Weaving method for captive balloon cable of polyethylene fiber with ultra-high molecular weight

A technology of polyethylene fiber and ultra-high molecular weight, which is applied in the field of cable braiding, can solve problems such as obvious shortcomings, achieve the effects of weight reduction, sufficient immersion, and improvement of overall wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

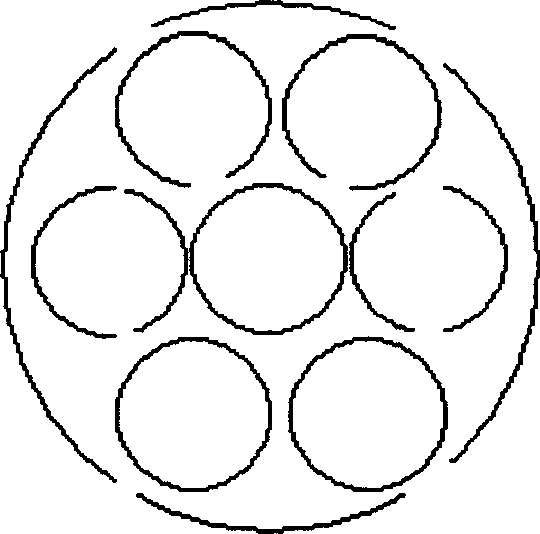

[0020] The braiding method of the ultra-high molecular weight polyethylene fiber mooring balloon cable, comprises the following steps:

[0021] (1), close the yarn, choose 7, fineness is the ultra-high molecular weight polyethylene fiber of 800 deniers, twist synthetic roving,

[0022] (2), combined small strands, 7 aforementioned synthetic rovings are twisted into small strands,

[0023] (3), impregnating resin, impregnating the aforementioned small strands with resin, and drawing through small holes, extruding excess resin,

[0024] (4), close the middle strand, 3 small strands of the aforementioned synthesis are twisted into the middle strand,

[0025] (5), braiding, adopting 12 braiding machines to weave middle strands into cables,

[0026] In the process of combining yarns, combining small strands and combining middle strands, keep the tension on each fiber basically the same, and the twist length is 20-30 centimeters.

[0027] (6) A special post-processing method is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com