Abnormal section management method in chemical industry production based on data driving

A chemical production, data-driven technology, applied in the direction of data exchange network, digital transmission system, electrical components, etc., can solve the problems of lagging alarm information, difficulty in establishing a priori knowledge base, singleness, etc., and achieve the effect of ensuring timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

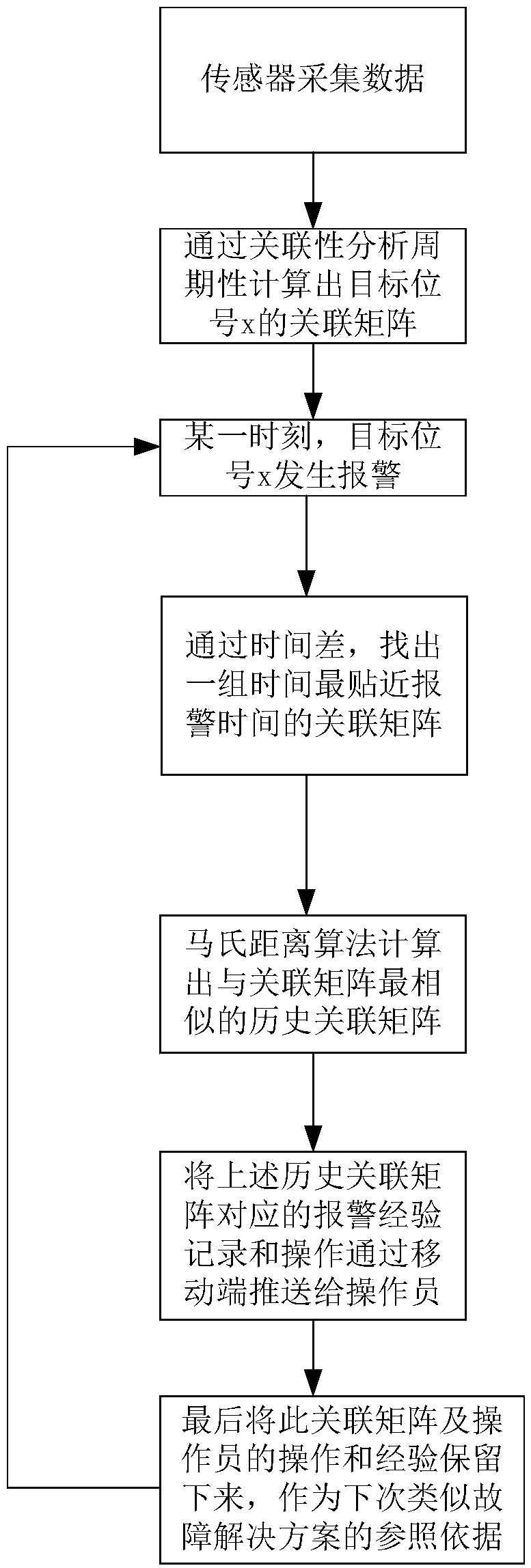

[0032] Example 1: see figure 1 , a data-driven abnormal slice management method for chemical production, the method comprising the following steps:

[0033] Step 1: Use the sensor to realize the collection of various parameters;

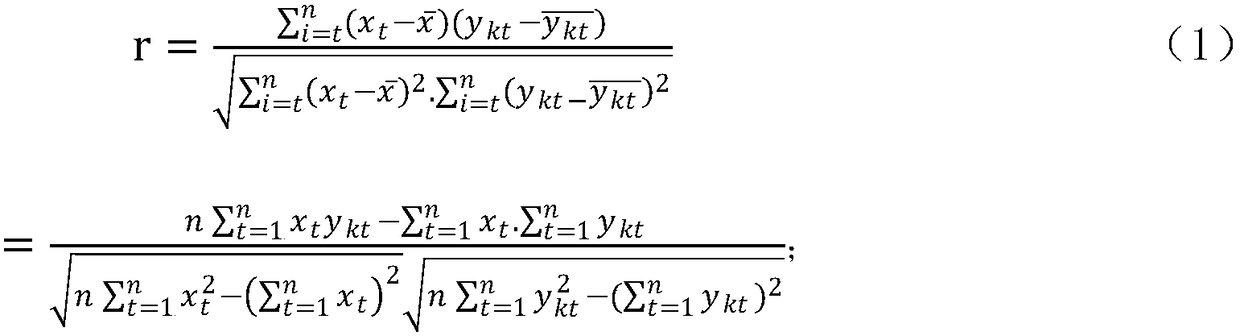

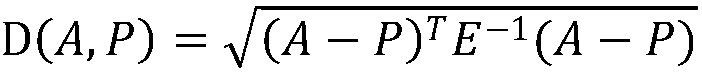

[0034] Step 2: Correlation calculation, conduct periodic correlation analysis on the bit number, and obtain the correlation matrix at different times; the specific calculation method is as follows,

[0035] In the normal production process, periodically calculate the tag that is strongly related to the target tag and form a related tag group, for example, calculate the tag that is strongly related to the A.WL.MT.LT901A tag, then use the correlation coefficient algorithm Calculate other digit numbers that have a greater correlation with the change of A.WL.MT.LT901A, denote A.WL.MT.LT901A by x, and y refers to other k digit numbers involved in the correlation calculation. First calculate the correlation coefficient between x and y x=[x1,x2,x3,...xn]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com