Hydro-driving radial vibration well cementing short segment and using method thereof

A technology of radial vibration and hydraulic drive, which is applied in the direction of vibration generating devices, earthwork drilling and production, wellbore/well components, etc., and can solve wellbore unsafe accidents, soft formation medium falling or collapsing, and pipe strings that are easy to touch wells to improve cementing quality, wide effective vibration range, and improve displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

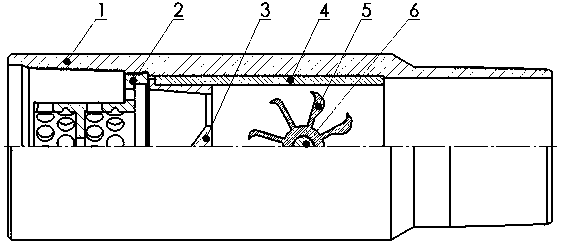

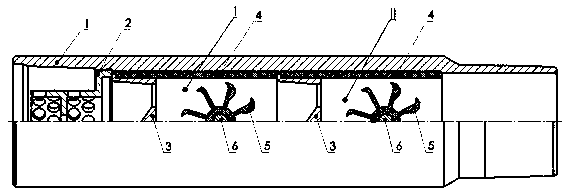

[0030] A hydraulically driven radial vibration cementing pup joint at least includes a body 1, which is characterized in that: the body 1 is a tubular cylinder with two ends open, and the two ends are provided with threads connected with matching casing strings. The body 1 A filter device is fixed inside the opening at one end, and a limit mechanism is fixed on the inner wall of the end of the body 1 far away from the filter device. A plurality of vibration units connected end to end are arranged in the body 1 between the filter device and the limit mechanism. The diameter matches the diameter of the body 1; the axis of the filter device, the vibration unit and the axis of the body 1 coincide, and the inner diameter of the filter device and the vibration unit form a flow passage.

[0031] When the present invention is used, due to the design of multiple vibration units, such as Figure 1-2 The shown includes two vibration units, which can produce superimposed vibration effects dur...

Embodiment 2

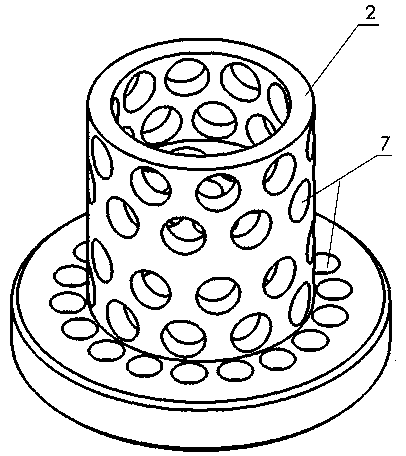

[0034] Such as Picture 1-1 , Figure 1-2 , figure 2 As shown, it is an improvement on the basis of embodiment 1. The filter device is threadedly connected to the opening at one end of the body 1. The filter device is a filter basket 2. The side wall of the filter basket 2 is provided with several filters along its radial direction. Hole 7.

[0035] The filter basket 2 is a cylindrical structure with two ends open, wherein the filter basket 2 is provided with a convex edge at one end close to the vibration unit, and the convex edge is provided with an external thread fixedly connected with the internal thread of the end of the body 1; A number of filter holes 7 are also opened in the length direction, and a number of filter holes 7 on the convex edge are arranged along the circumferential direction.

[0036] When in use, the filter basket 2 is made of aluminum alloy material. The filter basket 2 has high strength, good statues, excellent thermal conductivity, and good corrosion res...

Embodiment 3

[0038] Such as Picture 1-1 , Figure 1-2 ,, Figure 4 As shown, it is an improvement on the basis of embodiment 1 and embodiment 2. The vibration unit includes a support sleeve 4 and a deflector tube 3 located inside the support sleeve 4, a polarized waterwheel ball wheel 5 and a bearing 6. The support sleeve 4 and the guide tube 3 are both cylindrical structures with open ends. The guide tube 3 is fixed on the side of the support sleeve 4 close to the filter device, and the side wall of the support sleeve 4 away from the filter device runs along the radial direction. A set of through holes 9 for mounting the bearing 6 is opened, the bearing 6 is vertically fixed inside the support sleeve 4 through the through hole 9, and the polarized waterwheel ball wheel 5 is fixed on the rotating shaft of the bearing 6.

[0039] When in use, the liquid that has been filtered out of impurities by the filter basket 2 then enters the vibration unit. First, it passes through the guide tube 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com