Thermoplastic resin composition for cleaning applications, and cleaning method

A technology of thermoplastic resin and composition, which is applied in the field of thermoplastic resin composition for cleaning, and can solve the problems of increased manufacturing cost of thermoplastic resin composition, generation of foaming agent, harmful gas from decomposition residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

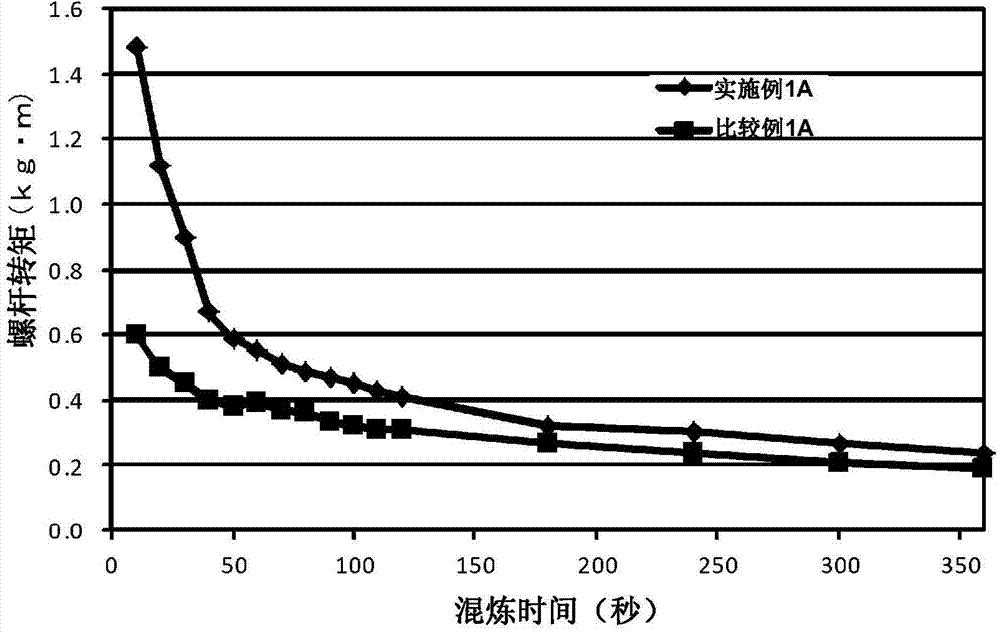

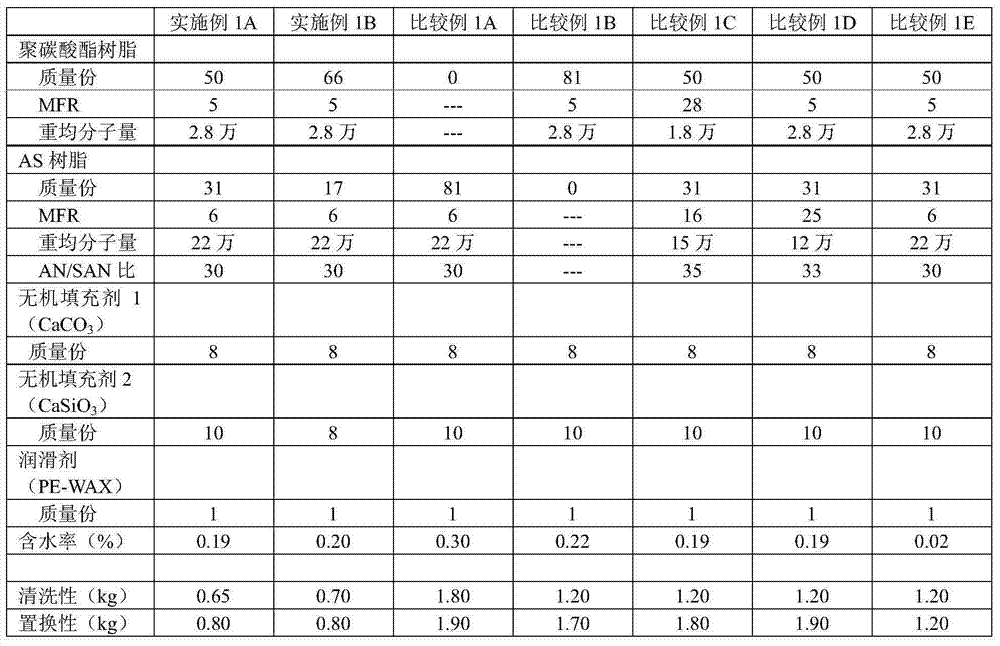

Embodiment 1

[0046] Example 1 relates to the cleaning thermoplastic resin composition and cleaning method of the present invention. The thermoplastic resin composition for cleaning of Example 1 contains:

[0047] (A) 30 parts by mass to 90 parts by mass of polycarbonate resin with a melt mass flow rate (MFR) of 1 g / 10 minutes to 12 g / 10 minutes at a test temperature of 300°C and a nominal load of 1.2 kg share;

[0048] (B) 5 parts by mass of acrylonitrile-styrene copolymer with a melt mass flow rate (MFR) value of 4 g / 10 minutes to 10 g / 10 minutes at a test temperature of 220°C and a nominal load of 10 kg ~70 parts by mass;

[0049] (C) 0.5 to 5 parts by mass of one or more lubricants; and

[0050] (D) 5 to 40 parts by mass of one or more inorganic fillers,

[0051] The water content of this cleaning thermoplastic resin composition is 0.1 mass % or more.

[0052] Furthermore, in the cleaning method of Example 1, the cleaning thermoplastic resin composition of Example 1 was used to cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com