Processing system for sandwich bread

A processing system and sandwich technology, applied in metal processing, filling bakery items, baking, etc., can solve the problems of large movement resistance, difficulty in realizing full automation, and low degree of automation, so as to ensure hygiene and safety and reduce manpower input cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

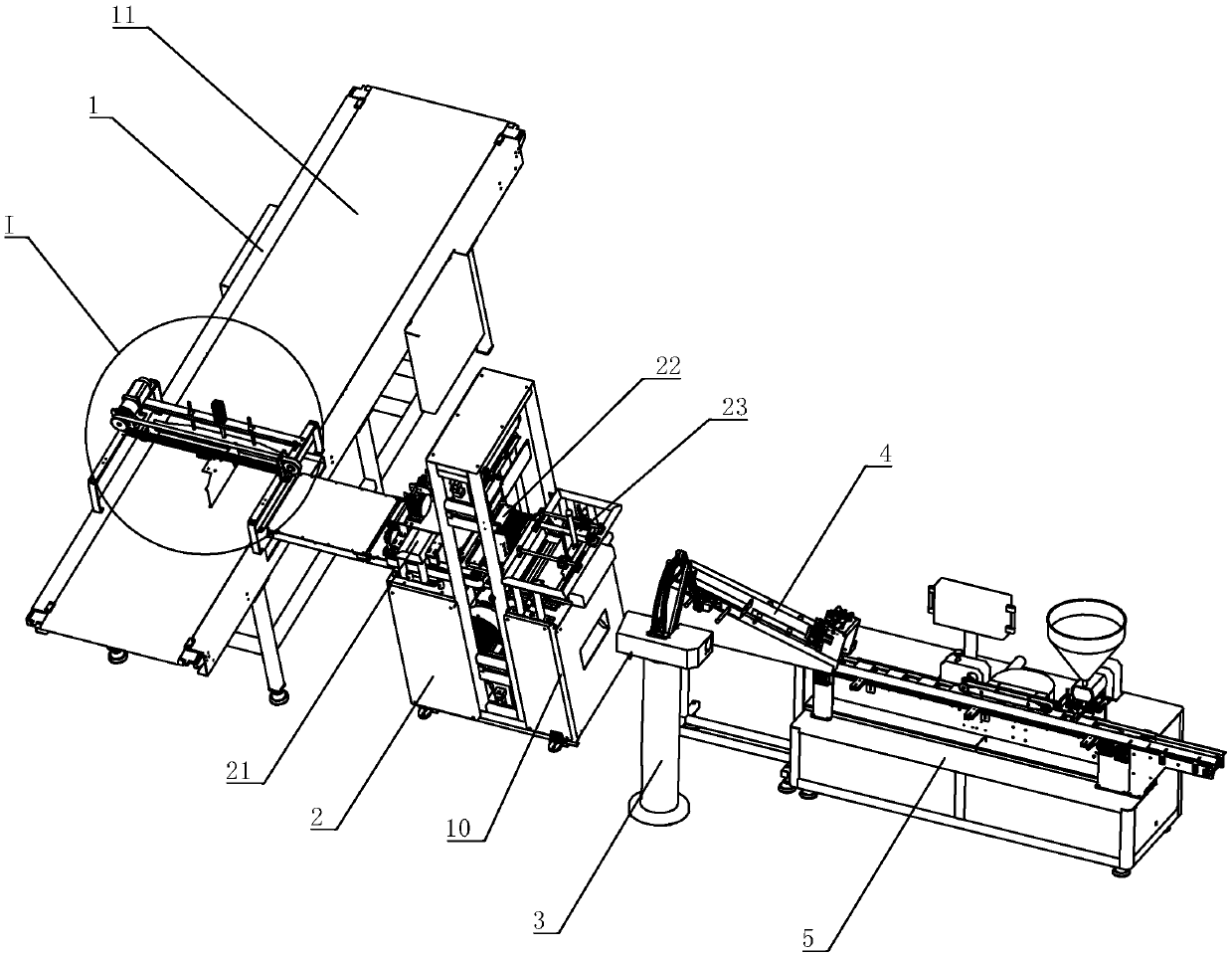

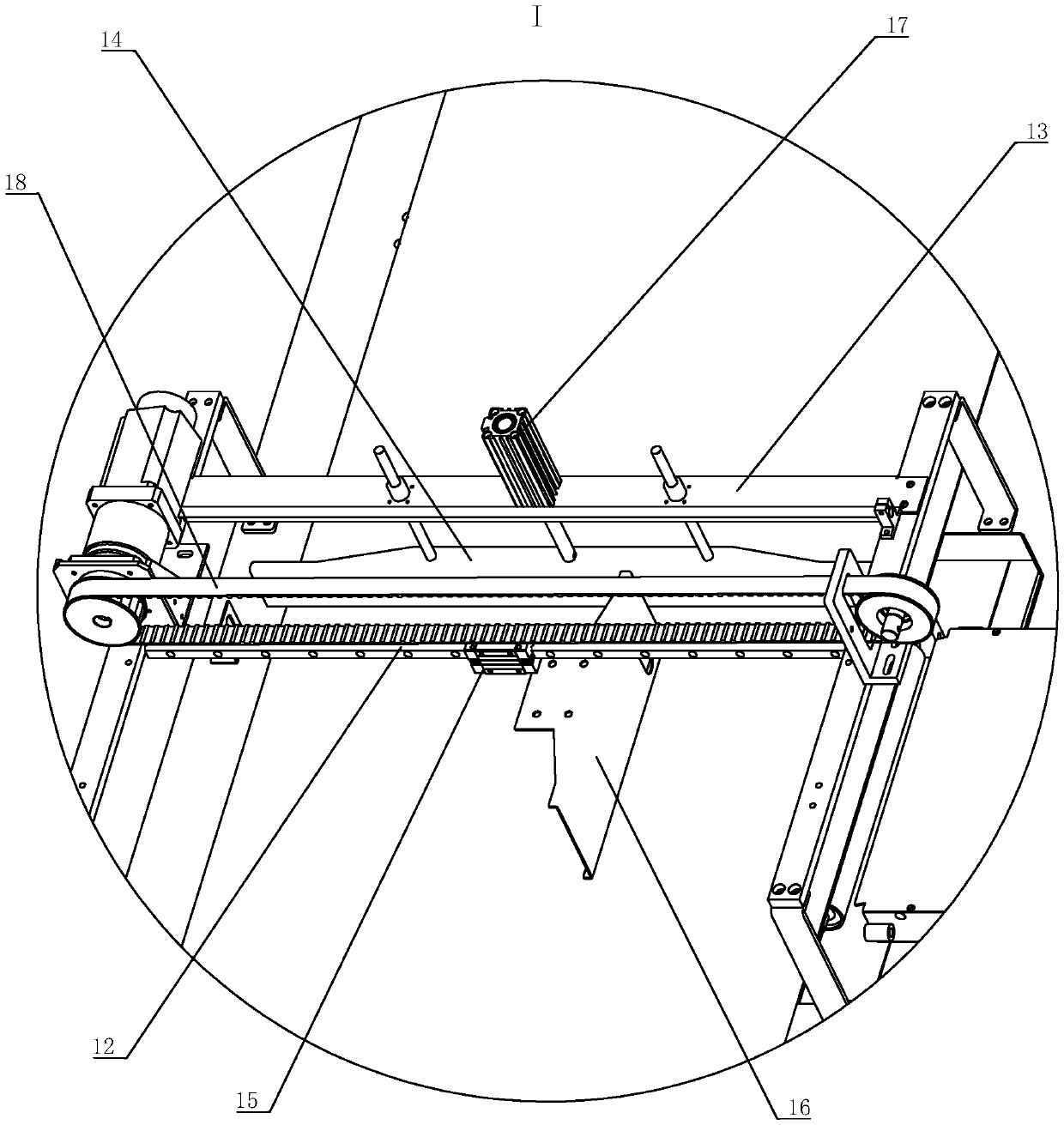

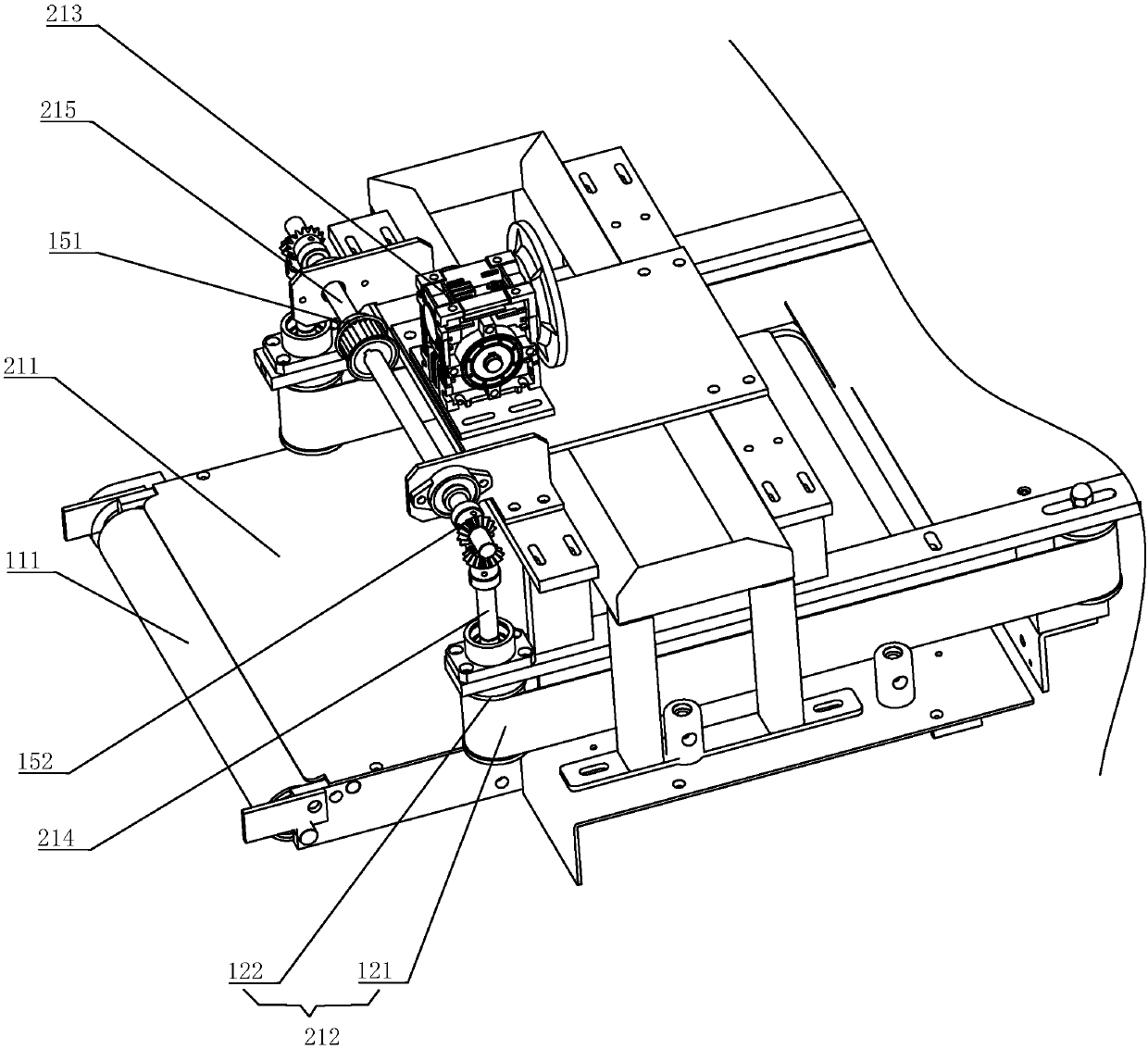

[0030] refer to Figure 1 to Figure 8 , a kind of sandwich bread processing system of the present invention, comprises the conveyer belt pushing device 1 of starting end, the bread cutting conveyer 2 that is connected with it and the mechanical handling hand device 3 that is arranged at the rear of bread cutting conveyer 2, is arranged in turn on mechanical handling The bread feeder 4 behind the hand device 3, the cutting and filling mechanism 5; a plurality of cuboid breads placed side by side move on the conveyor belt pushing device 1 along the length direction, and stop being pushed by the conveyor belt at the connection of the bread cutting conveyor 2 The device 1 is pushed vertically to the bread cutting conveyor 2, and the bread is preliminarily cut and pushed to the mechanical hand device 3, which transfers the bread to the subsequent bread feeder 4 in an all-round motion, and then feeds the bread through the bread The machine 4 cuts the bread pieces sequentially, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com