Flexible job shop scheduling method considering preparation time and workpiece batching

A flexible operation and workshop scheduling technology, applied in genetic rules, constraint-based CAD, resources, etc., can solve the problem of lack of flexibility in sub-batch batches, achieve batch division optimization, total production scheduling time optimization, improve convergence speed and run efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

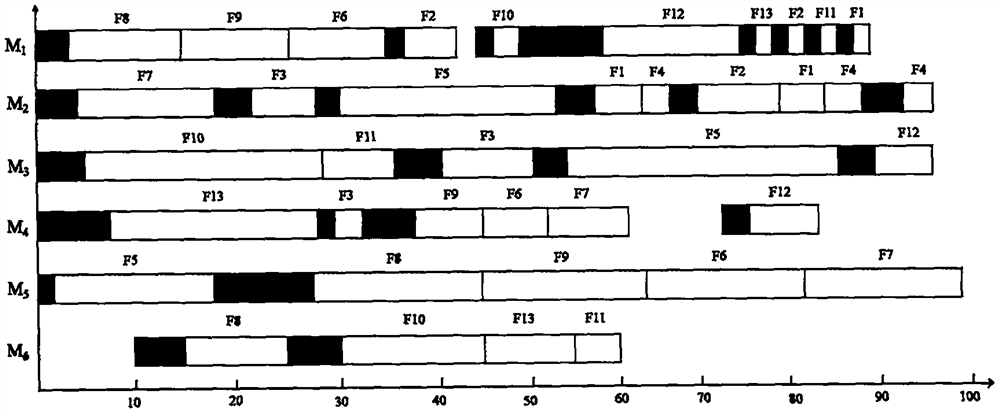

[0025] Such as figure 1 , figure 2 Shown:

[0026] Step 1: Establish a flexible job shop scheduling model considering preparation time and workpiece batching;

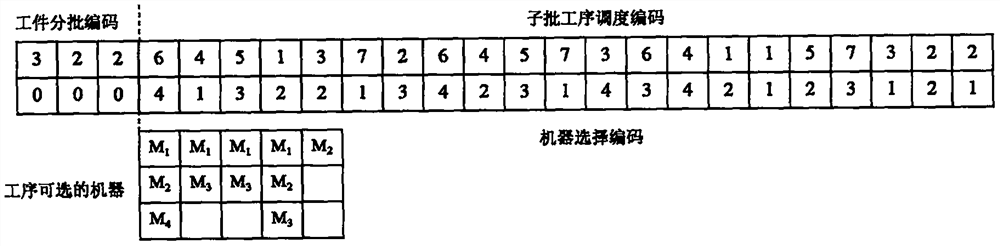

[0027] Step1, the flexible job shop scheduling problem can be described as: there are n types of workpieces processed on M machines, each type of workpiece can be divided into several sub-batches in batches, and the batch number of each sub-batch is randomly assigned; each type of workpiece has a sub-batch Each process of each batch can be processed on several machines according to a certain process sequence, with a flexible processing path, and a certain amount of processing preparation time is required between different processes of each sub-batch of workpieces.

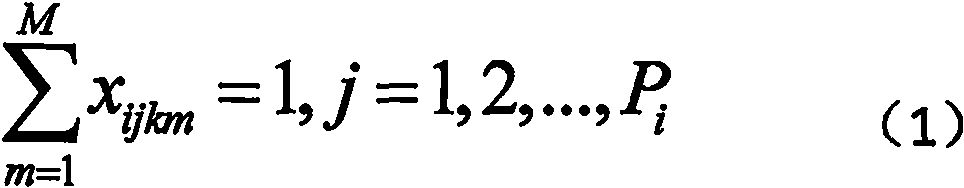

[0028] Step2, the symbol definition in the flexible job shop scheduling model considering the preparation time and workpiece batching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com