Vacuum vessel, vacuum vessel manufacturing method, vacuum processing apparatus, and electronic device manufacturing method

A vacuum container and container technology, applied in semiconductor/solid-state device manufacturing, electrical components, mechanical equipment, etc., can solve the problems of vacuum performance reliability degradation, increase manufacturing cost, etc., and achieve reduced manufacturing cost, simple structure, and easy vacuum container. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Detailed embodiments of the present invention will be described below with reference to the accompanying drawings.

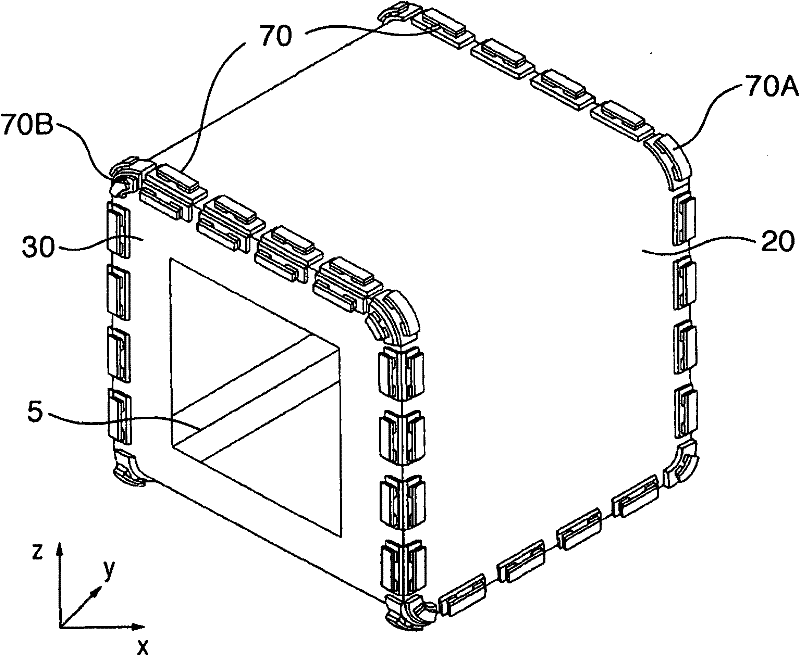

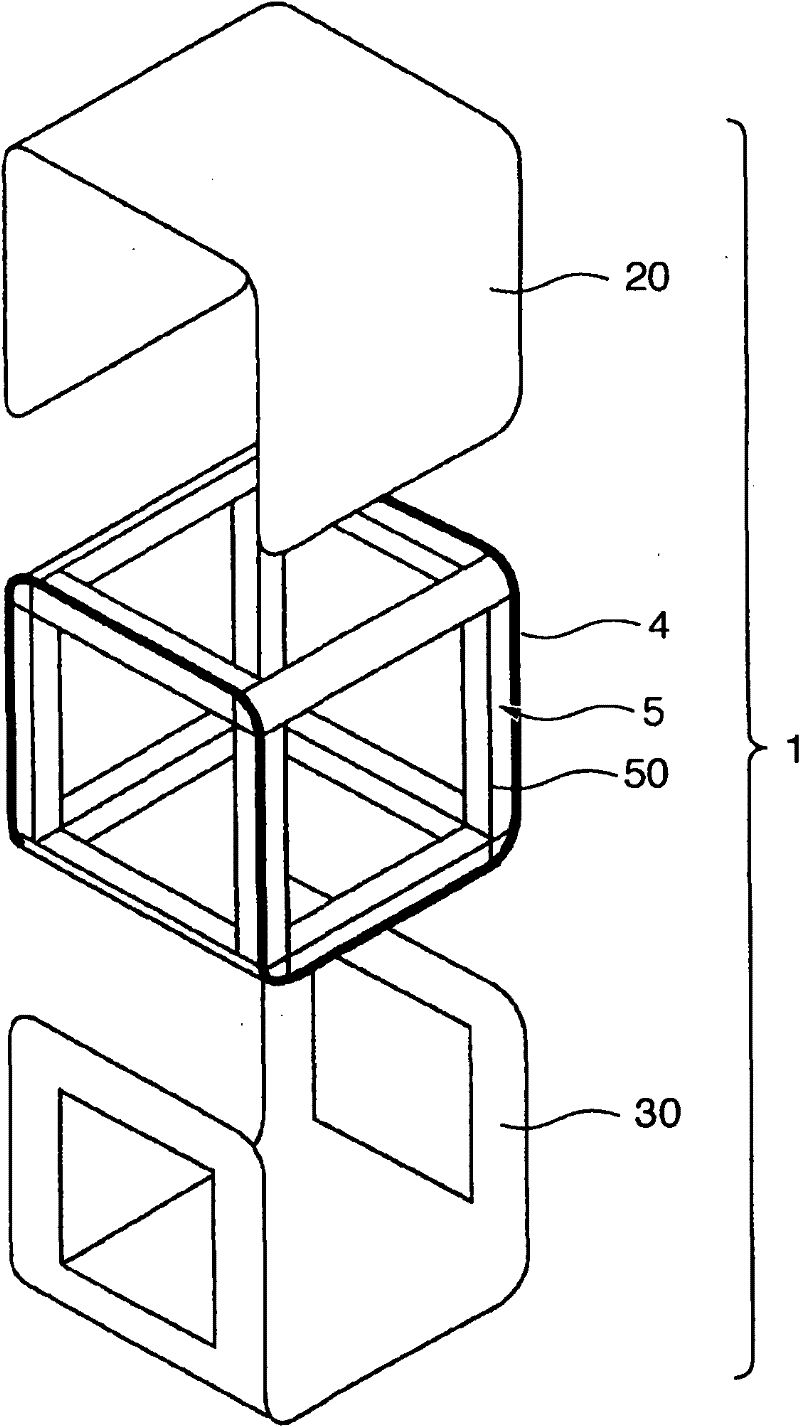

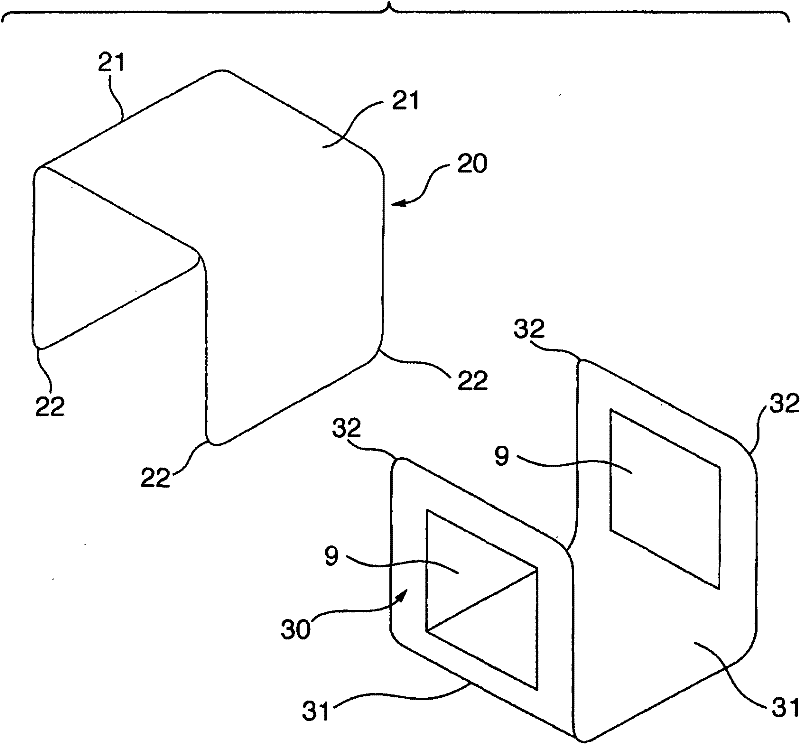

[0040] figure 1 A vacuum container according to one embodiment of the present invention is shown. This example will illustrate a hexahedral vacuum vessel. figure 2 yes figure 1 An exploded perspective view of the vacuum vessel shown in .

[0041] Such as figure 1 with2 As shown in , the vacuum container 1 includes a pair of curved members 20 and 30 . The bending members 20 and 30 are formed by bending a metal plate into a predetermined shape. The vacuum vessel 1 is formed by combining the curved members 20 and 30 with each other to form a closed space inside the curved members 20 and 30 . The vacuum vessel 1 also includes a sealing member 4 and a cubic lattice structure 5 . The sealing member 4 seals the gap in the joint portion between the bent members 20 and 30 . The structure 5 is housed in the closed space while abutting against the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com