Biscuit surface oil spraying device

An oil spraying device and biscuit technology, which is applied in the direction of cleaning/oiling the baking surface machinery, etc., can solve the problems of difficulty in ensuring the quality of biscuits, waste of energy, leakage loss of oil supply pipelines, etc., to ensure the appearance, color and taste, The effect of reducing oil leakage and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

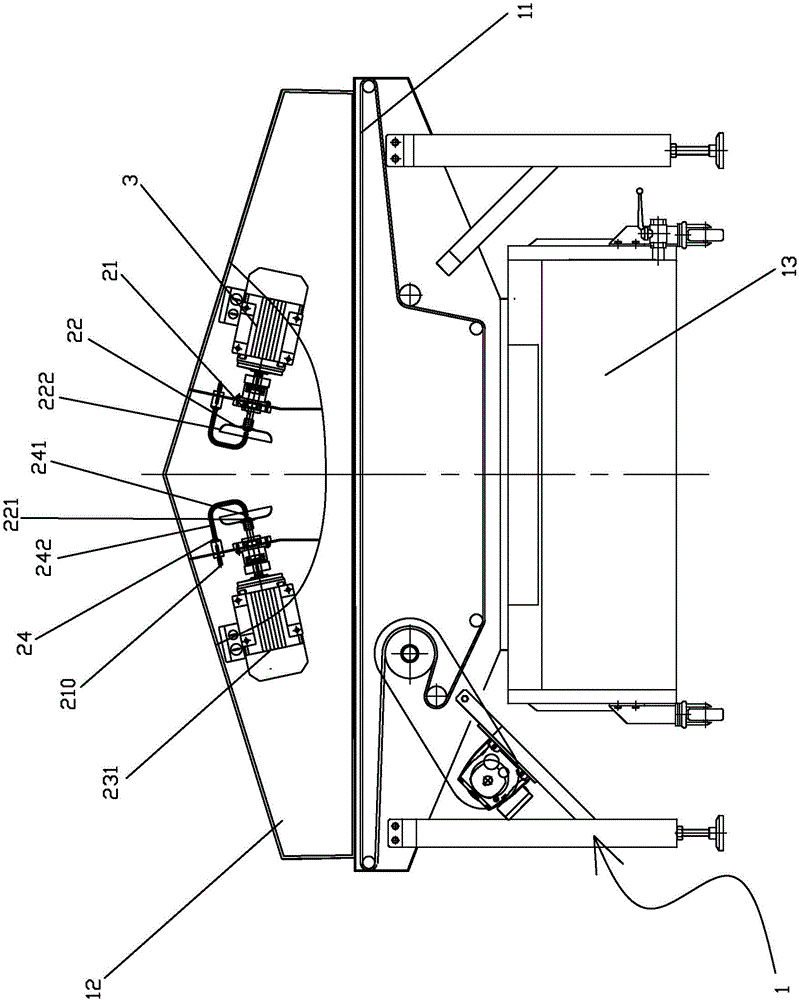

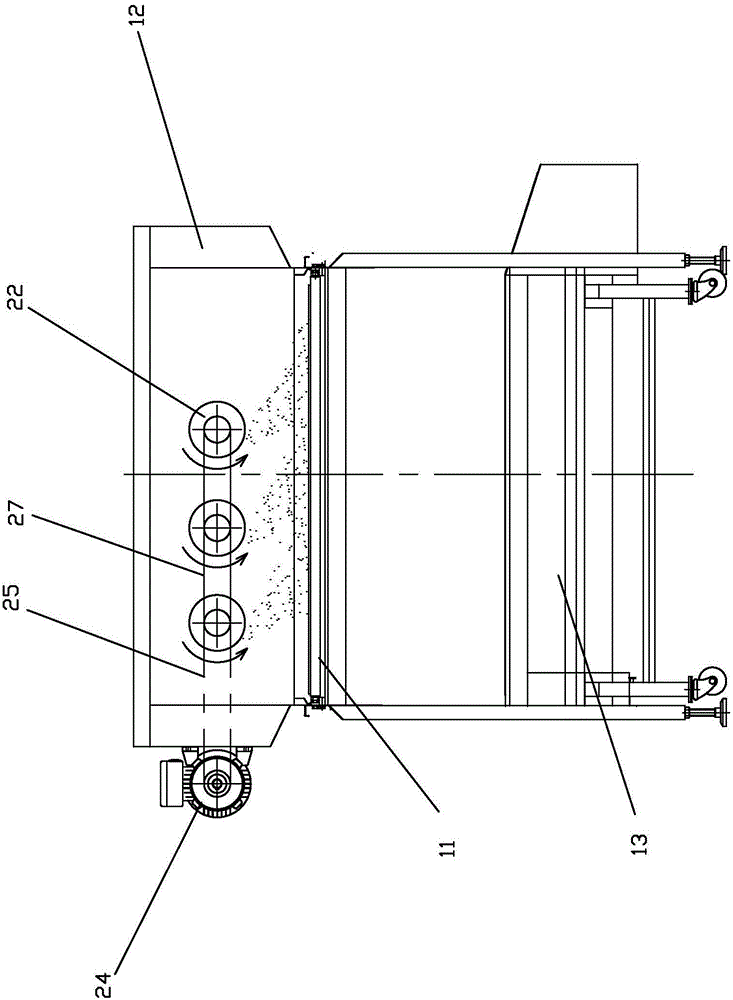

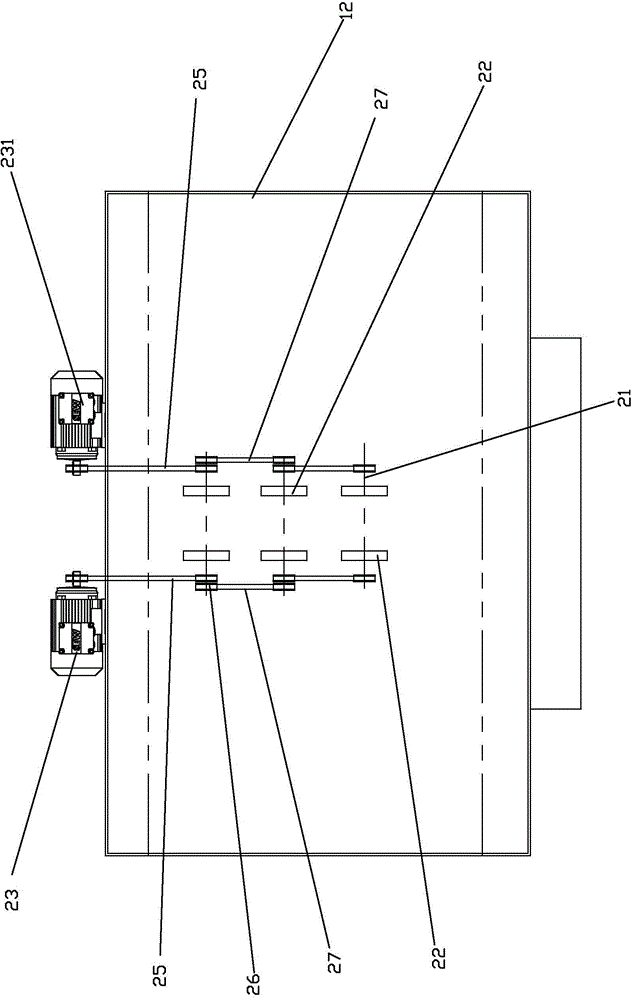

[0017] A biscuit surface oil spraying device, comprising a frame 1, the frame 1 is provided with a conveying device 11 for conveying biscuits, and the frame 1 is provided with an oil throwing device 2 above the conveying device 11, the The oil throwing device 2 includes a rotating shaft 21 located above the frame 1, one end of the rotating shaft 21 is provided with an oil throwing pan 22 with an opening inclined upward, and the other end is connected with a driving device 23 for driving it to rotate. The frame 1 is provided with an oil spraying device 24 for spraying oil to the middle of the oil throwing pan 22 . The oil throwing device above the conveying device uses the rotating oil throwing plate to throw off the oil, and the oil is sprayed onto the surface of the biscuit on the conveying device.

[0018] The middle part of the oil throwing pan 22 is provided with an arc-shaped protrusion 221, and the periphery of the oil throwing pan 22 is provided with a flange 222 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com