Image forming apparatus

A technology for imaging equipment and extrusion components, which is applied in printing, printing devices, object supply, etc., can solve the problems of weakening the extrusion force of the nip roller device, high conveying speed of the conveyor belt, and image quality deterioration, so as to prevent image quality Deterioration, suppression of changes in conveying speed, and prevention of twisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

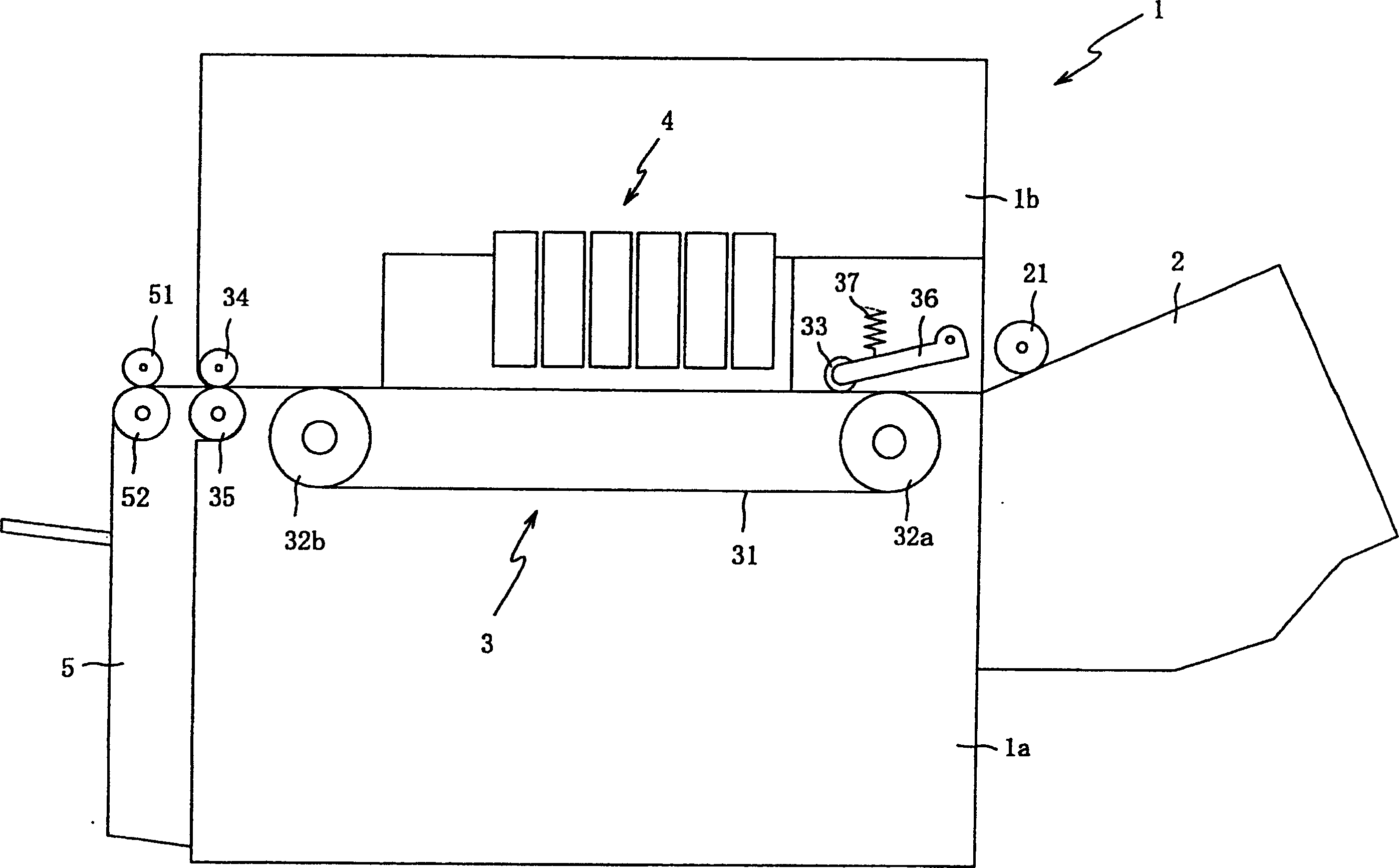

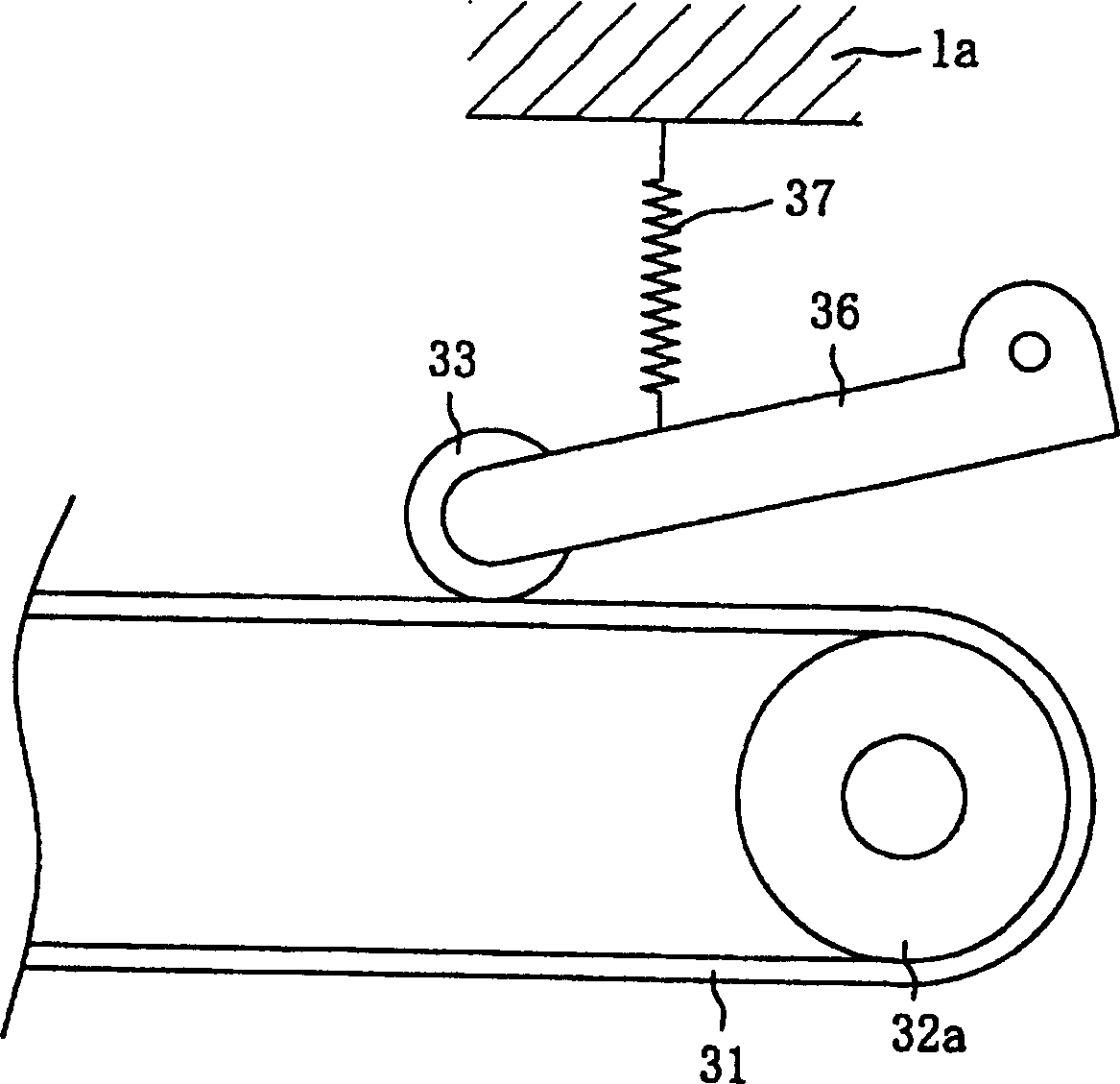

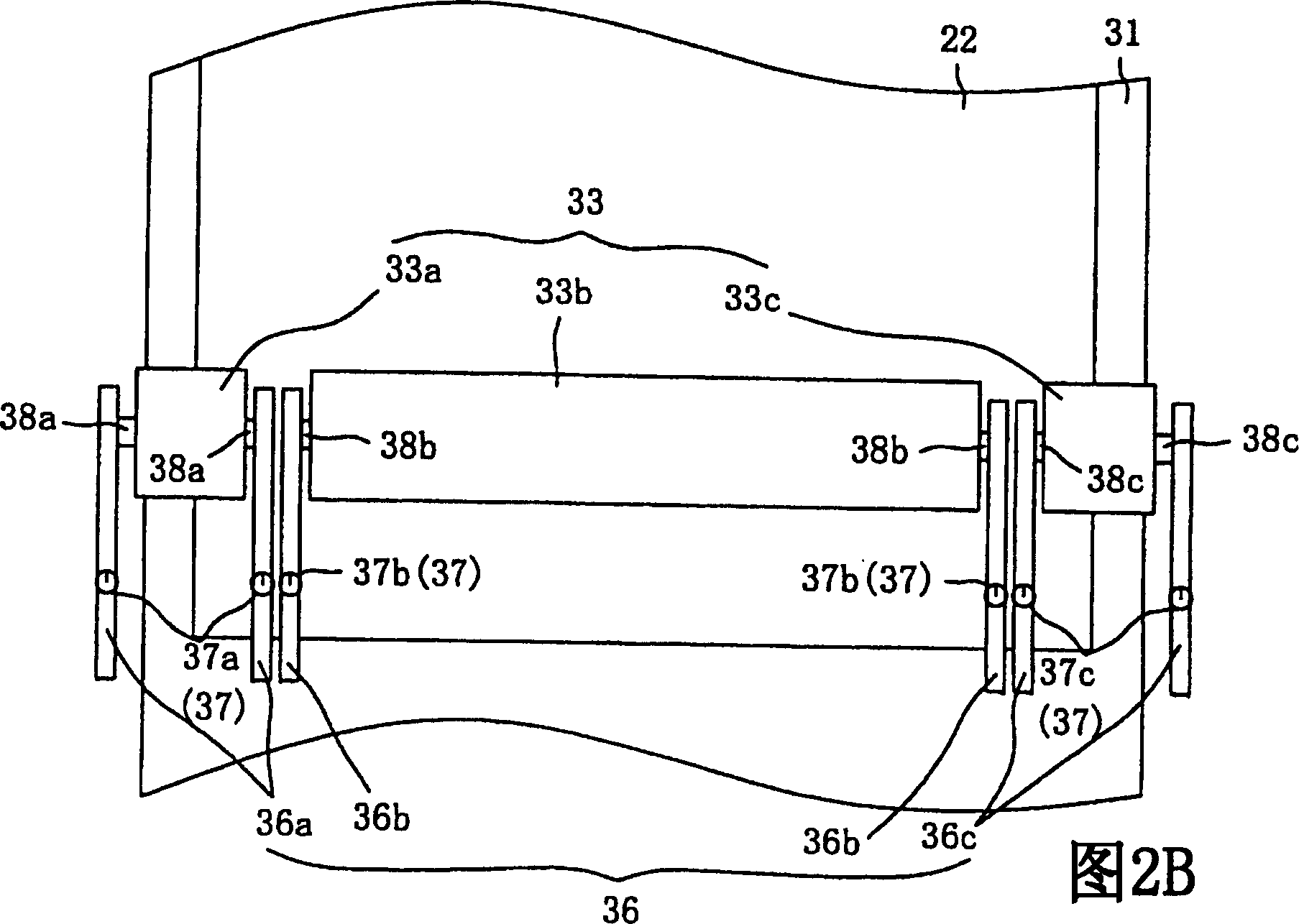

[0045] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. figure 1 is a schematic diagram of the image forming apparatus 1 according to the first embodiment of the present invention. First refer to figure 1 The general structure of the imaging apparatus 1 is described.

[0046] The image forming apparatus 1 mainly includes: a supply unit 2 that supplies a recording medium 22 (see FIG. 2B ) to the main body 1 a; a conveyance unit 3 that conveys the recording medium 22 supplied by the supply unit 2; , the recording head 4 ejects ink onto the recording medium 22 conveyed by the conveying unit 3 to form an image; and a stacker 5 that stores the recording medium 22 on which the image has been formed by the recording head 4 .

[0047]The supply unit 2 includes a tray (not shown) accommodating a recording medium 22 , and a pickup roller 21 that contacts the recording medium 22 accommodated in the tray. When dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com