Automobile engine flexible production line batching and scheduling method

A technology of automobile engine and scheduling method, which is applied in the directions of genetic rules, data processing application, prediction, etc., can solve the problems of not being able to deal with complex flexibility, not considering batch processing methods, and uncertain production environment, so as to improve equipment utilization rate, The effect of shortening man-hours and meeting processing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

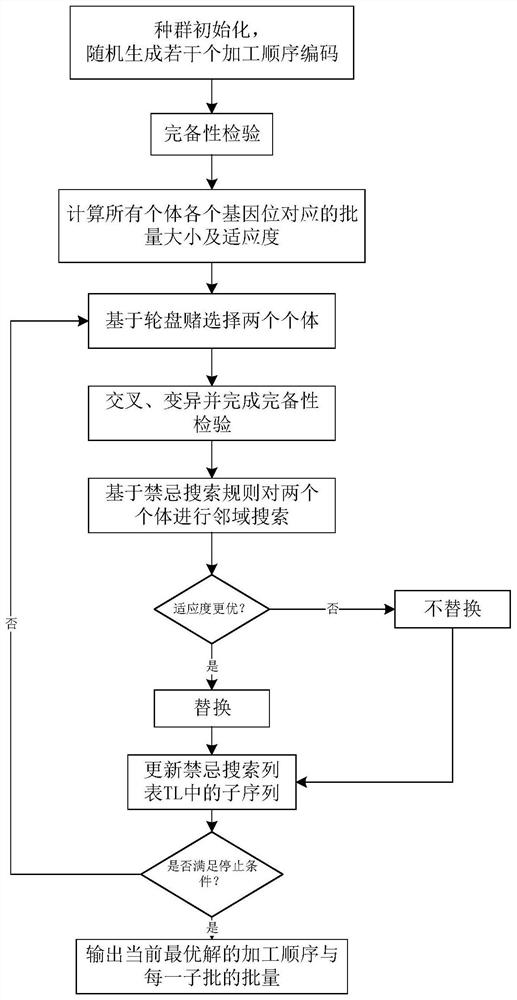

[0047] Such as figure 1 As shown, this embodiment relates to a batching and dispatching method for a flexible automobile engine production line, and this method is implemented for a passenger car engine cylinder head and valve body production line in Shanghai. The production line realizes the processing of two types of workpieces for the cylinder head and the valve body, that is, the number of workpieces is 4, and the total batch size of each workpiece is 500 pieces. The incoming time of the cylinder head obeys the uniform distribution of 0-100. The arrival time of the body obeys a normal distribution with a mean of 200 and a variance of 20. The production line involved includes 10 sets of equipment. The processing equipment is CNC vertical lathe, horizontal machining center, valve seat cold assembly line, etc. The time for each machine to process a workpiece is determined. Before the workpiece enters the production line for processing, it is necessary to determine the The to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com