A Critical Chain Buffer Setting Method Based on Production Uncertainty

An uncertainty and buffer technology, applied in the critical chain field, to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the implementation methods and accompanying drawings.

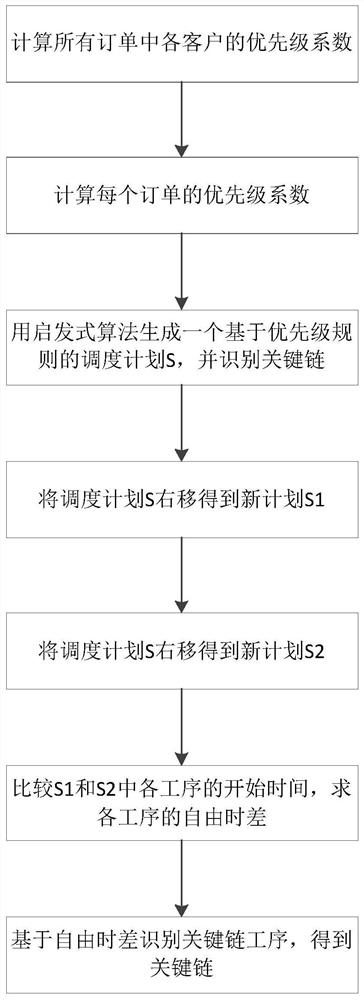

[0027] The present invention adopts the CARVER matrix and the system evaluation method to design the priority rules, then uses the heuristic algorithm to identify the critical chain based on the designed priority rules, and finally completes the buffer setting through the factory physics variability theory and resource utilization measurement. On the premise of ensuring the accuracy of the buffer setting, the multi-objective critical chain production scheduling is realized. Its specific implementation steps are as follows:

[0028] Step 1. Design priority rules.

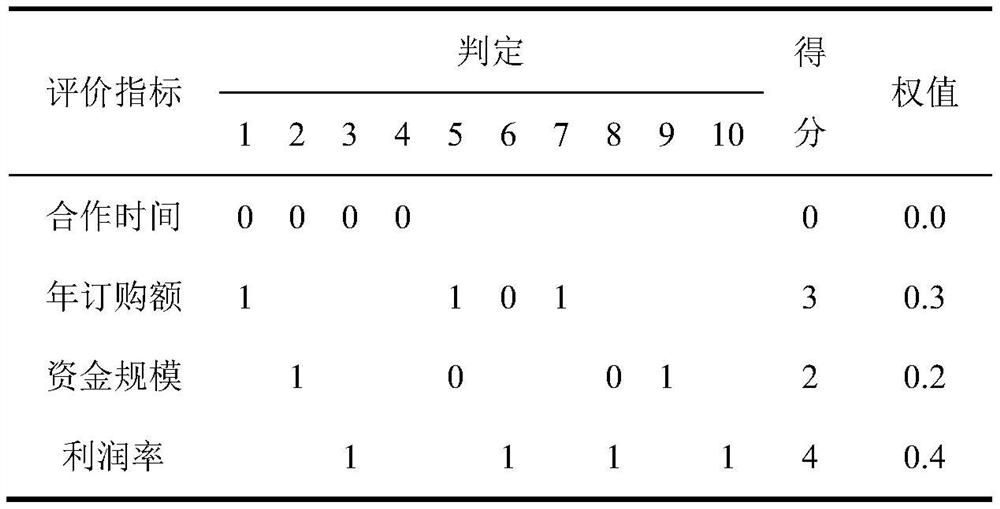

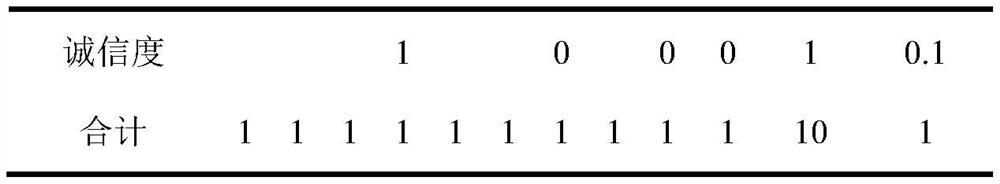

[0029] 1.1 Set customer importance:

[0030]For the production scheduling of multiple orders, in the case of the same order, the orders of more important customers should be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com