Connecting device

A technology of connecting device and inner joint, which is applied in the direction of hose connecting device, non-detachable pipe connection, pipe/pipe joint/pipe fitting, etc., can solve problems such as difficulty in available space, and achieve the effect of realizing cost and simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

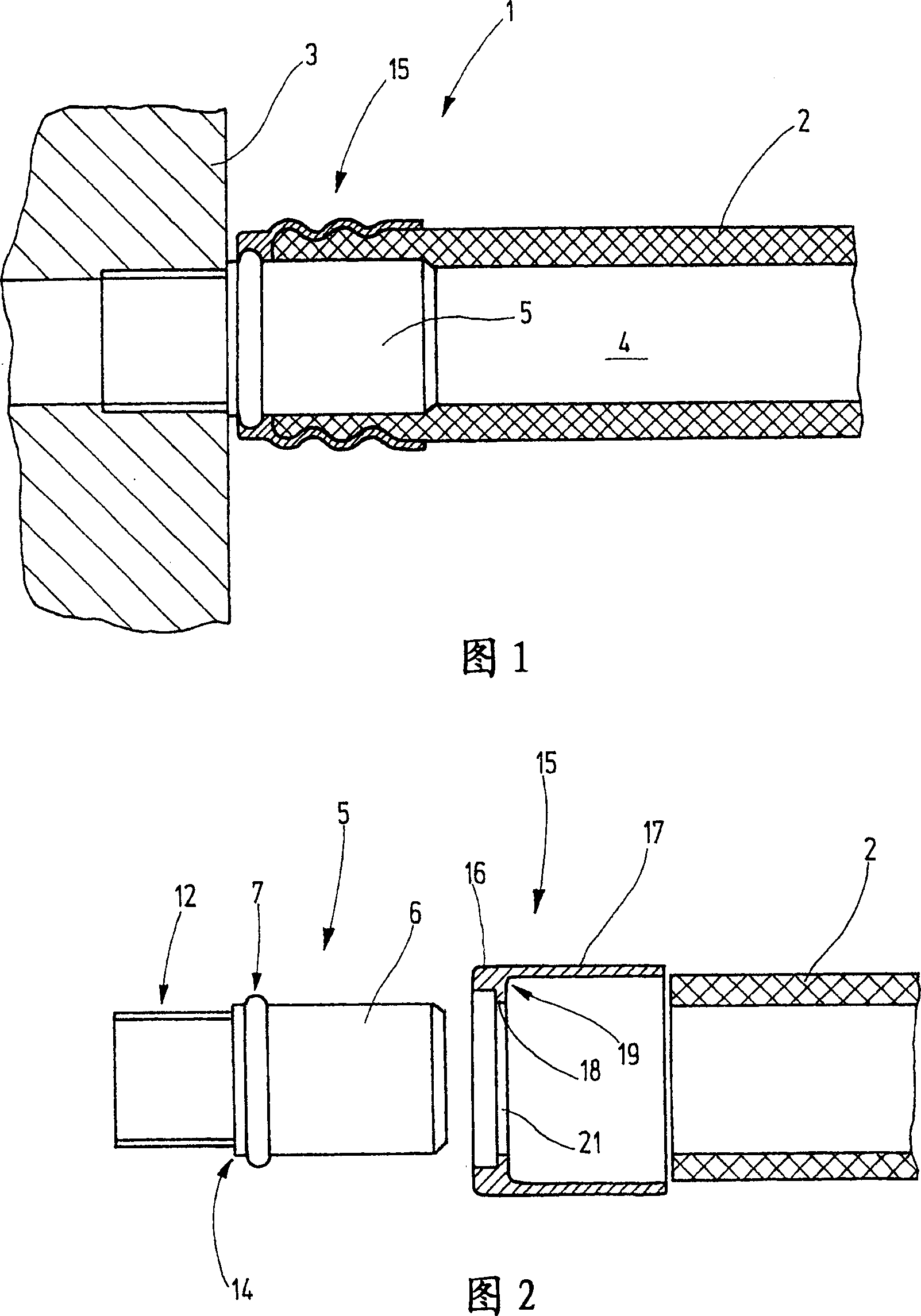

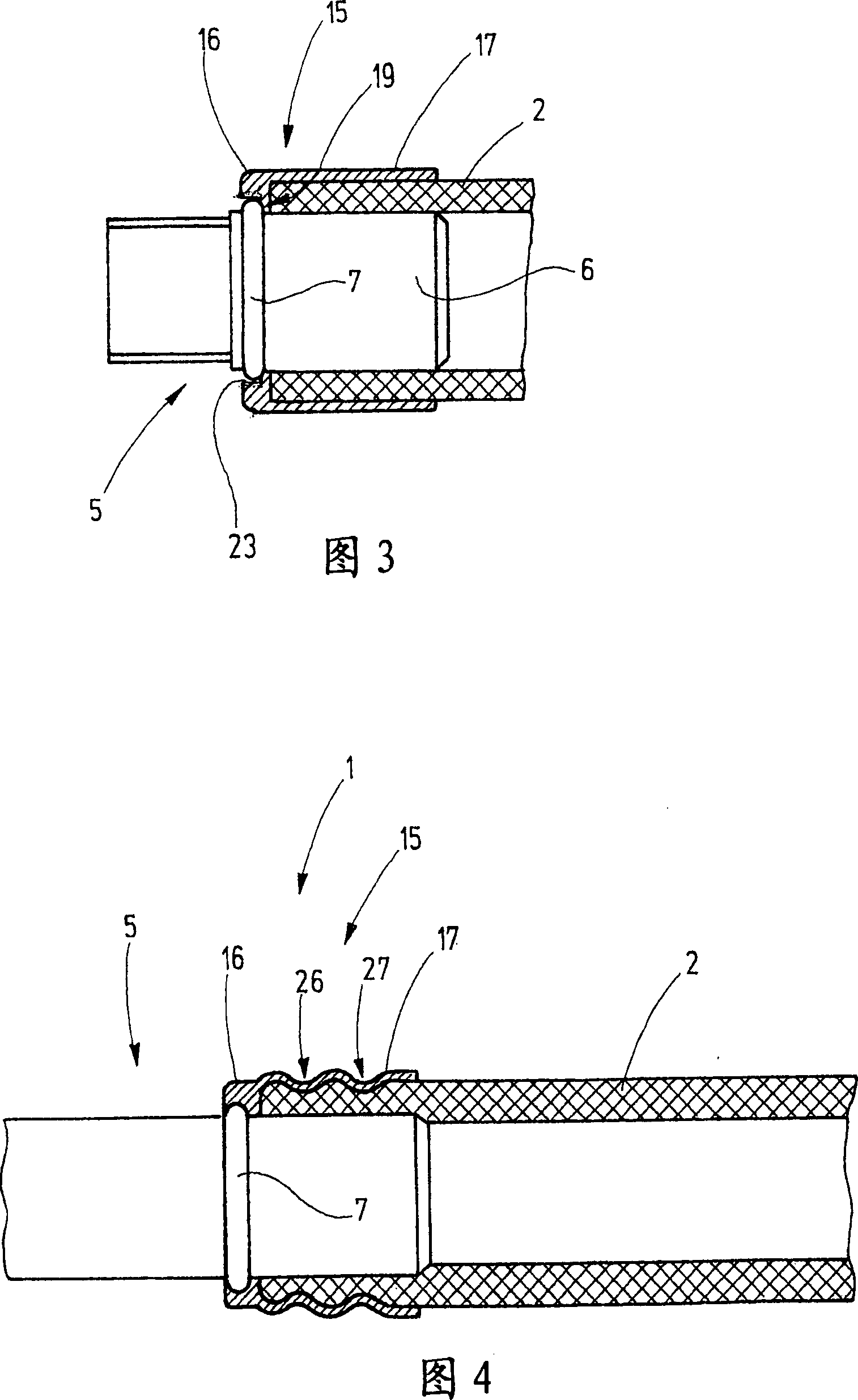

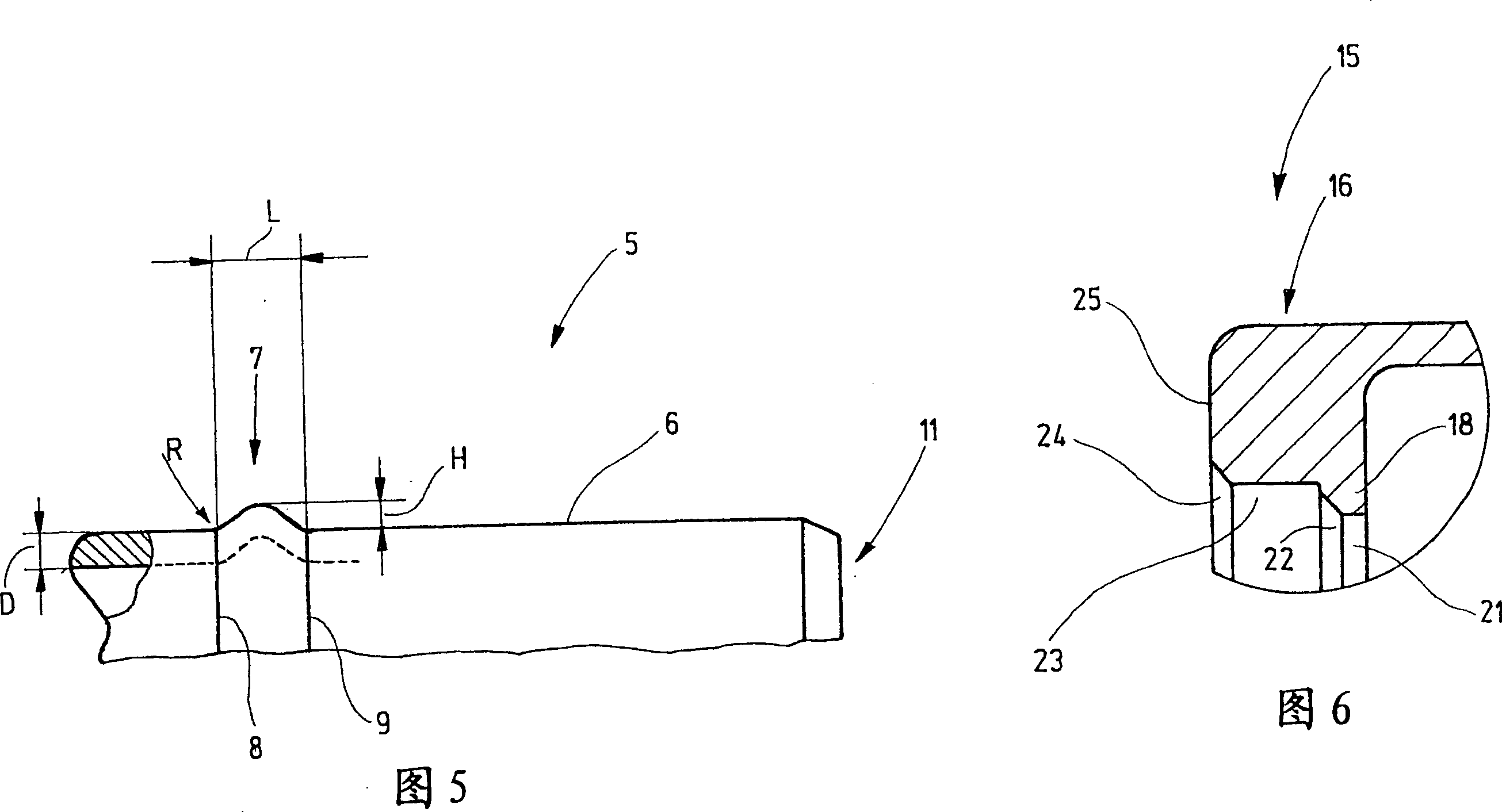

[0019] FIG. 1 shows a connection device 1 via which a hose 2 , in particular a hose 2 for conducting fluid, is connected to a component 3 , such as an oil-conducting component configured as a coolant compressor, such as a hydraulic device etc. The hose 2 and the assembly 3 enclose a fluid-conducting channel 4 . This channel runs through a connecting nipple 5 - which is shown separately in FIG. 2 . The connection nipple is substantially tubular and encloses a fluid channel (not shown in detail) which extends from one end side to the other. The connecting nipple has a cylindrical shell surface 6 on the outside, which can also be designed in a frusto-conical shape. But in this case, the cone angle is very small. On one end of the cylindrical shell 6, precisely on the end facing away from the hose, an annular flange 7 is formed on the connection nipple 5, the shape of which can be seen from FIG. 5 detail. The annular flange has a substantially arcuate cross section and a heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com