Automatic two-sided pancake machine

A pancake machine, double-sided technology, applied in the direction of baking pancakes, cleaning/oiling the baking surface, baking, etc., can solve unsuitable assembly line, large-scale production, affect processing efficiency, increase product cost, etc. problems, to achieve the effect of improving the degree of automation, processing efficiency and product quality, high utilization rate of oil, and reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

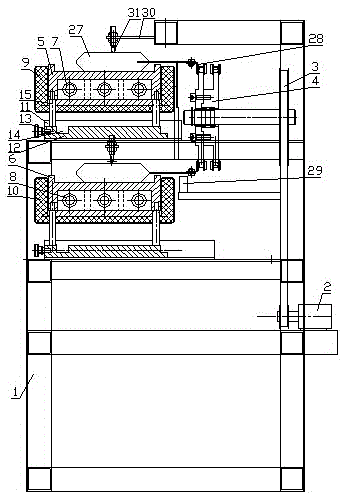

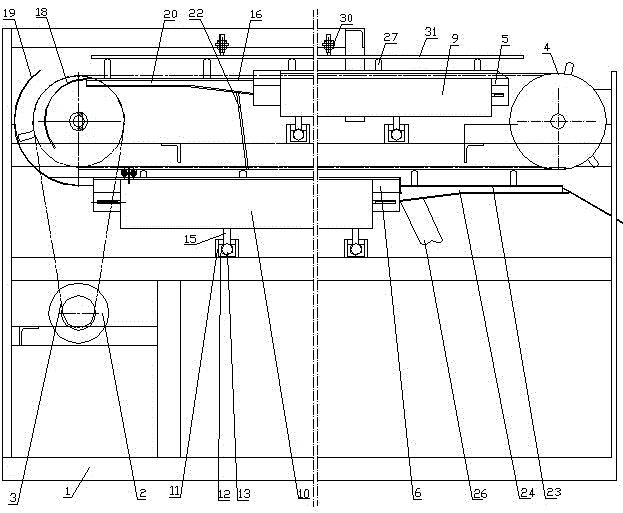

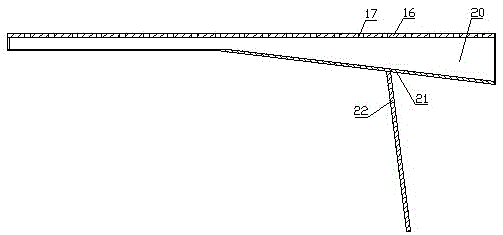

[0015] like Figure 1 to Figure 3 As shown, the automatic double-sided pancake machine includes a frame 1, a motor 2, a sprocket chain mechanism 4 that is connected to the motor 3 through a pulley mechanism 3 as a transmission device and is vertically arranged on the frame 1, and is located on the frame 1. The upper pot body 5 and the lower pot body 6, the upper pot body 5 and the lower pot body 6 are all provided with a horizontal groove and an inner cavity located below the groove, and three electric heating tubes 7 are arranged in each inner cavity. Or 8, both sides and the bottom of the upper pot body 5 and the lower pot body 6 are all connected with an insulating layer 9 or 10; Groove 11 is all provided with support seat 12 in the chute 11, is connected with screw 13 in the outside of support seat 12, is provided with two sinking grooves 14 on support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com