A short process preparation method of gh4169 alloy welding wire

A technology of GH4169 and alloy welding wire, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as uneven structure, low plastic toughness of welded joints, and many microscopic cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

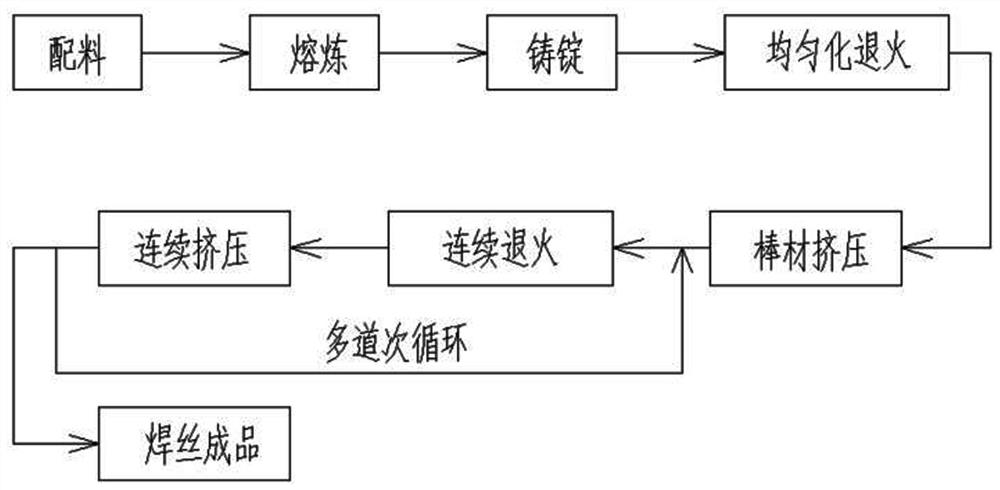

[0029] A short-process preparation method for GH4169 alloy welding wire. The raw materials used in the manufacture of the alloy welding wire are composed of the following components by weight percentage: Ni: 50.0%-55.0%, Cr: 17.0%-21.0%, Nb: 5.00% %~5.50%, Mo: 2.80%~3.30%, Ti: 0.75%~1.15%, Al: 0.30%~0.70%, C: 0.02%~0.06%, the rest is Fe and a small amount of impurities, the preparation process is as follows figure 1 shown, including the following steps:

[0030] Step (1), batching; when batching the welding wire chemical composition range, determine the batching ratio according to the technical requirements of different weldments, that is: when batching the welding wire chemical composition interval, fine-tune the performance requirements of different weldments (±0.3- 0.5%) alloy ingredient ratio;

[0031] Step (2), smelting: use a vacuum induction electroslag remelting furnace to smelt the alloy, put Ni, Cr, Nb, Mo, C, Fe and other raw materials weighed according to the prop...

Embodiment 1

[0040] A short-process preparation method for GH4169 alloy welding wire. The raw materials used in the manufacture of the alloy welding wire are calculated by weight percentage and consist of the following components: Ni: 50.0%, Cr: 17.0%, Nb: 5.00%, Mo: 2.80% , Ti: 1.15%, Al: 0.70%, C: 0.06%, the rest is Fe and a small amount of impurities, the preparation process is as follows figure 1 shown, including the following steps:

[0041] Step (1), batching; when weighing the batching of each component, fine-tune the batching ratio of ±0.5 alloy according to the performance requirements of different weldments;

[0042] Step (2), smelting: use a vacuum induction electroslag remelting furnace to smelt the alloy, put Ni, Cr, Nb, Mo, C, Fe and other raw materials weighed according to the proportion of ingredients into the crucible, then vacuumize, and then Heat to 1320°C to melt all the raw materials, turn off the power and supply argon, then continue heating to 1320°C, then add Ti an...

Embodiment 2

[0049] A short-process preparation method for GH4169 alloy welding wire. The raw materials used in the manufacture of the alloy welding wire are calculated by weight percentage and consist of the following components: Ni: 55.0%, Cr: 21.0%, Nb: 5.50%, Mo: 3.30%, Ti: 0.75%, Al: 0.30%, C: 0.02%, the rest is Fe and a small amount of impurities, the preparation process is as follows figure 1 shown, including the following steps:

[0050] Step (1), batching; when weighing the batching of each component, fine-tune the batching ratio of ±0.3 alloy according to the performance requirements of different weldments;

[0051] Step (2), smelting: use a vacuum induction electroslag remelting furnace to smelt the alloy, put Ni, Cr, Nb, Mo, C, Fe and other raw materials weighed according to the proportion of ingredients into the crucible, then vacuumize, and then Heat to 1400°C to melt all the raw materials, turn off the power and supply argon, then continue heating to 1320°C, then add Ti and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com