A device and method for quickly removing metal sealing rings of small catheters

A technology of metal sealing rings and small conduits, applied in the manufacture of tools, hand-held tools, etc., can solve problems such as hidden dangers in quality, and achieve the effects of prolonging service life, reducing production costs, and reliable extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

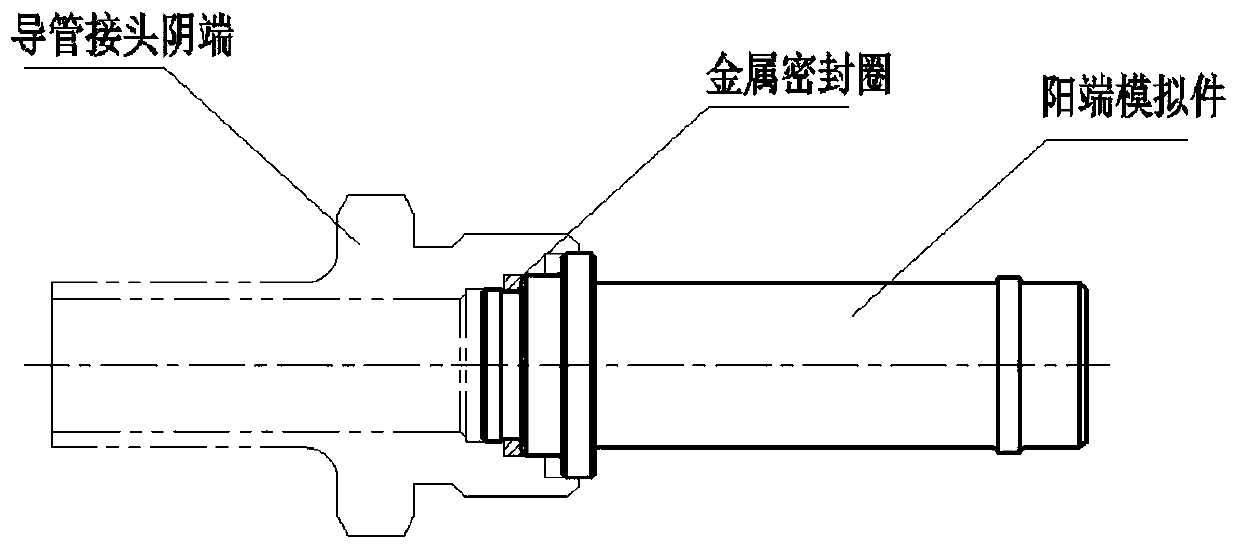

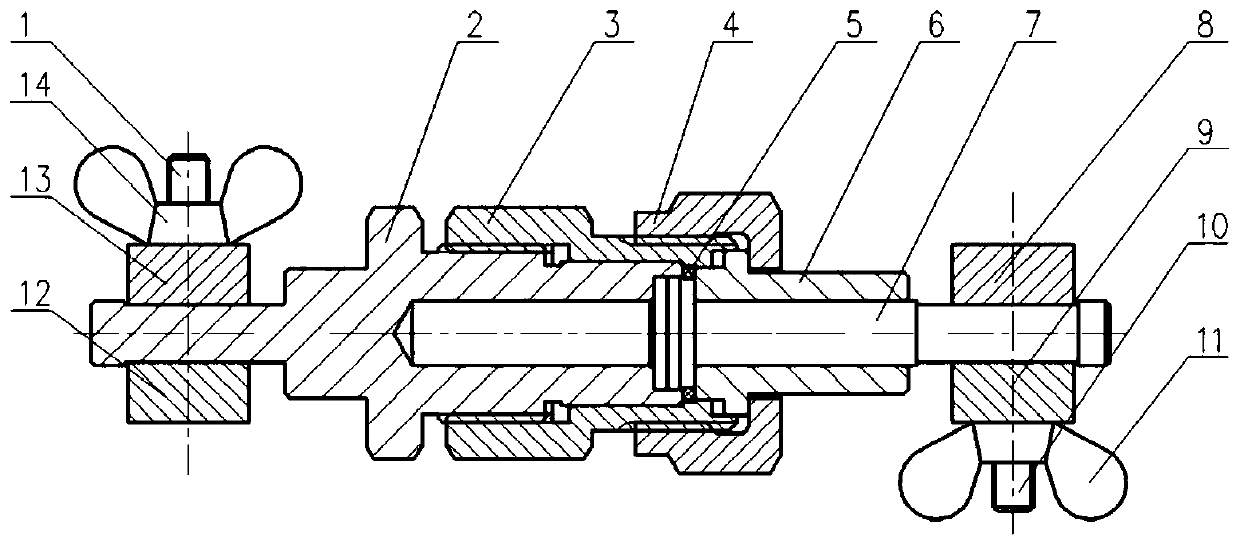

[0072] Take the metal sealing ring at the female end of the small conduit connector such as Figure 7 shown. The convex step combination is matched with the female end 17 of the small conduit connector, wherein the end of the small conduit connector is inlaid with a metal sealing ring 5, and the female end 17 of the small conduit connector is held by an open-end wrench, and the tooling outer nut 4 is tightened clockwise with another open-end wrench , and a torque of 50N·m is applied. At this time, the metal sealing ring is located between the small conduit joint and the top shaft 6, and is deformed under pressure. hook structure such as Figure 10 shown. Then loosen the tooling overcoat nut 4 with a wrench, pull the pull shaft 7 out by pulling the pull plate assembly, and the metal sealing ring is pulled out. At this time, loosen the wing nuts 11, 14, and separate the upper pressing block 9 and the lower pressing block 8, so that the drawing plate assembly can be separated ...

Embodiment 2

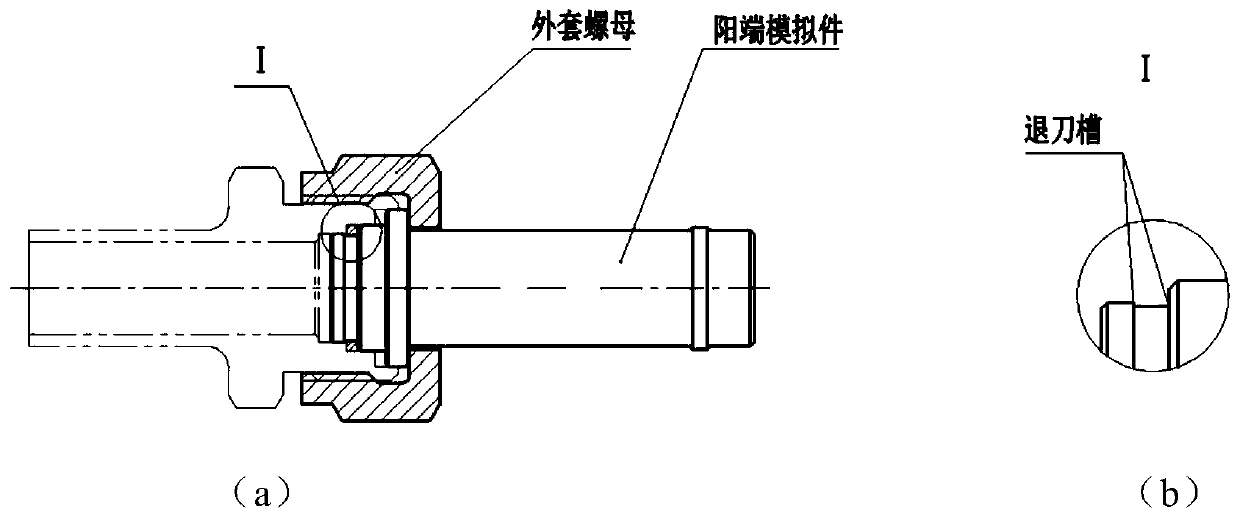

[0074] Take the metal sealing ring at the male end of the small conduit connector such as Figure 8 shown. The concave step combination is matched with the male end 16 of the small conduit joint, wherein the small conduit joint end is inlaid with a metal sealing ring 5, and the pull sleeve 3 is held by an open-end wrench, and the small conduit male end is tightened clockwise with the jacket Nut 15, and apply a 50N·m torque, at this time, the metal sealing ring is located between the small conduit joint and the top sleeve 2, deformed under pressure, the outer diameter of the metal sealing ring becomes larger, and embedded in the hole-shaped ring hook of the pull sleeve 3, Hole ring hook structure such as Figure 9 shown. Then loosen the overcoat nut 15 at the male end of the small conduit with a wrench, and pull the pull sleeve 3 out by pulling the pull plate assembly, and the metal sealing ring is pulled out. At this time, the wing nuts 11 and 14 are loosened, and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com