Blast furnace hearth activity evaluation and prediction method and system based on big data

A prediction method and active technology, applied in the field of data processing, can solve problems such as waste of data resources, many model experience coefficients, and intricate influencing factors, so as to avoid waste and improve data quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

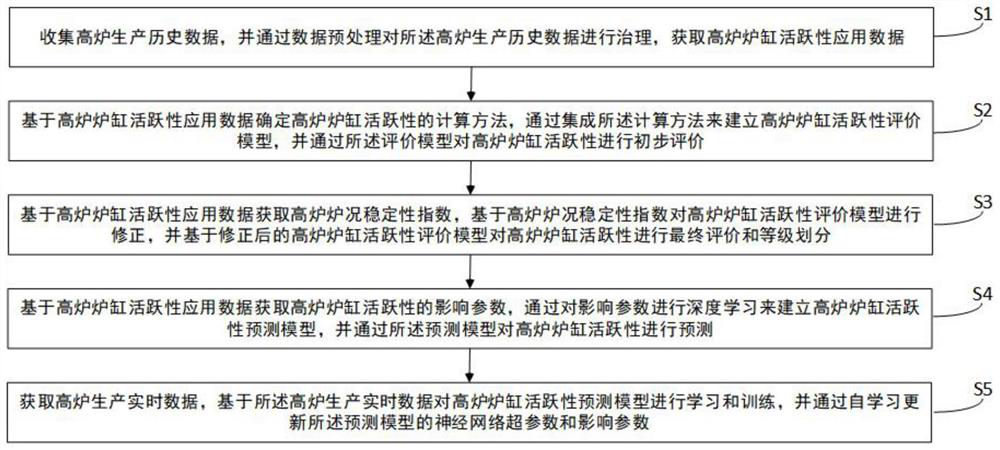

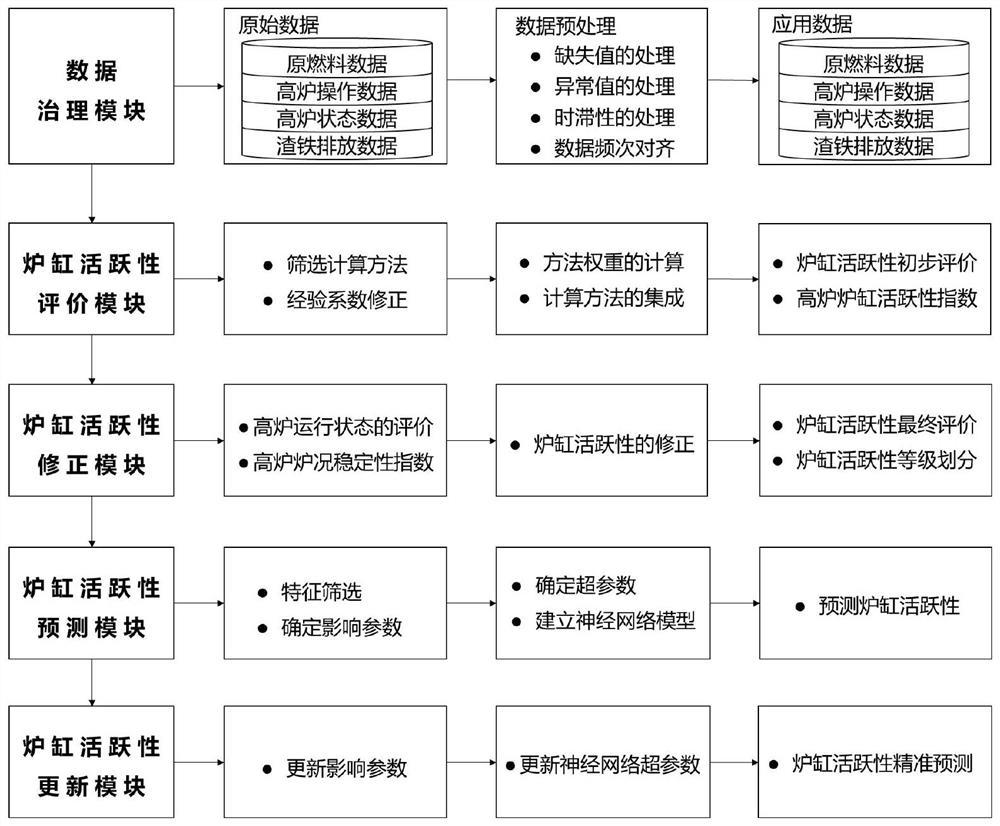

[0050] Embodiment 1 provides a method for evaluating and predicting the activity of a blast furnace hearth based on big data, such as figure 1 The specific method steps are as follows:

[0051] S1. Collect historical data of blast furnace production, and manage the historical data of blast furnace production through data preprocessing to obtain application data of blast furnace hearth activity.

[0052] In this embodiment, the blast furnace historical data includes blast furnace raw fuel data, blast furnace operation data, blast furnace smelting state data, and slag iron discharge data.

[0053]In this embodiment, the preprocessing includes data missing value processing, outlier processing, data frequency alignment, and time lag processing.

[0054] S2. Determine the calculation method of the blast furnace hearth activity based on the blast furnace hearth activity application data, establish a blast furnace hearth activity evaluation model by integrating the calculation metho...

Embodiment 2

[0060] The second embodiment provides a method for evaluating and predicting the activity of a blast furnace hearth based on big data. The specific method steps are as follows:

[0061] S1. Collect historical data of blast furnace production, and manage the historical data of blast furnace production through data preprocessing to obtain application data of blast furnace hearth activity.

[0062] Based on the above S1, it should be noted that:

[0063] For the acquisition of blast furnace hearth activity application data, an optional processing method is to obtain the blast furnace production historical data in the last two years, and manage the acquired blast furnace production historical data through data preprocessing, and then obtain the blast furnace hearth activity. Sex App Data.

[0064] In this embodiment, for the preprocessing of historical data of blast furnace production, the historical data of blast furnace production can be converted, cleaned and integrated throug...

Embodiment 3

[0110] Embodiment 3 provides the calculation method of blast furnace hearth activity, and the specific calculation method includes:

[0111] The first calculation method: Among them, A is the blast furnace condition activity, T 0 is the mean value of the thermocouple temperature on the sidewall of the hearth, T C is the average value of the central thermocouple temperature of each layer at the bottom of the furnace.

[0112] Second calculation method: Among them, Y is the daily hot metal output of the blast furnace, and D is the daily iron tapping times of the blast furnace.

[0113] The third calculation method: where, t p is the physical heat of molten iron, and [Si] is the silicon content of molten iron.

[0114] Fourth calculation method: Among them, DMT is the furnace core dead column temperature, t C is the mean value of the thermocouple temperature of each layer of the sidewall of the hearth.

[0115] In this embodiment, the above four calculation methods a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com