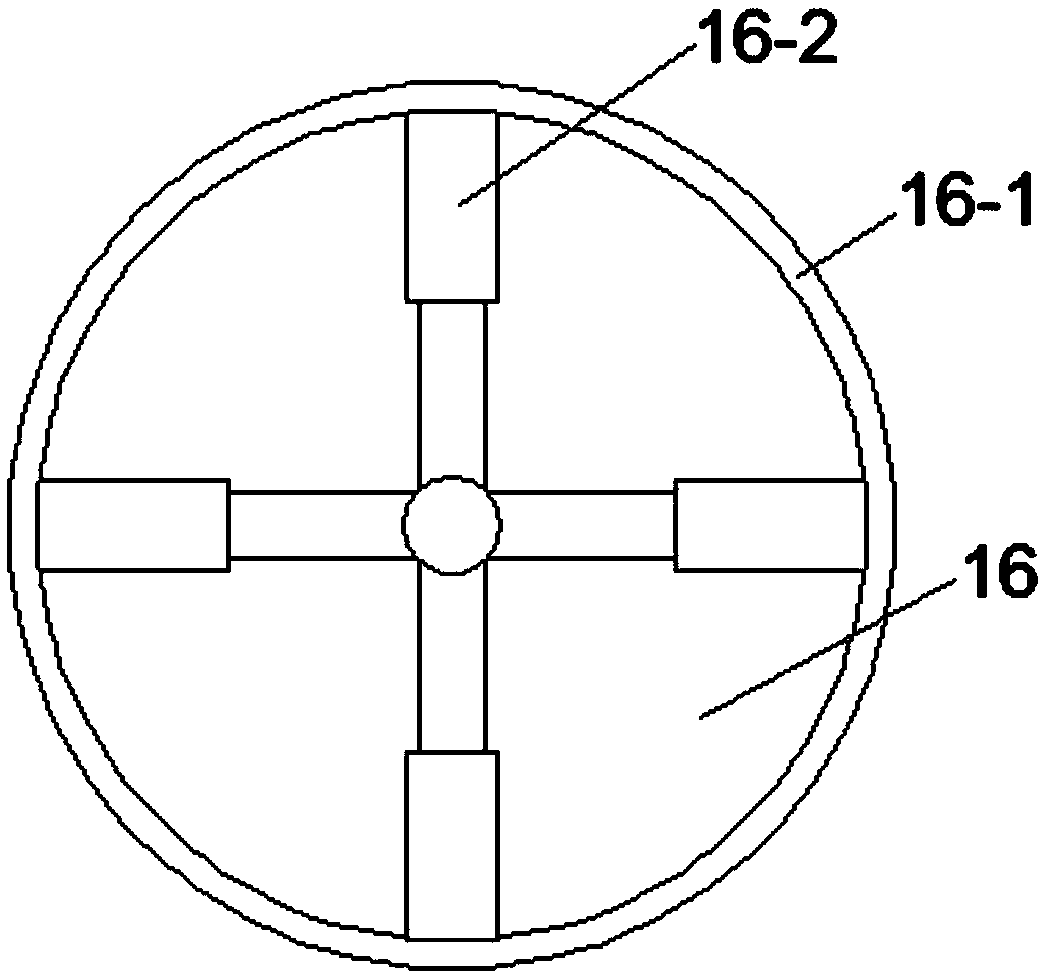

[0016] Such as figure 1 with figure 2 As shown, an intelligent bulk material suction system includes a cargo rack and a material suction device; the cargo rack 2 is loaded on the roof of the transport vehicle 1, and several storage systems 21 are loaded in the cargo rack 2, and the A material suction device 20 is arranged on the left side of the cargo rack 2, and the material suction device 20 stands on the ground through a load-bearing base 4. The upper end of the load-bearing base 4 is connected with a hydraulic rod 3, and the upper end of the hydraulic rod 3 is sleeved with a The driven rod 5, the top of the driven rod 5 is movably connected with the feeding sleeve 7, and the telescopic tube 8 at the front end of the feeding sleeve 7 is equipped with a vertical suction pipe 9. Among them, the present invention takes the material suction device 20 and the material storage system 21 as the main body. The transport personnel drive the transport vehicle 1 into the operable r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com