Plate-frame type sludge and slurry filter press

A filter press and plate-and-frame technology, applied in the field of plate-and-frame sludge mud filter presses, can solve the problems of the filter frame and the filter plate shaking, the inconvenient installation and replacement of the filter frame and the filter plate, and the inability to lock and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

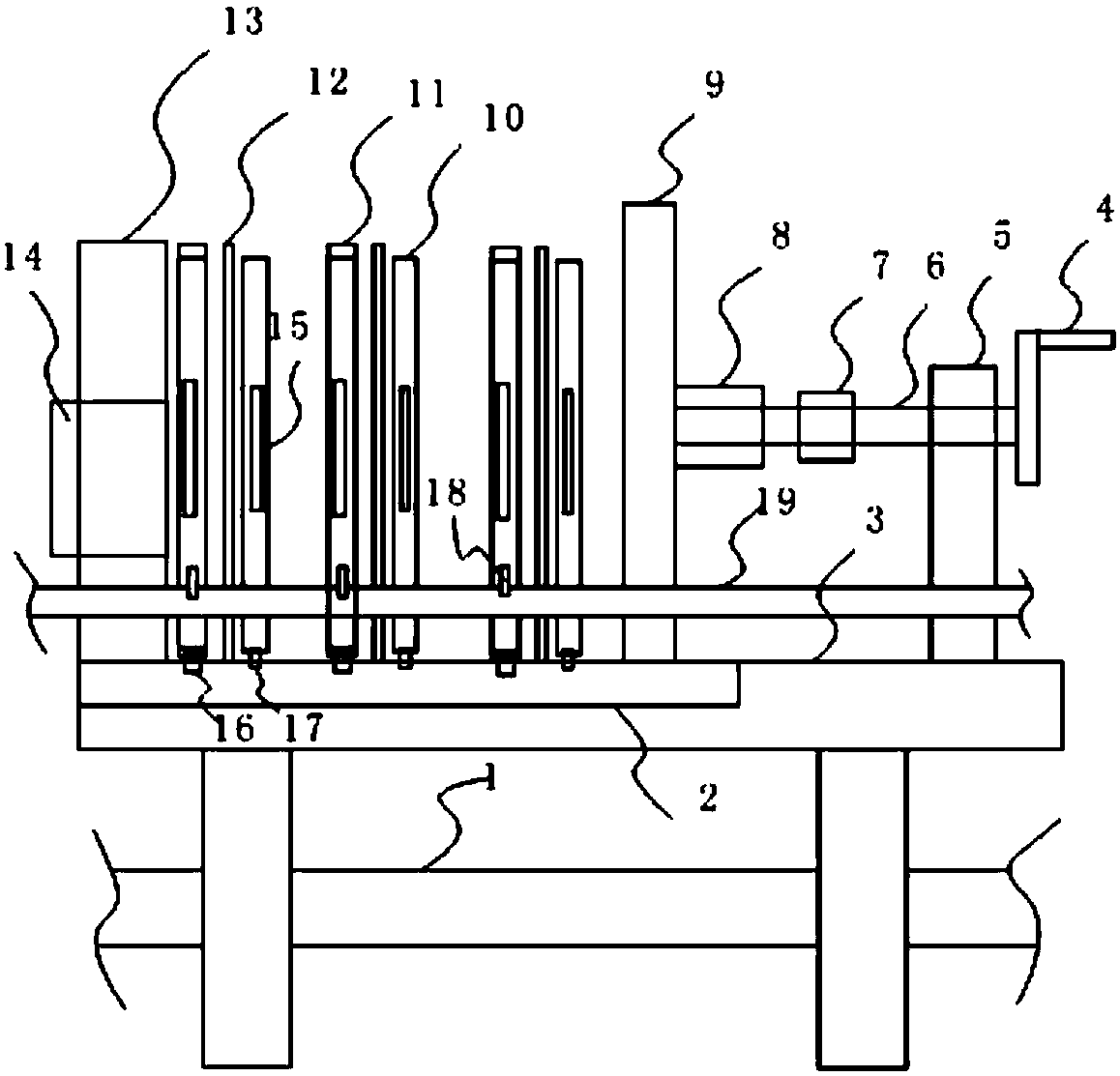

[0018] A plate-and-frame sludge sludge filter press, which includes a frame 3, a filter press device and a compacting device, and the filter press device includes a plurality of filter frames 11, filter cloths 12 and filter plates 10 arranged in sequence, so that A thrust plate 13 is fixedly installed at one end of the frame, and a slide rail 2 is provided at the lower part along the extension direction of the frame. The thrust plate is provided with a feed port 14, and a plurality of filter frame sliding brackets 16 and filter holders are arranged alternately on the slide rail. Plate sliding support 17, the filter frame sliding support is provided with a filter frame slot (not shown), the filter plate sliding support is provided with a filter plate slot (not shown), and the filter frame is installed in the filter frame slot , the filter plate is installed in the filter plate slot, the filter frame and the filter frame sliding bracket are provided with a filter plate sliding br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com