Production process of home textile velvet

A production process, velvet technology, applied in the field of home textile velvet production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

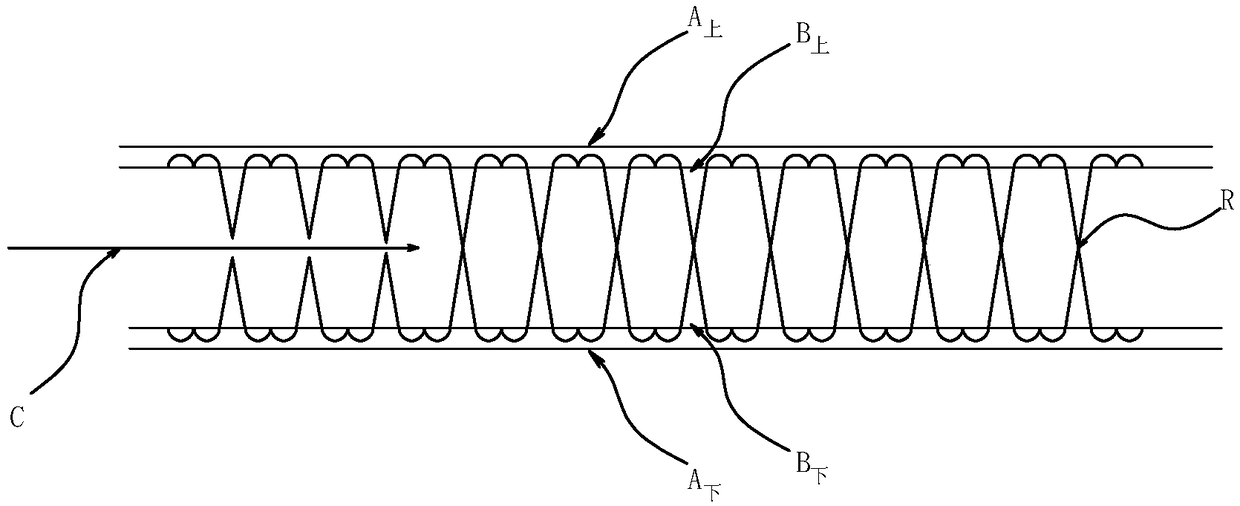

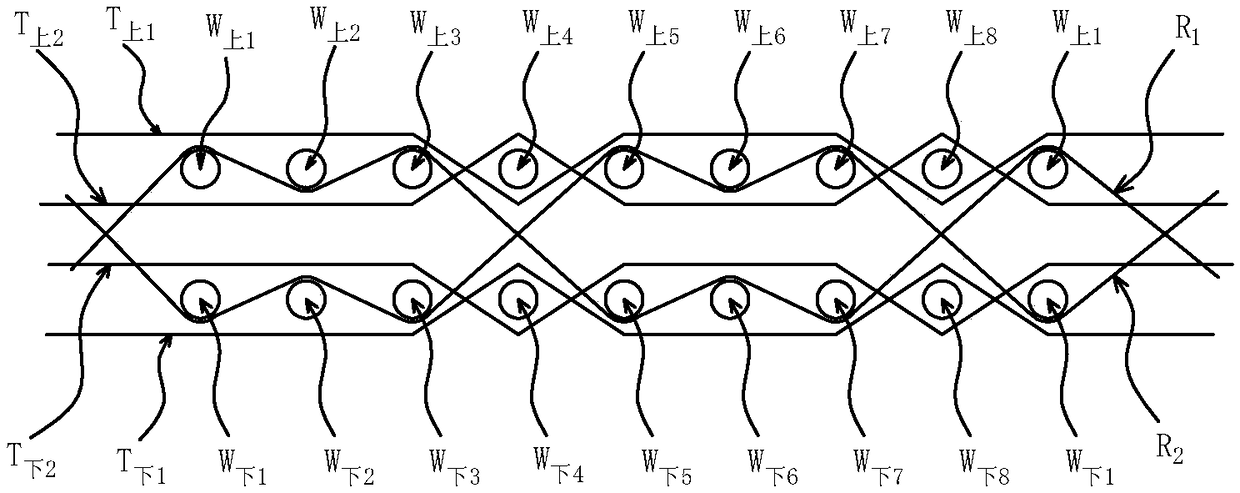

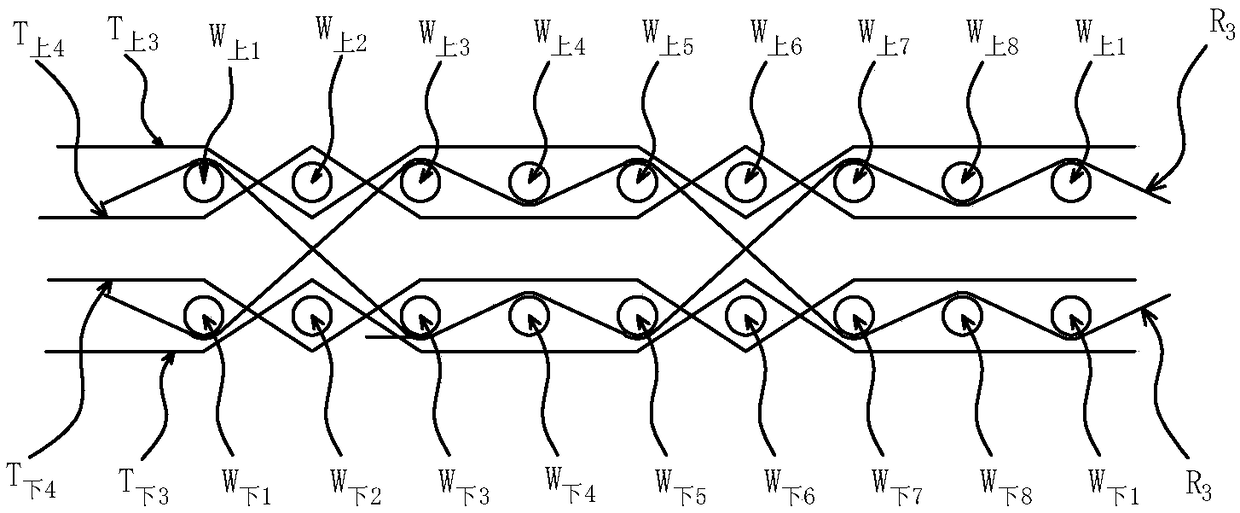

[0086] combine Figure 1 to Figure 3 , to describe this embodiment in detail. The production process of a home textile velvet involved in this embodiment is formed by cutting the pile and finishing the double-layer fabric including the upper base fabric, the lower base fabric and the pile warp R. The fleece is connected to the upper base fabric and the lower base fabric through R, and is consolidated through the upper base fabric and the lower base fabric W.

[0087] The upper base fabric is interwoven with the warp yarns of the upper base fabric and the weft yarns of the upper base fabric, and the fabric structure adopted is 3 up and 1 down changing plain weave. The warp yarns of the upper base fabric include the first warp yarn T of the upper base fabric 上1 , The second warp yarn T of the upper base fabric 上2 , The third warp yarn T of the upper base fabric 上3 , The fourth warp T of the upper base fabric 上4 . The weft yarn of the upper base fabric includes the first we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com