Sludge dehydration and solidification device

A solidification and sludge technology, which is used in fixed/solidified sludge treatment, grinding/polishing safety devices, chemical instruments and methods, etc., which can solve the problems of tedious work and time, removing sludge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0059] (the whole frame)

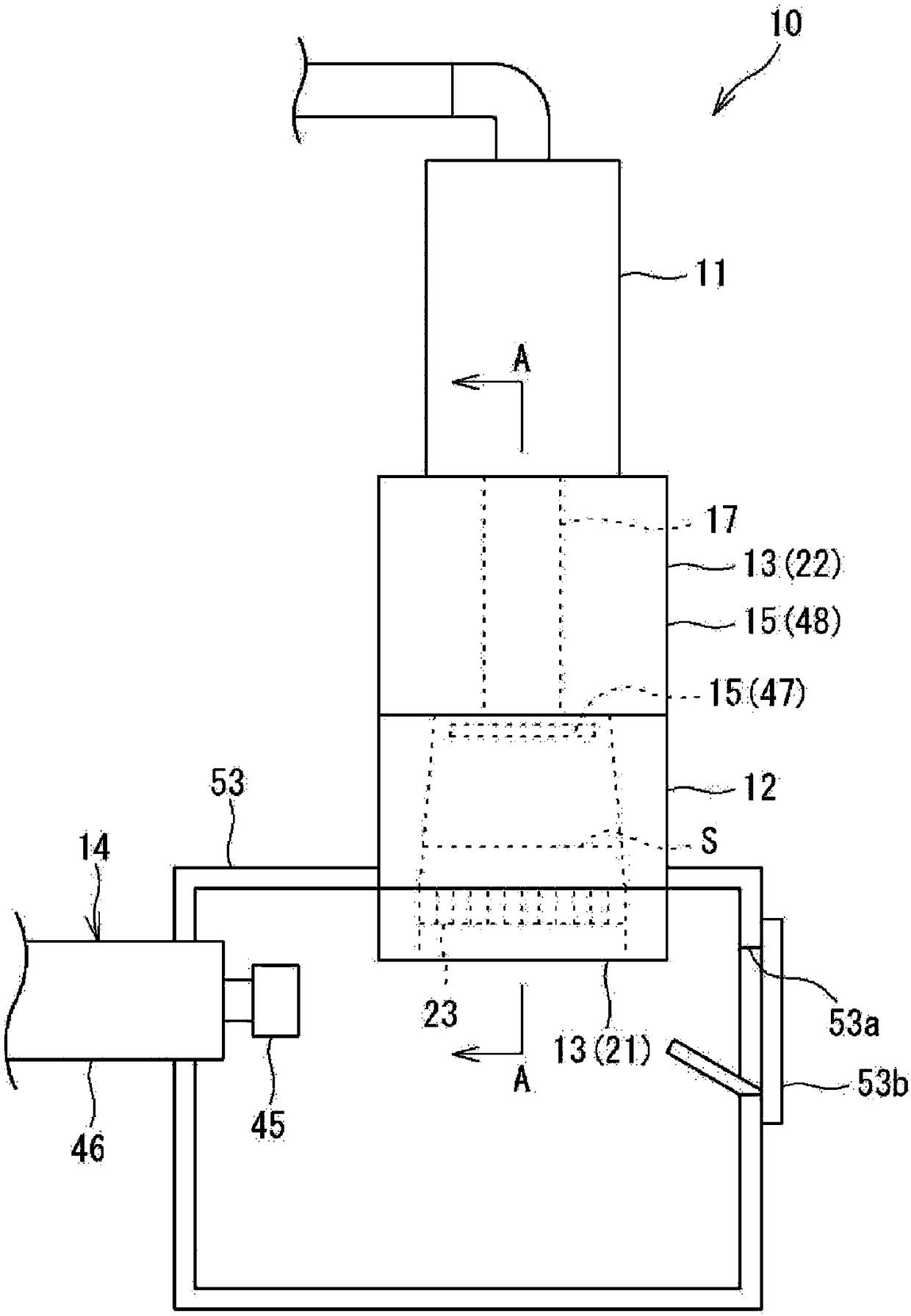

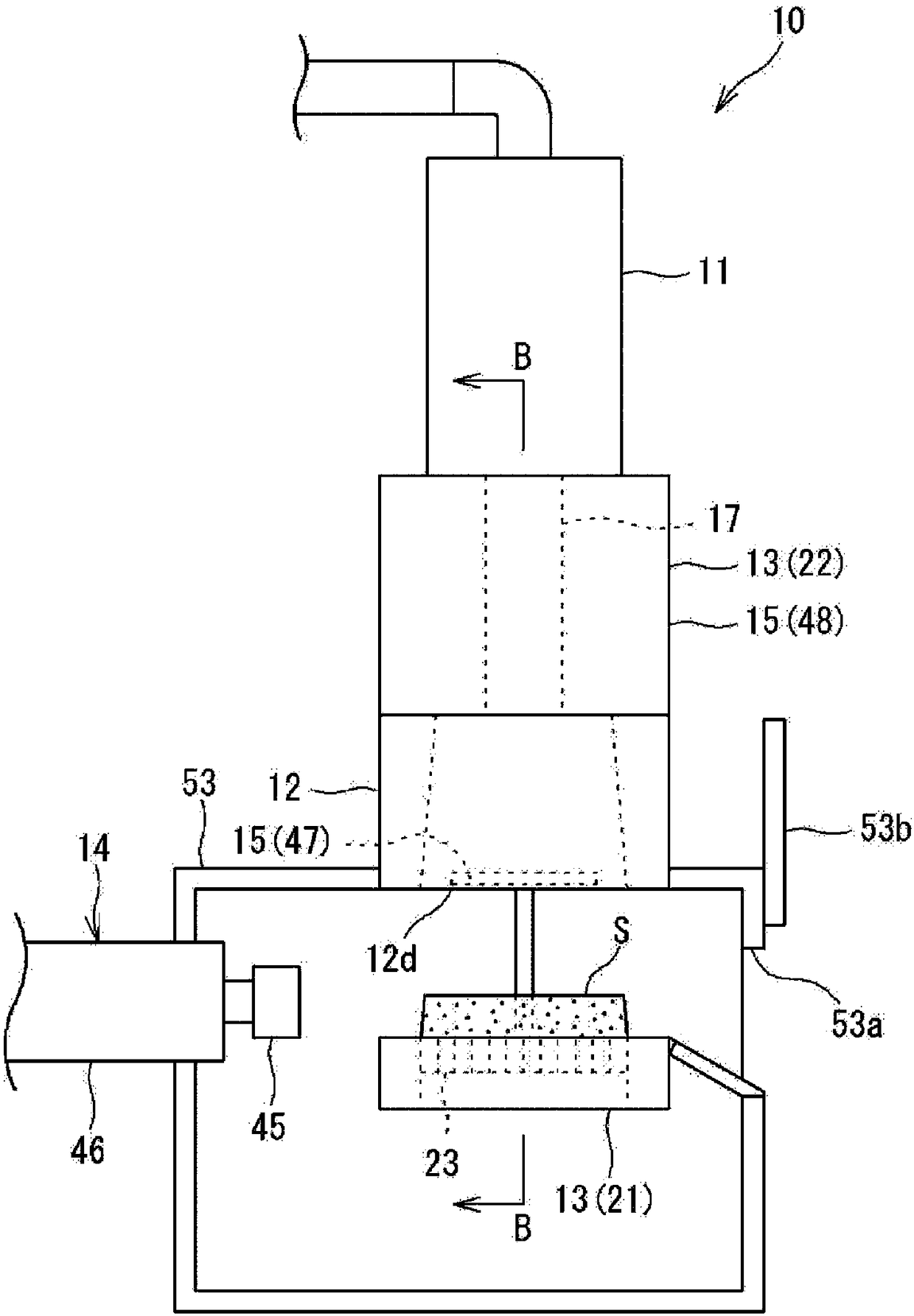

[0060] figure 1 and figure 2 It is a schematic overall view showing the sludge dehydration and solidification device according to the first embodiment of the present invention.

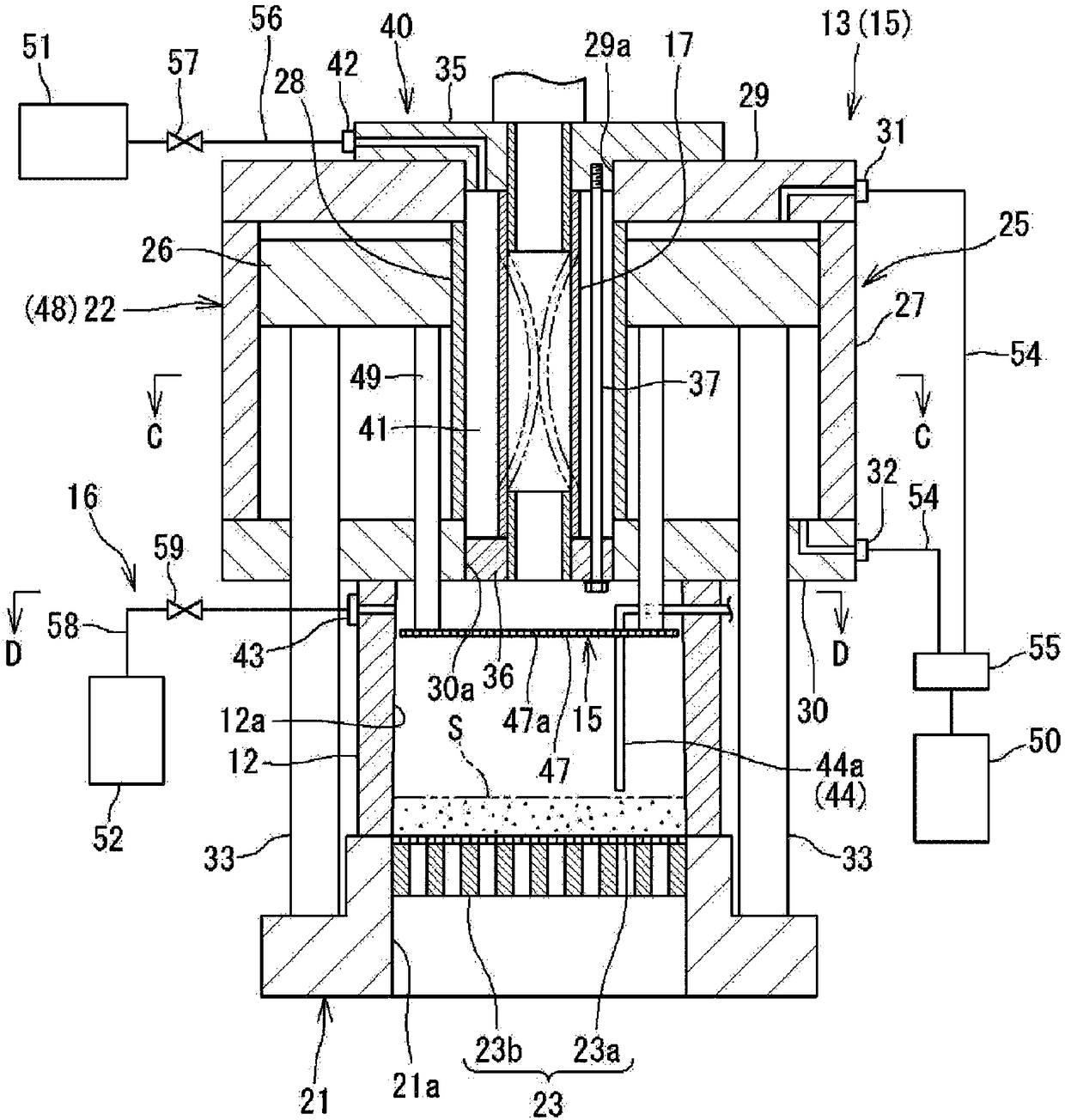

[0061] The liquid removal and solidification device 10 is used, for example, to purify the cooling medium used in machine tools such as honing machines. Described liquid removal and solidification device 10 is equipped with filtering device 11, processing container 12, opening and closing mechanism 13, liquid removal and solidification mechanism 16 (referring to image 3 and Figure 4 ), discharge mechanism 14 and extrusion mechanism 15. in addition, figure 1 shows the state when the sludge S is solidified in the processing container 12, figure 2 The state when the solidified sludge S is discharged from the processing container 12 is shown.

[0062] The cooling medium used in the machine tool is supplied to the filter device 11, and the filter device 11 removes sludge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com