Intelligent roller fermentation tank

A fermenter and drum technology, applied in animal husbandry wastewater treatment, biological sludge treatment, etc., can solve the problems that the fermenter cannot be enlarged, broken, and the auger is easy to deform, so as to achieve accurate inflation, neat and simple connection, Realize the effect of intelligent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The above-described objects, features, and advantages of the present invention will be more clearly understood, and the present invention will be further described below in connection with the embodiments.

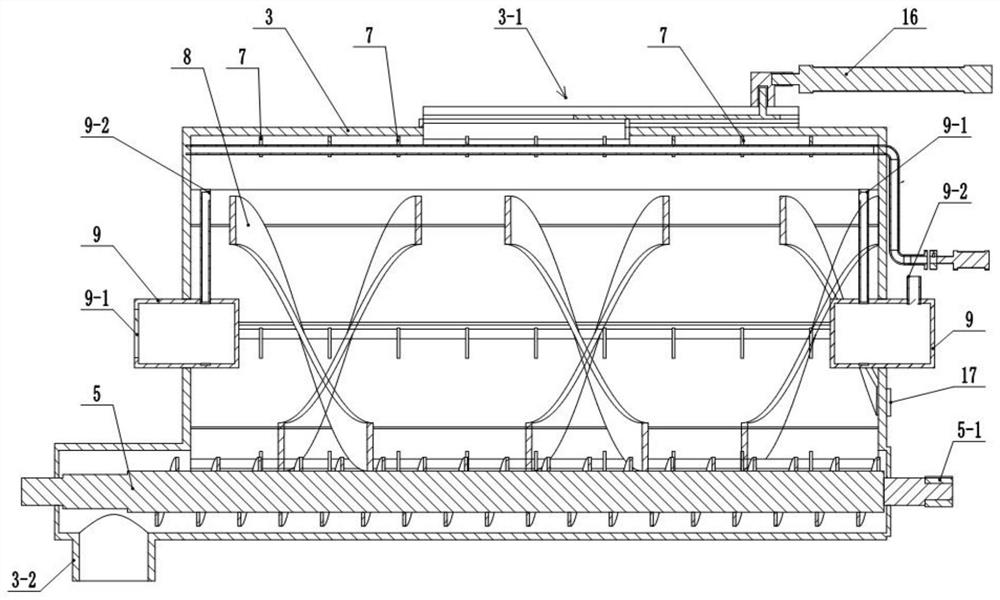

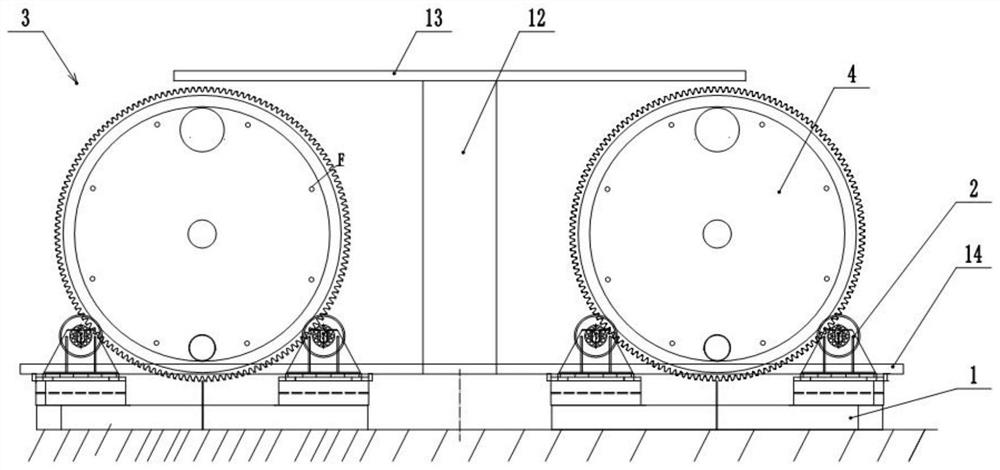

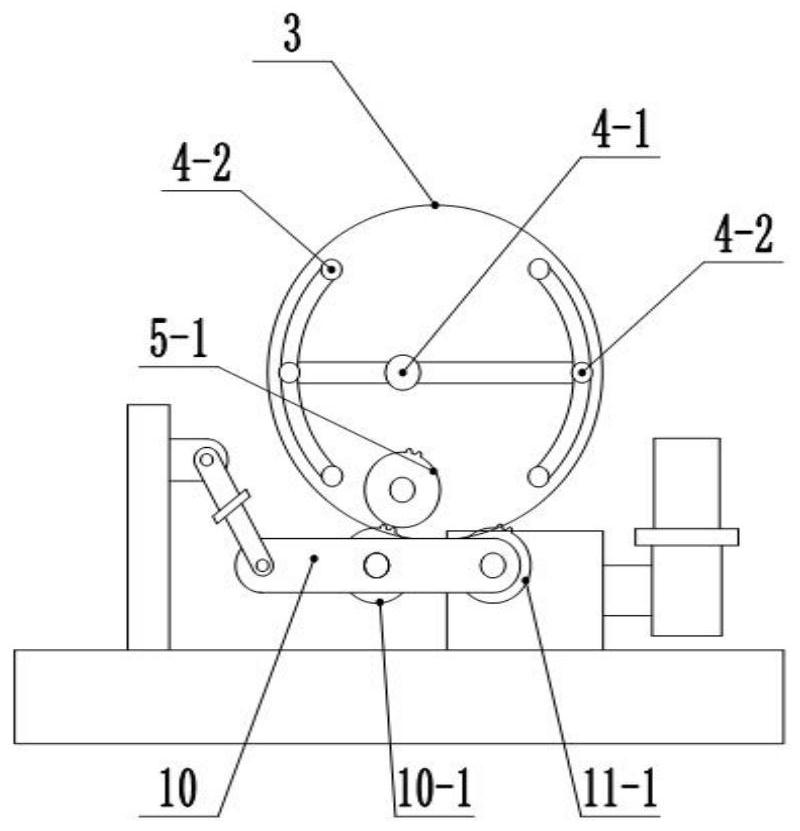

[0023] reference figure 1 and figure 2 This embodiment proposes an intelligent roller fermentor, including the frame 1, the frame 1 is attached to the rack 2, and the roller 3 is placed on the roller 2, and the roller 3 has an end cover 4, and the drum 3 is installed. The strap 5, the flap 6, stirring spiral 8, inflatable tube 15, and the vent case 9. The drum 3 is provided with a scorpion drive motor 11, the controller (not shown in the figure).

[0024] The stirring spiral 8 is a double helix blade, and the double helix blade is operated, and the upper and lower blades of the interleaved blade are in the rotation process, and the upper and lower blades are generated, and the upper and lower blades are generated. The material is sufficiently squeezed under this phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com