Lunar-based large-depth fidelity coring drilling device

A large-depth, coring bit technology, applied in the direction of sampling devices, etc., can solve the problem that moon-based coring cannot achieve large-depth and fidelity coring, and achieve the effect of improving drilling efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

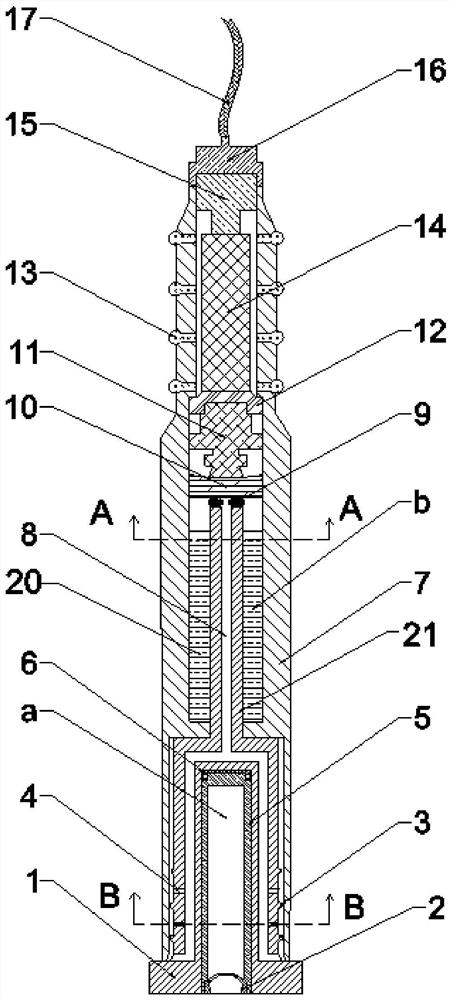

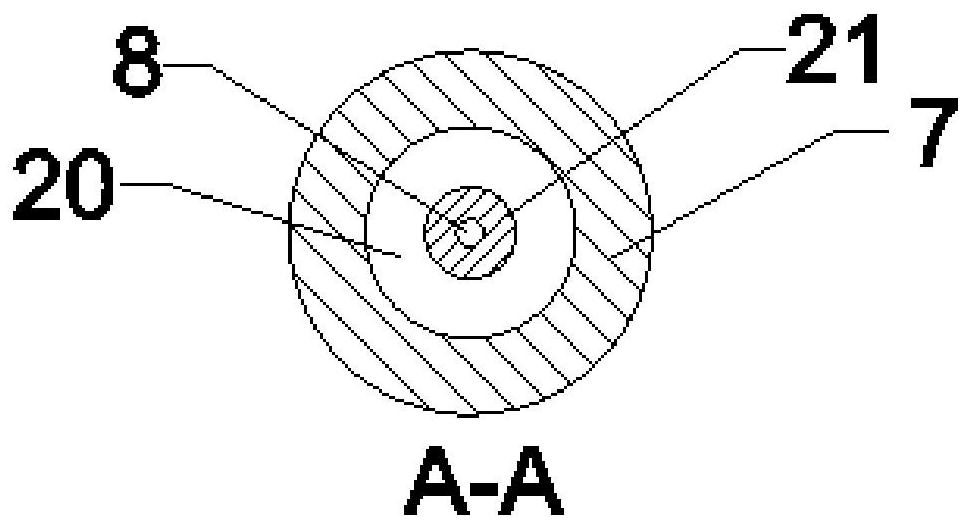

[0043] This embodiment is basically as Figure 1 to Figure 10 As shown: this embodiment provides a moon-based large-depth fidelity coring drilling device to solve the technical problem of "not getting deep" in the existing moon-based coring. The drilling device includes a controller 15, a coring device Outer pipe 7 and the coring bit 1 that is positioned at the coring device outer pipe 7 below; Be provided with drilling mechanism in the coring device outer pipe 7, drilling mechanism comprises push rod 19 and rotating mechanism, and push rod 19 and rotating mechanism respectively Connected with the controller 15, the rotating mechanism is used to apply torque to the coring bit 1, and the push rod 19 is used to apply axial drilling pressure to the coring bit 1, so as to ensure the rapid drilling of the coring bit 1; preferably, the controller 15 can be built into the inner side of the core remover outer tube 7 top, which is convenient to be close to the drilling mechanism, so th...

Embodiment 2

[0050] Embodiment 2 is basically the same as Embodiment 1, the difference is that this embodiment provides a moon-based large-depth fidelity core drilling device, as a preferred solution of Embodiment 1, combined with figure 2 and image 3 As shown, in this embodiment, a follow-up mechanism is provided between the drilling mechanism and the coring bit 1, so that during the coring process, the follow-up liquid b built in the outer tube 7 of the coring device will be It is discharged into the shaft; with the above structure, the protective liquid b is used in moon-based coring, and the protective liquid b can penetrate into the surrounding rock formations, and the solvent in the protective liquid b can be evaporated quickly through the vacuum action, and the heat can be taken away On the one hand, the evaporation of the solvent takes away a large amount of heat, which makes the core bit 1 cool down in real time, which is beneficial to the long-term use of the core bit 1 and ens...

Embodiment 3

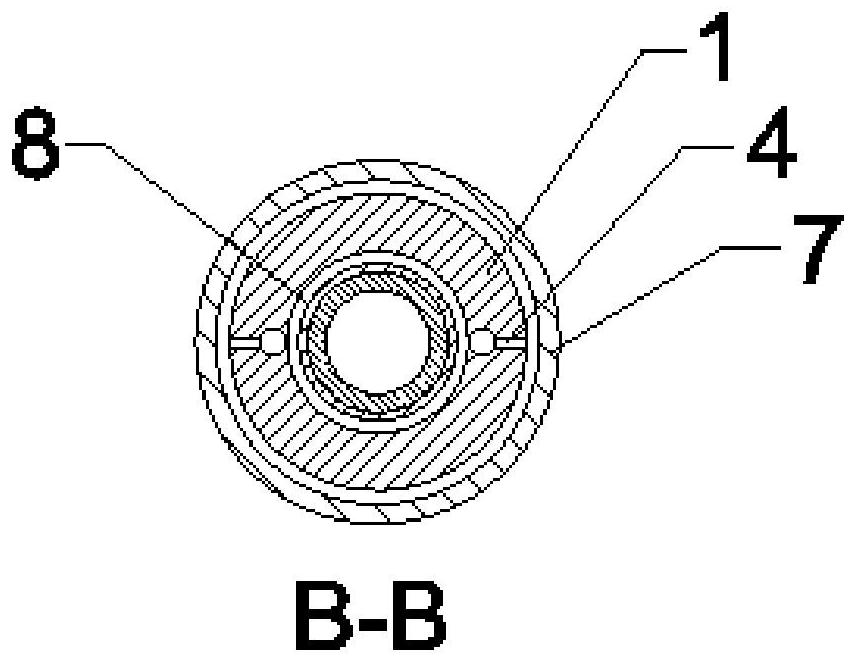

[0059] Embodiment 3 is basically the same as Embodiment 1, the difference is that this embodiment provides a moon-based large-depth fidelity core drilling device, as the preferred solution of Embodiment 1, combined with Figure 6 to Figure 10 As shown, in order to solve the technical problem of "not true" in the existing month-based coring, the key of this embodiment is that a coring inner cylinder 5 is arranged in the coring bit 1, and a bearing is connected to the top of the coring inner cylinder 5 6. A core sealer 2 is provided at the bottom of the coring inner cylinder 5, and a self-healing viscoelastic body a is provided in the coring inner cylinder 5, so that during the coring process, the self-healing viscoelastic body a can Move along the annular gap between the coring inner cylinder 5 and the core 18 to cover the surface of the core 18 to be drilled.

[0060] Therefore, the realization principle of the basic scheme of this embodiment is: to propose the application of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com