Regional rotary water flowing type croquette deep frying equipment

A deep-fried meatball, flowing water technology, applied in oil/fat roasting, loading/unloading of ovens, etc., can solve the problems of stop of the frying process, low efficiency, insufficient number of fried meatballs, etc., and achieve good taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings and embodiments.

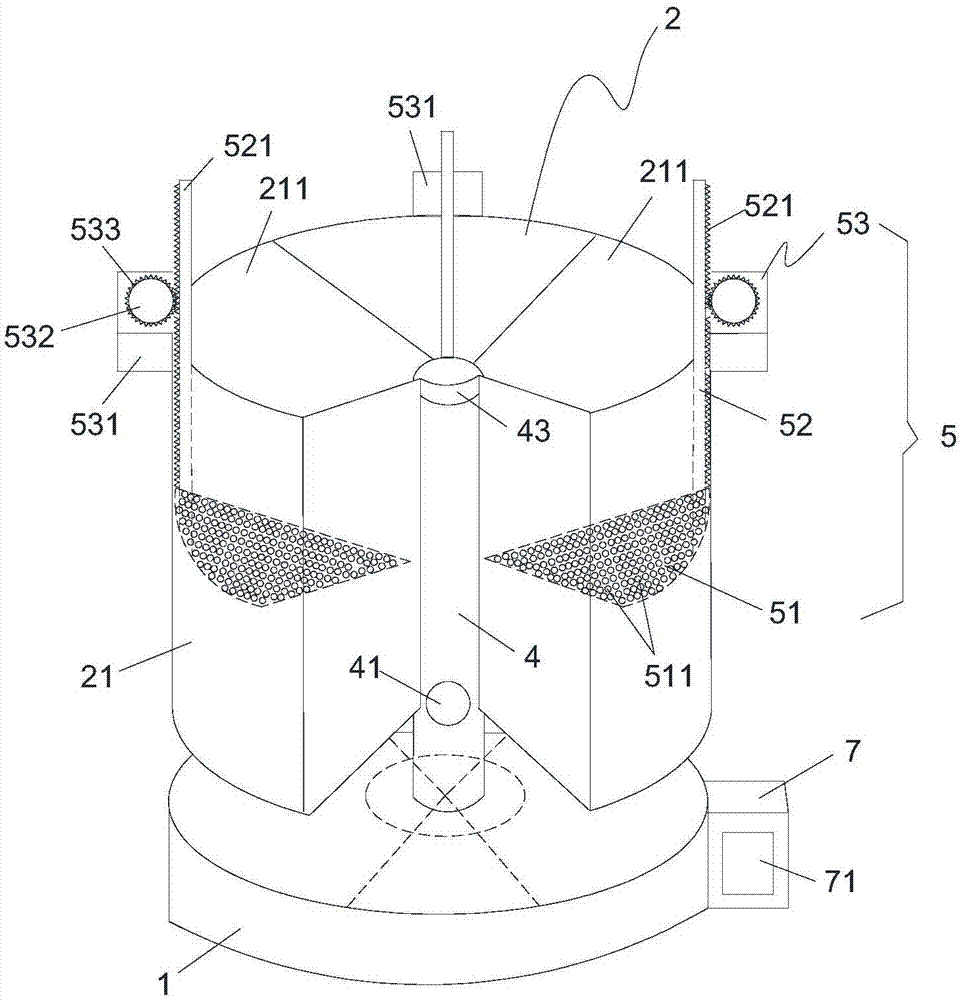

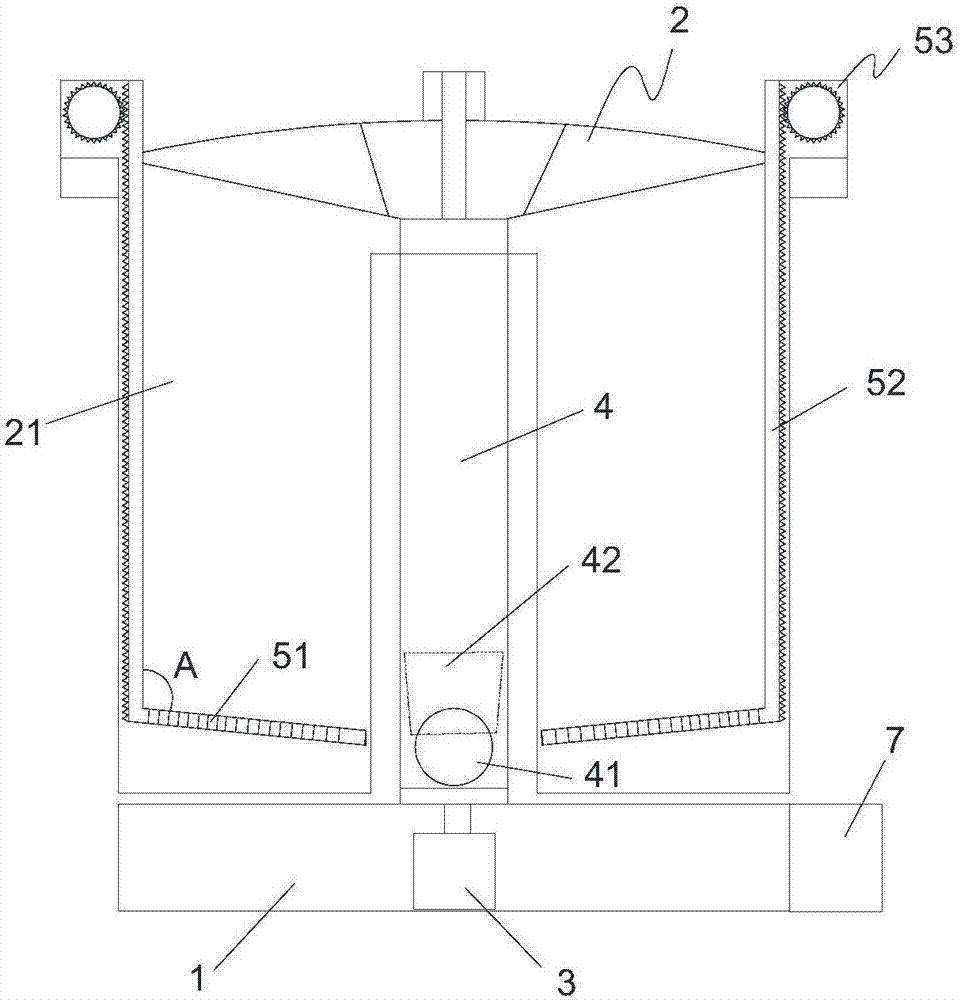

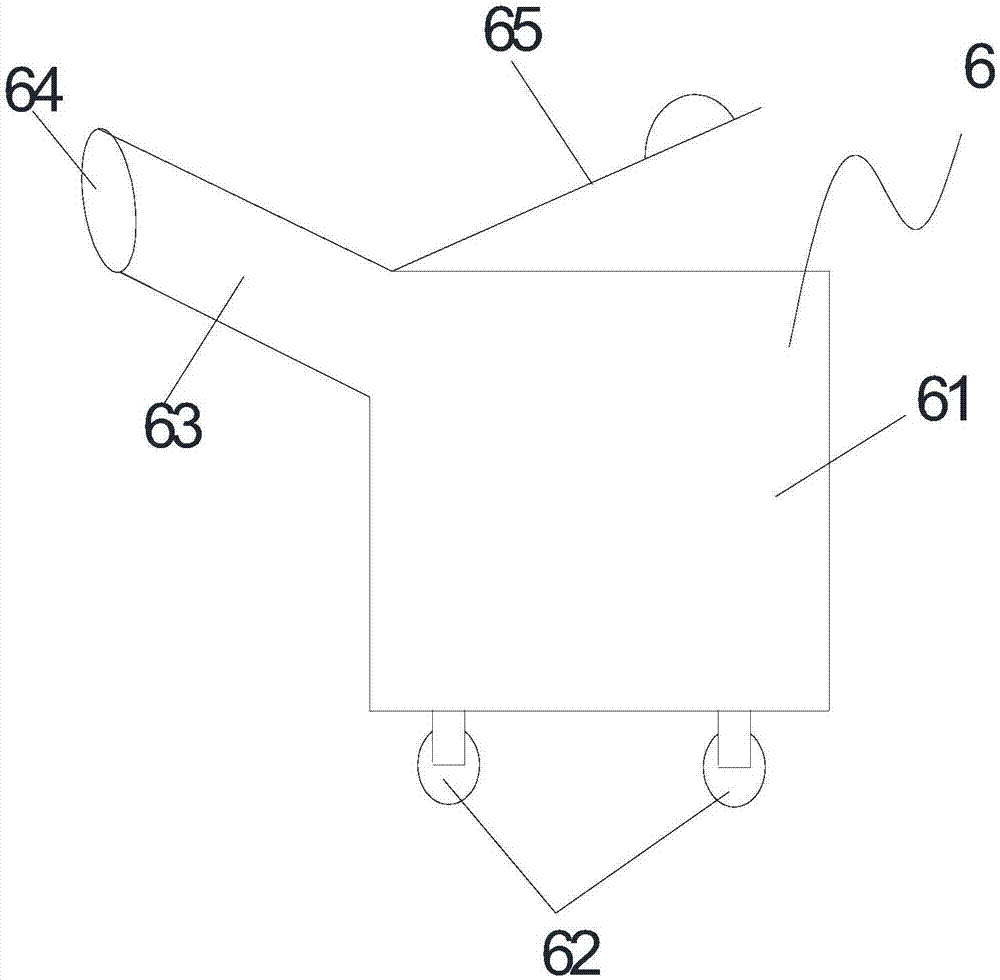

[0017] like Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a sub-area rotating flow-type deep-fried ball equipment, including an induction cooker base 1 and a fryer assembly 2, the induction cooker base 1 is divided into four areas, and the four areas There are at least three induction cookers (not shown) at the bottom of the base of the induction cooker in the three areas spliced in sequence. The three induction cookers can be three induction cookers with different powers; in practical applications, there can also be four induction cookers. When the pot rotates to different positions, the corresponding induction cooker is opened for frying operation; a drive motor 3 is arranged in the base of the induction cooker, and a hollow discharge sleeve 4 is fixed on the rotating shaft of the drive motor 3; The top of the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com