Method for manufacturing prepreg for printed wiring board and device for manufacturing prepreg for printed wiring board

A technology for printed wiring boards and manufacturing methods, applied in the field of manufacturing prepregs for printed wiring boards and manufacturing devices for prepregs for printed wiring boards, capable of solving the problems of insufficient removal of air bubbles, poor productivity of prepregs, and discharge Problems such as slow substrate plate 3 conveying speed, to achieve the effect of speeding up conveying speed, improving productivity, and preventing residual air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

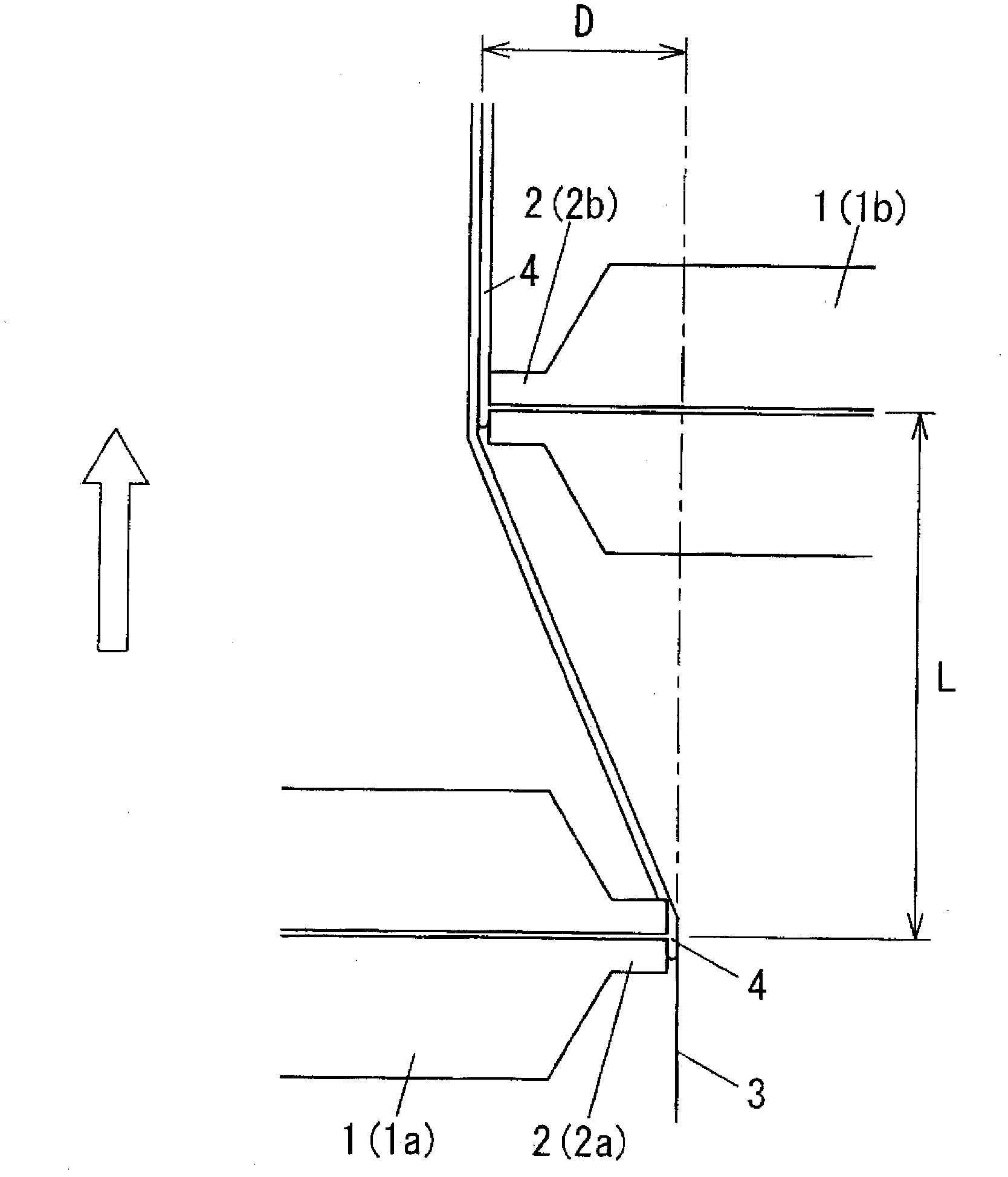

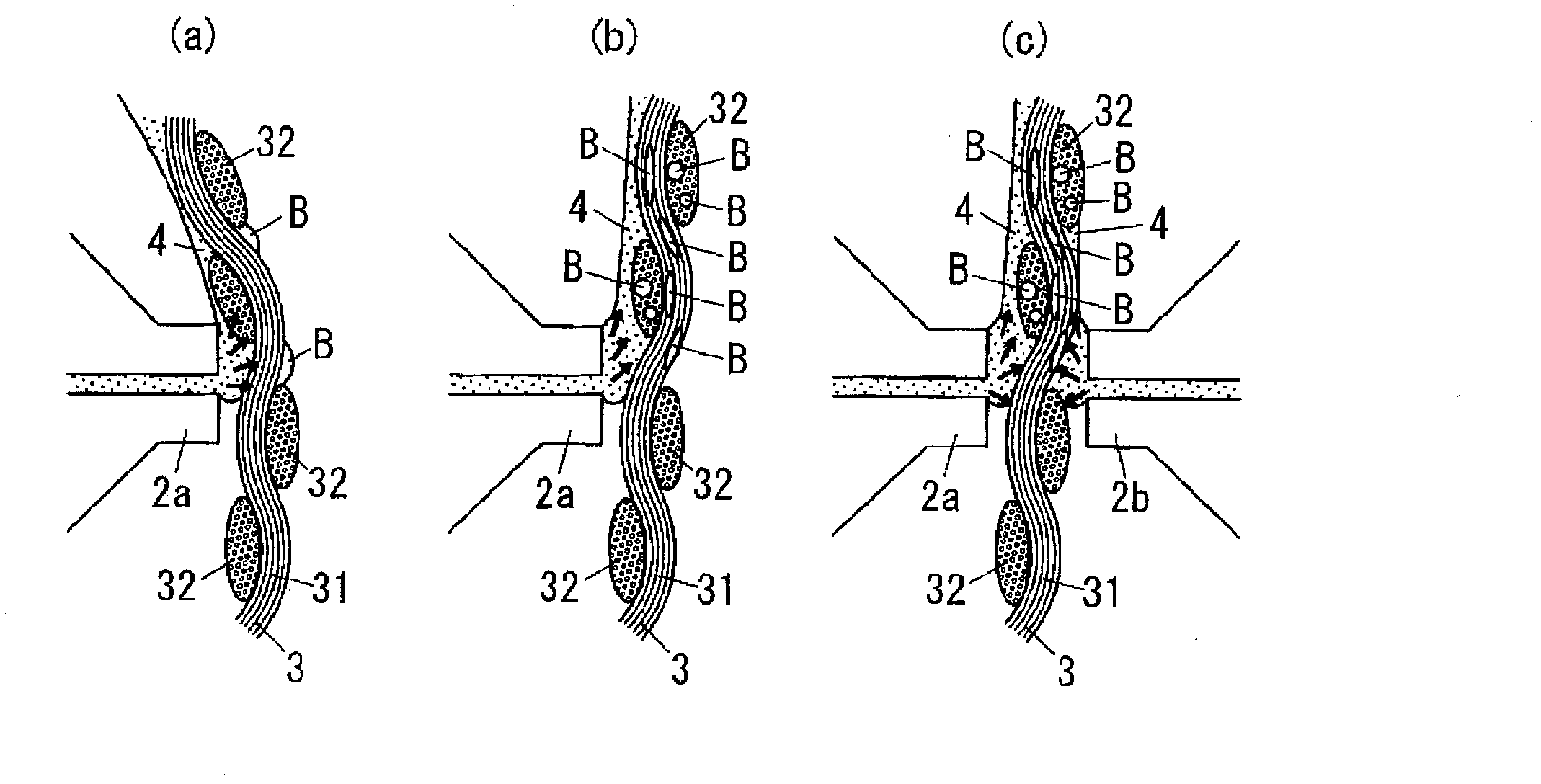

[0028] figure 1 An example of the manufacturing method of the prepreg for printed wiring boards of this invention, and its apparatus is shown in . This prepreg manufacturing apparatus for printed wiring boards is equipped with the 1st coating apparatus 1a and the 2nd coating apparatus 1b which are two coating machines. The base plate 3 is conveyed in the arrow direction (from bottom to top) in the figure so as to pass between the two coating machines, and the resin liquid 4 is applied to both surfaces individually. In addition, although the same coater was used for the 1st coater 1a and the 2nd coater 1b in this embodiment, you may use a different coater.

[0029]The first coating device 1 a and the second coating device 1 b each have a coating tip 2 , and each coating tip 2 is formed elongatedly along the width direction of the base plate 3 . Moreover, the first coating tip 2a as the coating tip 2 of the first coating device 1a protrudes toward one surface of the base plat...

Embodiment approach 2

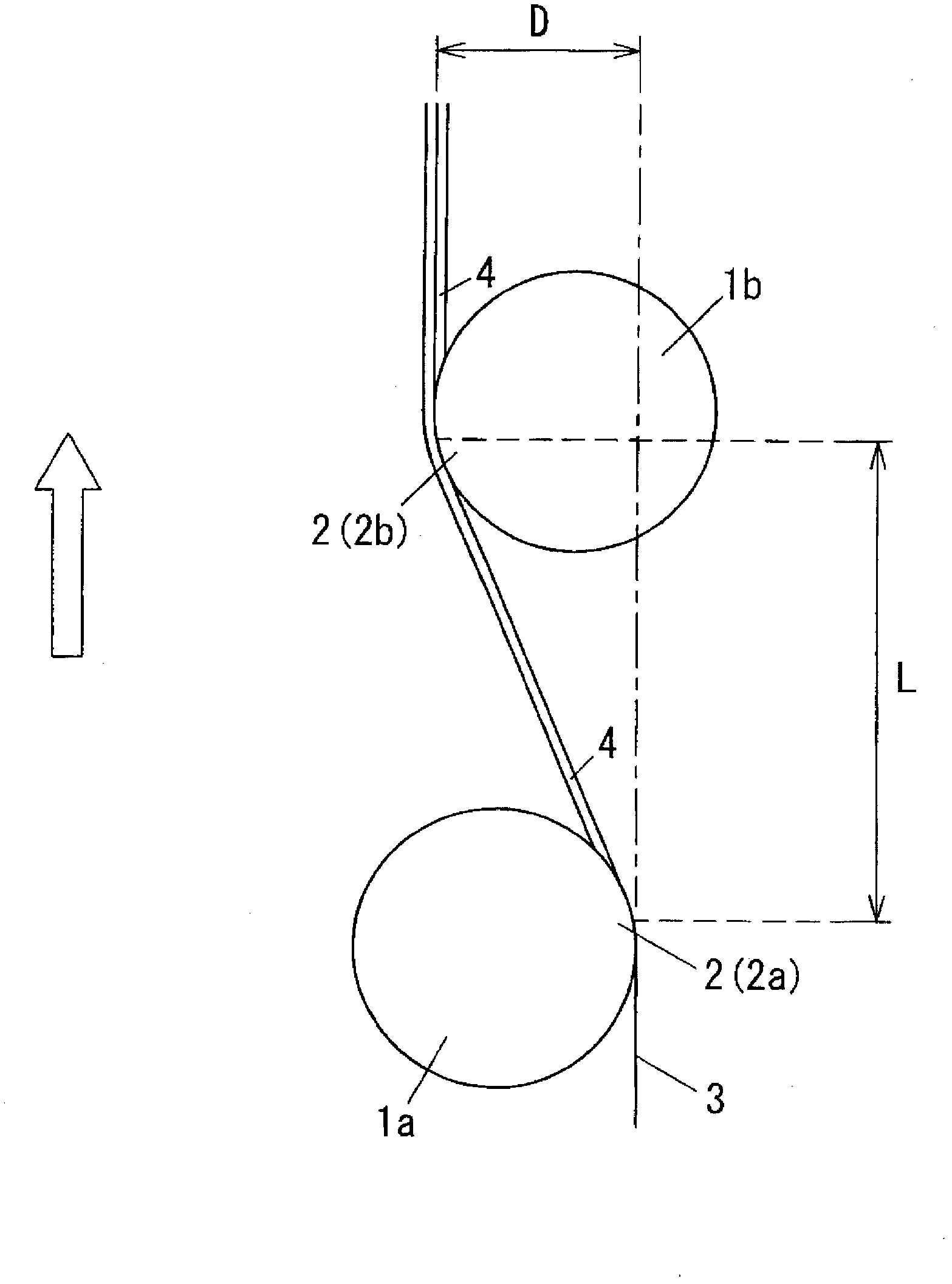

[0045] In the first embodiment described above, an example in which a coater is used as the first coater 1 a and the second coater 1 b has been described. In this embodiment, an example using a roll coater as the first coating device 1a and the second coating device 1b will be described.

[0046] image 3 The main part of the manufacturing method of the prepreg for printed wiring boards of this embodiment, and the apparatus is shown. In the present embodiment, as the first coating device 1 a and the second coating device 1 b , a roll coater, which is a cylindrical device, is used respectively, and the outer peripheral surface of the cylinder serves as the coating tip 2 . And between the 1st coating front end part 2a and the 2nd coating front end part 2b, the distance L between coatings is provided along the conveyance direction of the substrate sheet 3, as these coating front end parts 2 and the substrate sheet 3 The overlap distance in the vertical direction, set the front ...

Embodiment

[0050]Prepregs were manufactured under the conditions shown in Table 1 using a prepreg manufacturing apparatus including two coating devices 1 that independently coat both surfaces of the base plate 3, and were evaluated. That is, with the coating device 1 shown in Table 1, the distance between coatings L, the overlapping distance D, the conveyance speed of the base plate 3, the line tension when the base plate 3 is transported, and the distance from the first coater 1a The weight ratio of the discharge amount of the resin solution per unit time with the second coating device 1b is used to apply the resin solution 4 to the base plate 3 to produce a prepreg, and evaluate the impregnation of the resin solution 4 under various conditions, and , Measure the resin film thickness ratio of the prepreg, and judge by comprehensively evaluating whether the prepreg for printed wiring boards is good or not.

[0051] The evaluation of the immersion property of the resin liquid 4 was based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com