Extrusion mechanism for kitchen garbage

A technology of extrusion mechanism and kitchen waste, applied in the direction of presses, manufacturing tools, etc., can solve the problems of breeding bacteria, mosquitoes and flies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

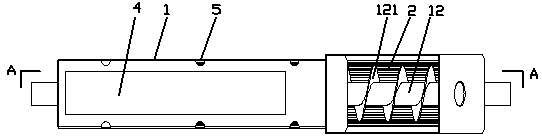

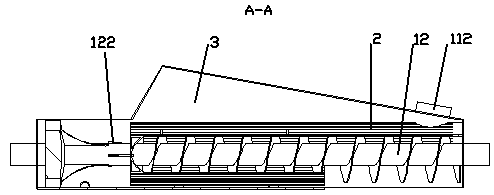

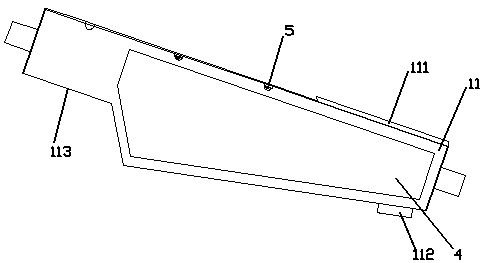

[0020] The present invention as Figure 1-4 As shown, it includes a screw conveyor 1 and a screen cylinder 2. The screw conveyor includes a conveying cylinder 11 and a rotating shaft 12. The conveying cylinder is arranged obliquely. There is a water outlet 112 (a water cylinder is placed under the water outlet to facilitate the recycling of waste water), and the other end is provided with a material outlet 113;

[0021] A helical blade 121 is provided on the rotating shaft, the sieve cylinder is arranged in the conveying cylinder, and a distance is set between the helical blade and the sieve cylinder;

[0022] One end of the rotating shaft located at the outlet of the conveying cylinder is provided with staggered separators 122 . The separator is ring-shaped and arranged on the rotating shaft to play the role of reliable material removal and dispersion.

[0023] In the working process of the present invention, the stirred and crushed food waste is sent to the extrusion mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com