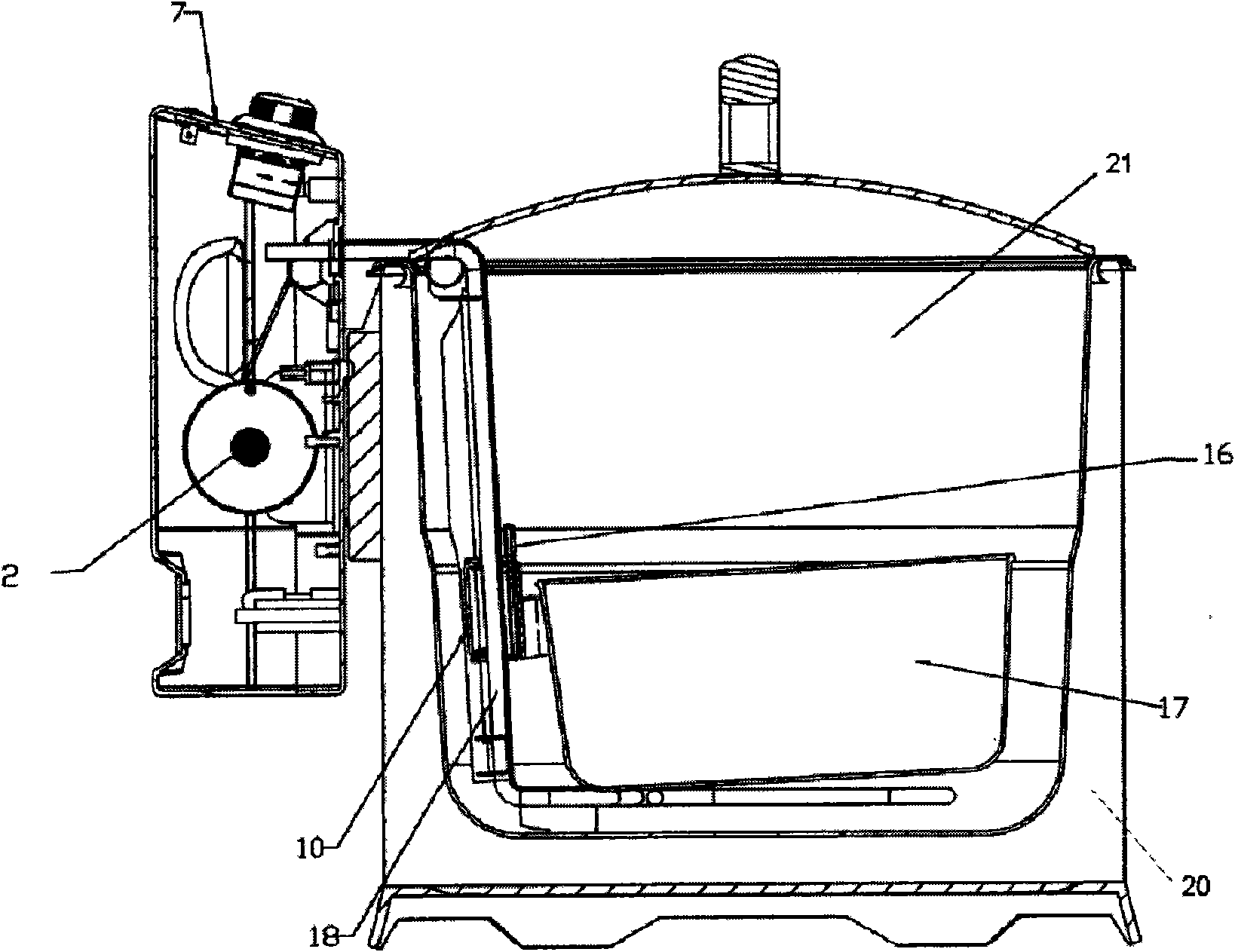

Oil frying equipment

A kind of equipment and frying basket technology, applied in oil/fat baking, baking, food science, etc., can solve the problems of not having automatic unloading function, scalding operators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

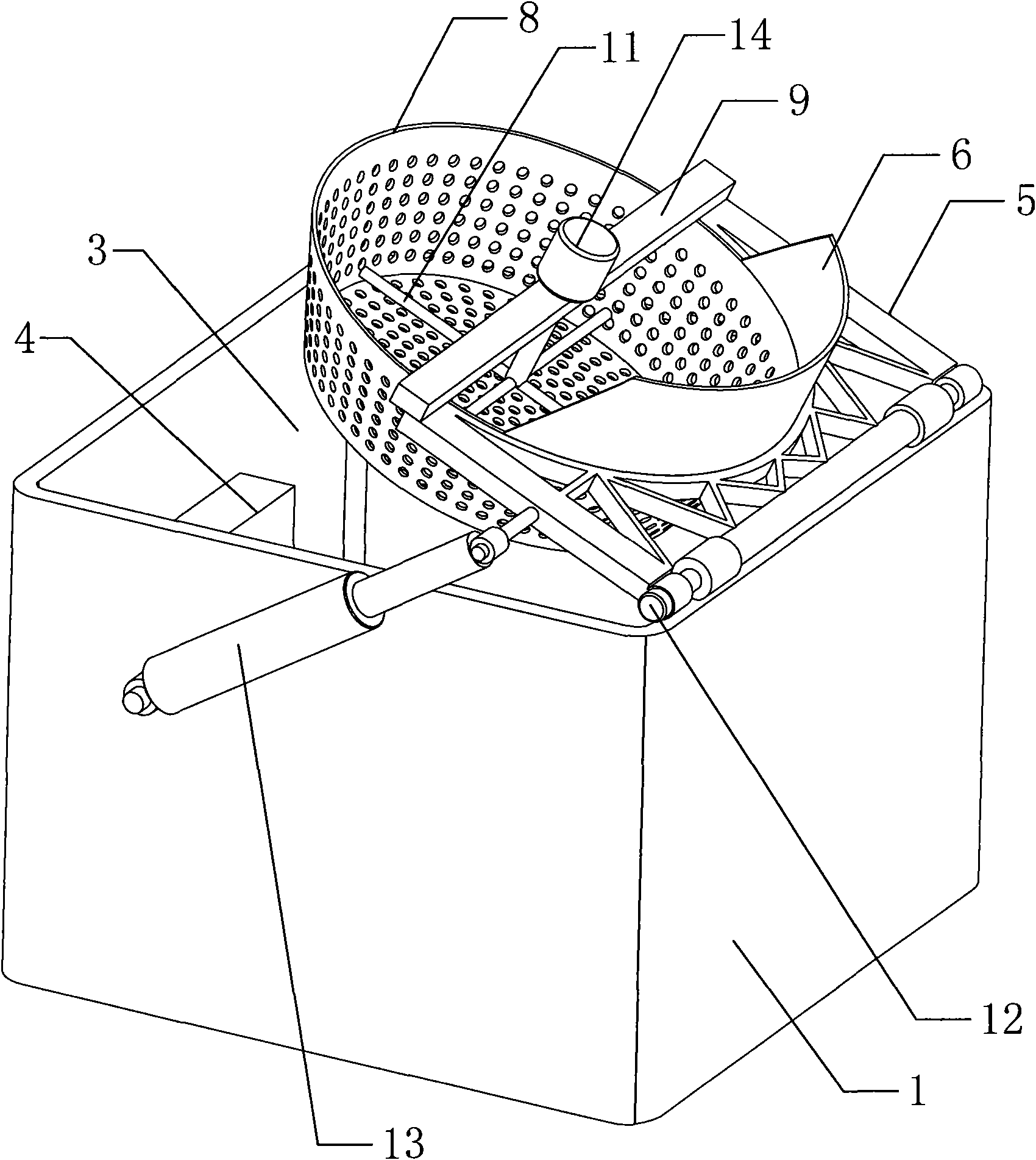

[0014] As shown in 2, the frying equipment of the present invention includes a rectangular furnace body 1, and the furnace body 1 has a rectangular oil-holding cavity 3 inside. The upper end of the furnace body 1 is rotated along a side wall direction through a rotating shaft 12 to assemble a frying basket bracket 5, and the side of the frying basket bracket 5 far away from the rotating shaft 12 is fixed with a bottom and the surrounding surface is evenly equipped with through holes. Hole for frying basket8. The upper end of frying basket bracket 5 away from the rotating shaft 12 side is also fixedly equipped with a crossbeam 9, and a stirring device is assembled on the crossbeam 9. A hydraulic cylinder 13 is assembled between the frying basket bracket 5 and the furnace body 1, which can certainly be a pneumatic cylinder. One end of the hydraulic cylinder 13 is rotatably connected with the fried basket bracket 5, and the other end is rotatably assembled with the support shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com