Patents

Literature

41results about How to "In line with the actual production situation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

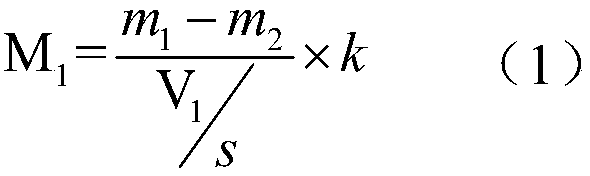

Method for predicting yield of gas well

ActiveCN104832156ASolve fixed proration coefficientIn line with the actual production situationSurveyRegression analysisStreamflow

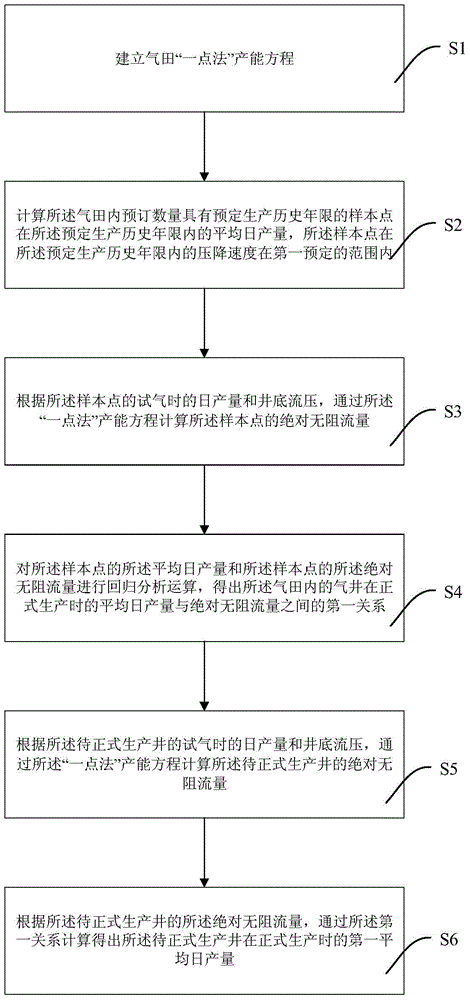

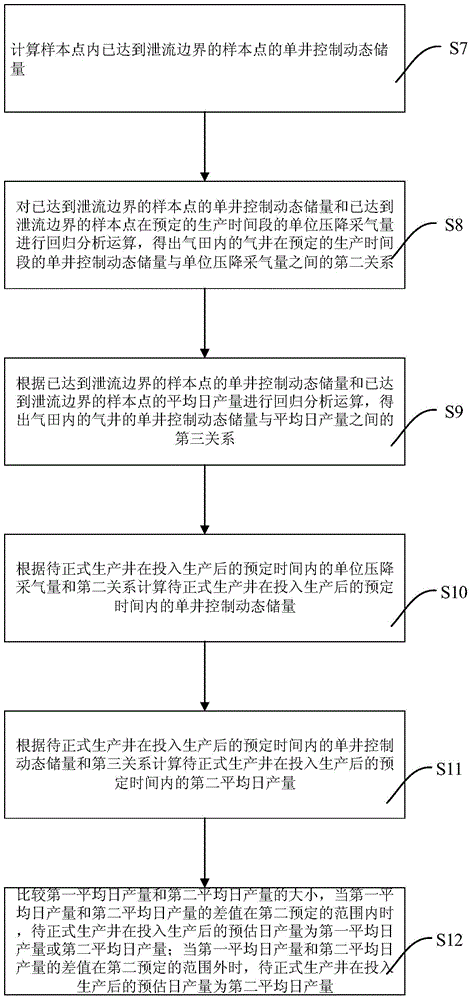

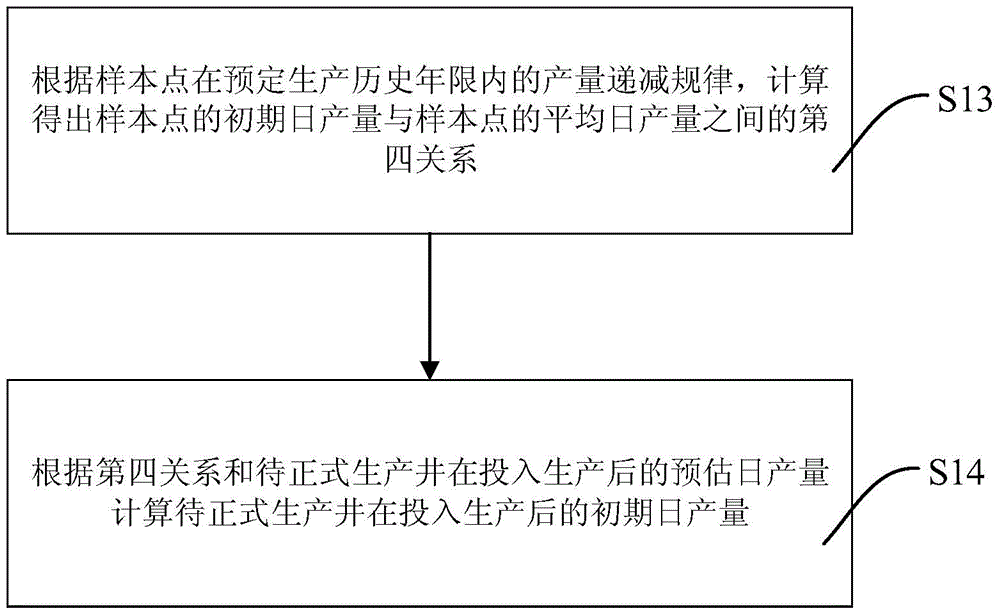

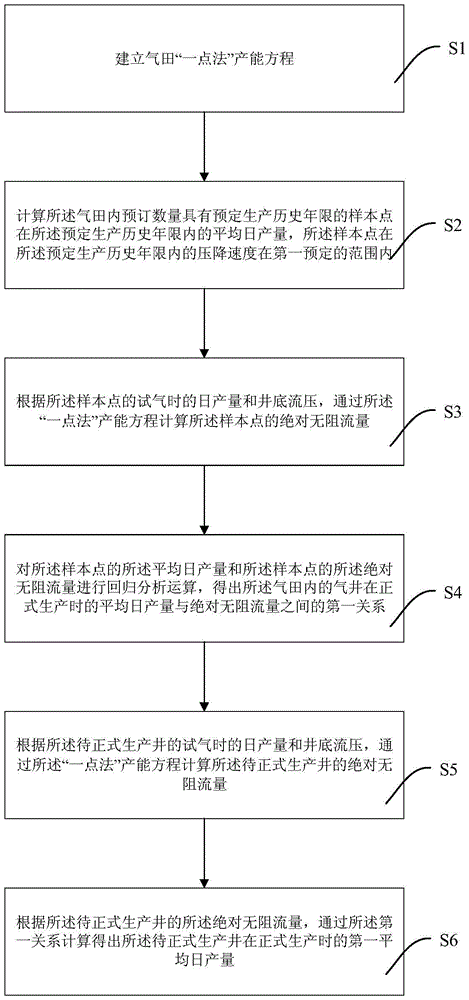

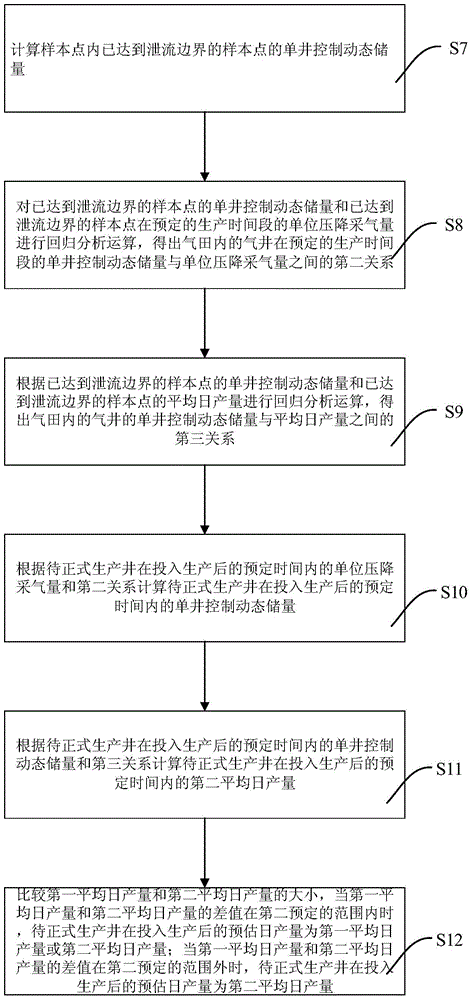

The invention provides a method for predicting the yield of a gas well. The method comprises the steps: establishing a one-point-method deliverability equation of a gas field; calculating average daily yield of sample points in the gas field in predetermined historical years, wherein the pressure drop speed of the sample points in the predetermined production historical years falls in a first predetermined range; calculating an absolute open-flow capacity of the sample points according to the daily yield and the bottom flow pressure of the sample points when in gas test; carrying out the regression analysis on the average daily yield of the sample points and the absolute open flow capacity of the sample points, and obtaining a first relation between the average daily yield and the absolute open flow capacity of the gas well in the gas field when in normal production; calculating the absolute open flow capacity of a to-be-put-into-production well according to the daily yield and the bottom flow pressure of the to-be-put-into-production well; calculating a first average daily yield of the to-be-put-into-production well according to the absolute open flow capacity of the to-be-put-into-production well. By adopting the method, the daily yield of the gas well can be predicted according to the real production situation after a compact sandstone gas reservoir is fractured.

Owner:PETROCHINA CO LTD

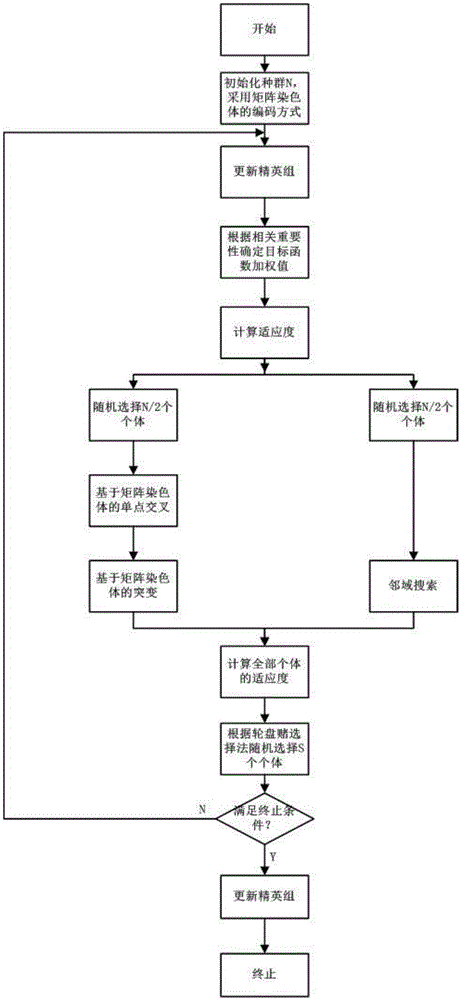

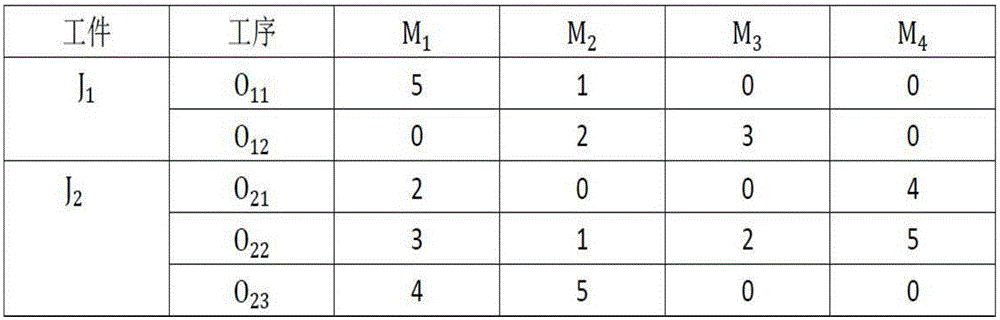

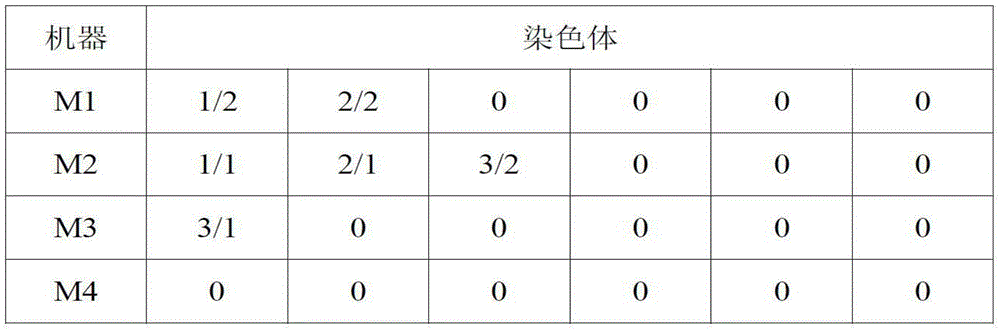

Hybrid genetic algorithm for solving multi-objective flexible job-shop scheduling problem

InactiveCN106610651AAvoid extra computing timeSimplify the coding processProgramme total factory controlCompletion timeAlgorithm

The invention provides a hybrid genetic algorithm for solving a multi-objective flexible job-shop scheduling problem. The algorithm takes three objectives of the completion time, the production cost and the equipment utilization rate in flexible job-shop scheduling into consideration, and aims at the circumstances that algorithms at present are difficult in decoding and long in computation time because of possession of a complicated coding method and that the genetic algorithm is faced with problems of global near optimum and insufficient search capability in local search. In allusion to the problems, the invention provides a new matrix chromosome coding method which almost does not need to perform decoding. In addition, the algorithm provided by the invention combines the global search capability and local search of the genetic algorithm, the search capability of the algorithm is enhanced, and a feasible solution is found more easily. The hybrid algorithm is high in practicability, and can be well applied to flexible job-shop scheduling.

Owner:SICHUAN YONGLIAN INFORMATION TECH CO LTD

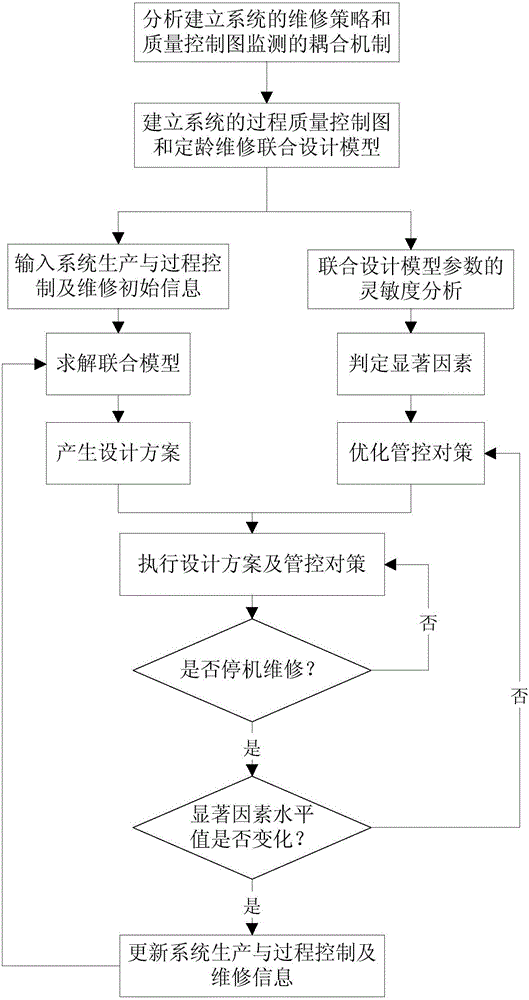

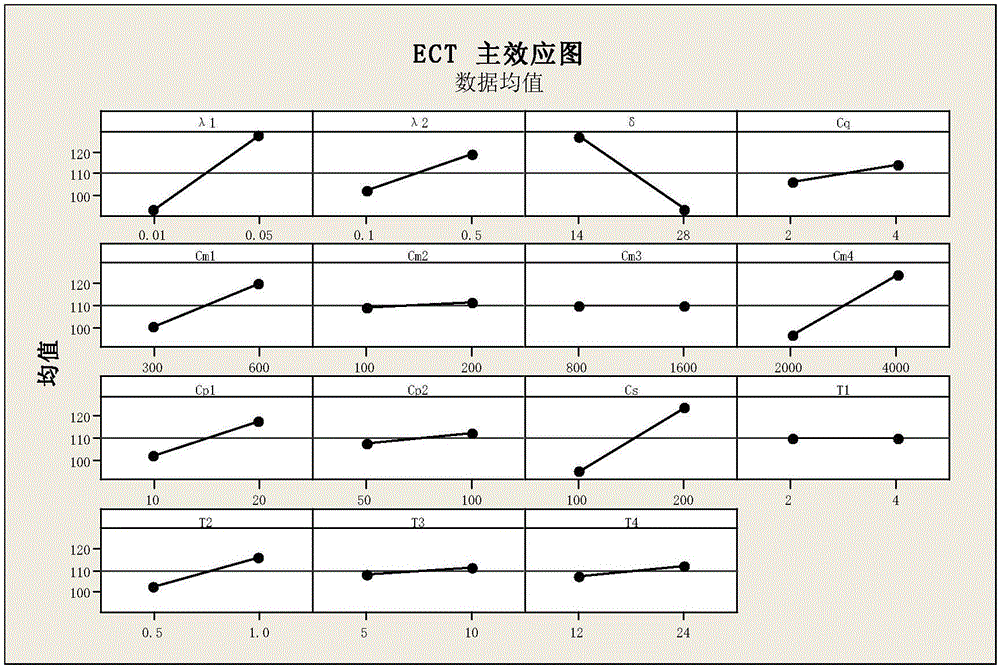

Dynamic optimization control method of process quality control graph and age-set maintenance combined design

ActiveCN106249709AIn line with the actual production situationAccurate dataTechnology managementTotal factory controlProcess qualityCountermeasure

The invention provides a dynamic optimization control method of a process quality control graph and age-set maintenance combined design, and the method is used to realize continuous optimization of a process quality control graph and age-set maintenance combined design scheme of a production system so as to minimize the integrated cost of production operation. The method comprises that 1) a process quality control graph and age-set maintenance combined design model, aimed at minimizing the integrated cost of production operation, of the production system is constructed; 2) a process quality control graph and age-set maintenance combined design scheme is solved according to the combined design model by utilizing a genetic algorithm; 3) an initial scheme and a cost management countermeasure are executed, and when shut-down maintenance is triggered during system operation, whether the cost level of a significance influential factor is changed obviously is determined; and 4) according to a determination result, the execution scheme is optimized and enforced, a new cost-reducing countermeasure is provided and the original design scheme are executed if there is no change, and if there is change, the design scheme needs to be optimized, and the design scheme is solved again according to a change result by utilizing the genetic algorithm, and execution of the scheme is determined.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Critical chain buffer area arrangement method based on production uncertainty

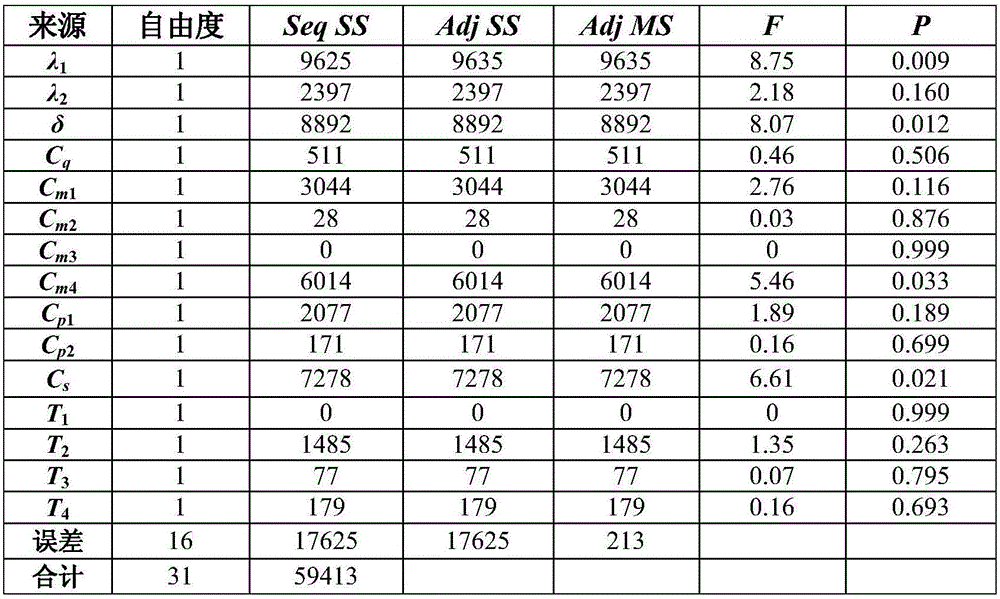

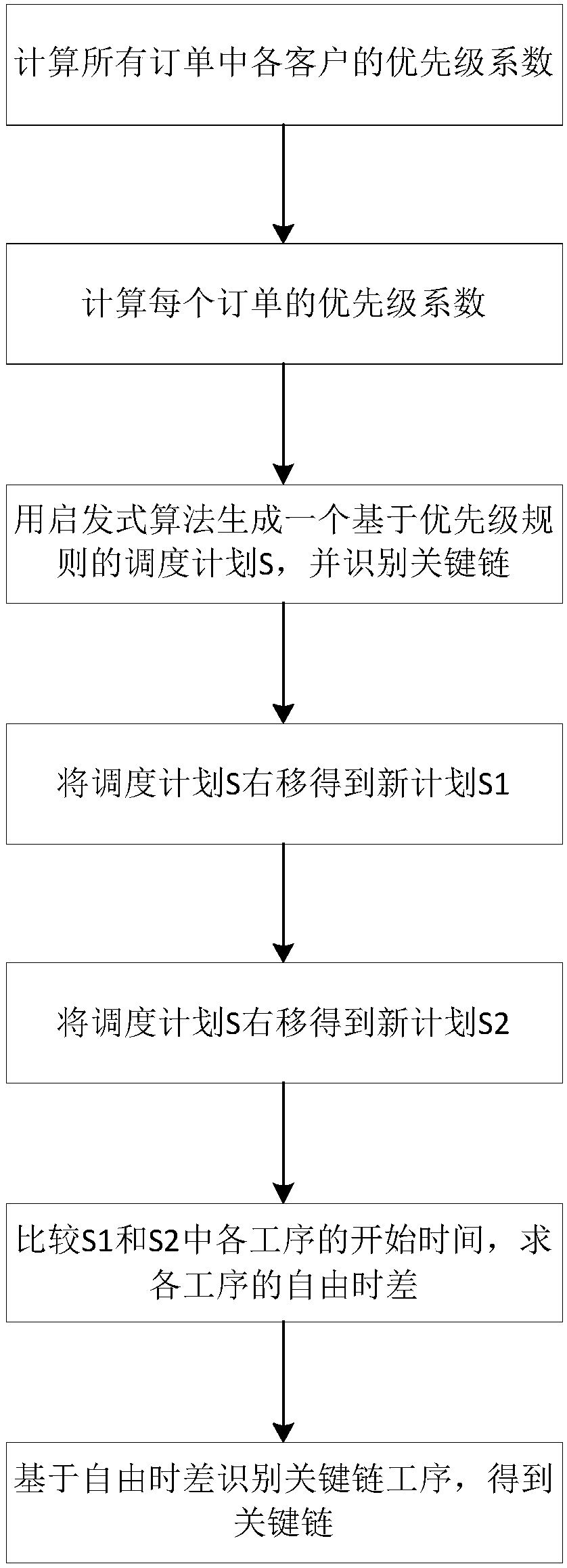

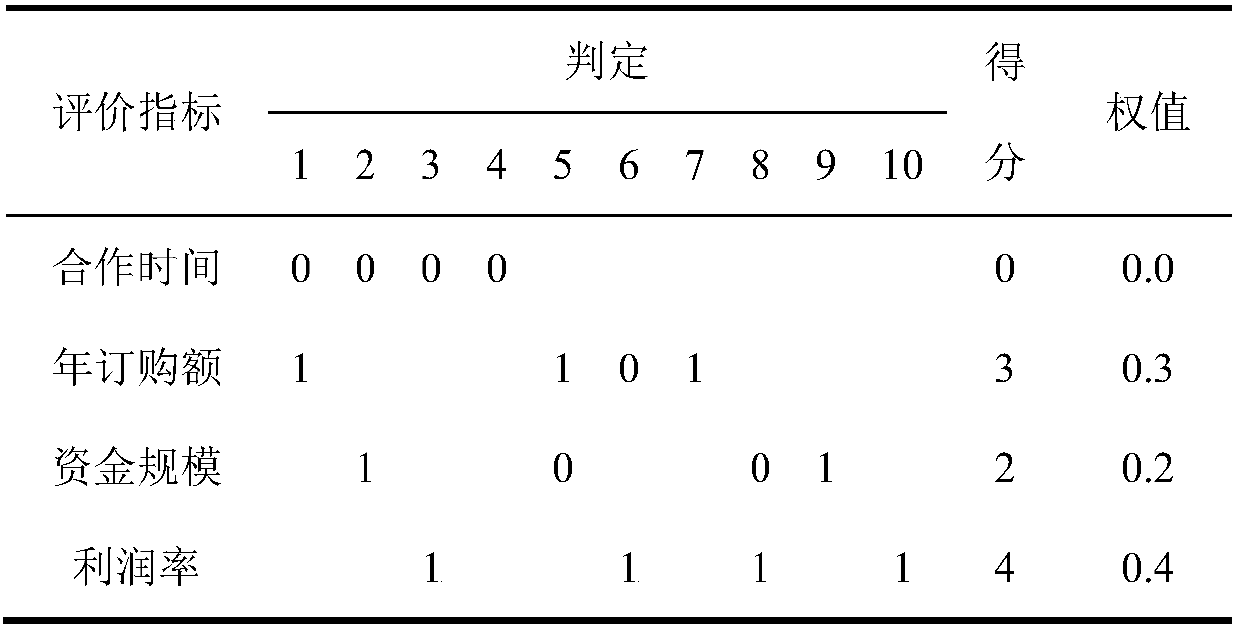

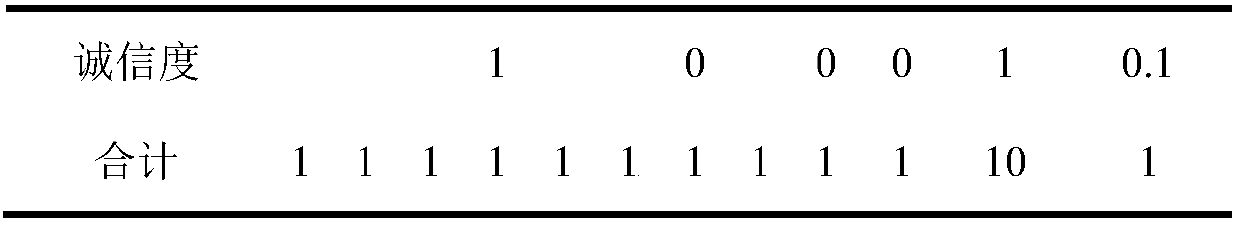

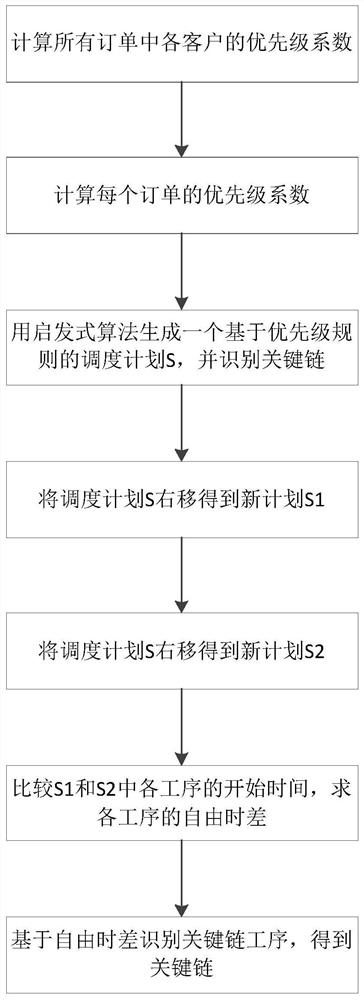

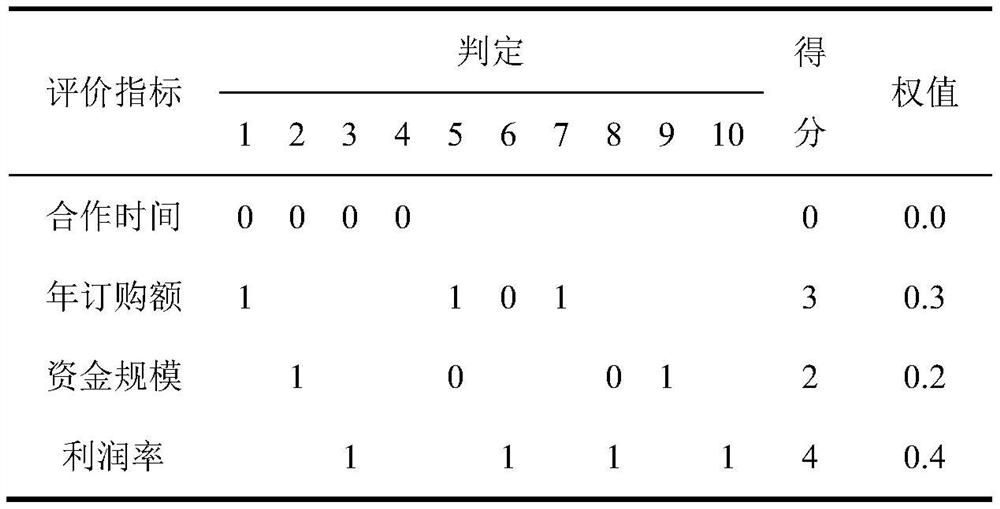

ActiveCN107944695AImprove accuracyIn line with the actual production situationResourcesManufacturing computing systemsStart timeRight shift

The invention discloses a critical chain buffer area arrangement method based on production uncertainty. Firstly the priority coefficient of the customer and the priority coefficient of the order areacquired, then a dispatching plan based on the priority rules is generated by using a heuristic algorithm, then left and right shift operation is performed on the obtained dispatching plan to obtain two new dispatching plans, the start time of all the processes is compared and the free time difference of each process is acquired, the process of which the free time difference is zero is the critical chain process and the critical chain is obtained, and then the input, the items and the buffer area size of the resource buffer area are set based on the free time difference and the improved root square difference method. The root square difference method is improved through combination of the resource utilization degree and the variability measurement, and the calculation result of the root square difference method is corrected through accurate measurement of the processing time variability of the process by aiming at the influence problem of a lot of uncertain factors on buffer area calculation under the complex production environment so that the accuracy of buffer area calculation can be effectively enhanced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

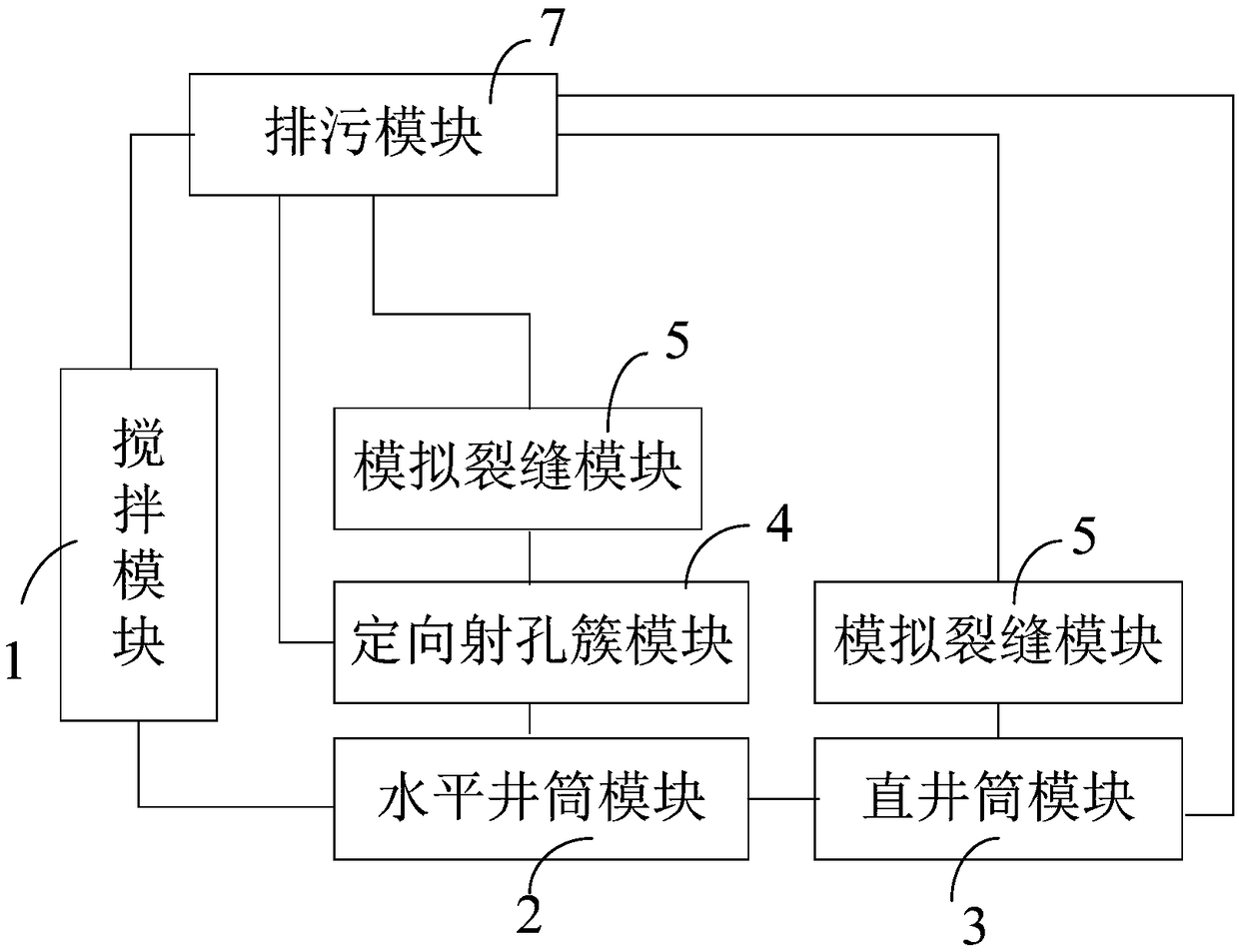

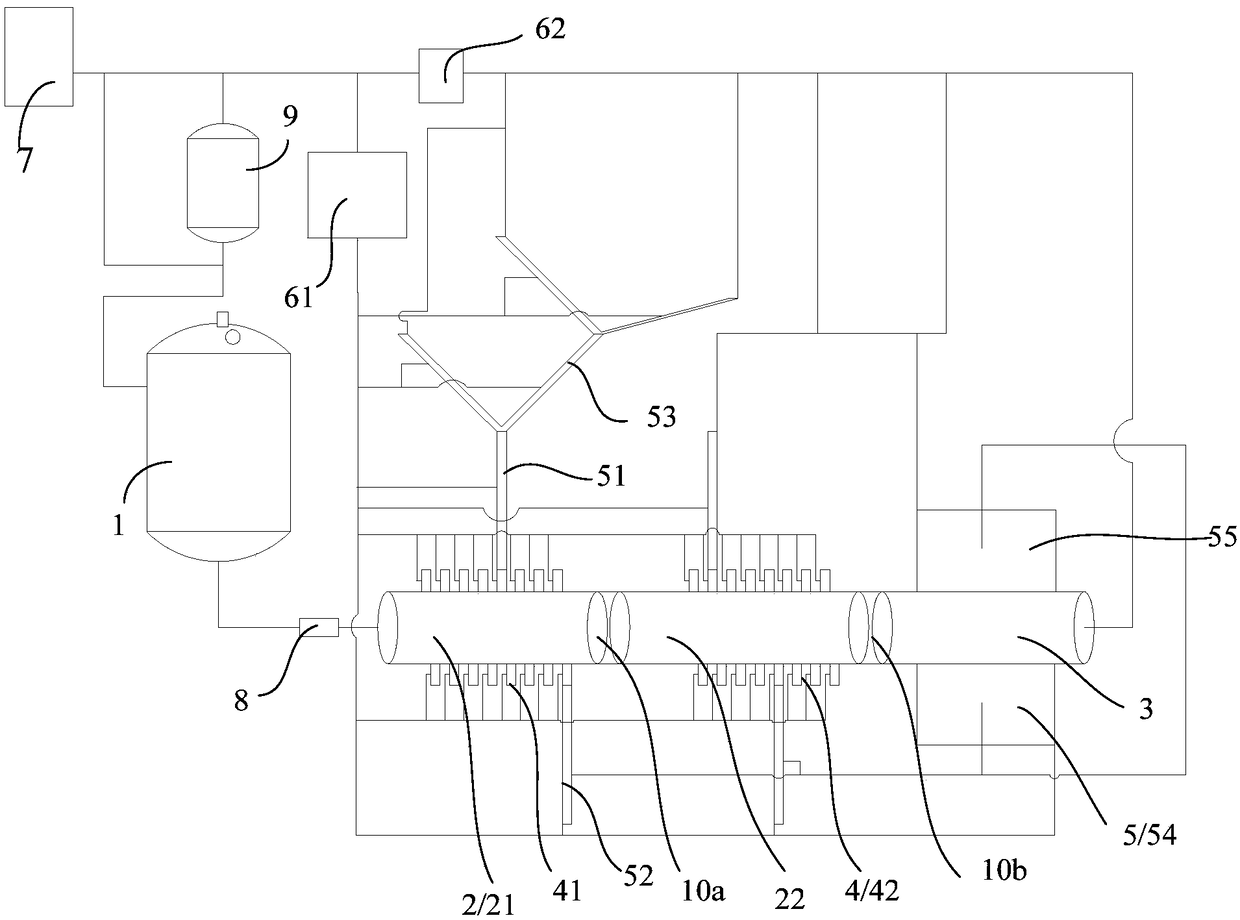

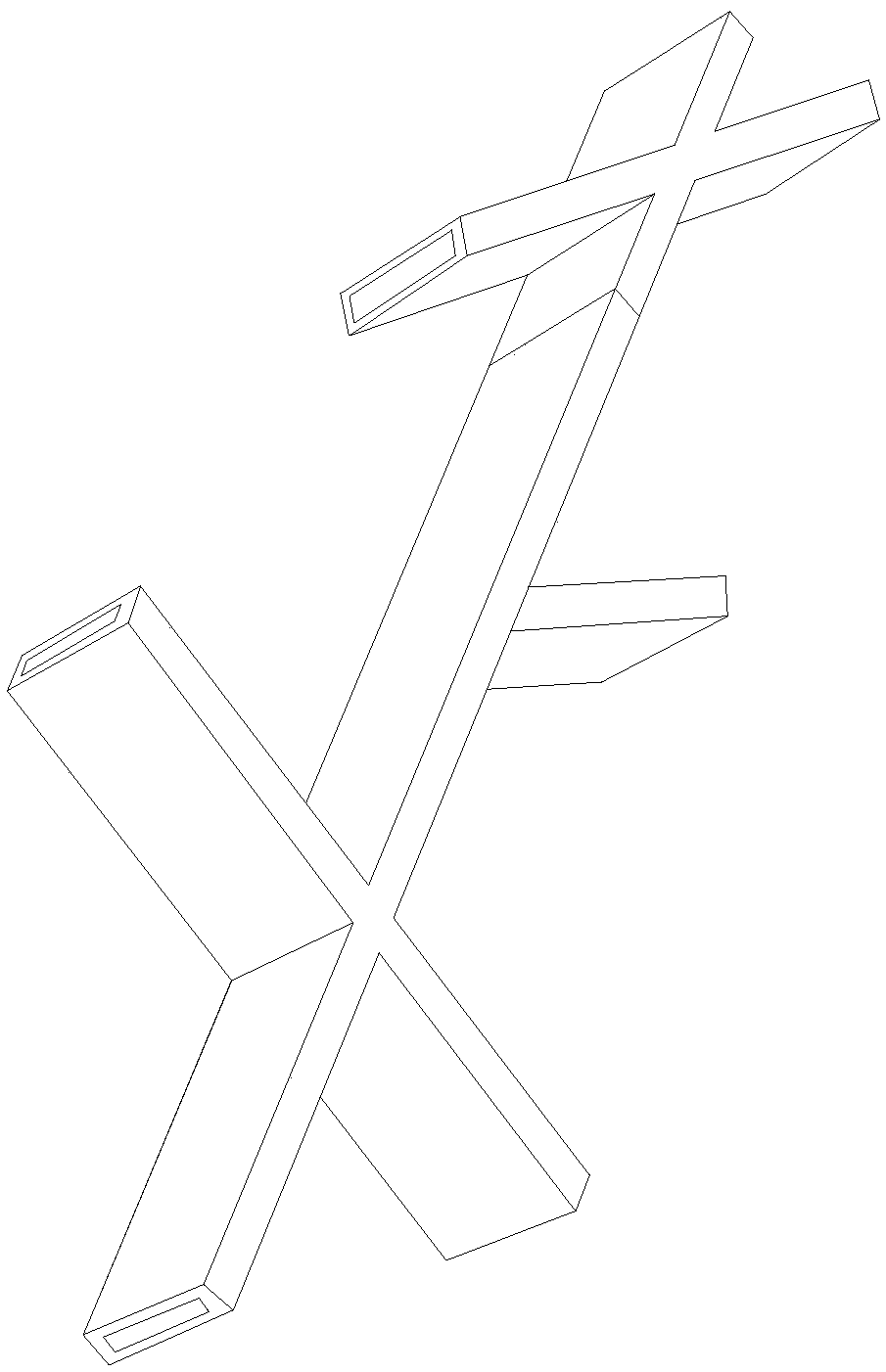

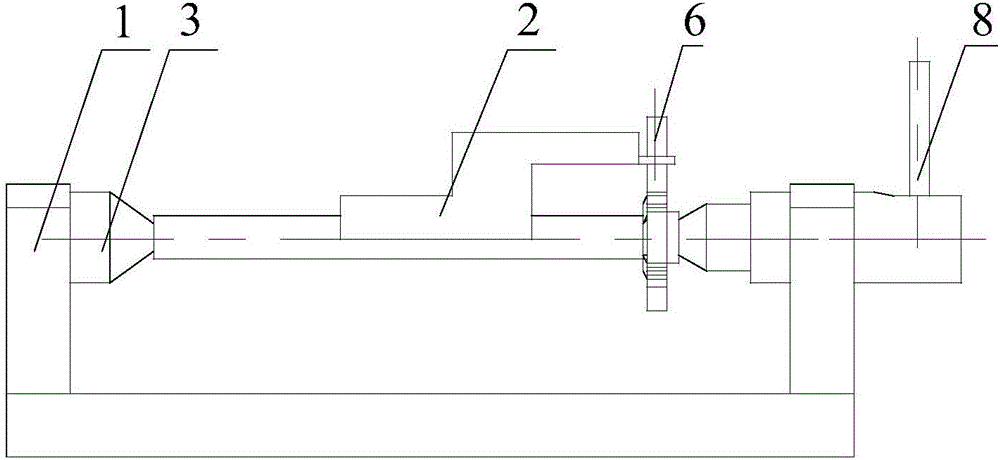

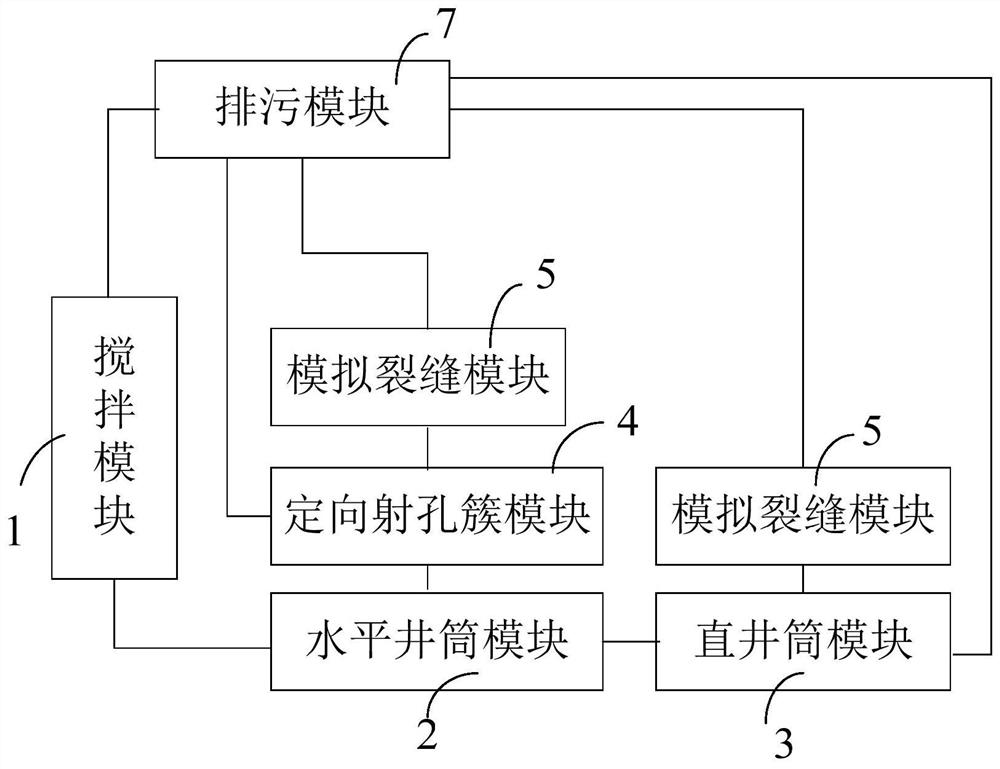

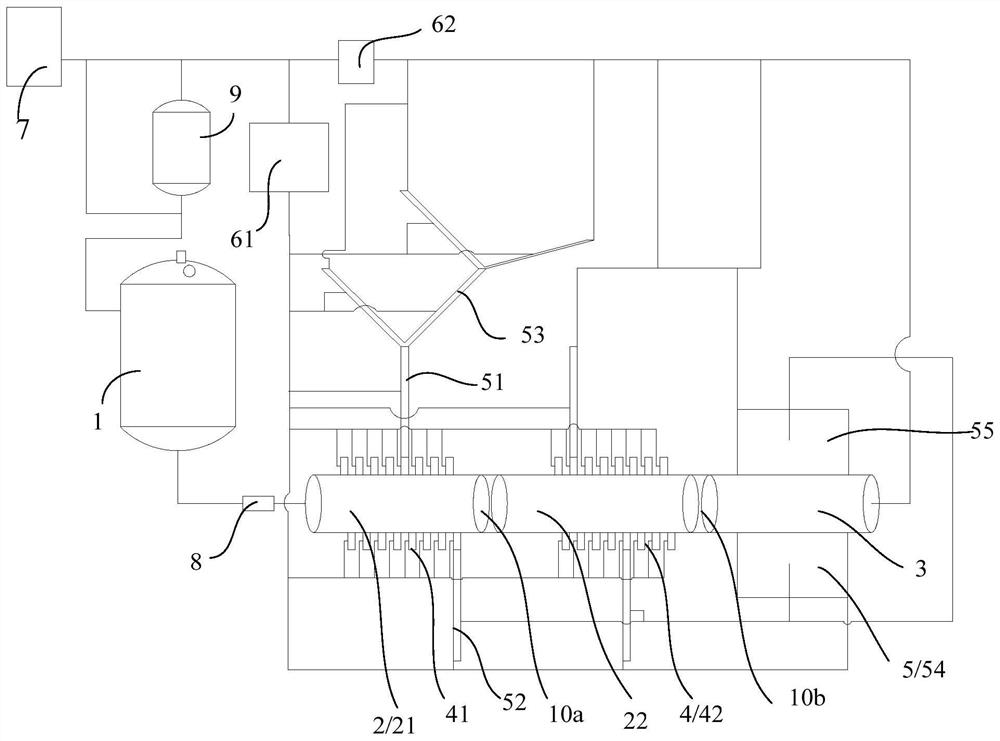

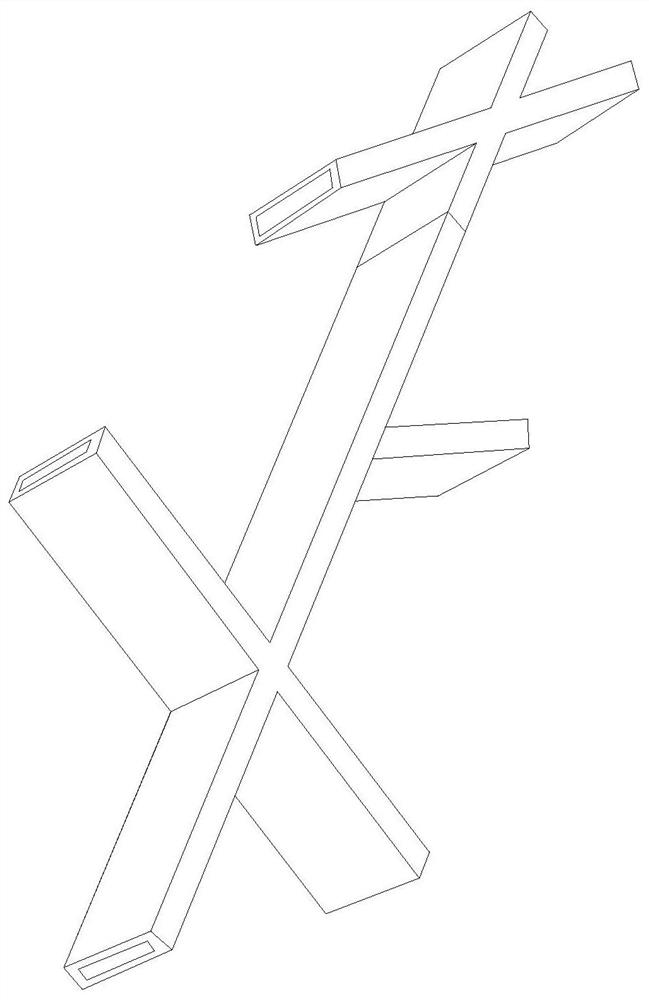

Device and method for researching transfer laws of temporary blockage agent in horizontal well or vertical well temporary blockage fracturing

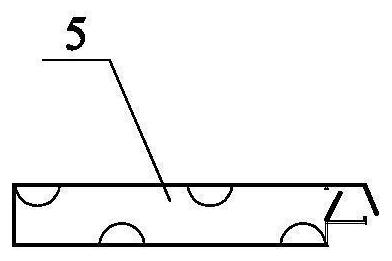

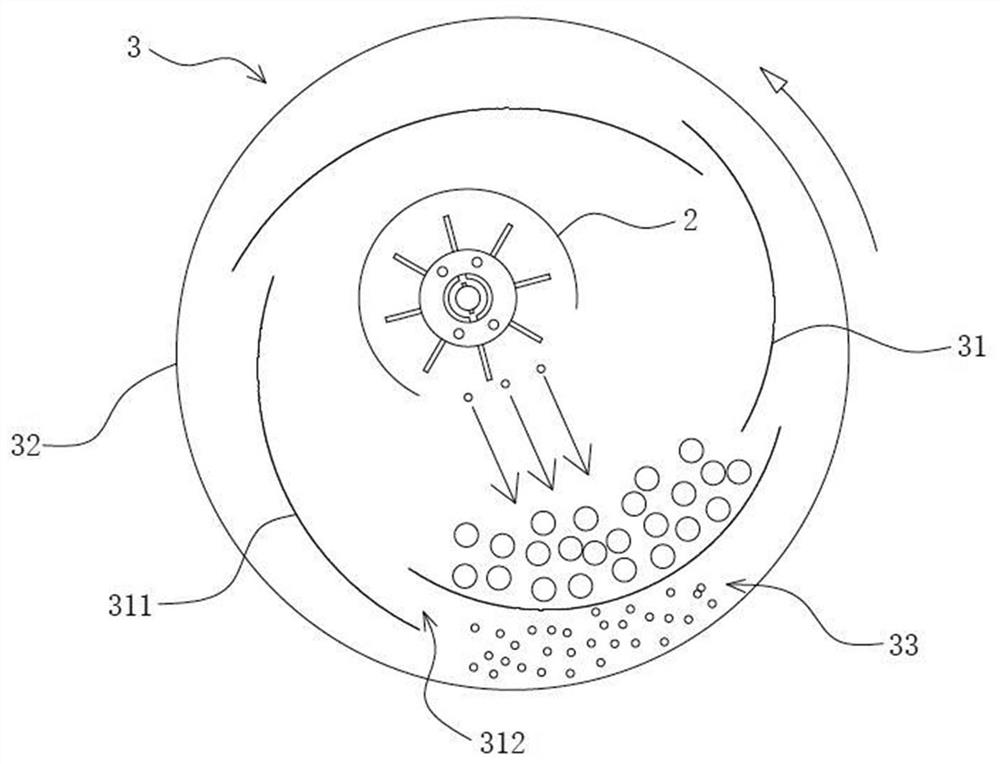

ActiveCN108708703AStick evenlyConducive to studying the effects of spacingSurveyConstructionsMaterial PerforationWellbore

The invention discloses a device and method for researching transfer laws of a temporary blockage agent in horizontal well or vertical well temporary blockage fracturing. The device for researching transfer laws of the temporary blockage agent in horizontal well or vertical well temporary blockage fracturing comprises a stirring module, a horizontal well shaft module, a vertical well shaft module,a directional perforation cluster module and a crack simulation module; the stirring module is used for stirring a working solution or a temporary blocking agent; the horizontal well shaft module isconnected with the stirring module and used for simulating the horizontal well shaft; the vertical well shaft module is connected with the horizontal well shaft module and used for simulating the vertical well shaft; the directional perforation cluster module is installed on the horizontal well shaft module and used for simulating horizontal well underground perforation; the crack simulation module is connected with the direction perforation cluster module and the vertical well shaft module and used for simulating underground cracks.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

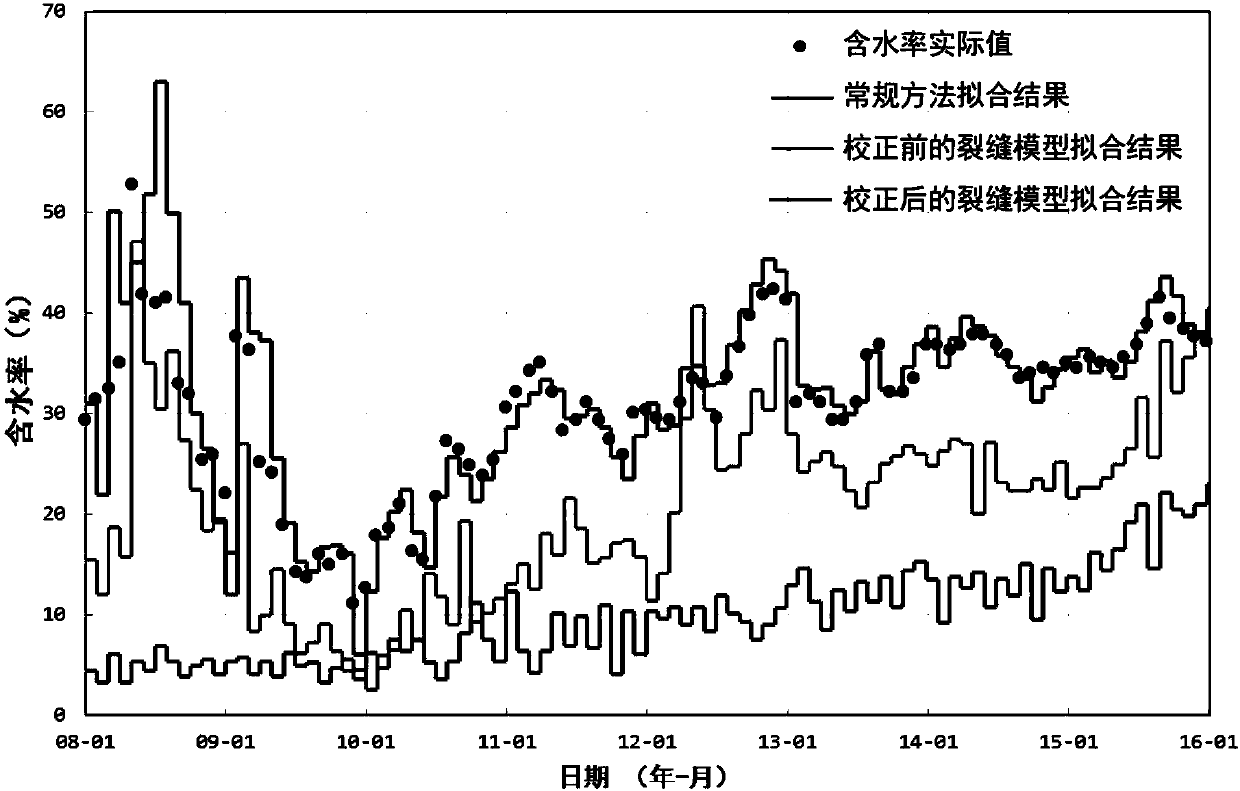

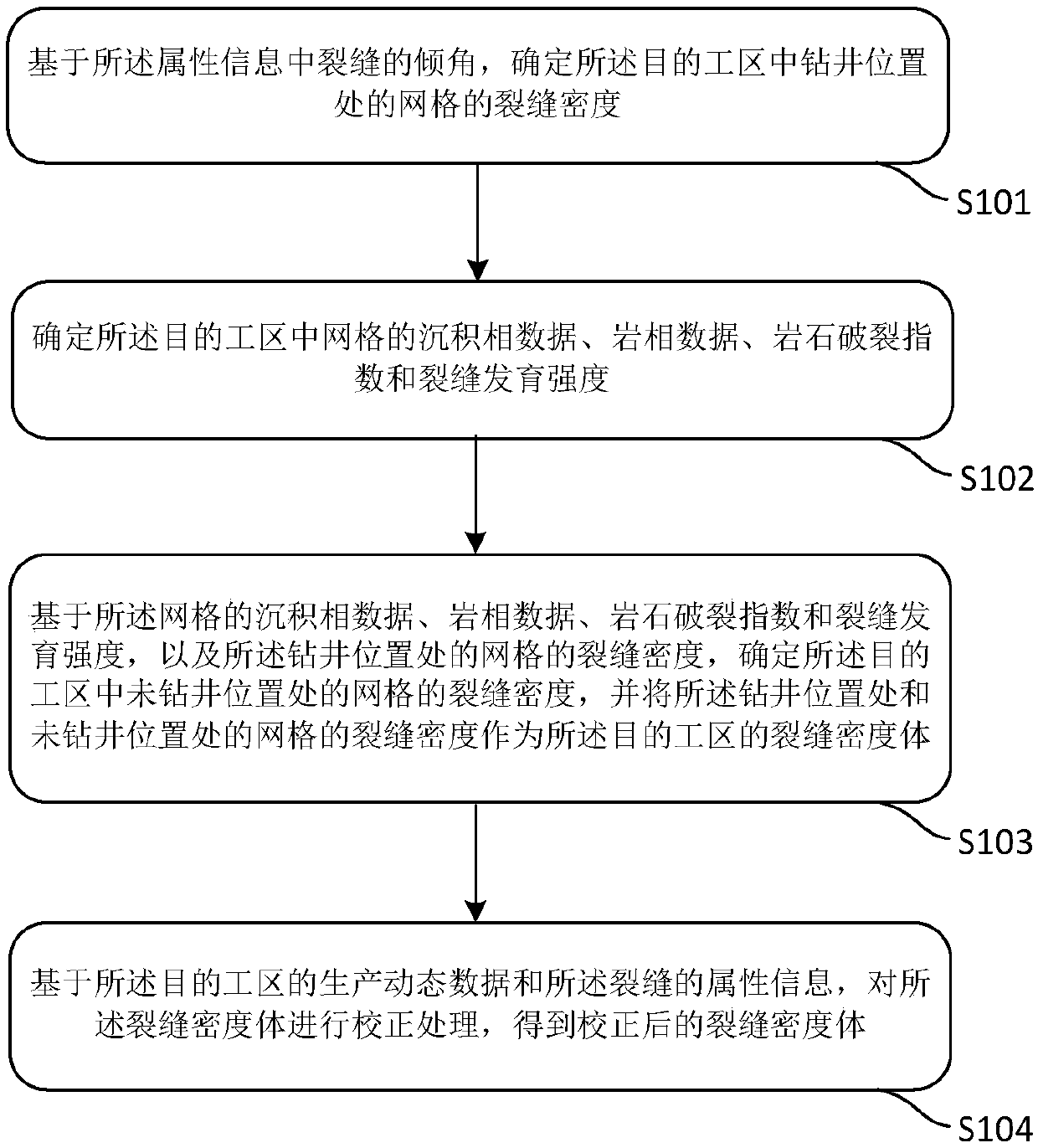

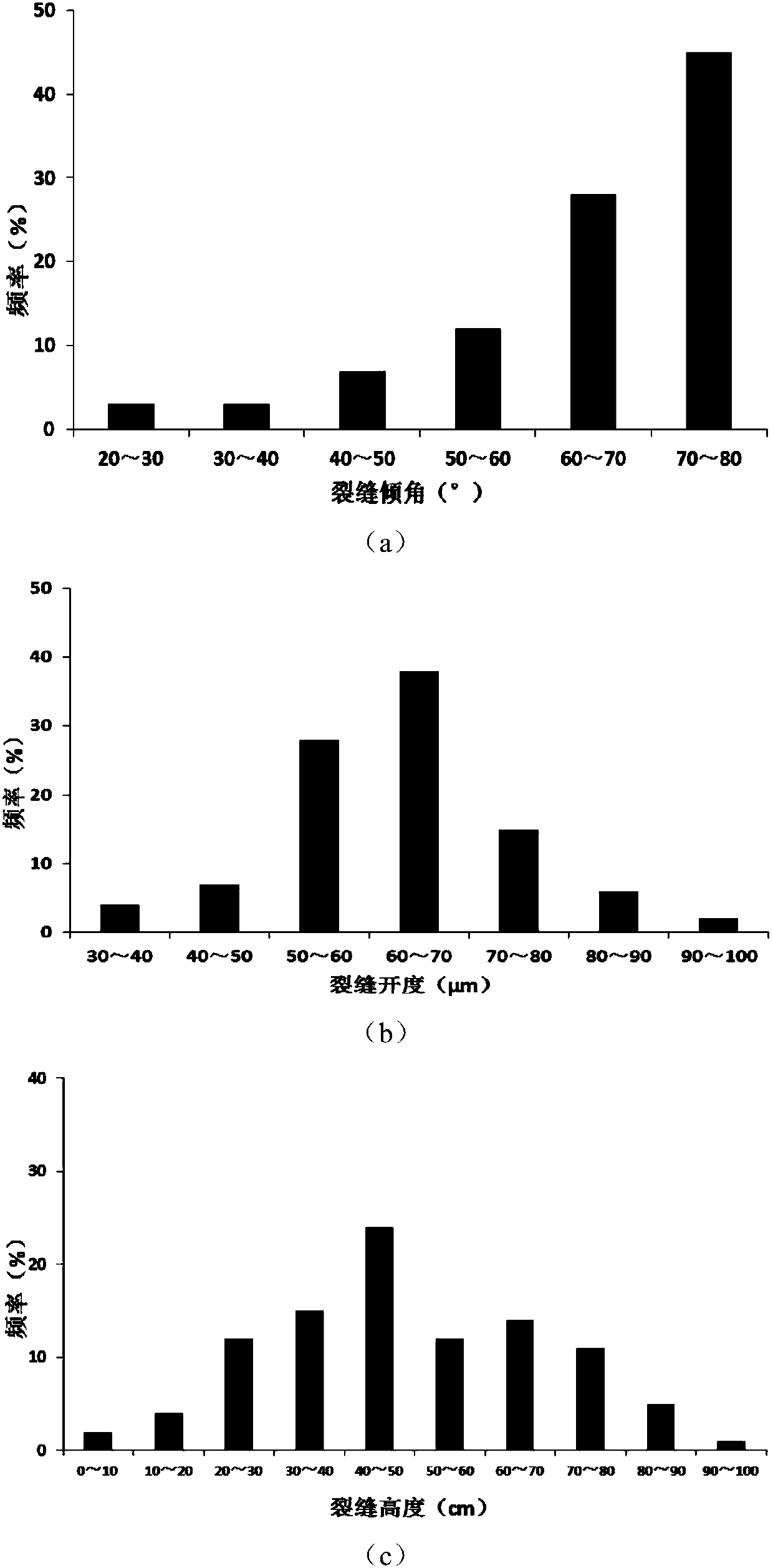

Method and device for determining fracture

ActiveCN107942404AHigh precisionIn line with the actual production situationEarth material testingGeological measurementsGeomorphologyFacies

Embodiments of the application disclose a method and device for determining a fracture. The method includes the steps of determining a fracture density of a grid at a drilling location in a target work area based on an inclination of a fracture in attribute information; determining the sedimentary facies data, facies data, rock fracture index and fracture development strength of the grid in the target work area; based on the sedimentary facies data, facies data, rock fracture index and fracture development strength of the grid and the fracture density of the grid at the drilling location, determining the fracture density of the grid at a non-drilling location in the target work area, and taking the fracture density of the grid at the drilling location and the fracture density of the grid at the non-drilling location as a fracture density body of the target work area; and based on production dynamics data of the target work area and the attribute information of the fracture, correctingthe fracture density body to obtain a corrected fracture density body. The technical scheme provided by the embodiments of the application can improve the precision of the determined fracture.

Owner:PETROCHINA CO LTD

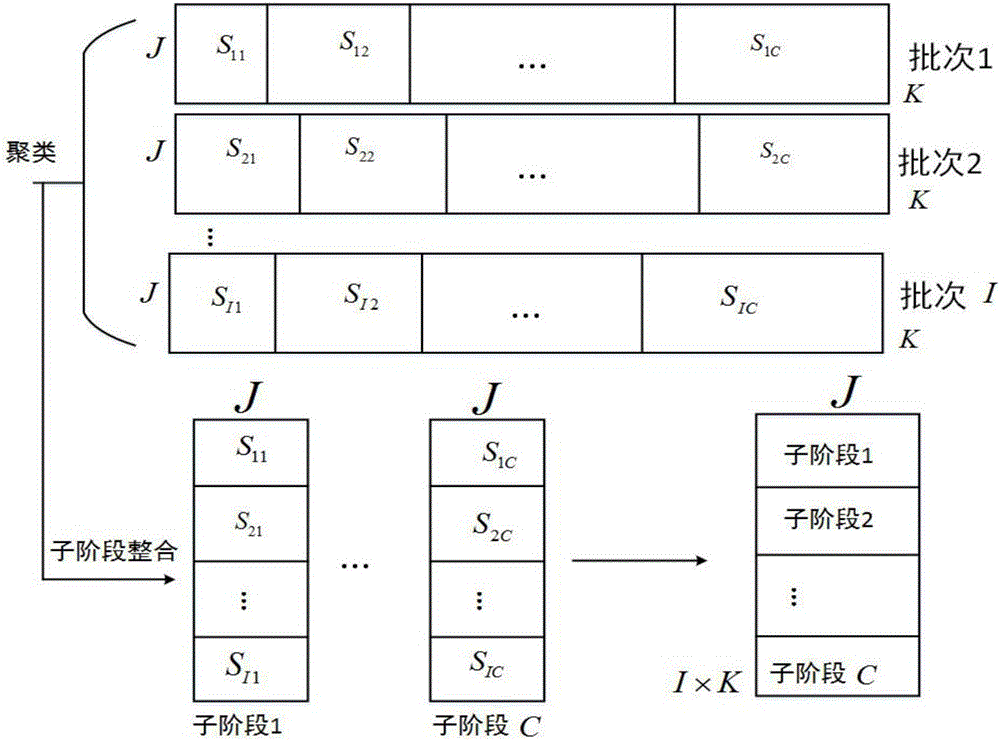

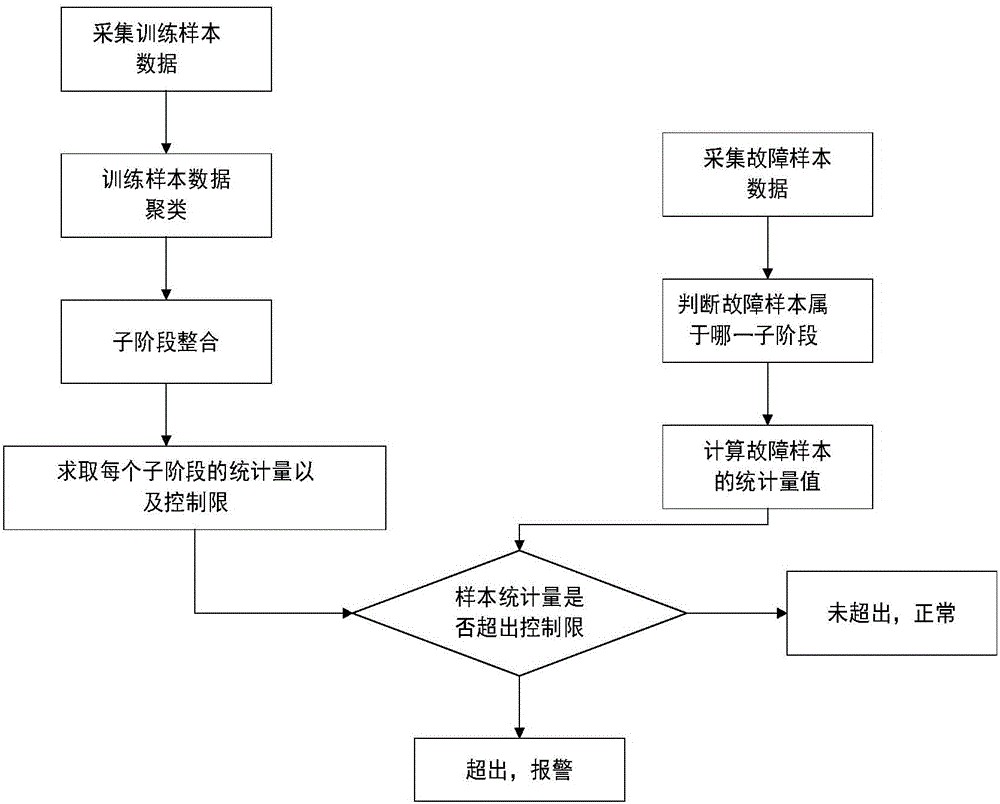

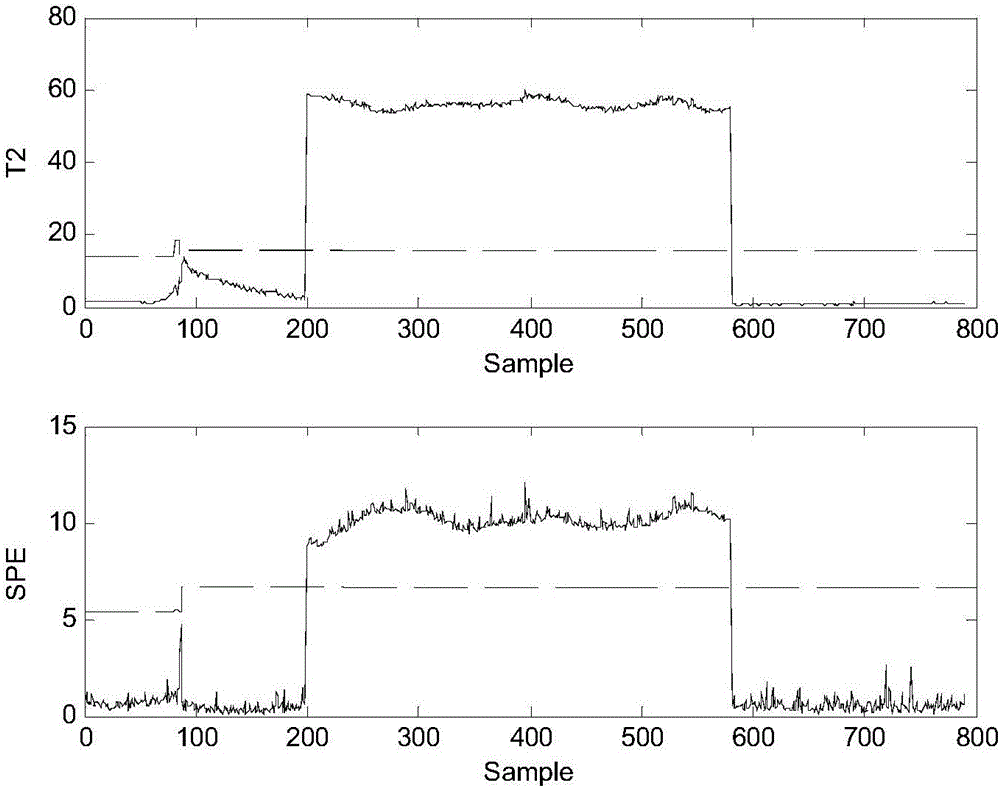

Batch process fault detection method based on sample timing sequence and neighborhood similarity information

InactiveCN105955214AImprove accuracyGuaranteed continuityTotal factory controlProgramme total factory controlAlgorithmControl limits

The invention relates to a batch process fault detection method based on the sample timing sequence and the neighborhood similarity information. The method comprises steps that the training sample data is acquired; clustering of the training sample data is carried out; training samples after clustering are integrated to acquire different sub stages; a T2 statistical magnitude and an SPE statistical magnitude of each sub stage and a control limit of the two are calculated; the fault sample data is acquired, which sub stage of the training samples the fault sample belongs to is determined; a t2 statistical magnitude and an spe statistical magnitude of the fault sample are calculated; whether the statistical magnitudes of the calculated fault sample exceed the control limit is determined, if the two statistical magnitudes do not exceed the control limit, no fault is generated, otherwise, a fault is generated. Compared with the prior art, the method is advantaged in that accuracy and detection performance are high, the method is in accord with the practical situation, and the false alarm rate and the alarm missing rate are reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

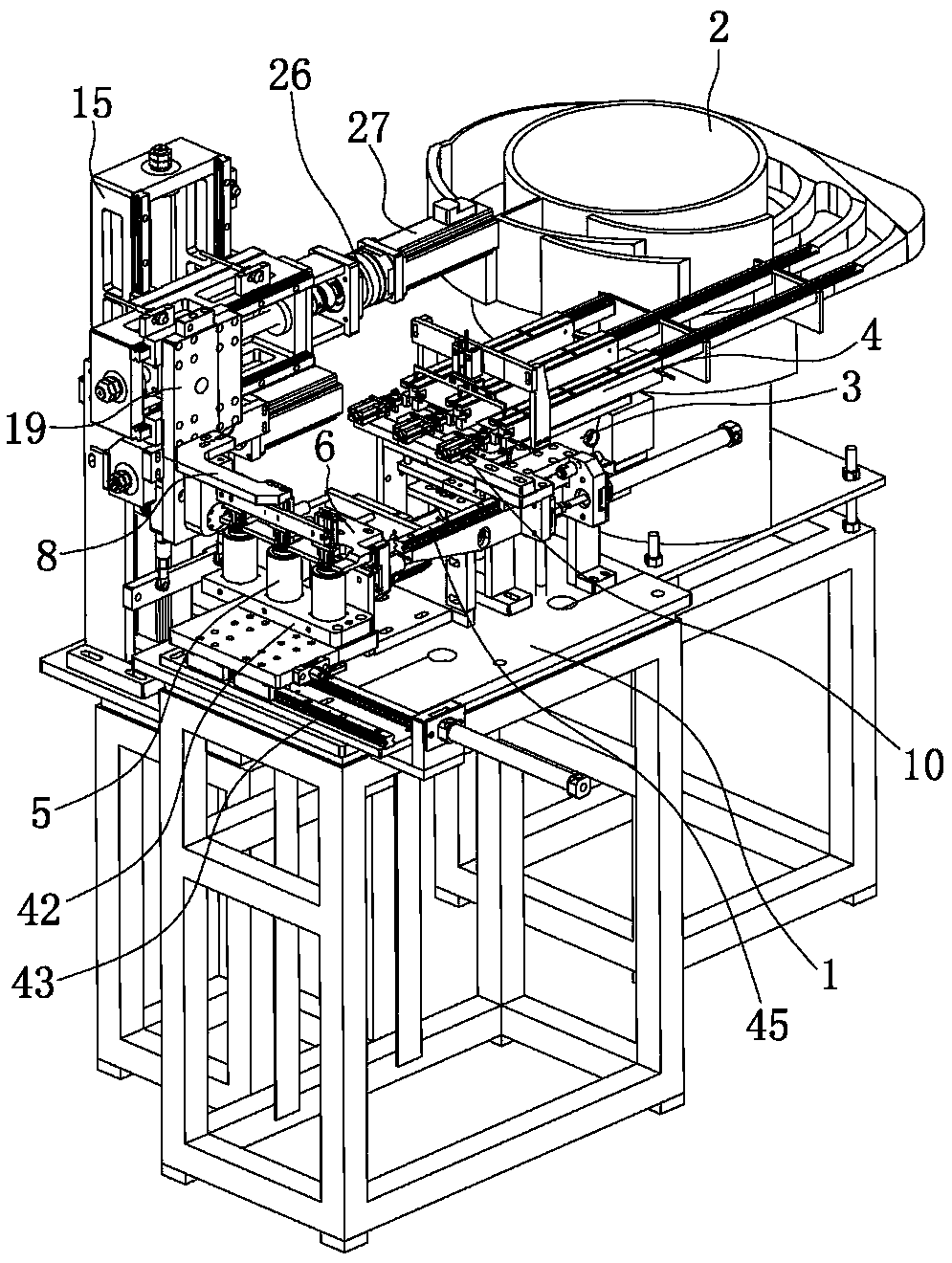

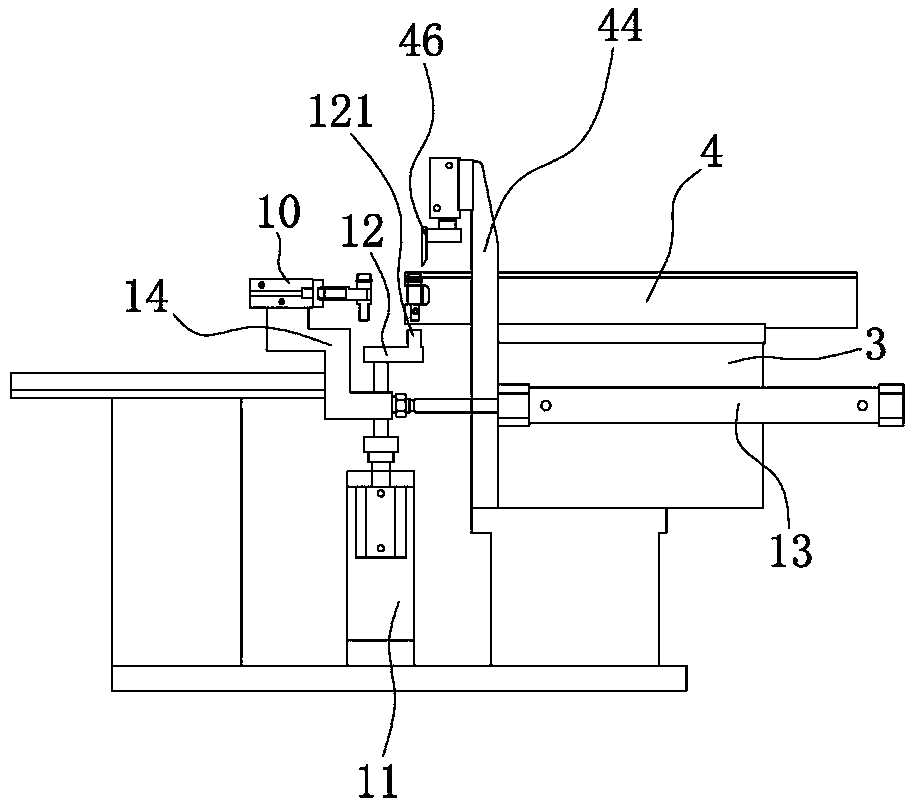

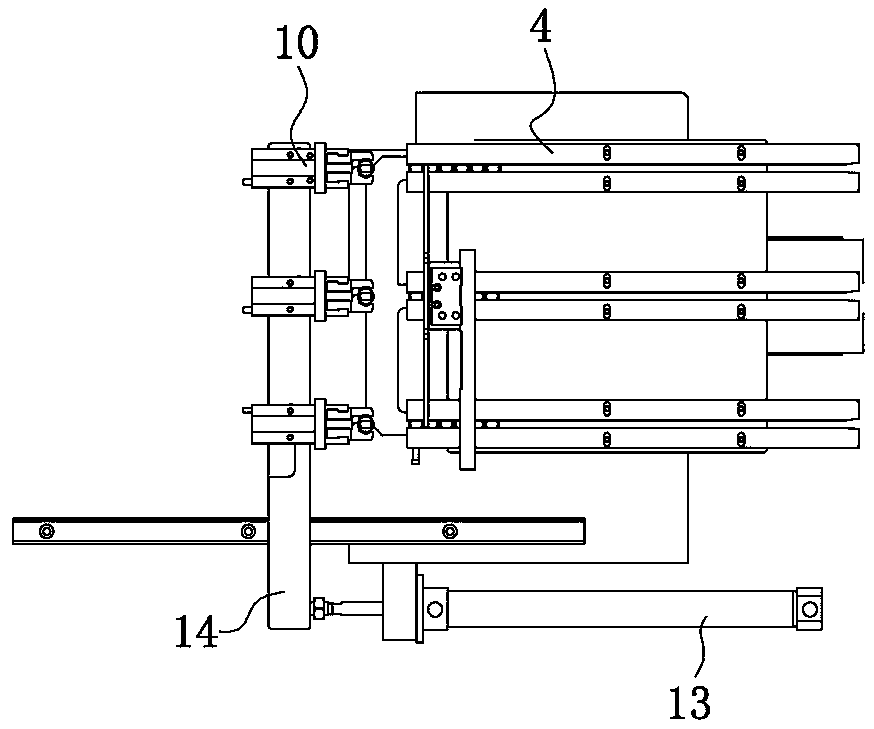

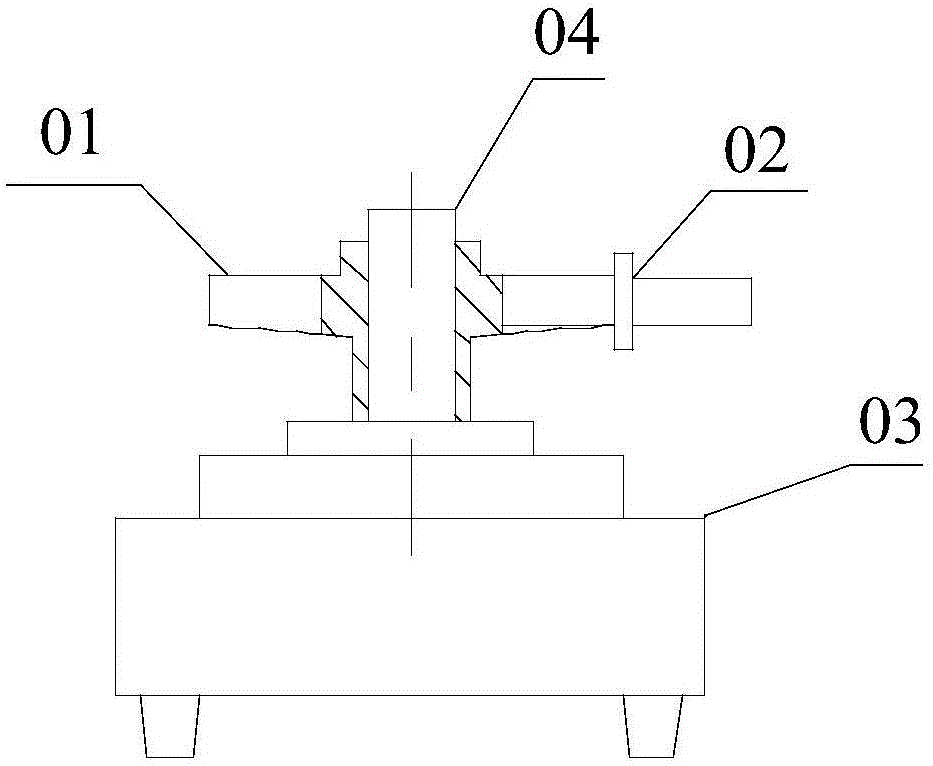

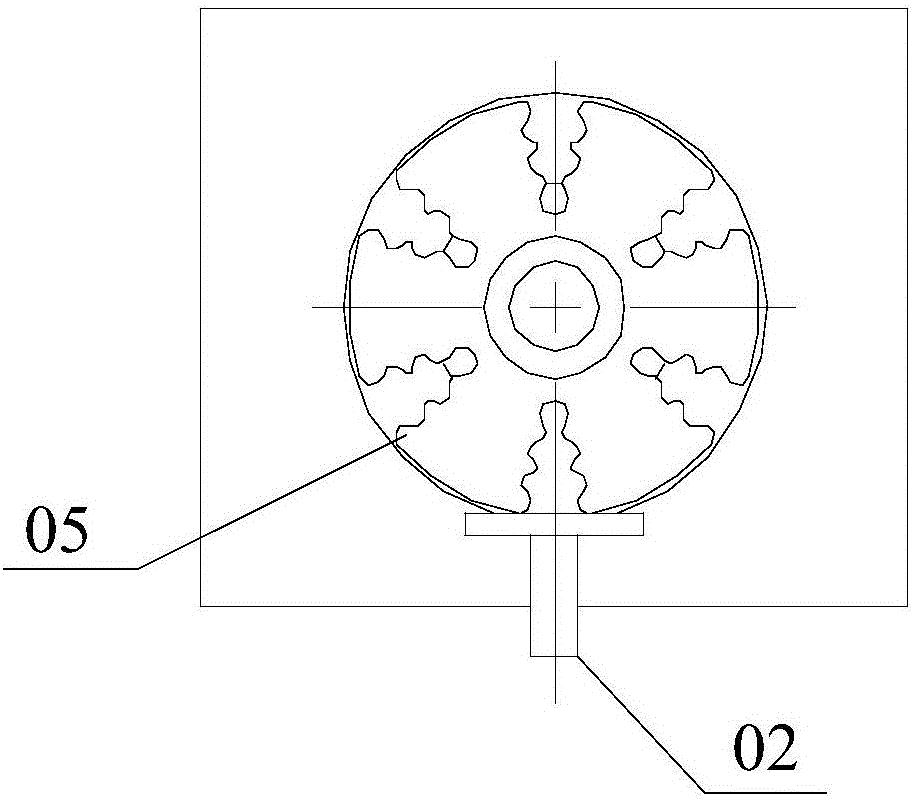

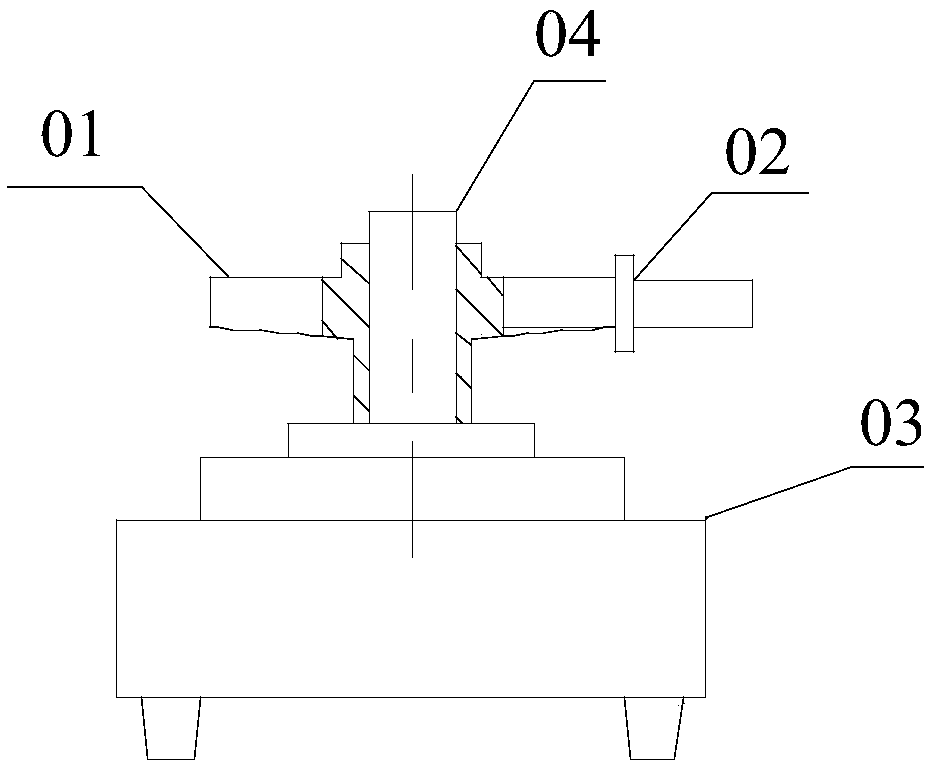

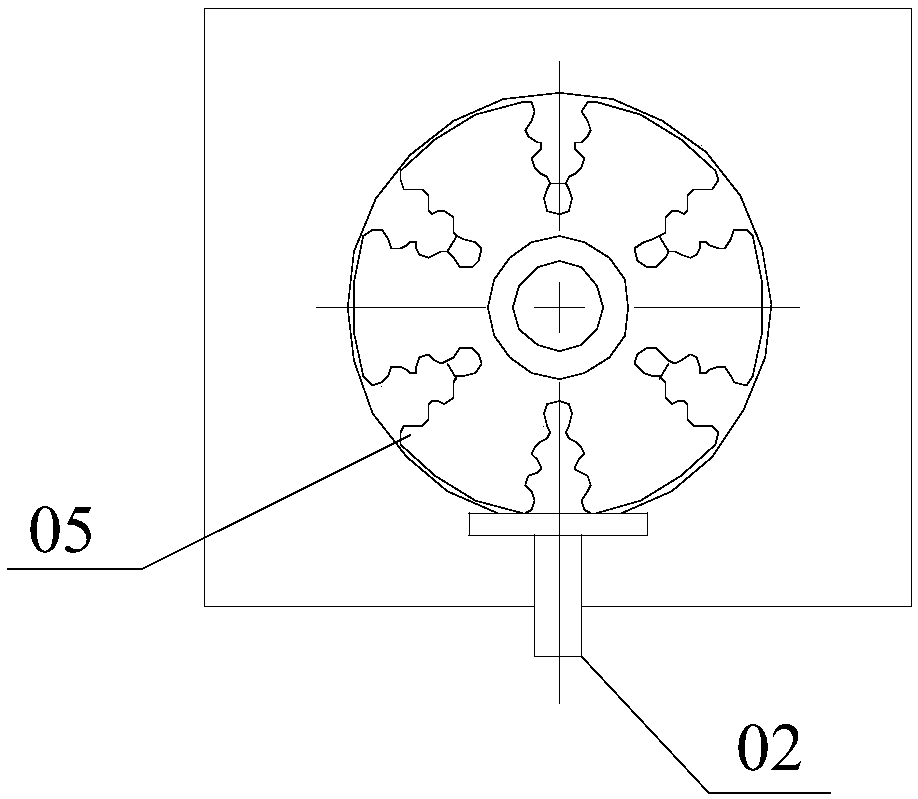

Valve rod and valve body assembling machine

PendingCN109304589AHigh positioning accuracyHigh clamping accuracyMetal working apparatusEngineeringVALVE PORT

The invention provides a valve rod and valve body assembling machine, and belongs to the technical field of machines. The problem that an existing valve rod and valve body assembling machine is low inassembling success rate is solved. The valve rod and valve body assembling machine comprises a workbench, a die base is provided with a notch for a valve rod hole of a valve body to be exposed, a positioning plate is located at the opening part position of an installing cavity for jacking contact of a valve port of the valve body, and the positioning plate is provided with an arranging port. Theworkbench is provided with a supporting structure and a positioning structure, and the die base and / or the positioning plate are / is driven by a displacement mechanism to move. A valve rod arranging device comprises a drive structure, a rotation shaft and a rotation base, the rotation shaft is located at the front end of the drive structure and driven by a rotation mechanism to rotate around the axis of the rotation shaft, the rotation base is fixedly connected to the rotation shaft and fixedly connected with a gas claw, and the distance is formed between the clamping end of the gas claw and the axis of the rotation shaft. After the gas claw clamps the valve rod, the circle center line of the bottom face of the valve rod is basically located at the extension line of the axis of the rotationshaft. The valve rod and valve body assembling machine has the advantages that the assembling precision is high, and the success rate is high.

Owner:台州中通智能科技有限公司

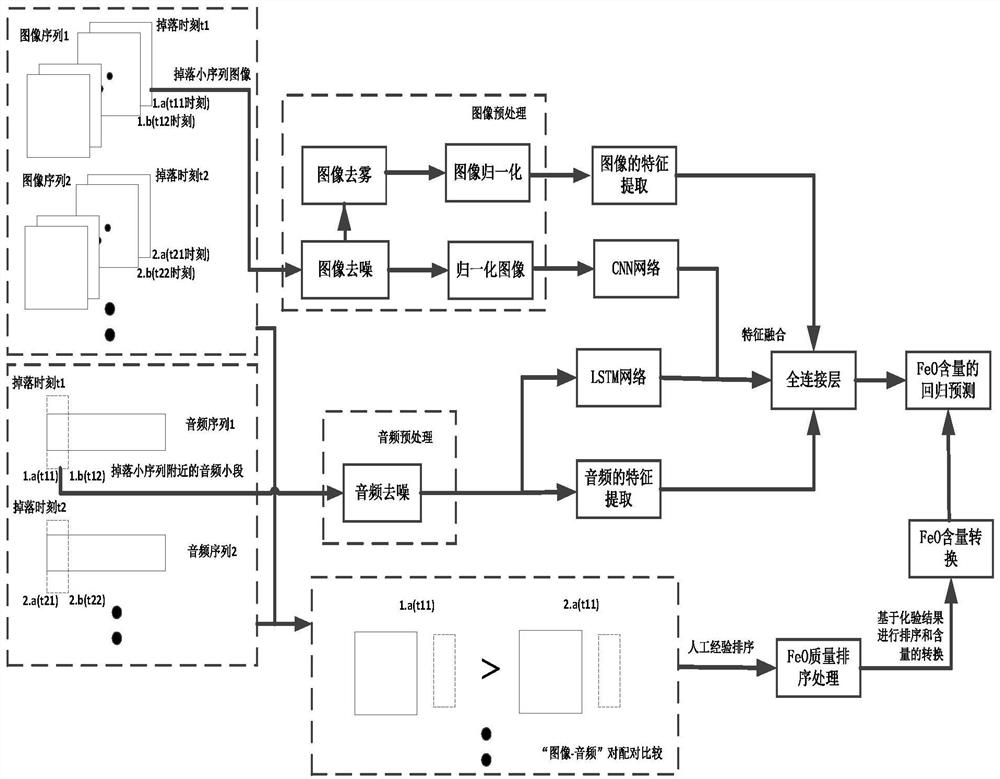

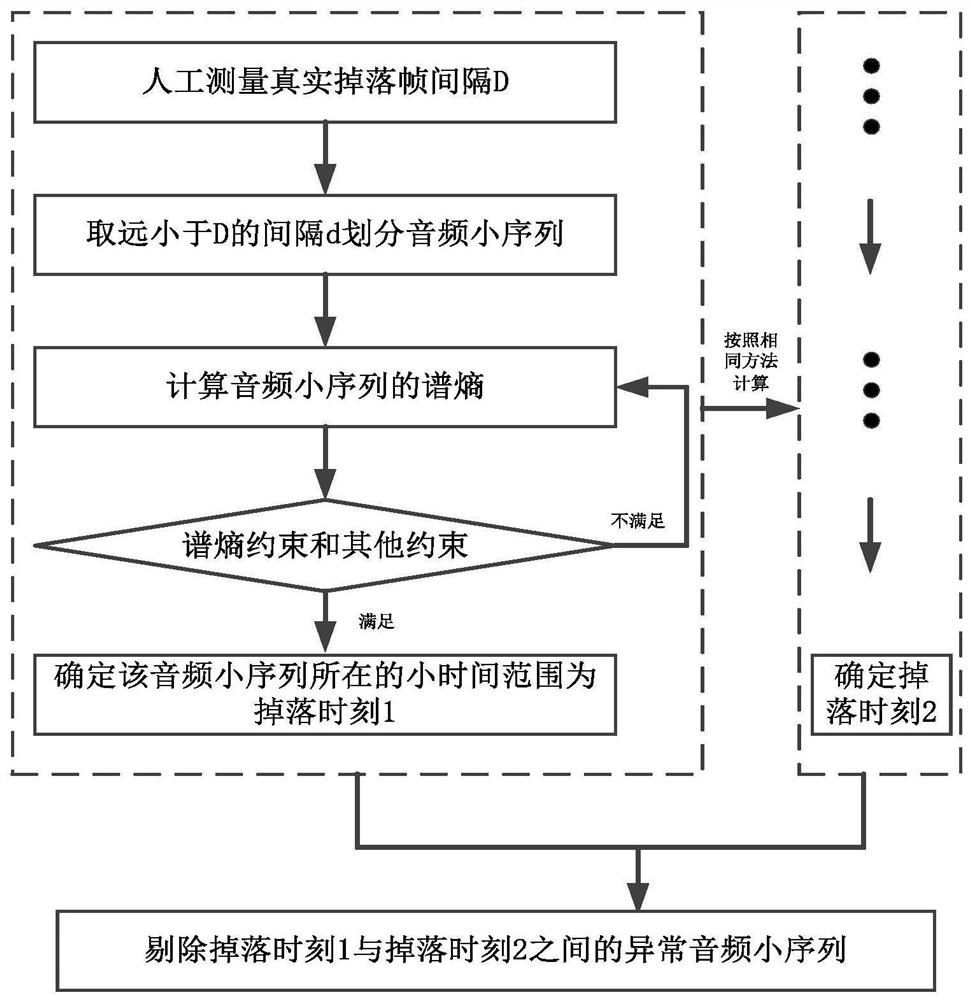

FeO content prediction method based on sintering machine tail section video

ActiveCN112329558AReduce the impact of quality judgmentsAccurate extractionImage enhancementImage analysisMachine learningImaging Feature

The invention discloses a FeO content prediction method based on a sintering machine tail section video, and relates to the field of steel production. The method mainly comprises the following steps:determining a falling moment, removing an abnormal audio sequence, dividing an image sequence and preprocessing, carrying out audio preprocessing, extracting image features, extracting audio features,constructing a video quality database, and constructing, training and testing a quality prediction model. Compared with the prior art, the method has the advantages that the severe conditions of thesintering machine tail are considered, the characteristics of the video information are represented more comprehensively from the aspects of images and audios, and quantitative prediction of the FeO content can be achieved.

Owner:SHANGHAI JIAO TONG UNIV

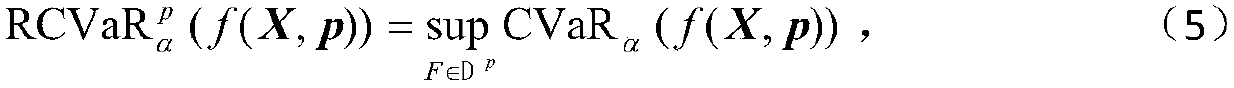

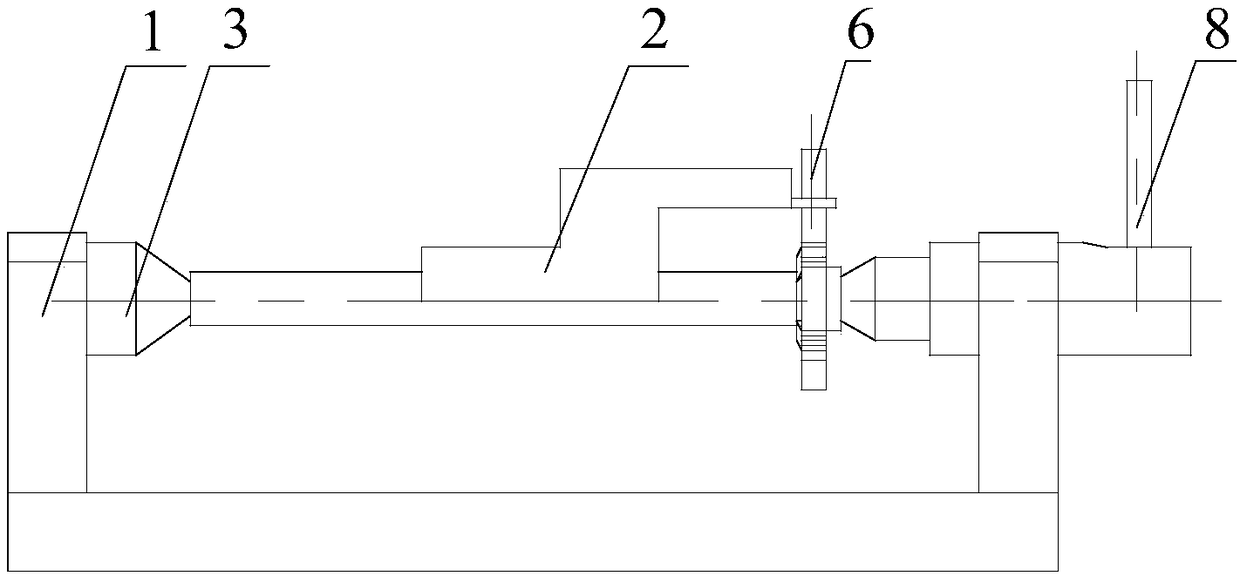

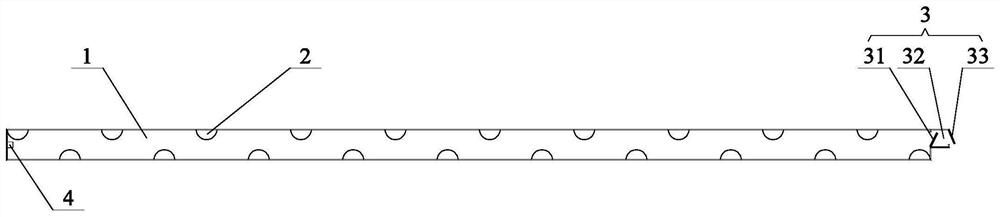

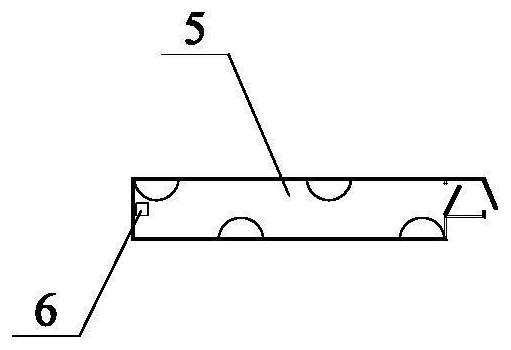

Horizontal gauge-aligning measuring device for measuring tenon groove center distance

ActiveCN106091884AEasy to operateImprove stabilityMechanical measuring arrangementsMeasurement deviceLong axis

The invention discloses a horizontal gauge-aligning measuring device for measuring a tenon groove center distance. The horizontal gauge-aligning measuring device includes a frame, a pair of finial devices (3) with superposed axes installed on the frame, a clamping device (7) controlling the finial devices (3) to loose or clamp a gauge-aligning piece and a part (4) to be measured, an adapter (6) capable of being installed in a standard tenon groove of the gauge-aligning piece, and a positioning device (2) capable of being installed on a long axis of the gauge-aligning piece. A radial face of the adapter (6) is in contact with that of the positioning device (2) and the two radial faces keep parallel. The horizontal gauge-aligning measuring device for measuring the tenon groove center distance effectively solves the inaccurate problem easily existing in a tenon groove measuring process.

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

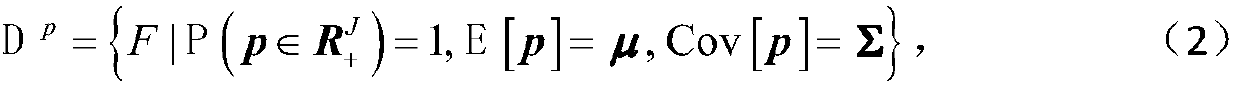

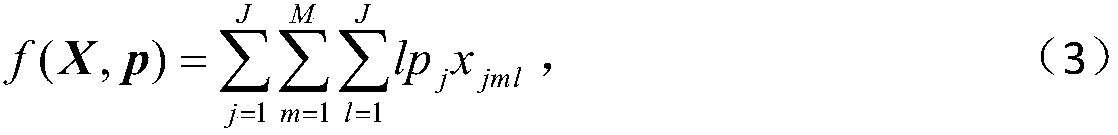

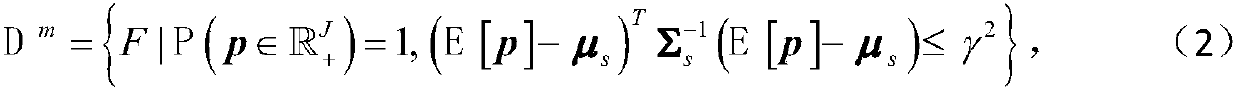

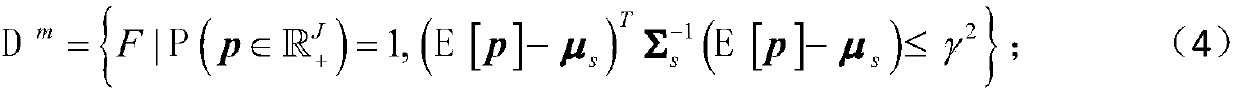

Production scheduling method based on distributed set robust parallel machine scheduling model

ActiveCN107622338ALess conservativeReduce decision riskResourcesComplex mathematical operationsMachine schedulingComputer science

The invention, which belongs to the field of production scheduling and operations research, provides a production scheduling method based on a distributed set robust parallel machine scheduling model.According to the method, a distributed set robust optimization model DR-PMSP-RA having a risk aversion characteristic is constructed; on the basis of an objective function and a constraint conditionof the model, an expression of an initial model DR-PMSP-RA1 is obtained; the objective function of the DR-PMSP-RA model is transformed to obtain an estimation upper bound of the objective function, the initial model is transformed into an estimation model DR-PMSP-RA2, wherein the estimation model can be decomposed into two independent sub models, the two sub models are solved and the optimal sub model solution is an optimal solution of the model, and thus an optimal production scheduling plan is obtained. The model established based on the method conforms to the actual production situation well; and with information in a production environment, the decision-making risk is reduced under the circumstance that the system performance is guaranteed.

Owner:TSINGHUA UNIV

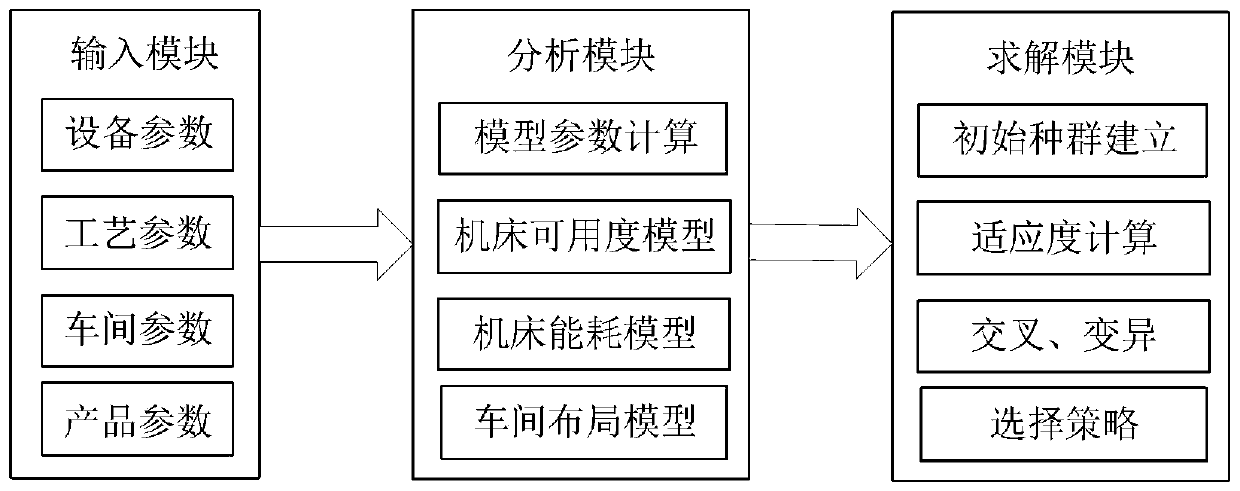

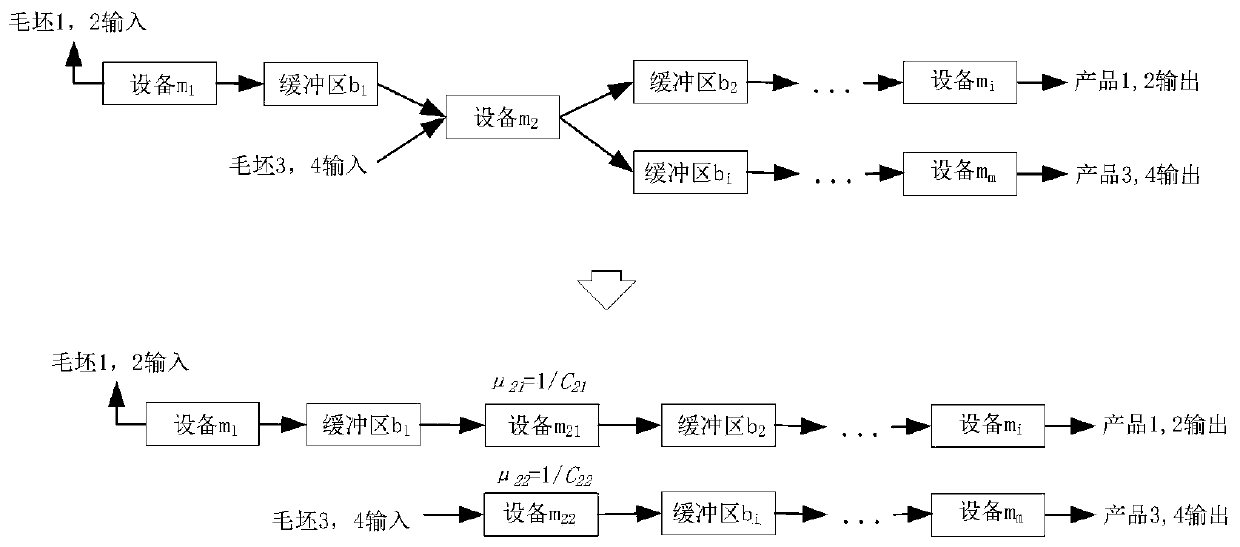

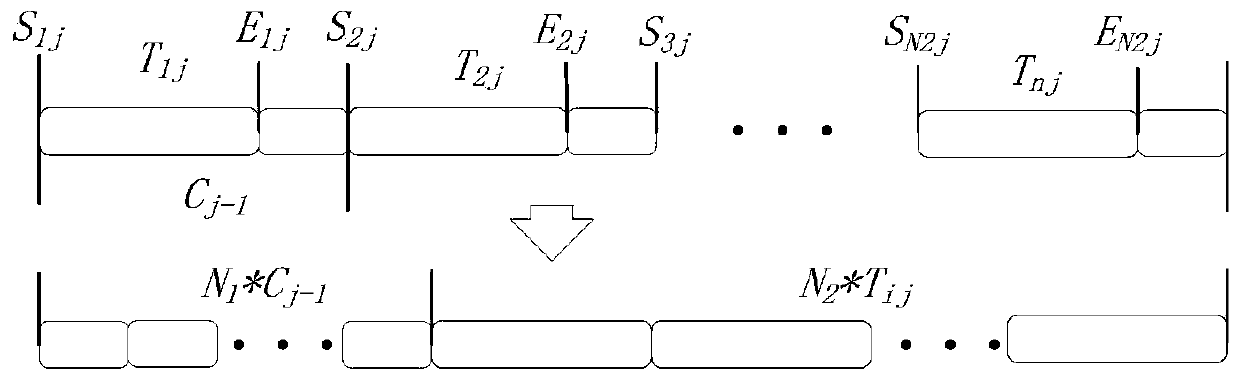

Production line buffer area configuration system and method considering machine tool energy consumption

ActiveCN111310924AImprove applicabilityImprove portabilityForecastingResourcesMathematical modelProcess information

The invention discloses a mixed flow production line buffer area configuration system and method considering machine tool energy consumption, and belongs to the field of production line planning and design. According to the method, workshop information, machine tool information, product information and process information are collected and input, a mathematical model with corresponding parametersis generated, calculated and optimized, and under the condition that the size of a workshop is given, the maximum utilization rate of a workshop machine tool is guaranteed, and meanwhile the production line buffer area configuration method with the minimum machine tool energy consumption is obtained. According to the method, different model parameter optimization solutions are carried out by inputting data, so that the method has relatively high universality and transportability, the energy consumption of a machine tool in a production line machining process can be effectively reduced, and thetotal area of a buffer area of a workshop is utilized to the maximum extent.

Owner:BEIJING UNIV OF TECH

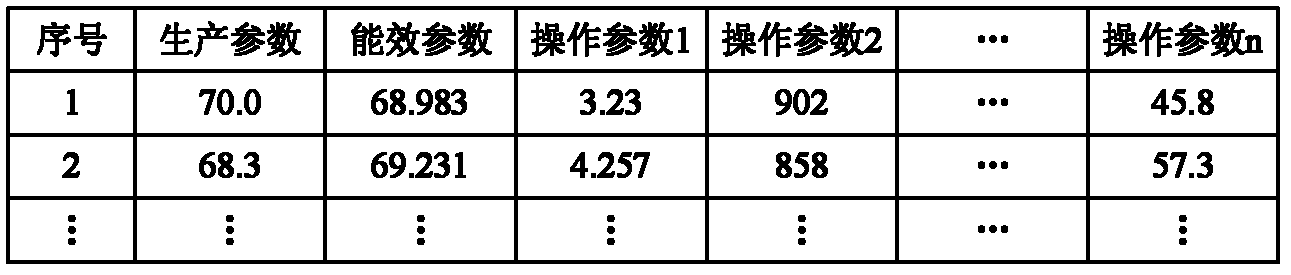

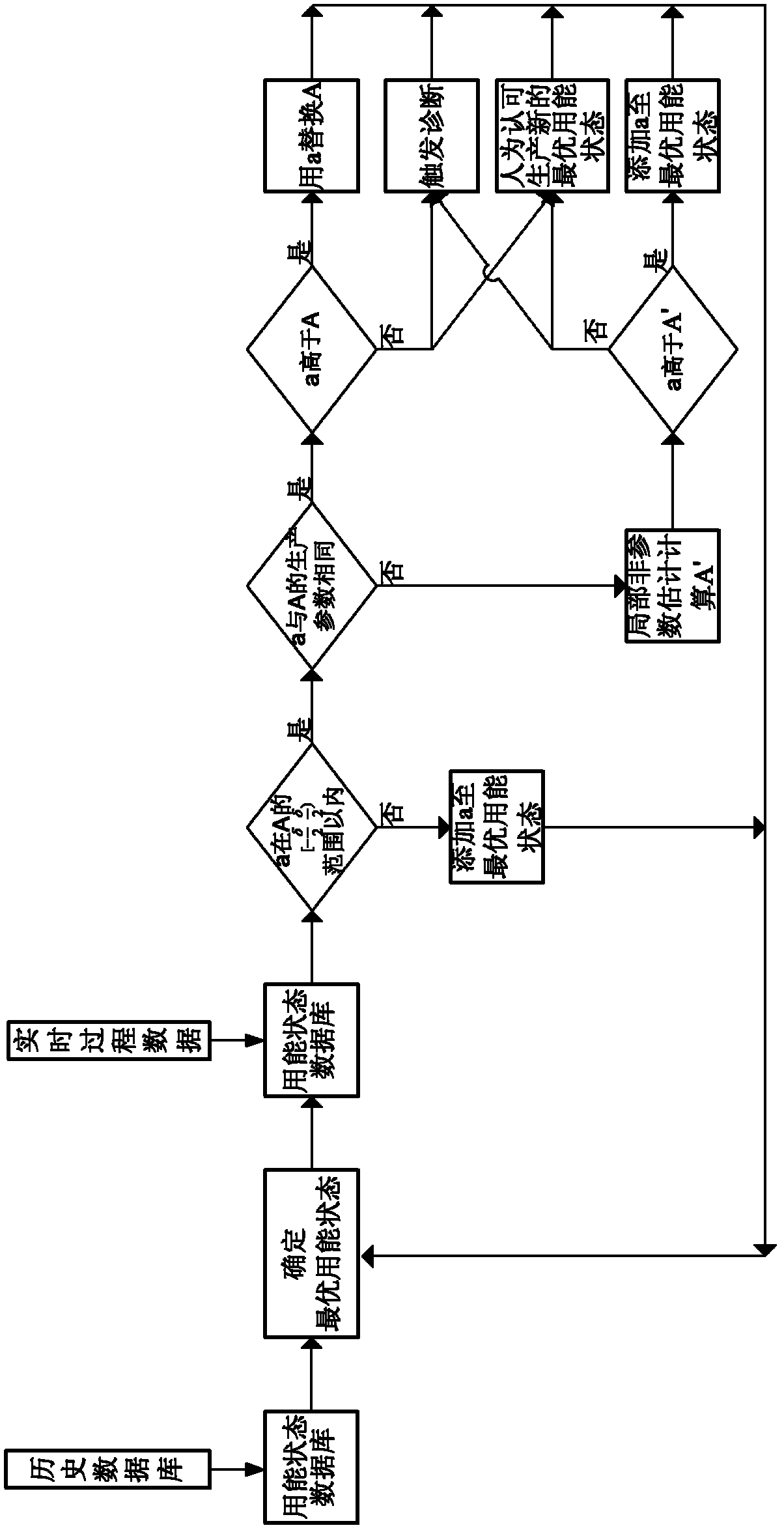

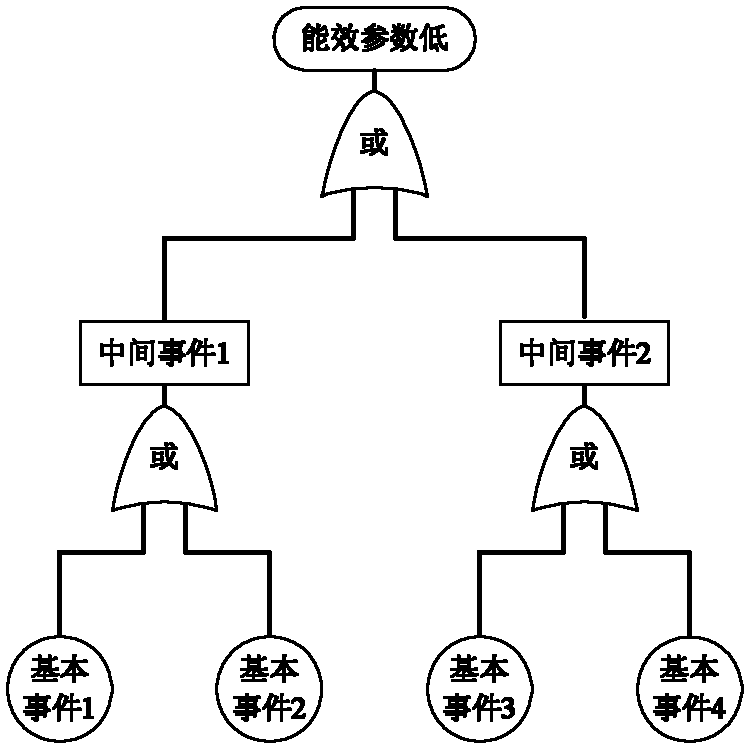

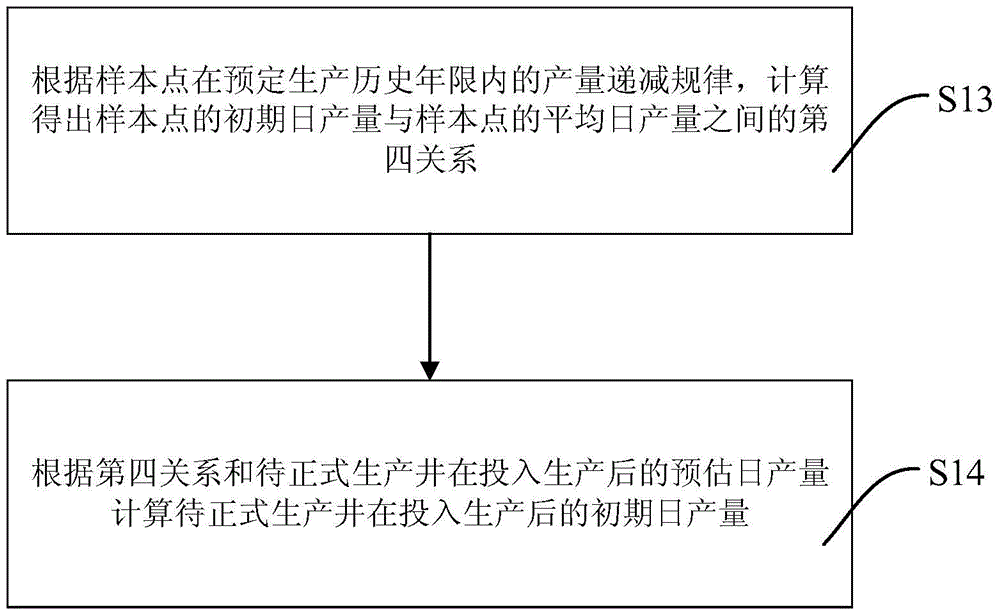

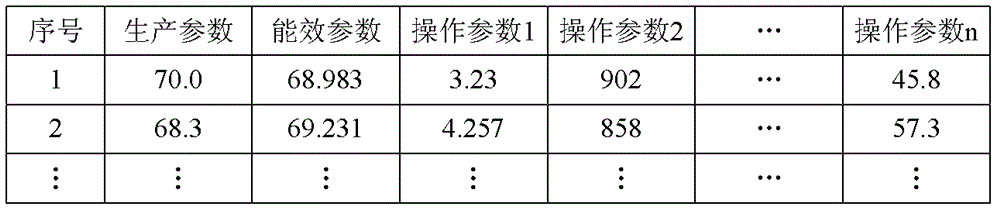

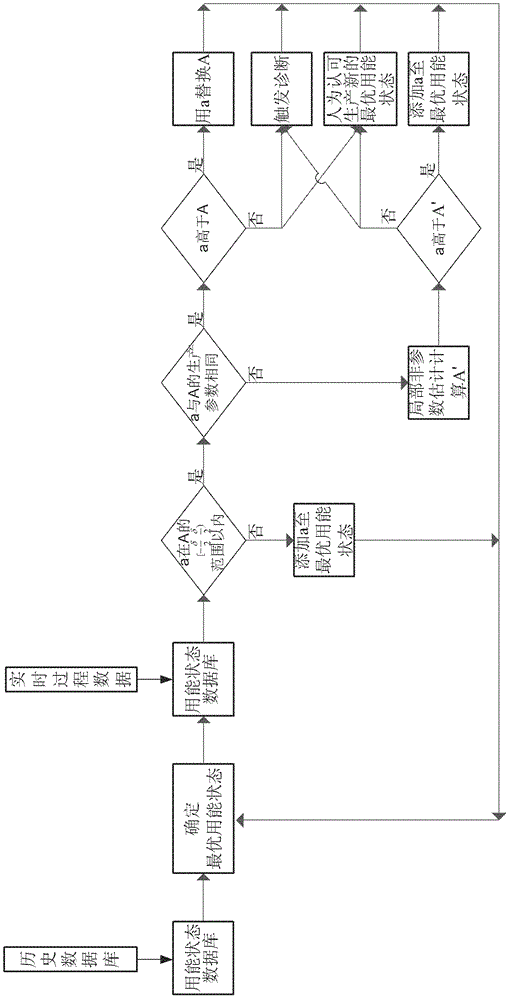

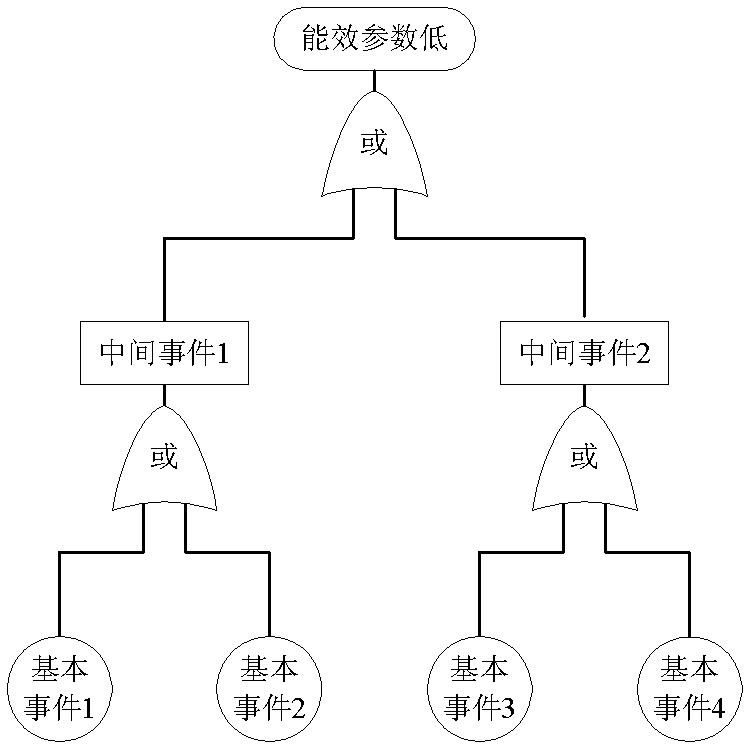

Energy utilization state diagnosis method for process industrial equipment

ActiveCN102231081ATimely referenceExact referenceElectric testing/monitoringDiagnosis methodsProcess engineering

Process industrial equipment serves as an analysis and diagnosis object, and an energy utilization state of the process industrial equipment is described through production parameters, energy efficiency parameters and operating parameters of the equipment. The method comprises the following steps of: in the process of operating the equipment, acquiring production process data of the equipment and determining the optimal energy utilization state; establishing an energy utilization state diagnosis tree according to expert knowledge, and comparing a real-time energy efficiency parameter with the optimal energy efficiency parameter; triggering diagnosis if a real-time energy utilization state of the equipment is lower than the optimal energy utilization state, reasoning according to the energy utilization state diagnosis tree, and giving reasons and recommended measures after the reasoning is finished. By the method, the energy utilization state of the equipment using fuel, power, heat and other energy in various process industries can be monitored and diagnosed, and the method has universality.

Owner:中广核智能科技(深圳)有限责任公司

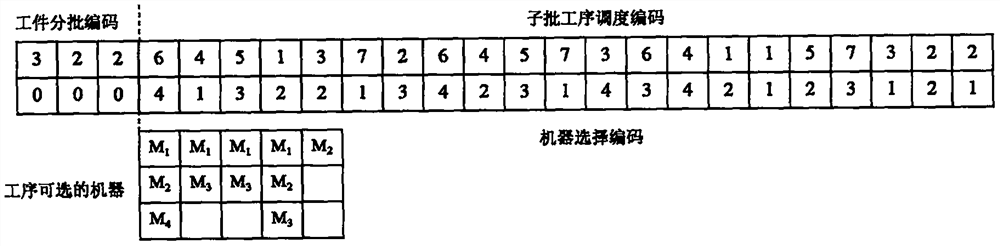

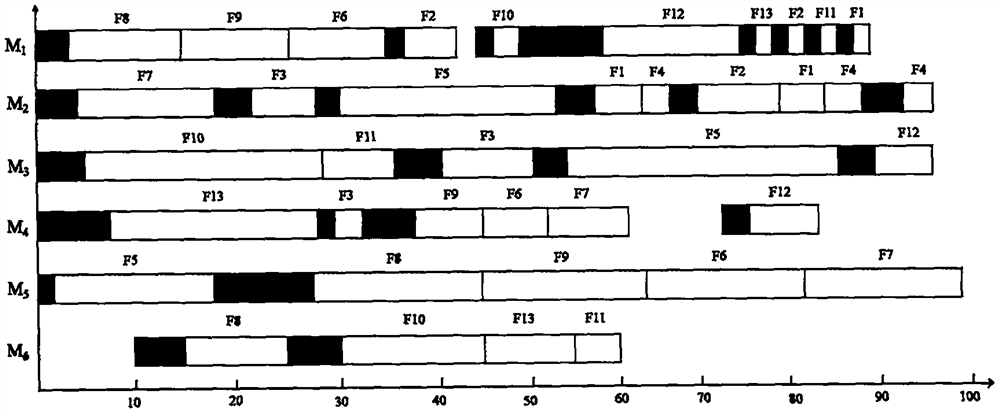

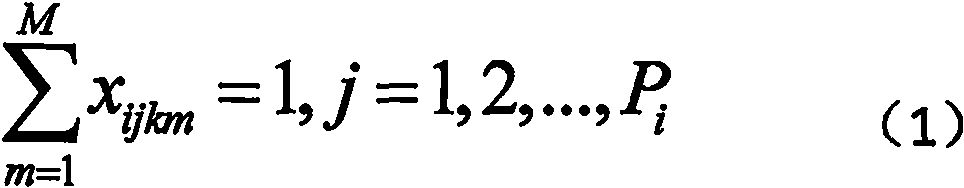

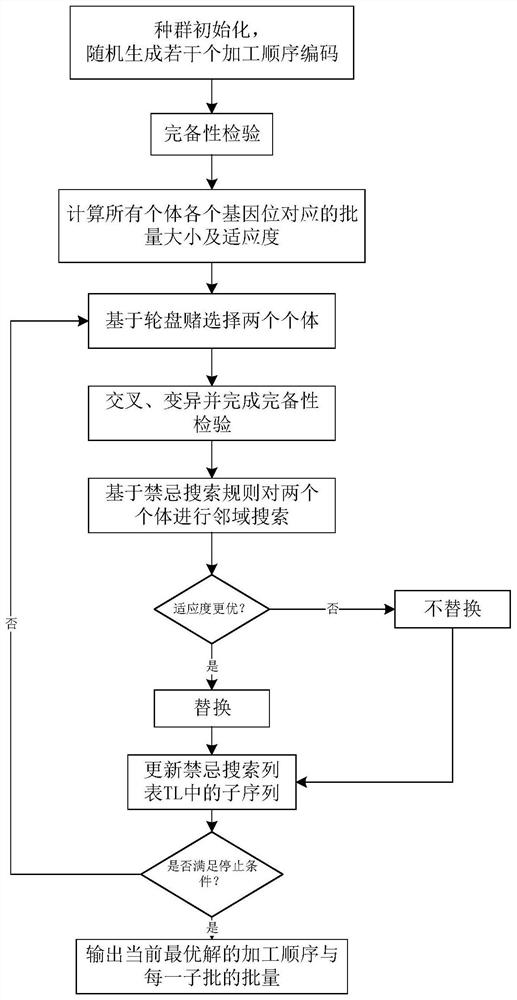

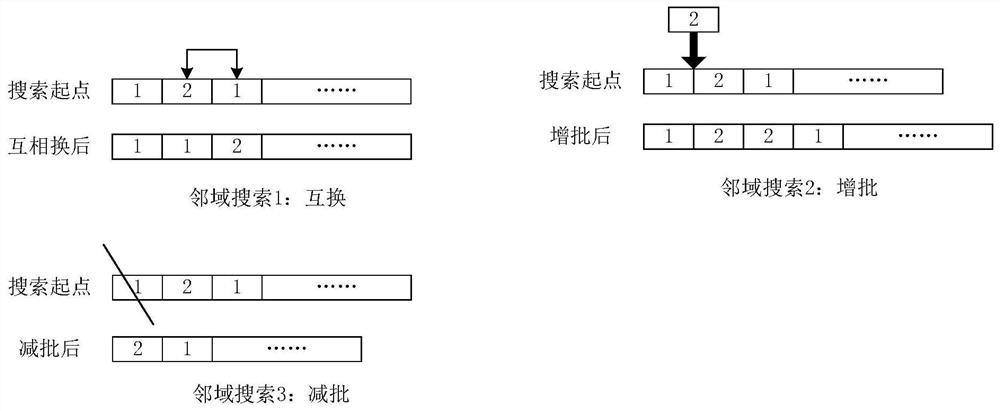

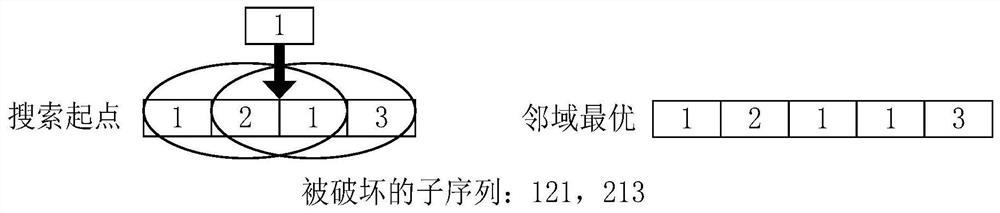

Flexible job shop scheduling method considering preparation time and workpiece batching

PendingCN112541694ASolve the problem of lack of flexibility in the number of sub-batches and the number of sub-batchesSolve the problem of lack of flexibilityDesign optimisation/simulationConstraint-based CADCompletion timeGenetics algorithms

The invention discloses a flexible job shop scheduling method considering preparation time and workpiece batching, which constructs a flexible job shop scheduling model considering the preparation time and the workpiece batch by combining the production requirements of an actual job shop and aiming at the influence of the production preparation time and the workpiece batch on flexible job shop scheduling. An improved genetic algorithm is adopted, based on a double-layer coding mode, the minimum maximum completion time is taken as an optimization target, and the optimization of a scheduling target is realized by reasonably dividing workpiece batches. Meanwhile, aiming at the characteristic of insufficient flexibility of an equivalent batching method during batch machining of the workpieces,the flexible batching method is adopted to dynamically divide the workpieces in batches. According to the method, the preparation time required by the workpieces in the actual production process of the workshop is combined with the batch machining of the workpieces, the actual production condition of the workshop is fully considered, the actual requirements of workshop production are met, and thescheduling problem of the actual flexible operation workshop is solved.

Owner:CHANGAN UNIV

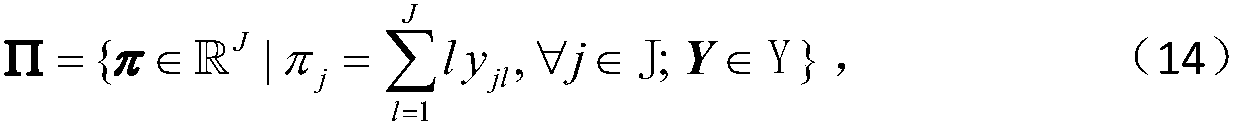

Automobile engine flexible production line batching and scheduling method

PendingCN114492895AIncrease productivityIn line with the actual production situationForecastingManufacturing computing systemsBatch processingMachine

An automobile engine flexible production line batching and scheduling method takes minimization of tardiness punishment as an optimization target, and an original optimization problem is solved through two stages, namely, the total number of sub-batches of each workpiece and the machining sequence of all sub-batches of different workpieces are solved through a heuristic algorithm of genetic taboo mixing, and then under the machining sequence, the number of sub-batches of all the workpieces is calculated through the heuristic algorithm of genetic taboo mixing. A mixed integer programming model is established by adopting a sample mean value approximation method according to the characteristics of random arrival time, that is, a plurality of scenes are generated according to the random characteristics of workpiece incoming time, the target is to minimize the overdue penalty mean value of all the scenes, and batch optimization is realized by solving the batch size of each sub-batch. According to the method, the genetic algorithm and the tabu search algorithm are combined, the minimum tardiness punishment is taken as the target, the total machining amount of each type of workpieces is processed in batches for a flexible flow production line which arrives at random of the workpieces to be machined and has machine die change time, a plurality of sub-batches are formed, and the machining sequence of the sub-batches is optimized.

Owner:SHANGHAI JIAO TONG UNIV

Same-type parallel machine production scheduling method considering moment information indeterminacy

ActiveCN107609678APracticalReduce conservatismForecastingResourcesComputer scienceRobust optimization

The invention provides a same-type parallel machine production scheduling method considering moment information indeterminacy, and belongs to the field of production scheduling and operational research. The method comprises the steps of firstly building a distribution set robust optimization model DR-PMSP-MU considering the moment information indeterminacy, and obtaining an expression of an initial model DR-PMSP-MU1 comprising an inner layer problem and an outer layer problem; converting a decision variable of the model DR-PMSP-MU, solving the inner layer problem, and equivalently converting the model DR-PMSP-MU1 into a solvable model DR-PMSP-MU2; and taking an optimal solution of the model DR-PMSP-MU2 as an optimal solution of the whole model, wherein the optimal solution corresponds to multiple optimal production scheduling schemes, and a decider can perform selection as needed. The built model better meets an actual production condition; and by utilizing more information in a production environment, the decision-making risk can be lowered under the condition of ensuring system performance.

Owner:TSINGHUA UNIV

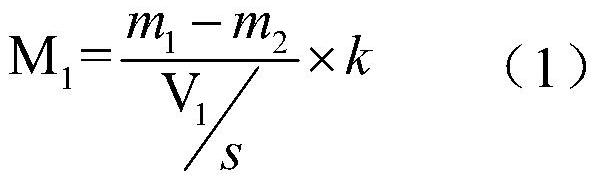

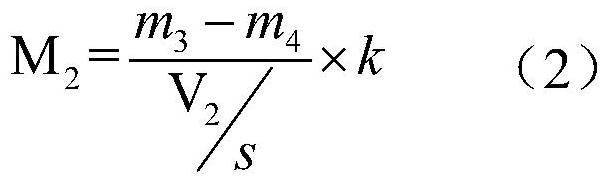

Method for identifying type of drilling fluid and method for identifying type of drilling and completion waste

ActiveCN110687271AAvoid problems with inaccurate or even impossible measurementsMeet actual needsEarth material testingProcess engineeringAsphalt

The invention provides a method for identifying the type of drilling fluid and a method for identifying the type of drilling and completion waste. The method for identifying the type of the drilling fluid comprises a step of measuring liquid phase fraction and asphalt content of drilling fluid to be identified, wherein the drilling fluid to be identified belongs to polymer drilling fluid or sulfonated drilling fluid, a step of obtaining drilling fluid filtrate of the drilling fluid to be identified and measuring the sulfo group content of the drilling fluid filtrate, a step of determining thesulfo group content of the drilling fluid to be identified according to the liquid phase fraction of the drilling fluid to be identified and the sulfo group content of the drilling fluid filtrate, anda step of determining the type of the drilling fluid to be identified according to the sulfo group content and the asphalt content of the drilling fluid to be identified. According to the identifyingmethods provided by the invention, the type of the drilling fluid and the type of the drilling and completion waste can be accurately judged, and so the drilling and completion waste can be treated in a targeted manner. Moreover, the whole identification process can be completed through an indoor experiment, the influence of human factors is small, the reliability is high, and the repeatability is good.

Owner:PETROCHINA CO LTD

A Critical Chain Buffer Setting Method Based on Production Uncertainty

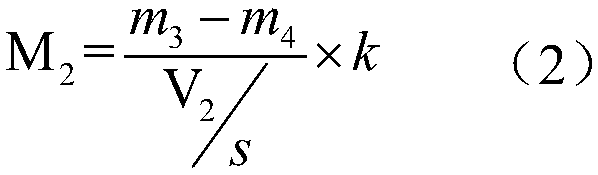

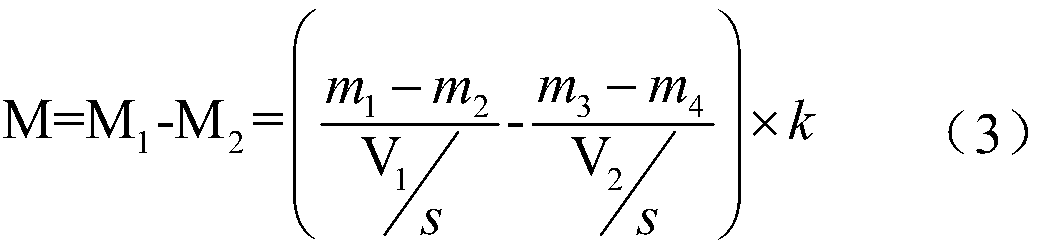

ActiveCN107944695BImprove accuracyIn line with the actual production situationResourcesManufacturing computing systemsResource utilizationOperations research

The invention discloses a key chain buffer setting method based on production uncertainty. The present invention first obtains the priority coefficient of the customer and the priority coefficient of the order, and then uses a heuristic algorithm to generate a dispatch plan based on the priority rule, and then performs left and right shift operations on the obtained dispatch plan to obtain two new dispatch plans, And compare the start time of each process to obtain the free time difference of each process, then the process with a free time difference of zero is the critical chain process, so as to obtain the critical chain, and then set the input, project and resource based on the free time difference and the improved root variance method The buffer size of the buffer. The invention improves the root variance method by combining resource utilization and variability measurement, and corrects the root variance method by accurately measuring the variability of process processing time for the problem of the influence of a large number of uncertain factors on buffer calculation in complex production environments The calculation result effectively improves the accuracy of the buffer calculation.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Abnormal section management method in chemical industry production based on data driving

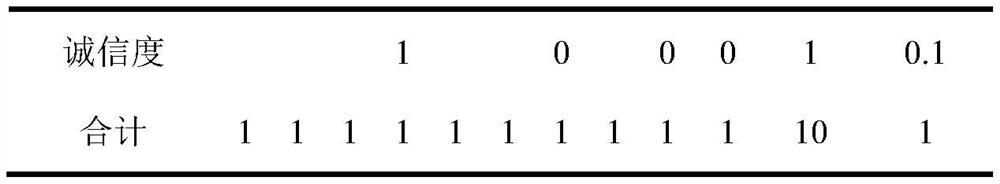

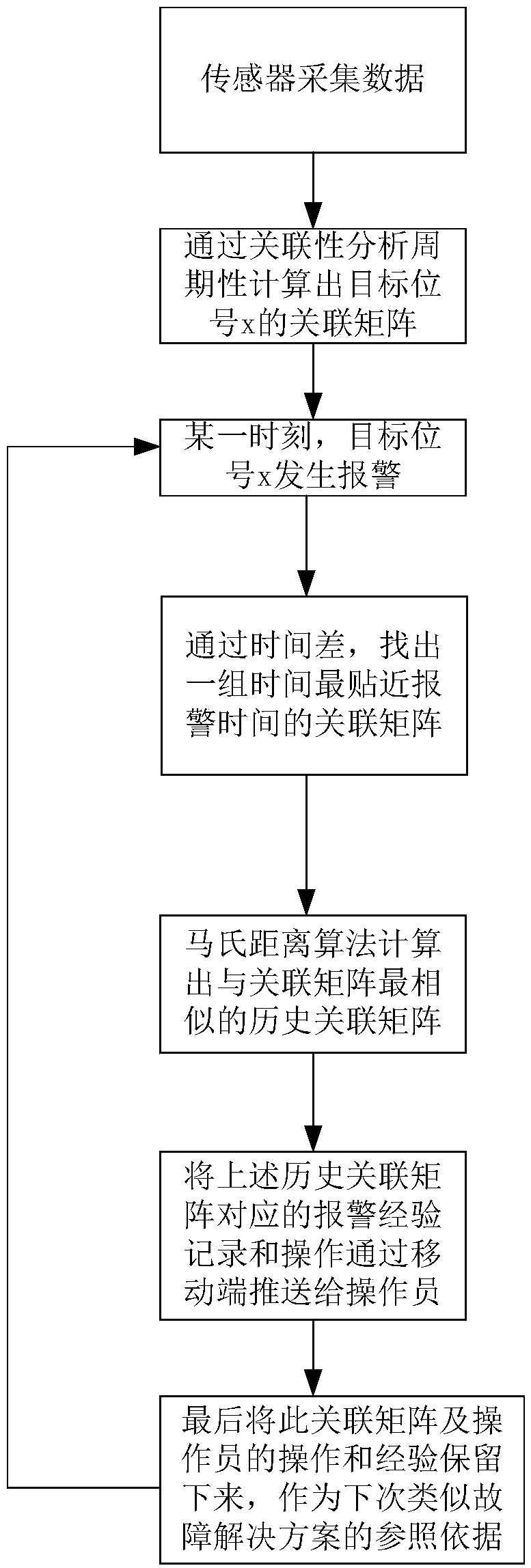

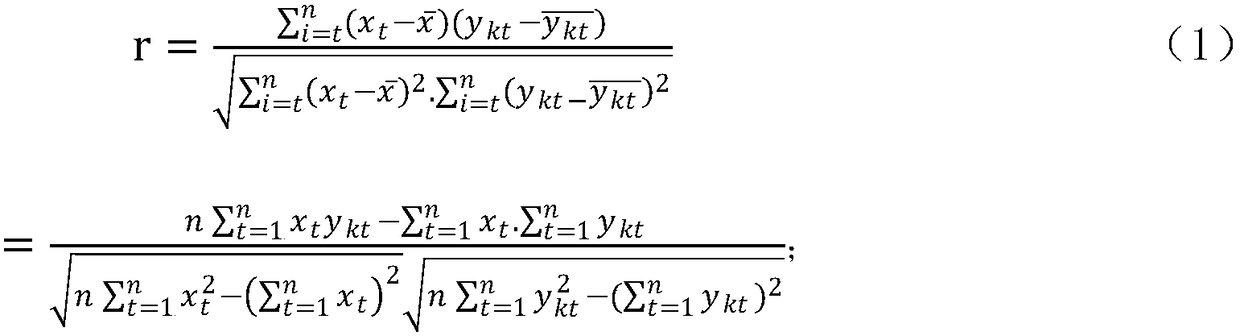

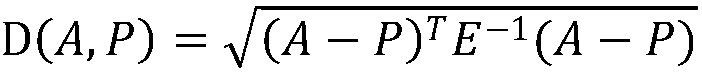

ActiveCN109327330AGuaranteed timelinessIn line with the actual production situationData switching networksChemical industryTime difference

The invention relates to an abnormal section management method in chemical industry production based on data driving. The method comprises the following steps of 1, collecting each bit number by usinga sensor; 2, analyzing periodical correlation on the bit number, to acquire correlation matrixes at different moments; 3, at the certain moment, giving an alarm by the target bit number, and findingthe correlation matrix closest to the alarm moment through time difference; 4, computing the similarity between the correlation matrixes and historical correlation matrixes, to acquire the historicalcorrelation matrix set with the highest similarity; 5, calling a historical operation corresponding to the most similar historical correlation matrix, and sending the same to an operation staff; and 6, after the alarm is solved, recording to the correlation matrixes and the operation records of the operation staff to form into knowledge sections, and putting the knowledge sections into a historical database. According to the method, the defect of traditional single alarm information is avoided, the correlation parameter of the alarm parameter is found via computation of the correlation matrix,and the operation staff can acquire more decision making bases and operation bases according to the correlation parameter.

Owner:南京科思倍信息科技有限公司

A horizontal table measuring device for measuring the center distance of tenons and grooves

ActiveCN106091884BEasy to operateImprove stabilityMechanical measuring arrangementsMeasurement deviceLong axis

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

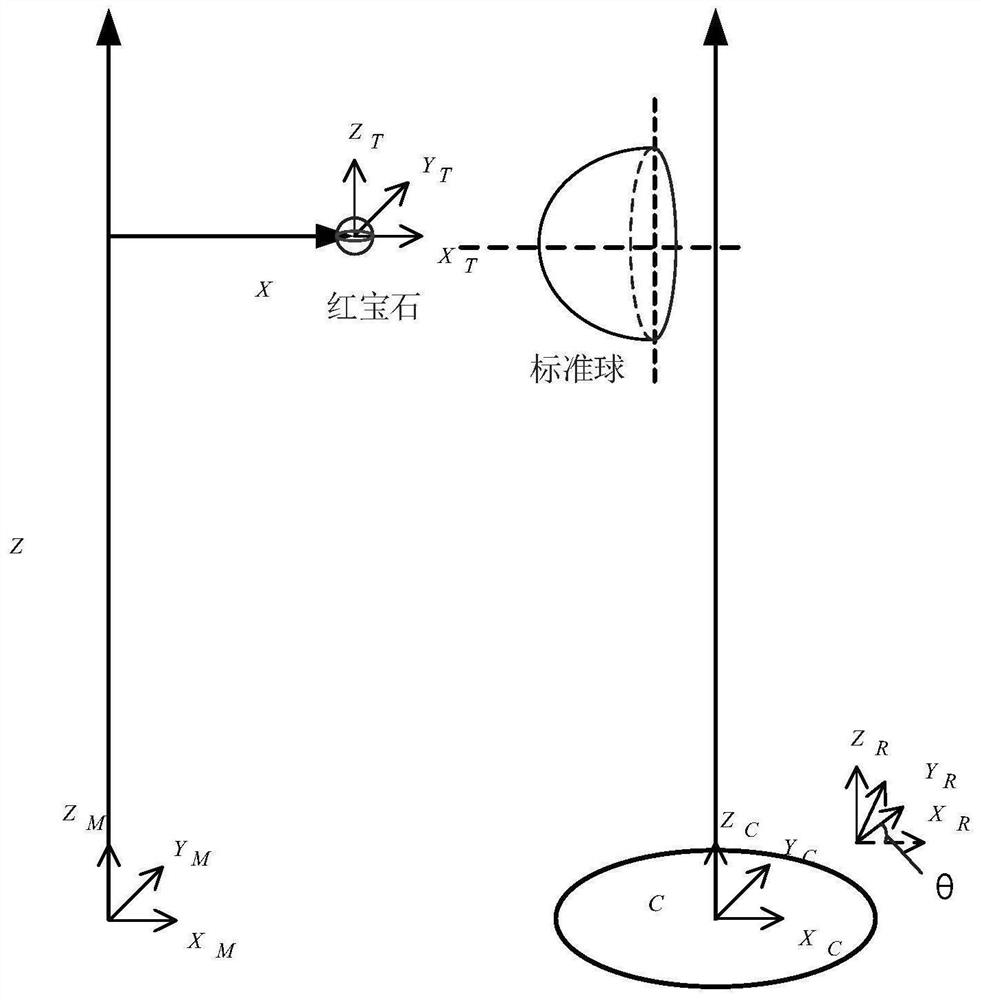

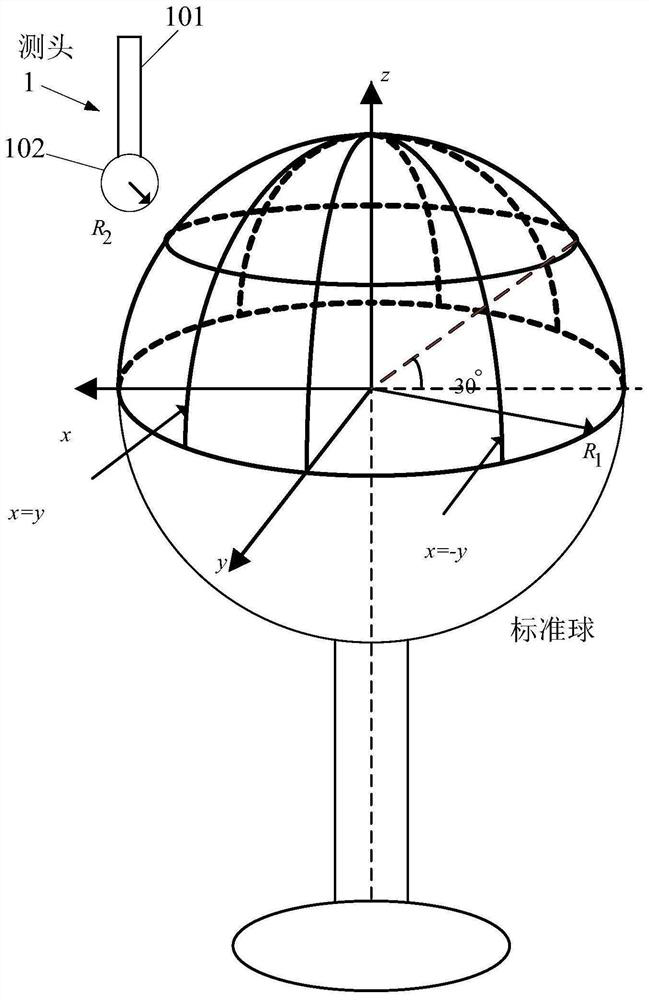

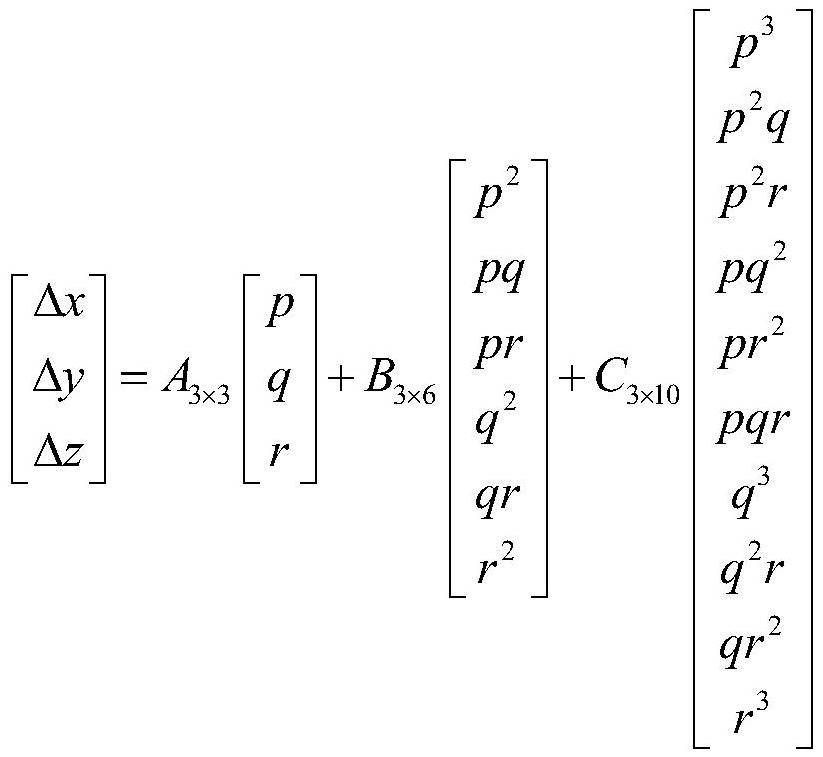

Calibration method of non-orthogonal nonlinear 3D scanning probe under cylindrical coordinate measuring machine

ActiveCN111678470BWide applicabilityIn line with the actual production situationMeasurement devicesAlgorithmEngineering

The invention provides a non-orthogonal nonlinear three-dimensional scanning probe calibration method under a cylindrical coordinate measuring machine, which includes: using a standard sphere as a calibration reference, constructing multiple scanning trajectories, establishing an optimization problem with spherical constraints as the objective function, and For the coefficient of the third-order item is too small, the coefficient estimation is adjusted to obtain a spherical constraint objective function suitable for optimization, and the Levenberg-Marquardt algorithm is used to realize the optimization. The third-order nonlinear optimization model of non-orthogonal 3D scanning probe is established by multivariate Taylor function expansion theory, which is the extension of orthogonal 3D scanning probe, and the model has wide applicability. The optimization is carried out twice, the first optimization of low-order coefficients, based on which the third-order coefficients are estimated, the order of magnitude of the coefficients is adjusted to the same order of magnitude in the second optimization, and the objective function is fine-tuned synchronously, directly optimizing all third-order coefficients, avoiding the When the third-order optimization is performed directly, the third-order coefficient cannot be optimized due to the large difference in magnitude.

Owner:无锡身为度信息技术有限公司

A kind of determination method for trapping and killing effect of Spodoptera litura adults

ActiveCN112034097BSatisfy the physiological lifeSatisfy mating and spawning activitiesBiological testingMatingTrapping

The invention discloses a method for measuring the trapping and killing effect of Spodoptera litura adults, which comprises the following steps: (1) Design of test plots: prepare several closed test plots without Spodoptera litura occurrence, divide the test plots into trapping and killing treatment zones and Blank control area; (2) Host plant planting: Spodoptera litura host plants were uniformly planted in each test plot, and the size and growth of the Spodoptera litura host plants were consistent; (3) Trapping treatment; (4) Pupa insertion; (5) Data recording; (6) Calculation of trapping effects. The present invention eliminates the uncertain factors of outdoor evaluation, and designs a larger closed community, which can not only meet the physiological life, mating and oviposition activities of Spodoptera litura, but also reflect the actual production situation, except that Spodoptera litura cannot fly outwards. The other conditions outside of flying in and out are basically consistent with the natural state, which ensures that the test data is close to the natural state, which not only reduces the area of the field test, but also shortens the period of the field test.

Owner:广西壮族自治区植保站

Carbon sequestration reinforced recycled aggregate preparation device and method based on returned material crushing

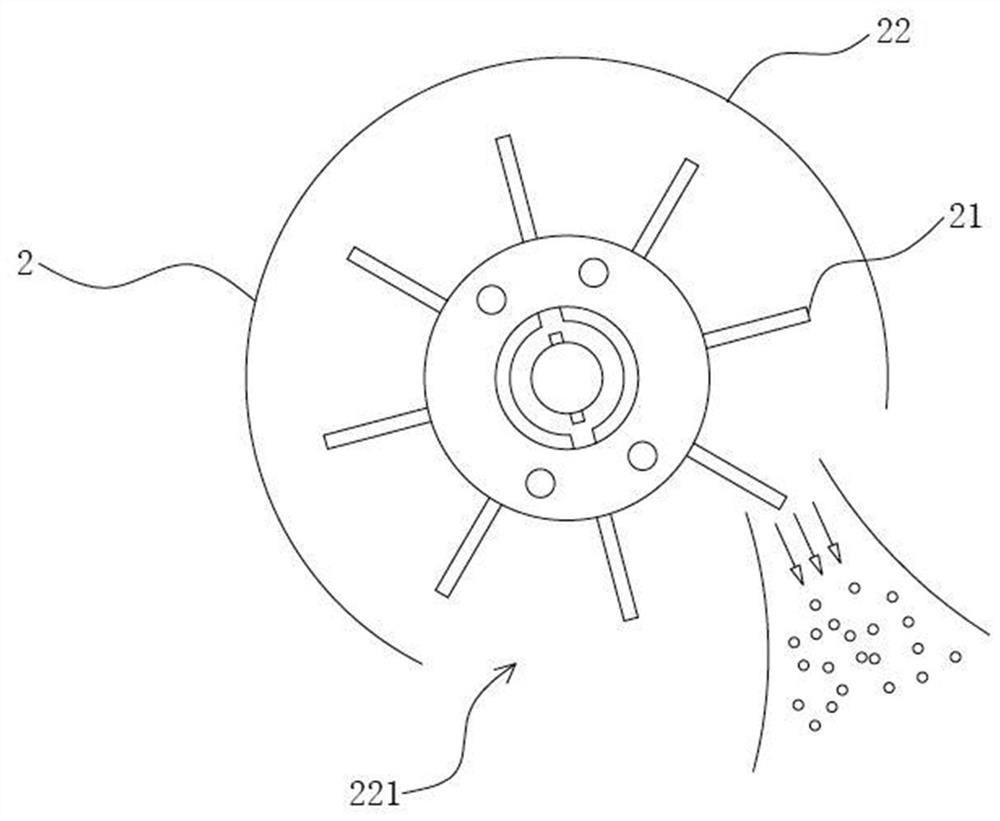

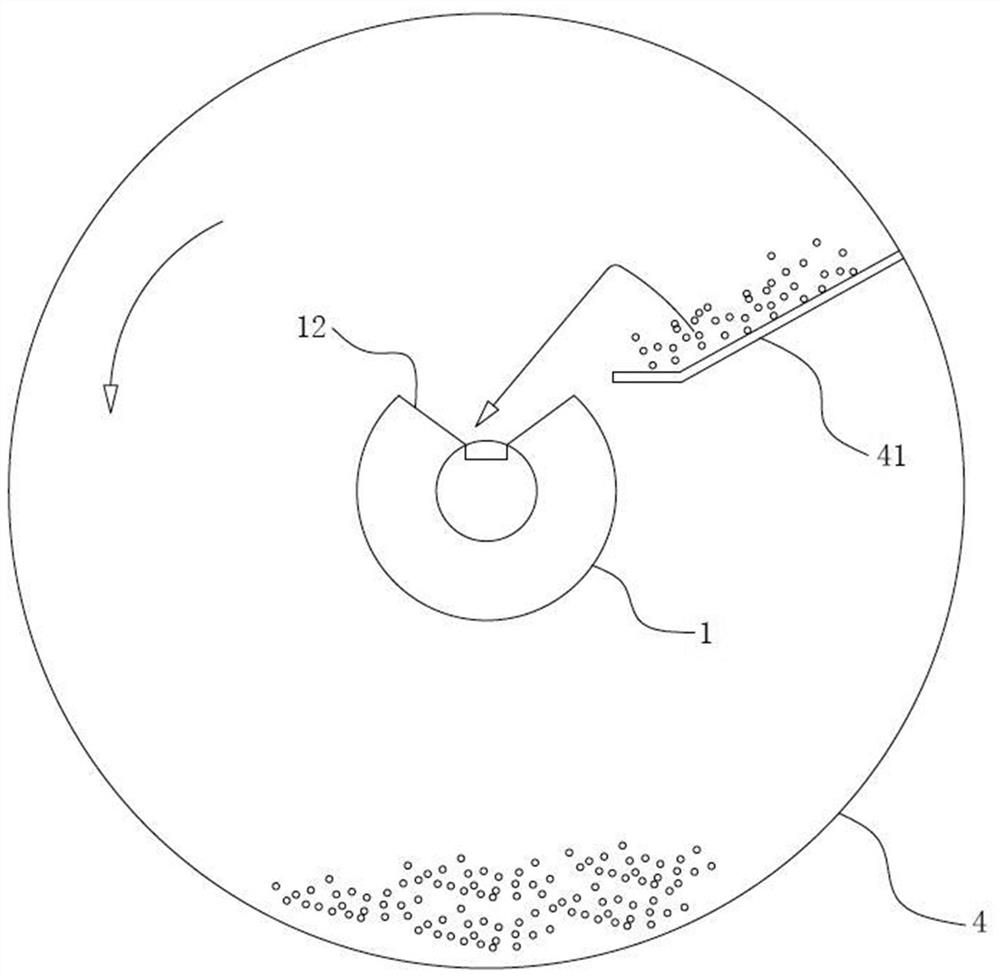

ActiveCN114768967AReduce volumeSmall impact contact surfaceSolid waste managementGrain treatmentsCarbonizationCarbon sequestration

The invention relates to the technical field of recycled aggregate recycling, in particular to a carbon sequestration reinforced recycled aggregate preparation device and method based on returned material crushing, and the device comprises a screw conveyor, a material throwing rotor, a screening rotary drum, a returned material rotary drum and a carbon dioxide input pipe; the spiral conveyor comprises a raw material inlet, a fine aggregate inlet and a discharge hole; the screening rotary drum comprises an inner drum body and an outer drum body, and the throwing rotor is used for throwing aggregates into the inner drum body in an accelerated manner, so that the aggregates collide with one another and are crushed; the spiral conveyor is sleeved with the material returning rotary drum, the fine aggregate inlet is located in the material returning rotary drum, and material returning blades of the material returning rotary drum drive fine aggregate to be fed into the spiral conveyor from the fine aggregate inlet; and the inlet end of the carbon dioxide input pipe is communicated into the screening rotary drum. The aggregates collide with one another to be crushed and shaped and fully react with carbon dioxide in the process, so that carbon dioxide is absorbed and solidified, carbonization of the recycled aggregates is enhanced, and the high-quality recycled aggregates are prepared.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL +1

A Method of Estimating Gas Well Production

ActiveCN104832156BSolve fixed proration coefficientIn line with the actual production situationSurveyRegression analysisPoint method

A method for estimating gas well production provided by the present invention includes: establishing a gas field "one-point method" productivity equation; calculating the average daily production of sample points in the gas field within the predetermined production history period, and the sample point is within the predetermined production history period The pressure drop rate of the sample point is within the first predetermined range; according to the daily production and bottom hole flow pressure of the sample point during the gas test, the absolute open flow of the sample point is calculated; the average daily production of the sample point and the absolute open flow of the sample point are calculated Regression analysis calculation, to obtain the first relationship between the average daily production of gas wells in the gas field and the absolute unobstructed flow rate during official production; according to the daily production and bottom hole flow pressure of the wells to be officially produced, calculate the absolute unobstructed flow of the wells to be officially produced Flow: According to the absolute unimpeded flow rate of the wells to be officially produced, the first average daily production of the wells to be officially produced when they are officially produced is calculated. The invention realizes that the daily production of the gas well can be estimated according to the actual production situation after fracturing of the tight sandstone gas reservoir.

Owner:PETROCHINA CO LTD

Energy utilization state diagnosis method for process industrial equipment

ActiveCN102231081BTimely referenceExact referenceElectric testing/monitoringIndustrial equipmentProcess engineering

Owner:中广核智能科技(深圳)有限责任公司

Device and method for studying migration law of temporary plugging agent in horizontal well or vertical well temporary plugging fracturing

ActiveCN108708703BStick evenlyConducive to studying the effects of spacingSurveyConstructionsHorizontal wellsMechanical engineering

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

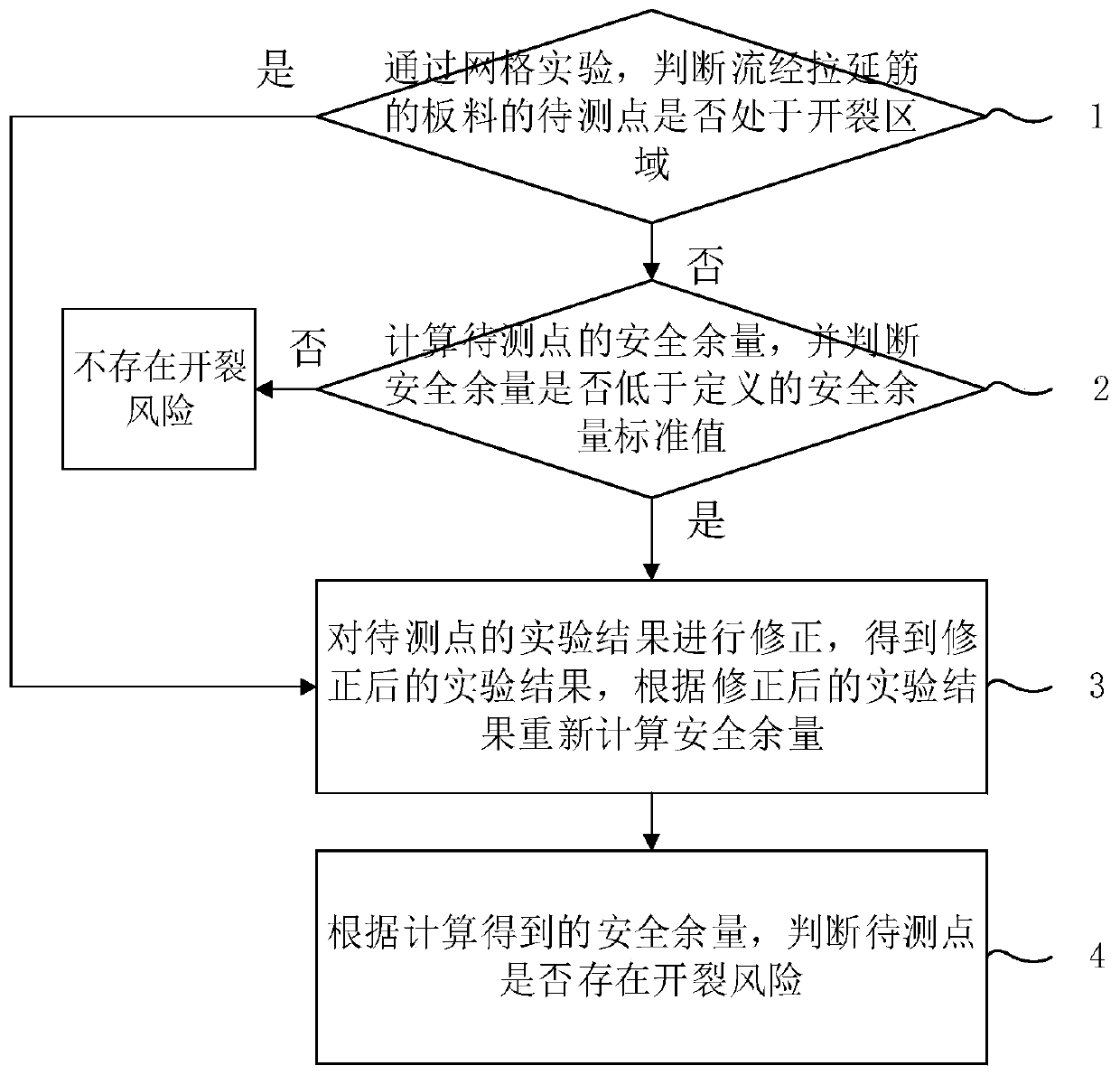

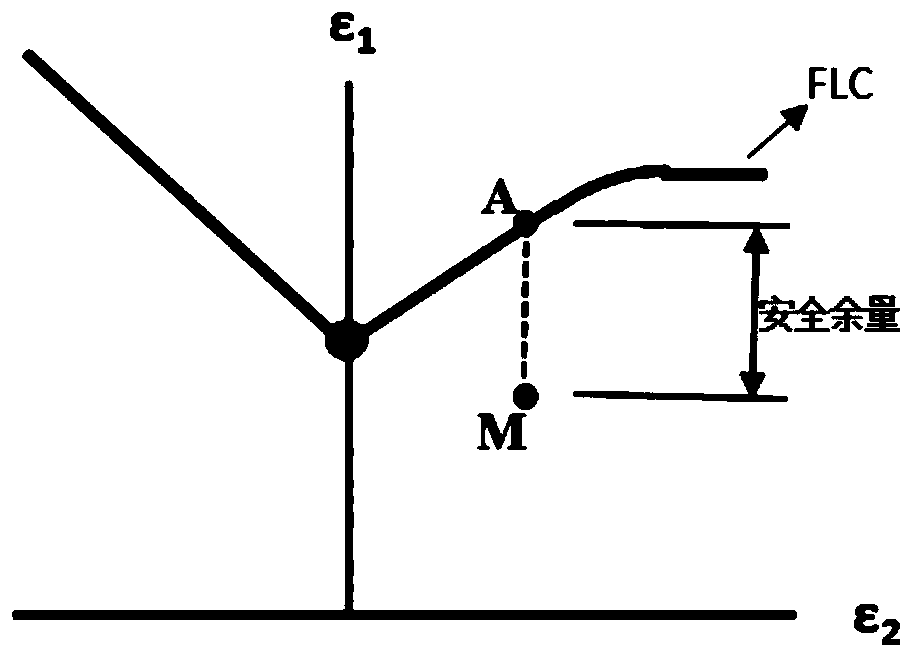

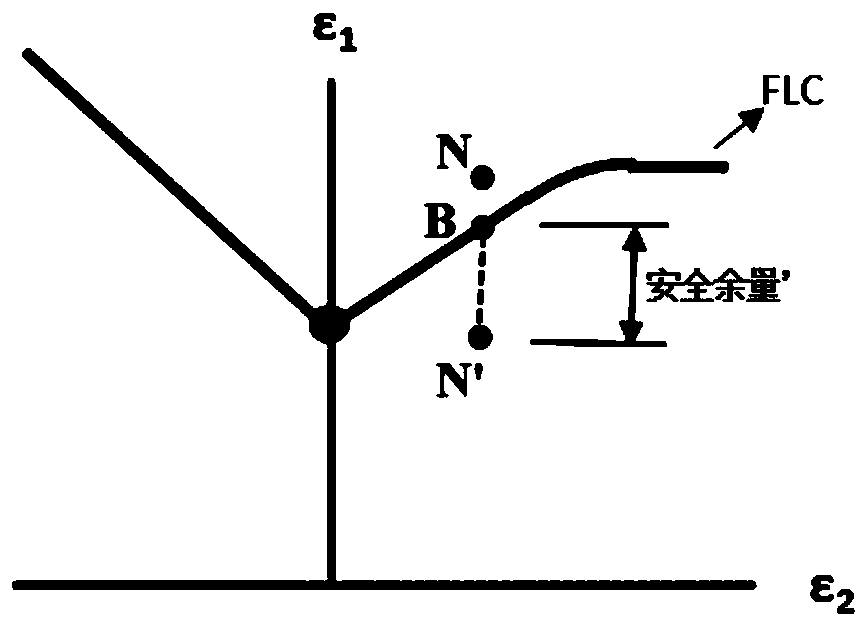

A Crack Evaluation Method for Sheets Flowing Through Drawbeads for Stamping

ActiveCN107766693BSafety Margin AccurateImprove accuracyGeometric CADInformaticsStructural engineeringMechanical engineering

The invention relates to a cracking judgment method for a plate material flowing through a drawbead and used for stamping. The method comprises the following steps of through a grid test, judging whether a to-be-tested point of the plate material flowing through the drawbead is in a cracking region or not, if the to-be-tested point is not in the cracking region, calculating a safe margin of the to-be-tested point, if the safe margin is greater than a standard value, indicating that a cracking risk does not exist, and if the safe margin is smaller than the standard value, correcting a test result; if the to-be-tested point is in the cracking region, directly correcting the test result; and after the test result is corrected, recalculating the safe margin and comparing the safe margin with the standard value to judge whether the cracking risk exists or not. Compared with the prior art, the method has the advantages of high judgment precision, no influence on performance after plate formation, easy realization and the like.

Owner:SHANGHAI COTECH AUTOMOTIVE ENG CORP LTD

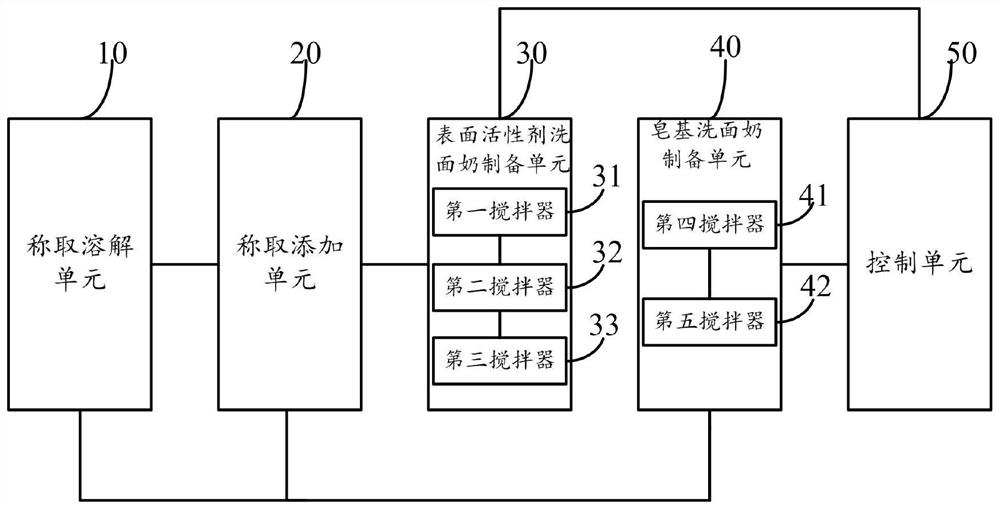

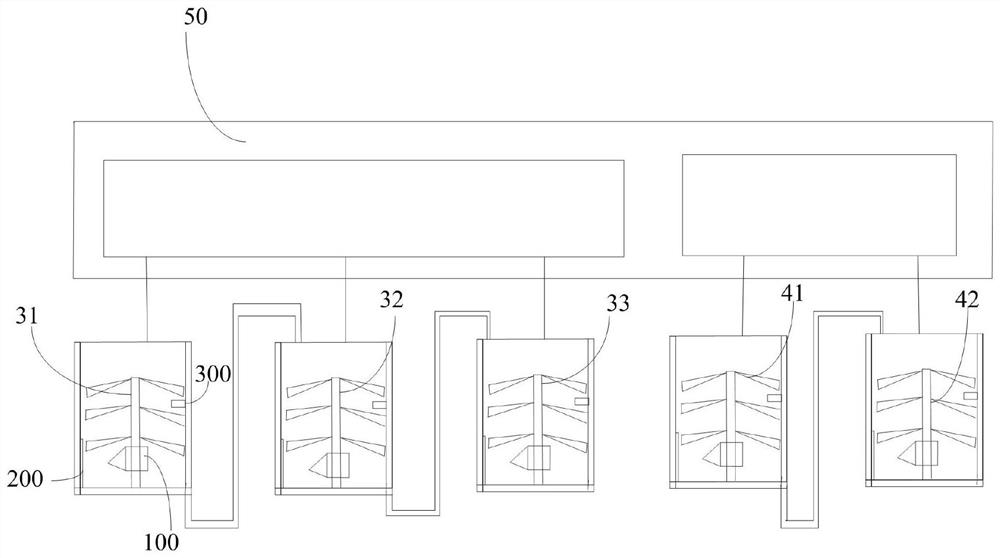

Preparation process of facial cleanser

InactiveCN112138595AEasy to cleanSoft touchCosmetic preparationsToilet preparationsMedicineActive agent

The invention relates to a preparation process of a facial cleanser. According to the process, a weighing and dissolving is unit for weighing a surfactant and dissolving the surfactant; a weighing andadding unit is used for weighing attapulgite and a preservative and adding the attapulgite and the preservative; and a surfactant facial cleanser preparation unit is used for preparing a surfactant facial cleanser, weighing the surfactant, adding the surfactant into the process water, stirring to dissolve the surfactant, weighing a thickening agent, adding a proper amount of process water, heating to dissolve the thickening agent, adding the dissolved thickening agent into the dissolved surfactant, carrying out stirring and cooling, adding the attapulgite and the preservative, and uniformly stirring again to obtain the surfactant facial cleanser. No matter whether the surfactant facial cleanser or the soap-based facial cleanser is used, the raw materials contain the attapulgite component,and the structure of attapulgite is specific, so that the prepared facial cleanser is moderate in bubble concentration, strong in cleaning power and softer in contact with skin, and meets the basic requirements of users on skin cleaning and comfort.

Owner:NANJING HUAKAI BIOLOGICAL TECH CO LTD

Identification method of drilling fluid type and identification method of drilling and completion waste type

ActiveCN110687271BAccurate distinctionHuman factors are smallEarth material testingProcess engineeringPolymer

The invention provides a method for identifying the type of drilling fluid and a method for identifying the type of drilling and completion waste. The identification method of the drilling fluid type includes: measuring the liquid phase fraction and bitumen content of the drilling fluid to be identified, wherein the drilling fluid to be identified belongs to polymer drilling fluid or sulfonated drilling fluid; obtaining the drilling fluid filtrate of the drilling fluid to be identified, and Determine the sulfo group content of the drilling fluid filtrate; determine the sulfo group content of the drilling fluid to be identified according to the liquid phase fraction of the drilling fluid to be identified and the sulfo group content of the drilling fluid filtrate; according to the sulfo group content and asphalt content of the drilling fluid to be identified, Determine the type of drilling fluid to be identified. According to the identification method provided by the present invention, the type of drilling fluid and the type of drilling and completion waste can be accurately determined, so that the drilling and completion waste can be treated in a targeted manner. Moreover, the entire identification process can be completed through indoor experiments, with little human influence, high reliability and good repeatability.

Owner:PETROCHINA CO LTD

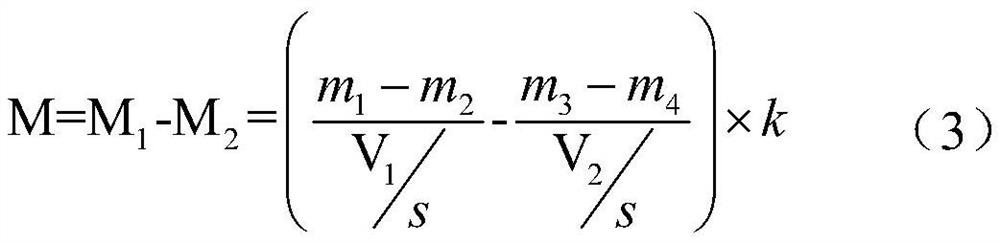

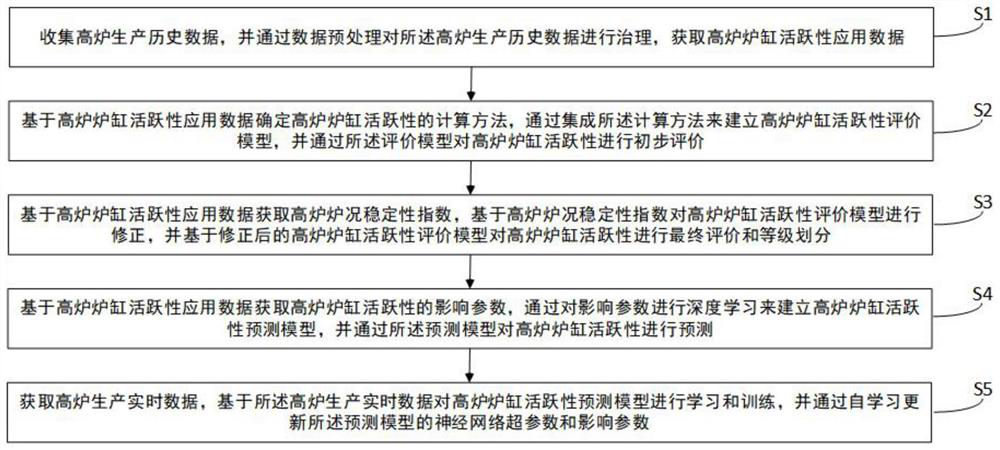

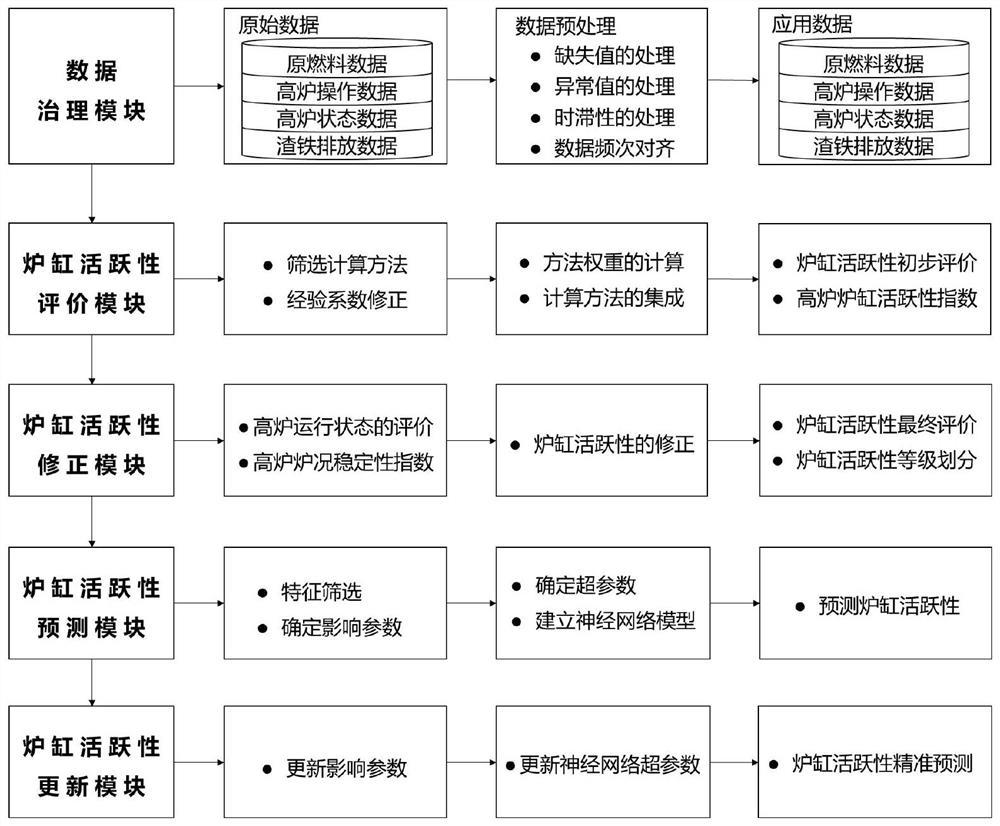

Blast furnace hearth activity evaluation and prediction method and system based on big data

PendingCN114819587AImprove production data qualityAvoid wastingBlast furnace componentsSteel manufacturing process aspectsProcess engineeringHearth

The invention relates to a blast furnace hearth activeness evaluation and prediction method and system based on big data. The method comprises the steps that blast furnace hearth activeness application data is obtained based on blast furnace production historical data and data preprocessing; establishing a blast furnace hearth activeness evaluation model based on the blast furnace hearth activeness application data and machine learning, and performing preliminary evaluation on the blast furnace hearth activeness through the evaluation model; correcting the blast furnace hearth activity evaluation model on the basis of blast furnace hearth activity application data and machine learning, and performing final evaluation and grading on the blast furnace hearth activity on the basis of the corrected evaluation model; and based on the blast furnace hearth activity application data, deep learning and self-learning, establishing a blast furnace hearth activity prediction model, and predicting the blast furnace hearth activity through the prediction model. Based on the method, accurate evaluation and accurate prediction of the activity of the blast furnace hearth are realized, and guarantee is provided for high quality, high yield, low consumption and smooth operation of the blast furnace.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com