Preparation process of facial cleanser

A preparation process and facial cleanser technology, applied in the field of daily chemical products, can solve problems such as tightness and false slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

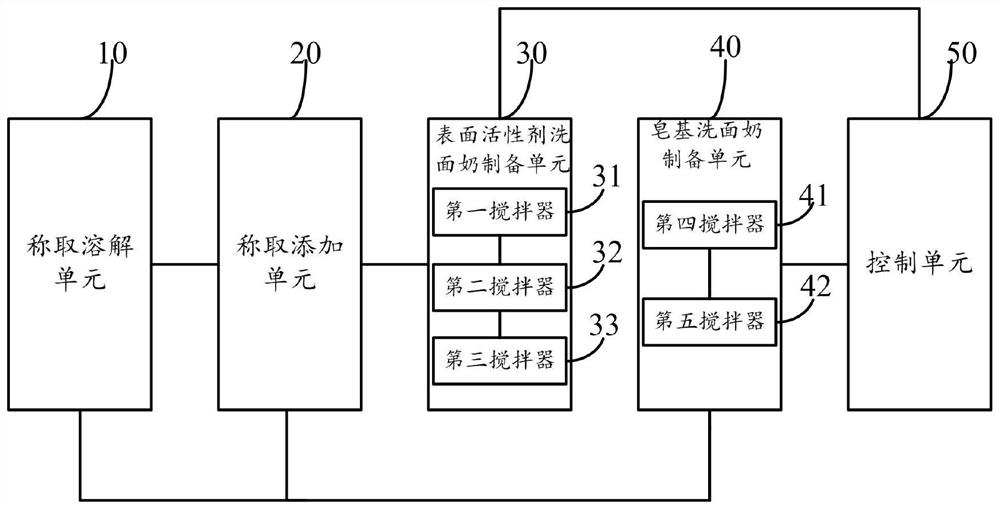

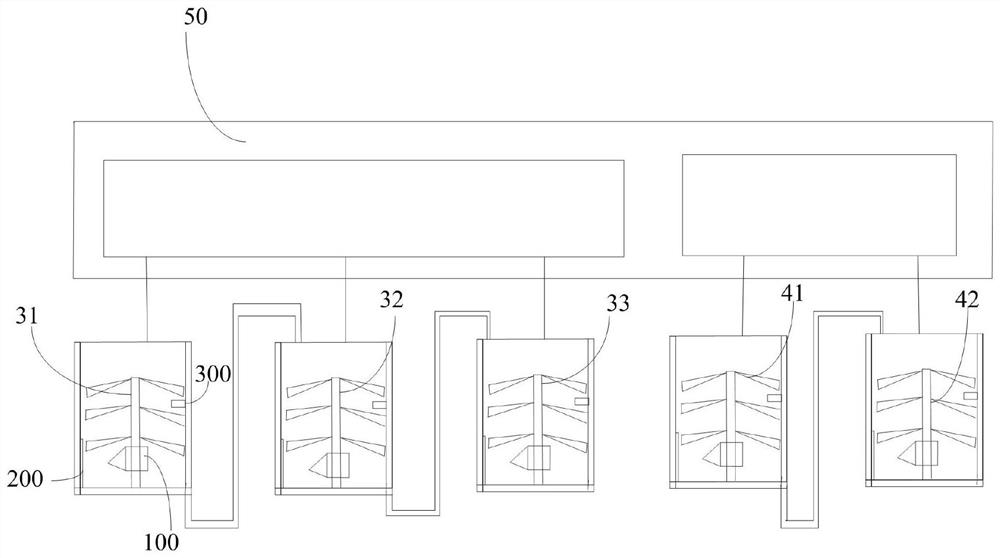

preparation example Construction

[0035]The preparation process of the facial cleanser provided by the embodiment of the present invention adjusts the stirring speed of each stirring tank by detecting the bubble density in real time, so that the bubbles of the finally obtained facial cleanser are dense. Reduce the stirring speed of the second stirring tank and the third stirring tank, so that the bubble density of the facial cleanser obtained at last is less; if the bubble density of the first stirring tank is less, then by increasing the second stirring tank and the third stirring tank The stirring speed is high, so that the bubble density of the finally obtained facial cleanser is moderate, which meets the production needs.

[0036] However, in practical applications, those skilled in the art can understand that there will be more or less certain errors in the preparation process of facial cleanser, whether it is the control of the concentration of bubbles, or the stirring speed and stirring time of the agita...

example 1

[0062] Sodium Cocoyl Glutamate 23% Glycerin 20% Propylene Glycol 3% Sodium Chloride 2% Sodium Cocoyl Isethionate 5% Ethylene Glycol Diostearate 1.5% Attapulgite (325 mesh) 10% Right Methylparaben 0.15% Chlorphenidin 0.15% Residue of process water

[0063] The preparation process steps are as follows: 1. Weigh sodium cocoyl glutamate, sodium cocoyl isethionate and glycerin into process water, heat to above 80 degrees Celsius, and stir to dissolve.

[0064] 2. Weigh sodium chloride, add appropriate amount of process water, stir to melt, and add to 1.

[0065] 3. Weigh methyl p-hydroxybenzoate and chlorphenidate, add propylene glycol, dissolve and add to 2, and stir evenly.

[0066] 4. Weigh the attapulgite, add it, stir evenly, cool down slowly, and stir slowly to prevent air bubbles.

[0067] The product forms a paste at about 20°C, the paste is rough, and it is fine and lubricated when used, with rich and fine bubbles, moderate cleaning power, mild and non-irritating, and th...

example 2

[0068] Example 2 (stearic acid palmitic acid and potassium hydroxide generate soap base, general pure soap base fatty acid addition is greater than 20%, add here relatively less, cooperate milder sodium cocoyl taurate, prepare the wash-off ability relatively better, but also milder facial cleanser)

[0069] Stearic Acid 10%, Palmitic Acid 4%, Potassium Hydroxide 2.87g, EDTA-2Na 0.1%, Sodium Cocoyl Taurate 10%, Propylene Glycol 16%, Cetearyl Ether 2%, Cathone 0.1%, Attapulgite 20% Process remaining amount of water

[0070] The preparation process steps are as follows: 1. Weigh stearic acid, palmitic acid and cetearyl ether, and heat to 80 degrees Celsius to dissolve;

[0071] 2. Weigh propylene glycol, EDTA-2Na, and potassium hydroxide, add purified water, and heat to 80 degrees Celsius;

[0072] 3. Add the lye to the dissolved fatty acid, stir evenly, and keep warm at 80°C for 30 minutes.

[0073] 4. Weigh sodium cocoyl taurate, heat to dissolve, add to 3 and stir evenly. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com