Heating device and method of gas insulated circuit breaker

A gas insulation and heating device technology, which is applied to high-voltage air circuit breakers, ohmic resistance heating parts, circuits, etc., can solve the problems of narrow application range, inability to transfer heat energy over long distances, and low transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

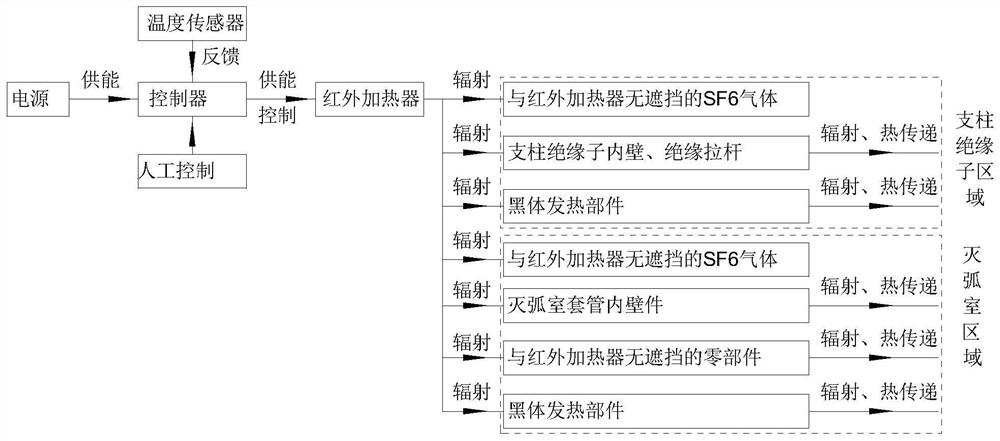

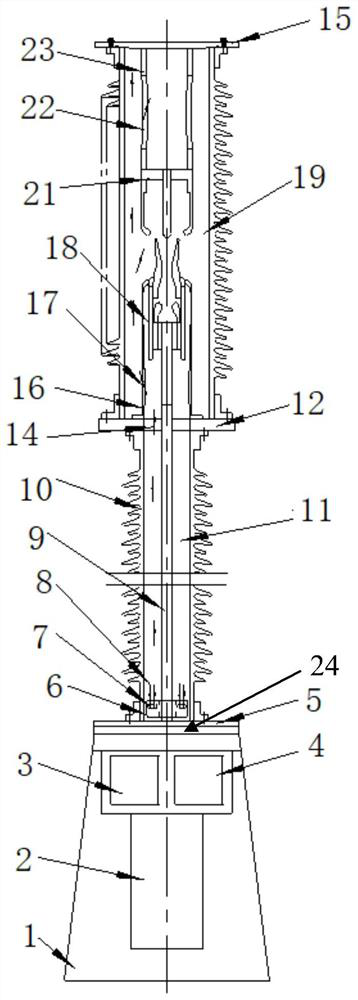

[0044] like Figure 1 to Figure 2 shown, figure 1 Heating scheme and thermal energy transfer path for single-phase strut circuit breakers.

[0045] The power supply 4 provides electrical energy for the controller, the temperature sensor feeds back the internal temperature of the circuit breaker to the controller, the controller 3 sends the work instruction and electrical energy to the infrared heater 7, controls the infrared heater 7 to enter and exit the heating state, and controls the infrared heater 7 The output energy value makes the heating and the heated target form a closed-loop working mode, and the controller can also be manually involved. When the circuit breaker is disconnected, the operating mechanism 2 moves to drive the moving contact of the arc extinguishing chamber to move.

[0046] The shape and power of the infrared heater 7 , the direction of emitting infrared rays 8 , and the distribution ratio of the infrared rays 8 conform to the structure and heating r...

Embodiment 2

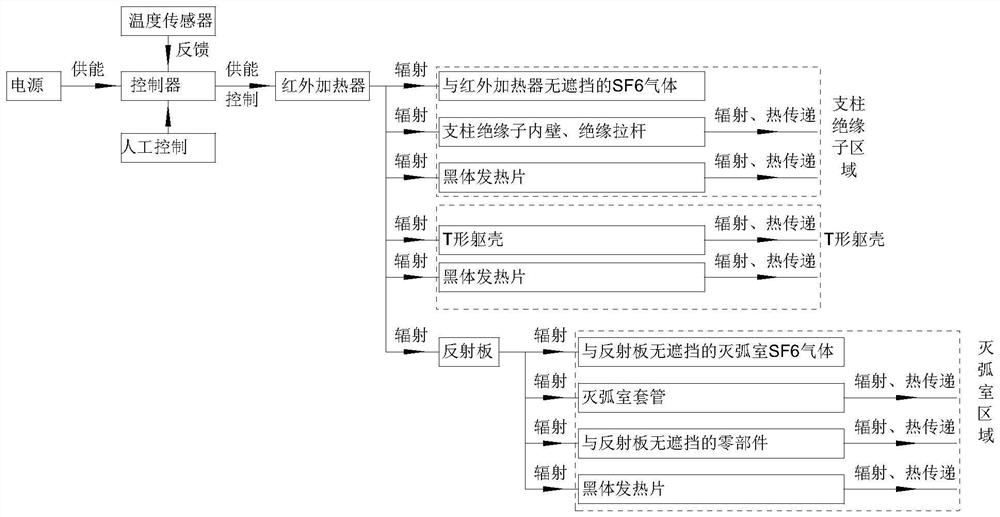

[0052] like Figure 3 to Figure 4 shown, image 3 Heating scheme and thermal energy transfer path for T-shaped double-break circuit breaker.

[0053] In the area inside the post insulator, the heating method is the same as that of the single-phase post circuit breaker in Example 1. In the circuit breaker of the T structure, because the circuit breaker pillar insulator and the two arc extinguishing chambers form a right angle, the infrared light of the infrared heater 7 at the bottom of the circuit breaker pillar insulator cannot be directly irradiated on the arc extinguishing chamber. 7's infrared rays are directly irradiated on the inner wall of the T body. At this time, the T-shaped body absorbs infrared rays, the temperature rises, and the heat is transferred to the surrounding SF 6 Gas, infrared rays that are not absorbed are reflected to other parts.

[0054] In order to improve the problem of the T-shaped body area, the heat-absorbing black body 13 can be installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com