FeO content prediction method based on sintering machine tail section video

A prediction method and video technology, applied in prediction, computer parts, structured data retrieval, etc., can solve problems such as missing information, FeO content cannot be well corresponded, and key frame extraction cannot be performed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The following describes several preferred embodiments of the present invention with reference to the accompanying drawings, so as to make the technical content clearer and easier to understand. The present invention can be embodied in many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned herein.

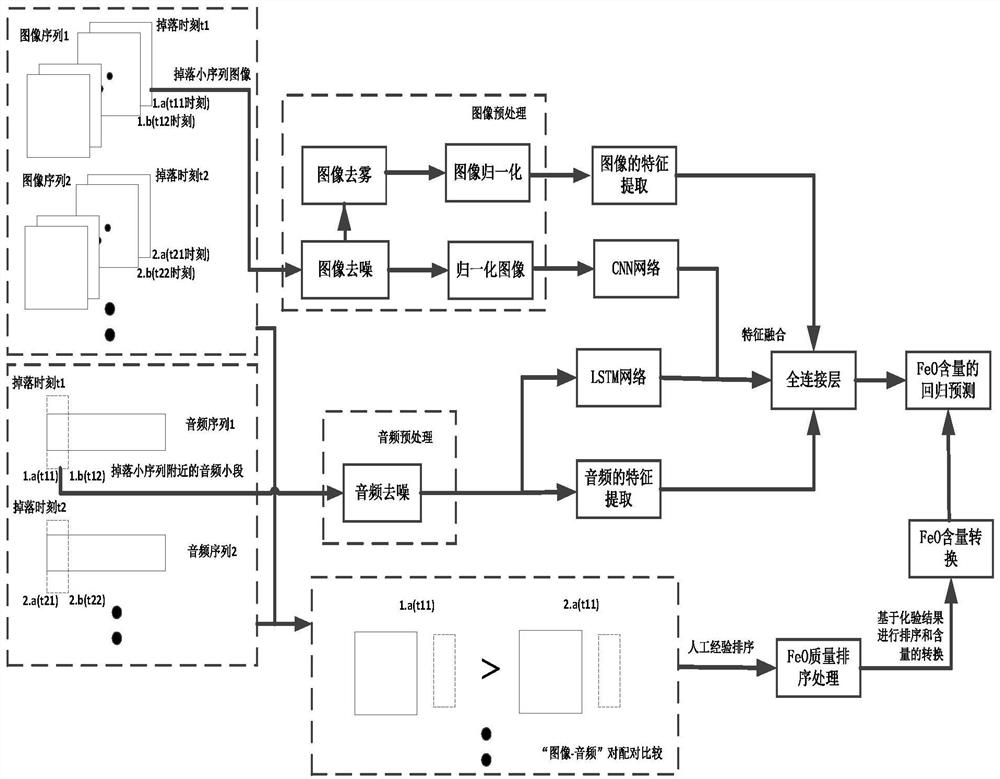

[0082] Such as figure 1 Shown is a schematic flow chart of a preferred embodiment of the present invention, which includes the following steps.

[0083] A method for predicting FeO content based on sintering machine tail section video, is characterized in that, comprises the following steps:

[0084] Step 1. Determine the drop time;

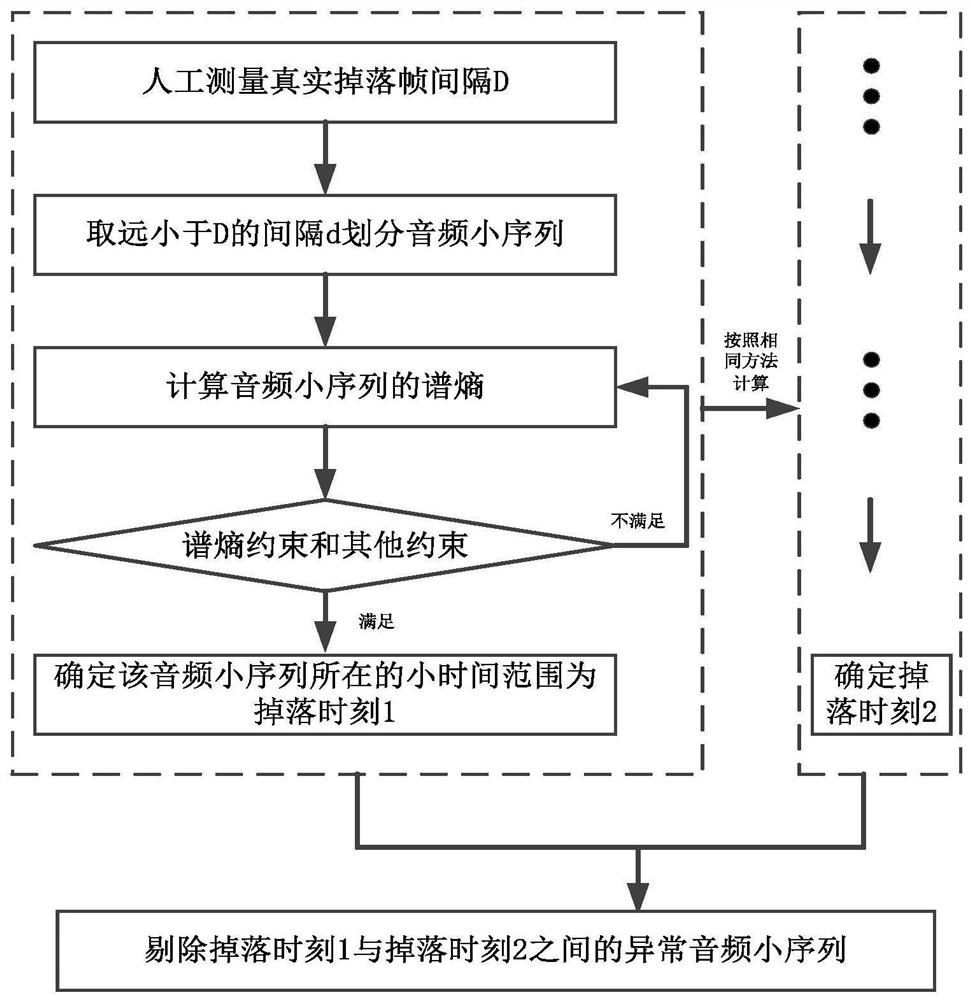

[0085] Such as figure 2 As shown, step 1 includes:

[0086] Step 1.1, manually measure the time interval D between two real drop moments, divide a series of standard audio small sequences with a small time interval d much smaller than the time interval D, and cycle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com