Cellulose-based integrated zinc ion battery and preparation method thereof

A zinc-ion battery, cellulose technology, applied in battery electrodes, secondary batteries, battery pack parts and other directions, can solve the problems of lack of flexibility of products, expensive copper foam, high preparation cost, and solve the problem of high modification cost , excellent flexibility and electrochemical performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Disperse 400mg of zinc powder, 50mg of nanocellulose and 50mg of carbon nanotubes in 50mL of deionized water, and disperse evenly;

[0027] (2) Disperse 500mg of micron-sized cellulose in 20mL of deionized water and disperse evenly;

[0028] (3) Disperse 28mg carbon nanotube / manganese dioxide composite positive electrode material, 4mg nanocellulose and 8mg conductive carbon black in 30mL deionized water, and disperse evenly;

[0029] (4) Vacuum filter the dispersion obtained in step (1), step (2) and step (3) in sequence, then freeze-dry and press at 5MPa high pressure, and finally add 2M zinc sulfate + 0.2M manganese sulfate Aqueous electrolyte.

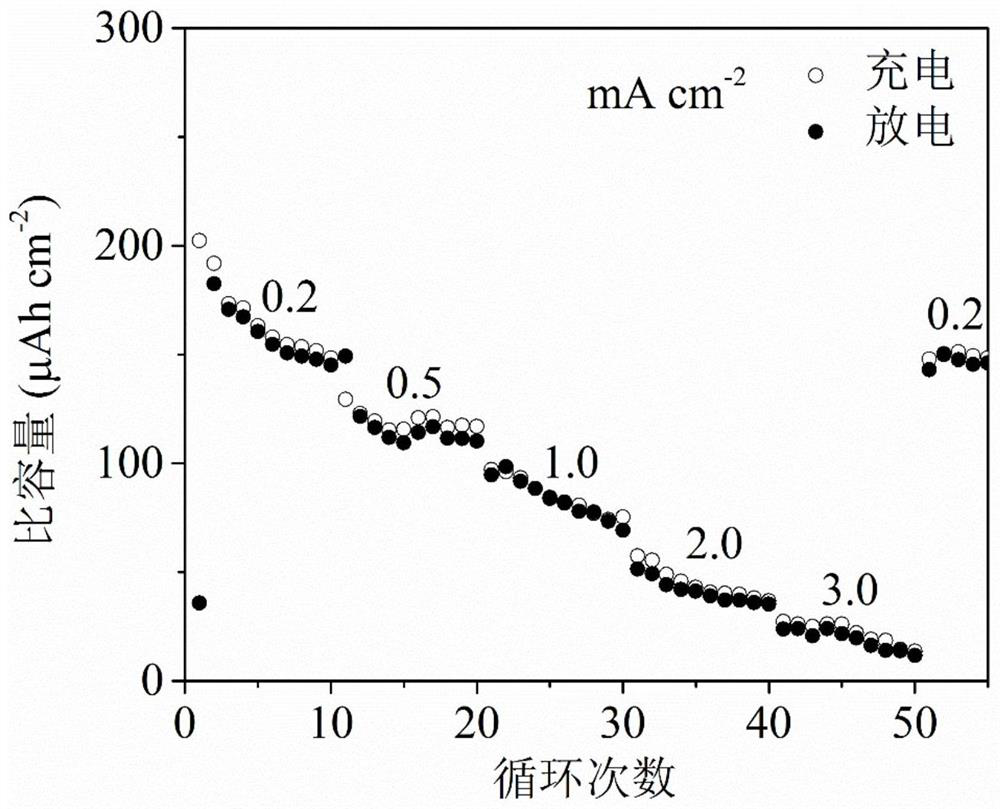

[0030] The integrated zinc ion battery obtained in this embodiment has excellent flexibility. The integrated zinc-ion battery obtained in this embodiment was tested at a voltage range of 1.0-1.85V. The zinc storage rate performance of the resulting zinc-ion battery is as follows: figure 1 shown, at an initial 0.2mA cm...

Embodiment 2

[0032] (1) Disperse 400mg of zinc powder, 50mg of nanocellulose and 50mg of carbon nanotubes in 50mL of deionized water, and disperse evenly;

[0033] (2) Disperse 500mg of micron-sized cellulose in 20mL of deionized water and disperse evenly;

[0034] (3) Vacuum filter the dispersion liquid obtained in step (1) and step (2) according to the positive sequence, then freeze-dry and press at 5MPa high pressure, as an integrated negative electrode and diaphragm, and finally add 2M zinc sulfate + 0.2M Manganese sulfate aqueous electrolyte and assembled with titanium foil coated with carbon nanotube / manganese dioxide composite cathode material.

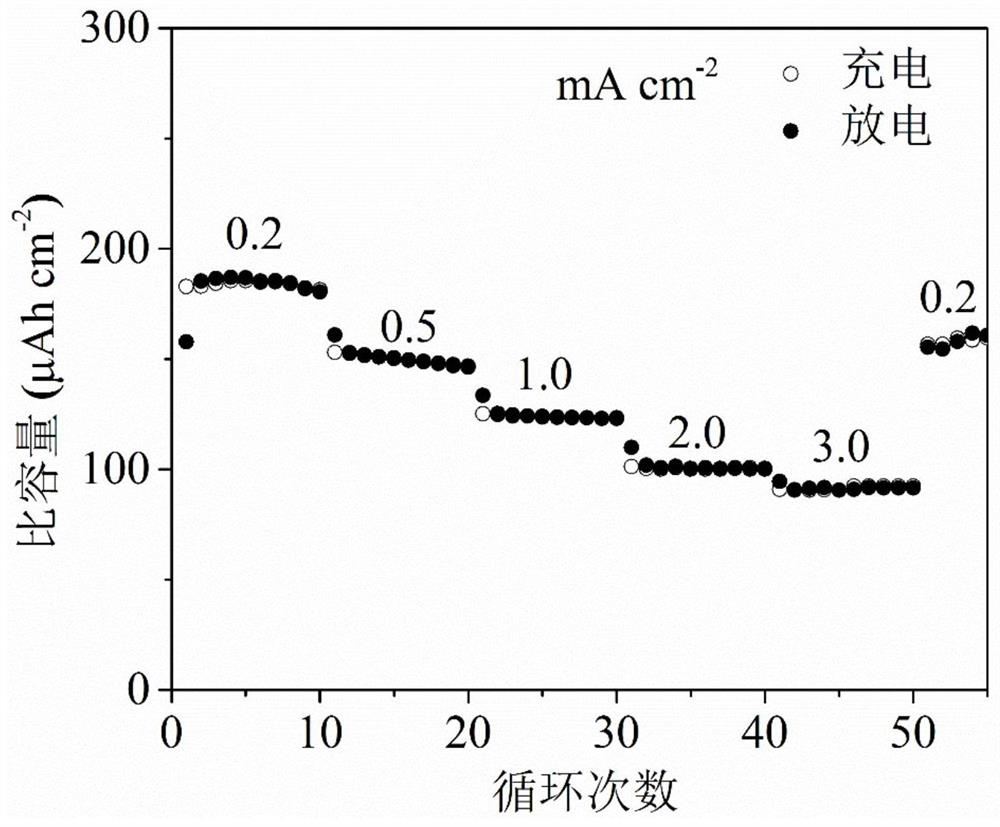

[0035] The integrated zinc-ion battery obtained in this embodiment was tested at a voltage range of 1.0-1.85V. The zinc storage rate performance of the resulting zinc-ion battery is as follows: figure 2 shown, at an initial 0.2mA cm -2 The discharge specific capacity of the 10th cycle under the current density is 180.4μAh cm -2 ; when ...

Embodiment 3

[0037] (1) Disperse 400mg of zinc powder, 50mg of nanocellulose and 50mg of carbon nanotubes in 50mL of deionized water, and disperse evenly;

[0038] (2) Disperse 250mg of nanocellulose in 80mL of deionized water and disperse evenly;

[0039] (3) Vacuum filter the dispersion liquid obtained in step (1) and step (2) according to the positive sequence, and then freeze-dry it as an integrated negative electrode and diaphragm, and finally add 2M zinc sulfate + 0.2M manganese sulfate for aqueous electrolysis liquid and assembled with titanium foil coated with carbon nanotube / manganese dioxide composite cathode material.

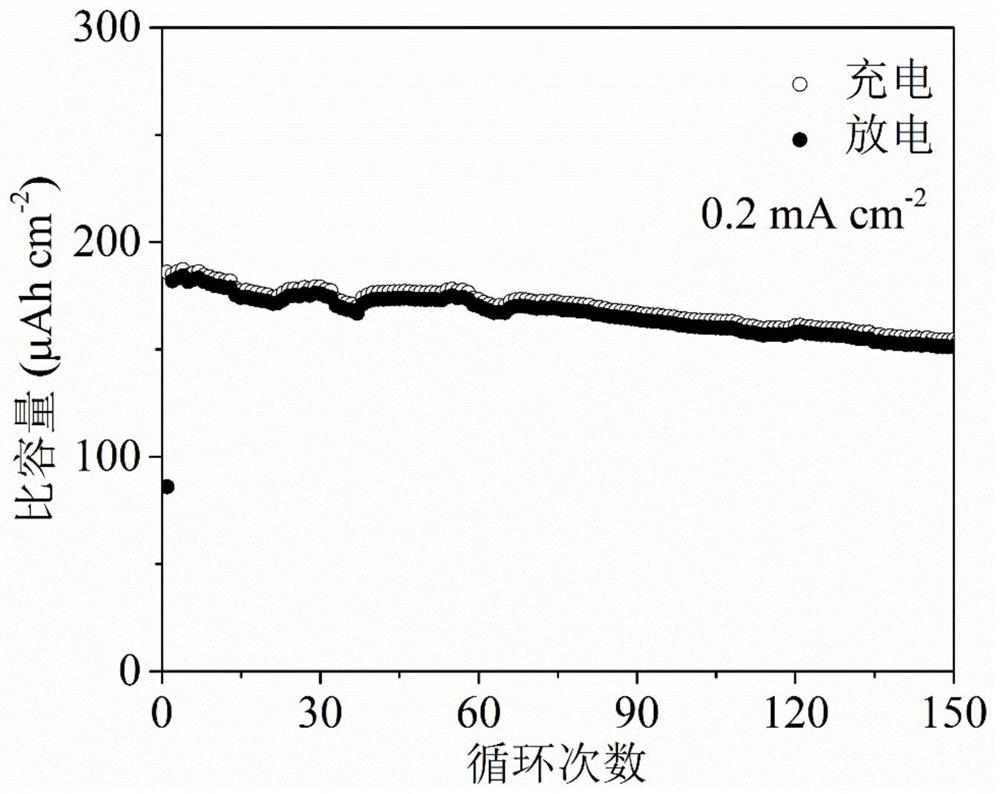

[0040] The integrated zinc-ion battery obtained in this embodiment was tested at a voltage range of 1.0-1.85V. The zinc storage rate performance of the resulting zinc-ion battery is as follows: Figure 4 shown, at an initial 0.2mA cm -2 The discharge specific capacity of the 10th cycle at the current density is 121.1 μAh cm -2 . When the current density incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com