An Image-Based Method for Acquiring Safety Margin of Sheet Metal Forming Process Parameters

A molding process and acquisition method technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as increased calculation costs, increased product design cycle, and no consideration of uncertainty, and achieve a safety margin fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

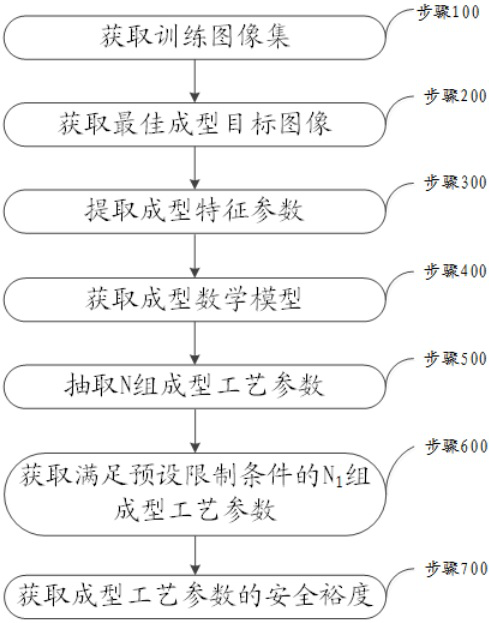

[0083] Please refer to figure 1 , is a schematic flowchart of a method for obtaining a safety margin of sheet metal forming process parameters in an embodiment, including:

[0084] Step 100, acquire a training image set.

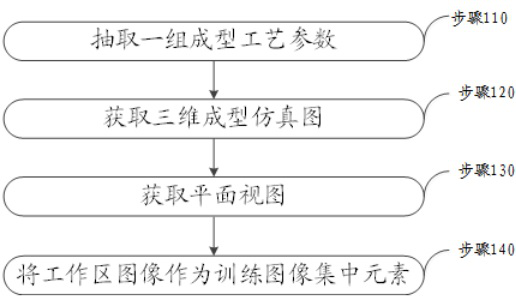

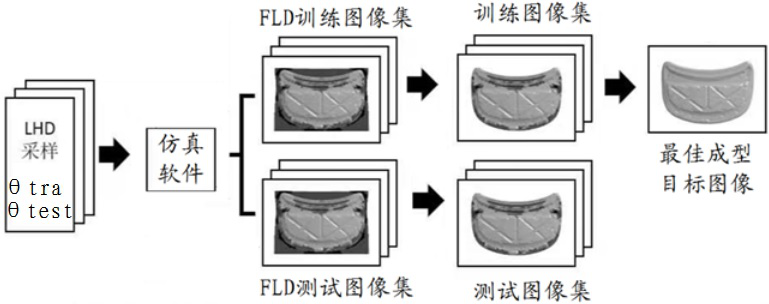

[0085] The training image set includes at least two plan views of preset shaped devices, each plan view being an element of the training image set. Please refer to figure 2 , which is a schematic flow diagram of a method for obtaining elements in a training image set in an embodiment, and the method for obtaining elements in a training image set includes:

[0086] Step 110, extract a set of molding process parameters.

[0087] Extract a group of molding process parameters from the molding process parameter range space of a preset molding device according to the first preset extraction method, the molding process parameter range space includes M types of molding process parameters, randomly selected from the preset range of each molding process parameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com