Polymer-Based Sausage Casing

a polyamide and sausage technology, applied in the field of polymer-based sausage casings, can solve the problems of inability to smoke pure polyamide casings, inability to penetrate moisture into the cellulosic casing, and inability to smokiness pure polyamide casings, etc., to achieve the effect of improving the peelability of cooked meat casings and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The present invention provides a method for producing a polymer-based sausage casing, where the film has suitable barrier properties for the specific type of sausage meat to be encased. The present invention also provides compositions for polymer-based films suitable for use in sausage casings.

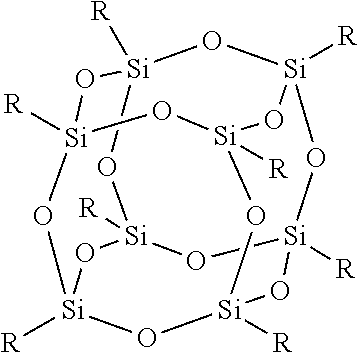

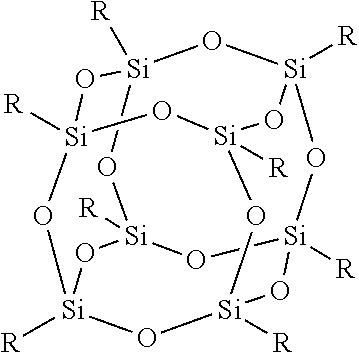

[0021]In a preferred embodiment, a polyamide resin is blended with a silicon-based barrier control agent at a specified silicon-based barrier control agent concentration to create a master blend. This master blend may then be blended or co-extruded with pure polyamide, and then biaxially stretch-oriented, to produce a polyamide-based film. The type of silicon-based barrier control agent used can be varied to provide a film with increased or decreased barrier properties relative to pure polyamide. The amount of pure polyamide blended or co-extruded with the master blend can also be varied to control the permeability of the polyamide-based film. Polyamides, as intended by the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com