A Crack Evaluation Method for Sheets Flowing Through Drawbeads for Stamping

A drawbead and sheet technology, applied in the field of automobile stamping, can solve the problems of insufficient sheet forming rigidity, unable to meet the cycle requirements, affecting the stress distribution of the sheet, etc., so as to improve the quality of the sheet and reduce the actual, Judging the effect of accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

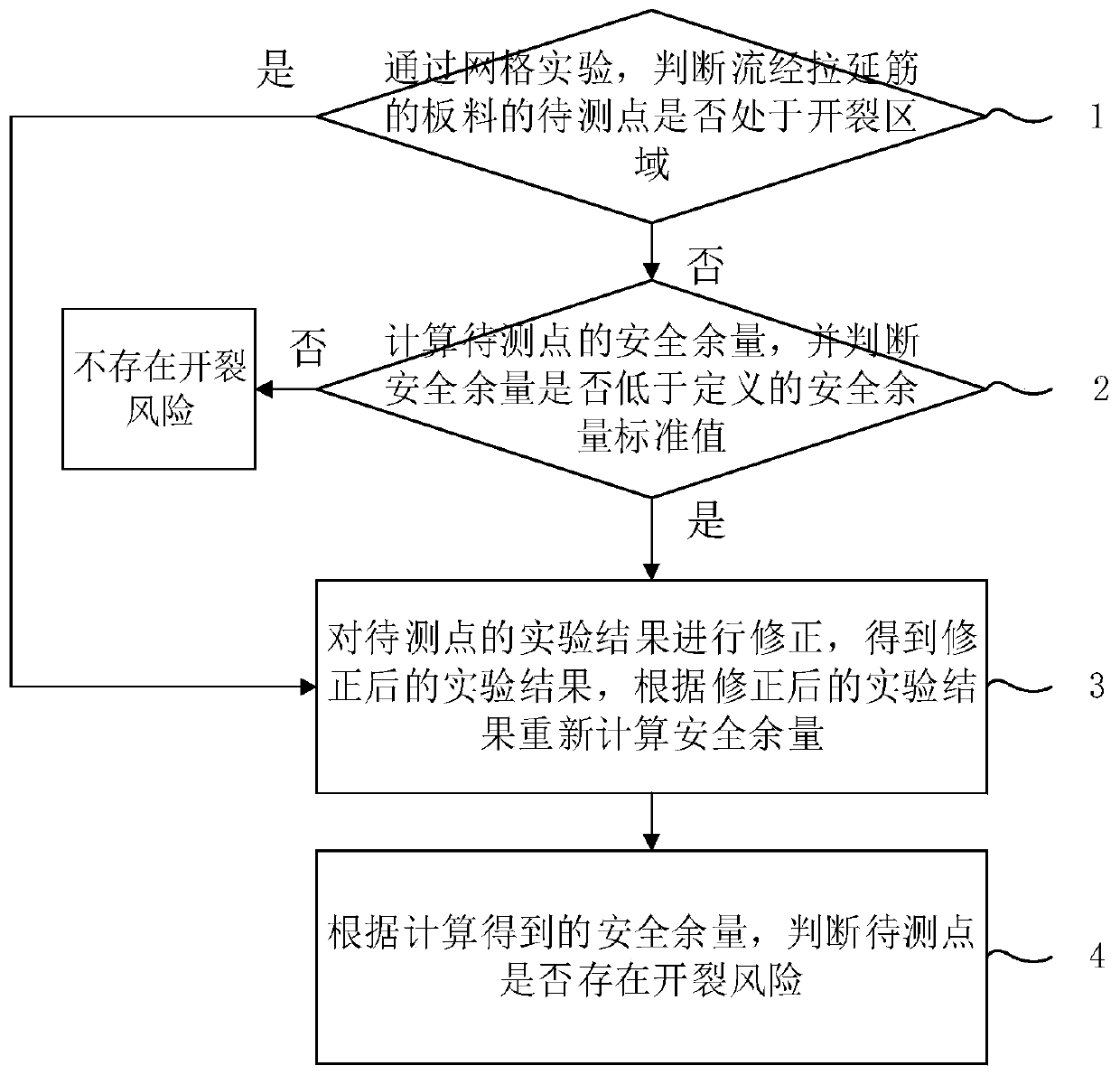

[0039] Such as figure 1 As shown, this embodiment provides a method for evaluating the cracking of the sheet material flowing through the drawbead for stamping, which mainly includes the following steps:

[0040] 1) Through the grid experiment, judge whether the point to be measured of the sheet material flowing through the drawbead is in the cracking area, if so, go to step 3), if not, go to step 2), specifically:

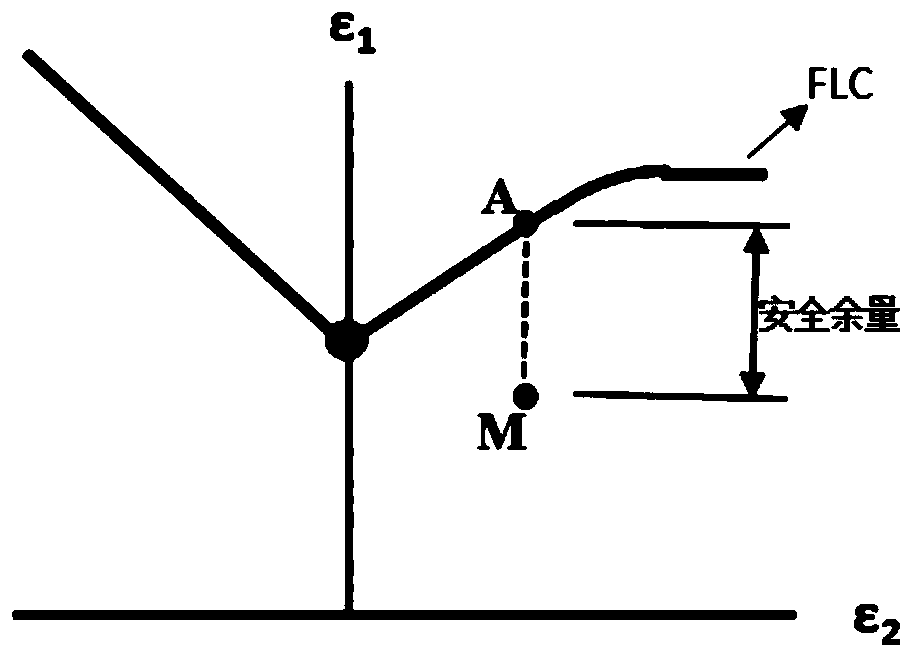

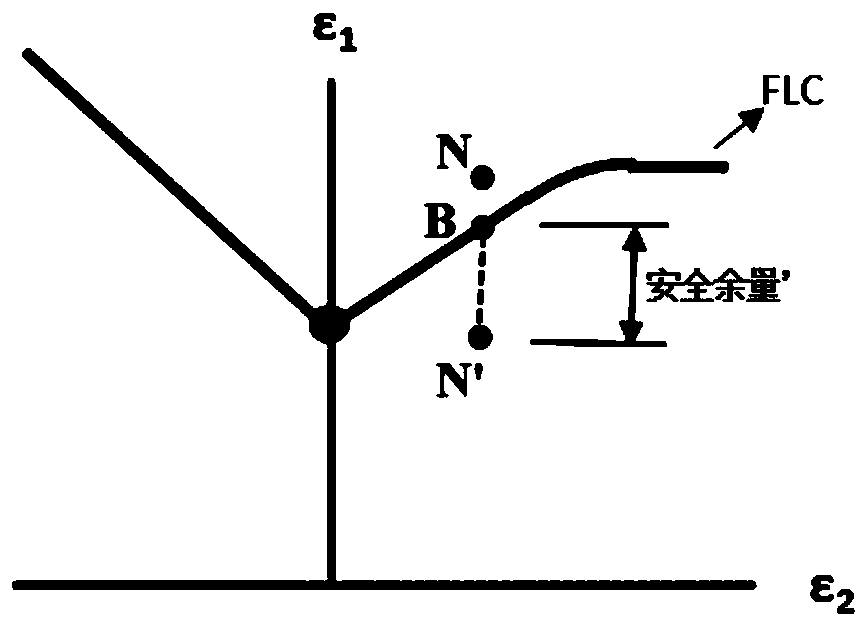

[0041] 11) Obtain the principal strain value and secondary strain value of the point to be measured through the grid experiment, so as to obtain the coordinates of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com