Packaging film for foodstuffs

一种食品包装膜、包装膜的技术,应用在包装、包装纸、运输和包装等方向,能够解决耗费时间和能源等问题,达到香料涂层浓厚、可靠性高、提升挤压效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

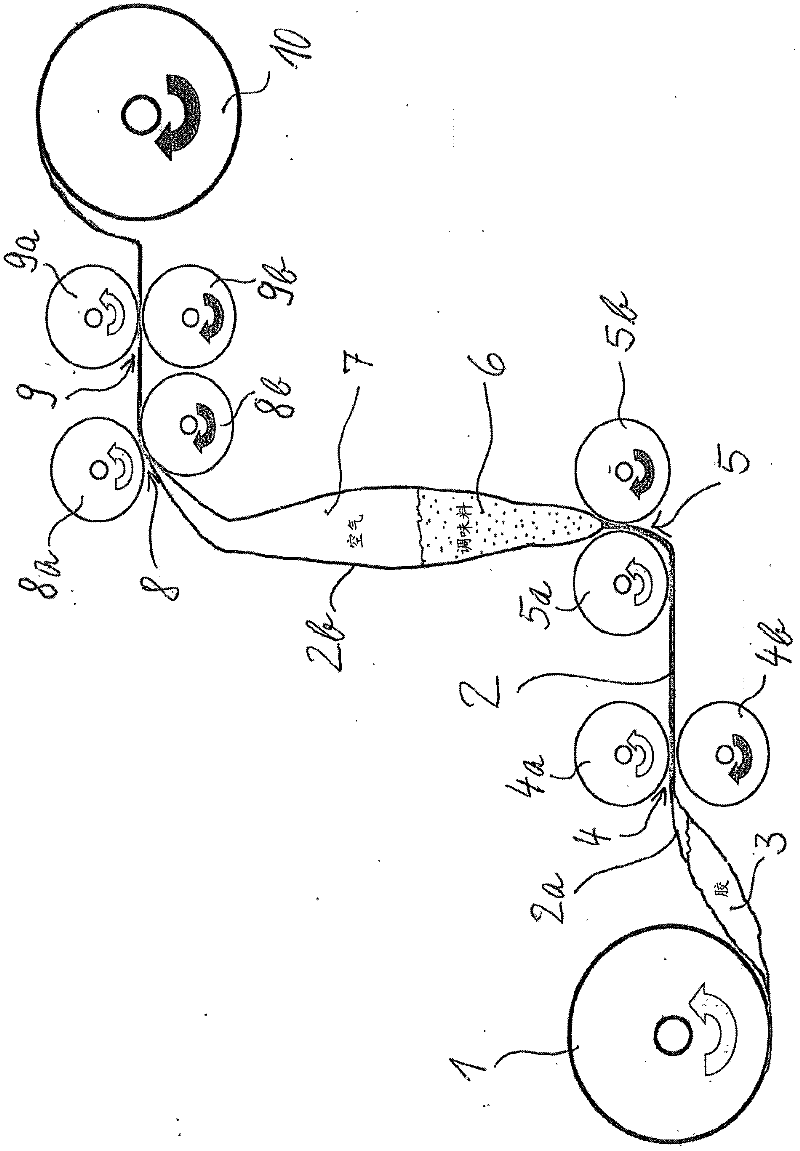

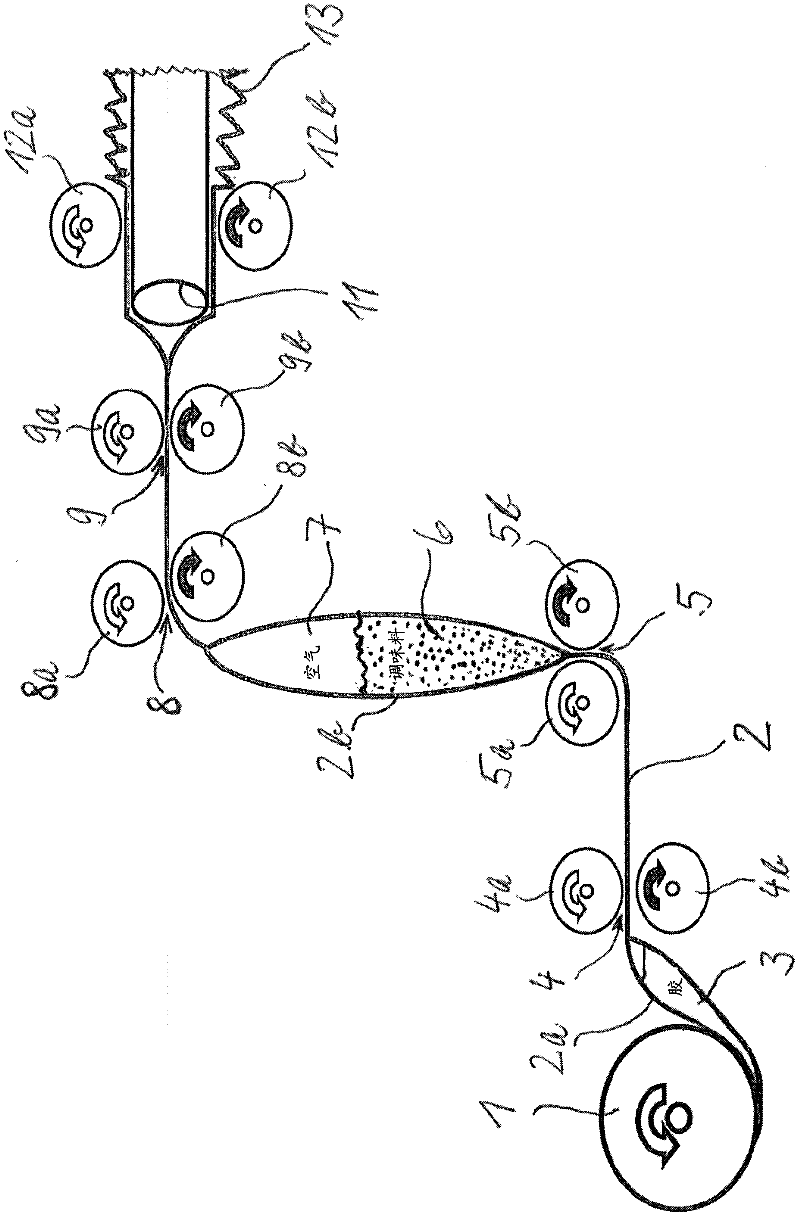

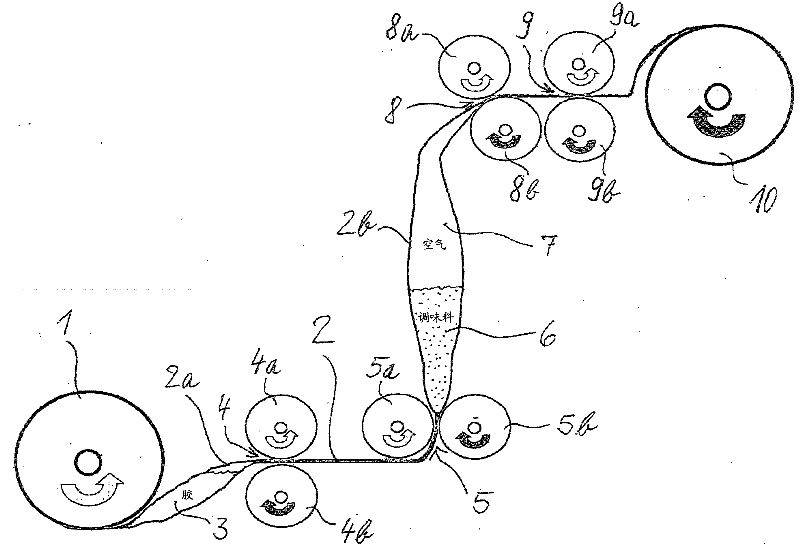

[0037] The process starts from the material roller shaft 1, on which the tubular packaging film 2 is laid flat, and the material roller shaft 1 can accommodate, for example, a packaging film with a length of 40-500 meters.

[0038] Casing casings of different materials can be used as raw materials for the packaging film. For example, fibrous casings reinforced with viscose, or collagen casings or dried natural casings, as well as coated fabric casings, synthetic casings with collagen, carrageenan and acrylate coatings, or other single-layer and multilayer casings can be used. Layer casings, as long as they are not too air permeable.

[0039] The beginning of the packaging film 2 is designed as an open hose port, and a known food-approved liquid adhesive 3 and supporting air are inserted, so that the packaging film is configured as a bag 2 a partially or completely filled with adhesive 3 . The amount of the adhesive is enough to smear the entire packaging film laid flat on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com