Casing structure and motor

A casing and structure technology, applied in the field of motors, can solve problems such as deterioration of waterproofness and electrical connection reliability, and achieve the effects of improving waterproofness, preventing poor electrical connection, and preventing water immersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

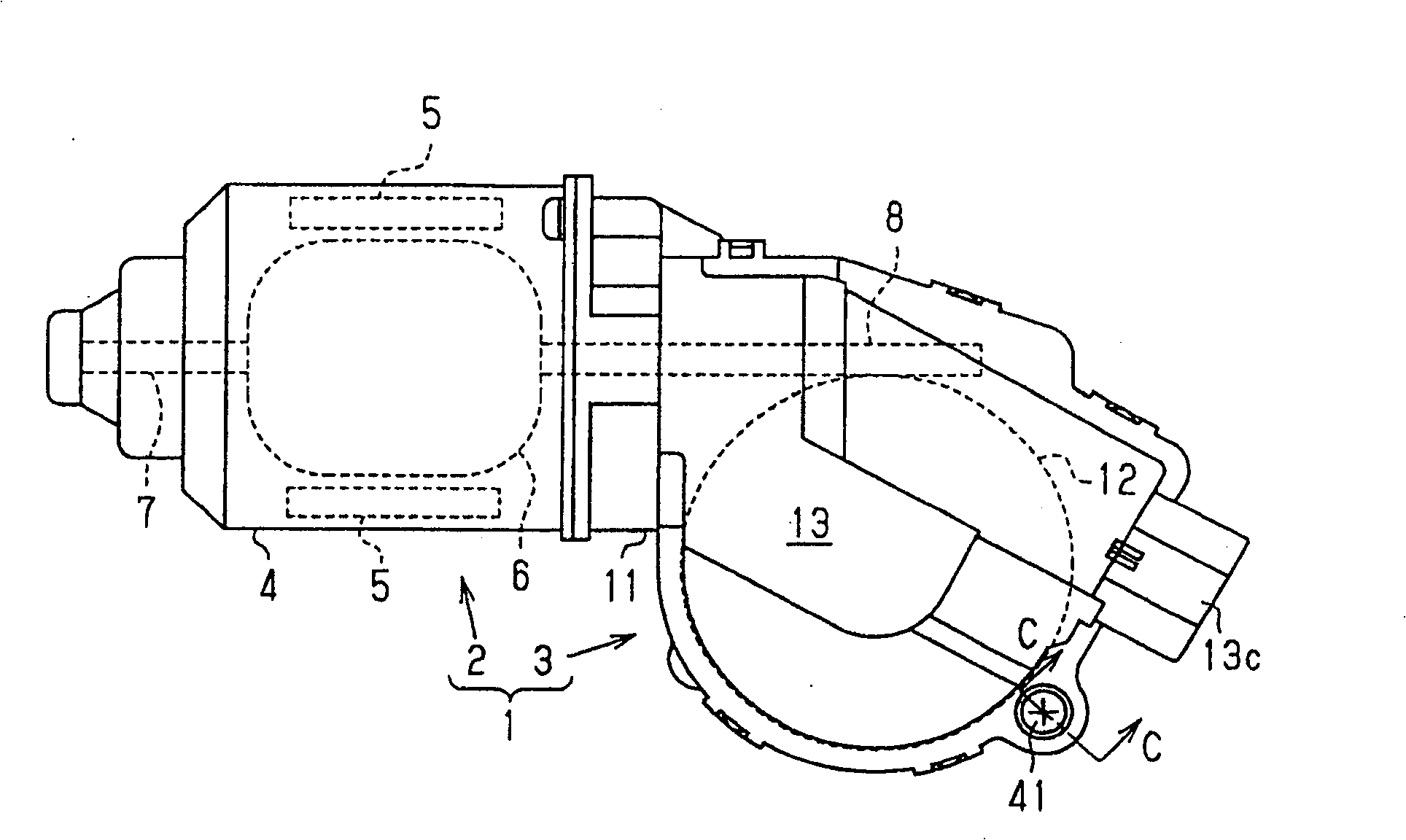

[0033] The following will be based on Figure 1 to Figure 15 An embodiment in which the present invention is embodied in a motor for a wiper device of a vehicle wiper device will be described.

[0034] Such as figure 1 As shown, a motor for a wiper device (hereinafter simply referred to as a motor) 1 has a motor main body 2 and a gear unit 3 . The motor main body 2 has a substantially bottomed cylindrical yoke housing (yoke housing) 4, a plurality of magnets 5 fixed to the inner peripheral surface of the yoke housing 4, and a rotor accommodated in the same yoke housing 4 ( Spinner) 6. The rotor 6 has a rotating shaft 7 , and a worm 8 is formed on the head end side of the rotating shaft 7 protruding from the opening of the yoke case 4 .

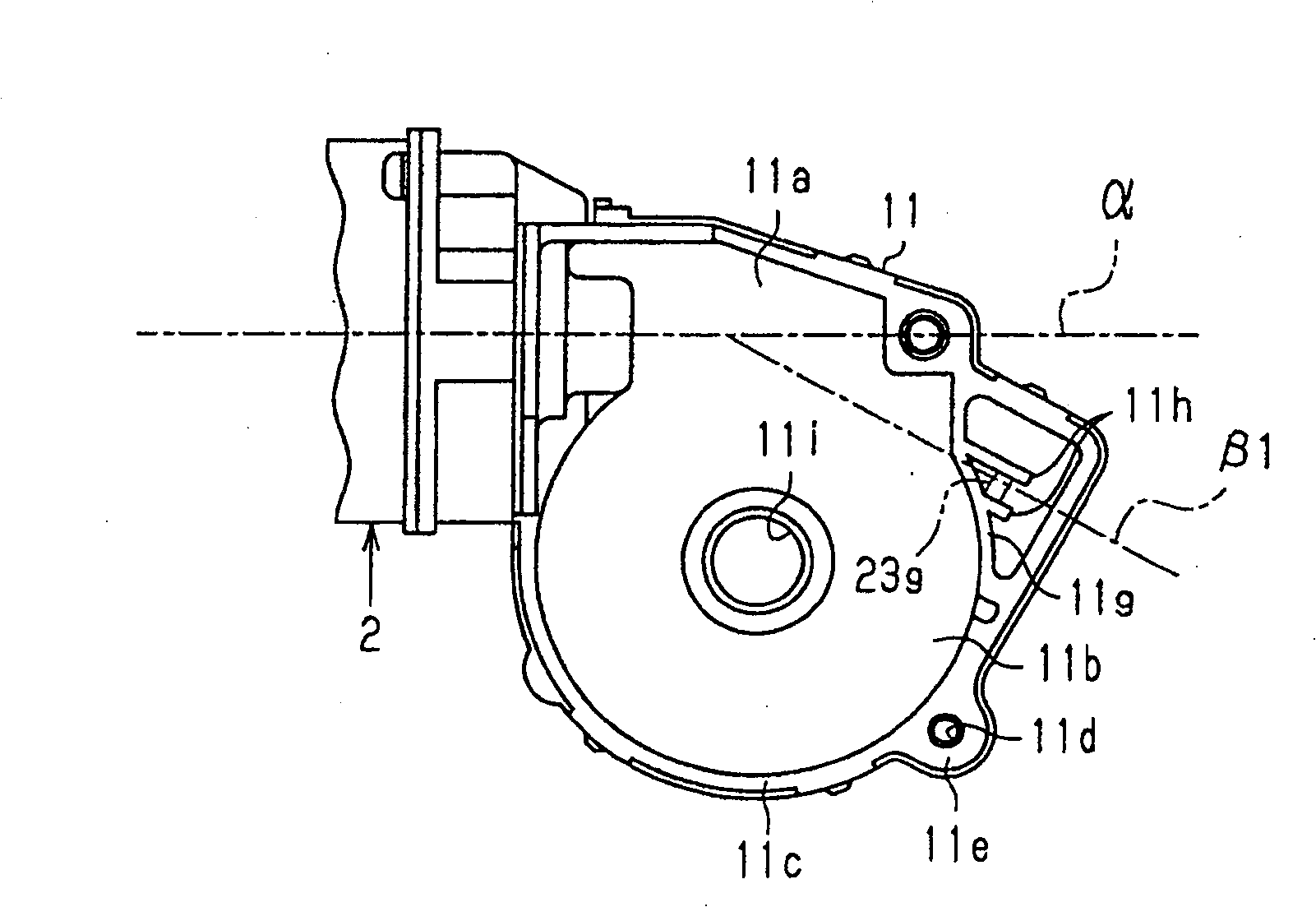

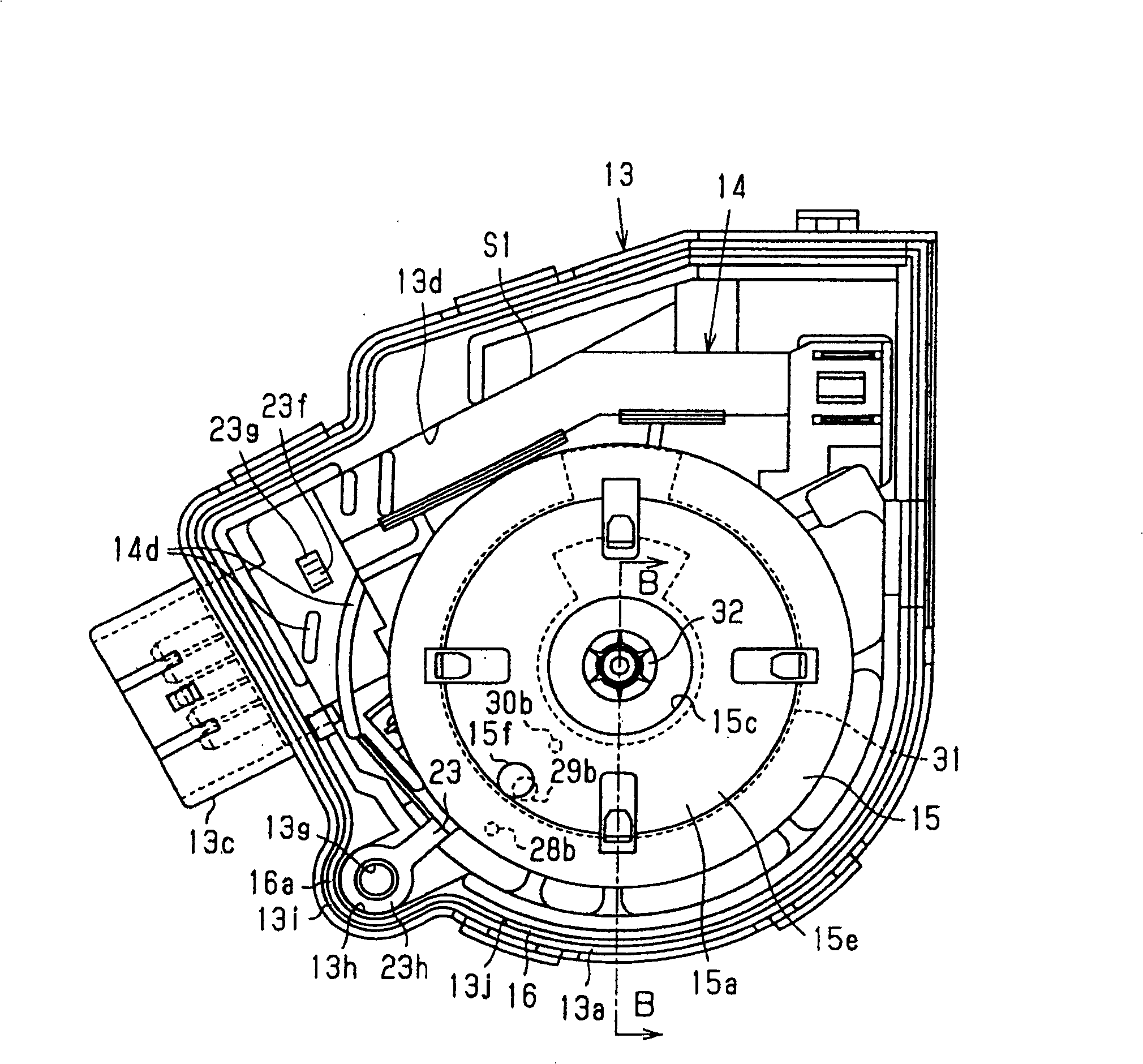

[0035] The gear part 3 has a case 11 as a gear case (refer to figure 2 ), worm gear 12 (refer to figure 1 ), the box cover 13 as a cover (refer to Figure 4 ), component board 14 (refer to Figure 6 ), rotating body 15 (refer to imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com