Molding technology of baked foods, production system for baked foods, and baked foods

A molding process and production system technology, applied in food ovens, food processing, baked foods with modified ingredients, etc., can solve the problems of high production cost, low efficiency, low nutritional content, etc., achieve a fast pace of life and reduce costs , comprehensive effect of nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

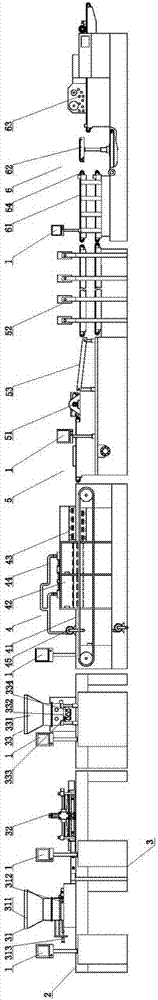

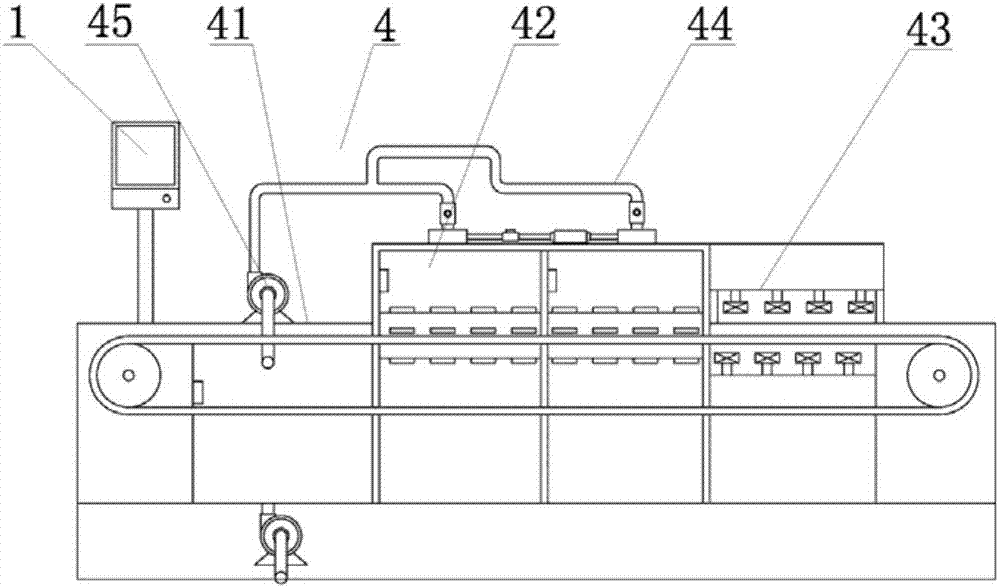

[0052] Embodiment 1: the molding process of above-mentioned baked food is:

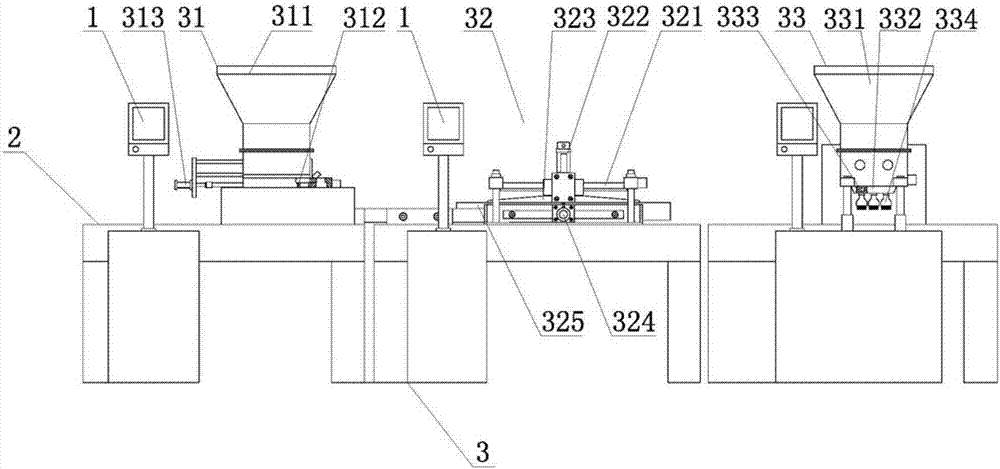

[0053] Raw material preparation: Mix 40 parts of wild jujube kernels, 40 parts of walnut kernels, 4 parts of longan meat and 1 part of black sesame, and use a grinder to crush them into nut mixed particles of a certain size, and put the mixed particles into the storage hopper 311 Set aside; after softening 50 parts of butter, mix with 20 parts of white sugar and 20 parts of brown sugar and beat until the color of the butter becomes lighter and the total volume increases to twice its original size. Add 50 parts of egg liquid and mix it into butter For the mixture, mix 90 parts of flour, 2 parts of baking powder, and 4 parts of soda powder into the butter mixture, add 120 parts of water, stir and mix to form a slurry, and put the slurry into the grouting hopper 331 for later use;

[0054] Quantitative feeding: the empty tray moves forward to the lower end of the storage hopper 311 of the quantitative fe...

Embodiment 2

[0061] Example 2: The difference from Example 1 lies in the preparation of raw materials. 45 parts of jujube kernels, 45 parts of walnut kernels, 4.5 parts of longan meat and 2 parts of black sesame seeds were mixed together and crushed into fruit of a certain size with a grinder. Kernel mixed granules, put the mixed granules into the storage hopper 311 for later use; after softening 55 parts of butter, mix and beat with 25 parts of white sugar and 25 parts of brown sugar, add 55 parts of beaten egg liquid to form a butter mixture, and mix 95 parts of 1 part of flour, 2.5 parts of baking powder, 4.5 parts of soda powder are mixed and poured into the butter mixture, 130 parts of water are added, stirred and mixed to form a slurry, and the slurry is put into the grouting hopper 331 for later use.

Embodiment 3

[0062] Example 3: The difference from Example 1 and Example 2 lies in the preparation of raw materials. 50 parts of jujube kernels, 50 parts of walnut kernels, 5 parts of longan meat and 3 parts of black sesame are mixed together and crushed with a grinder into nut mixed granules of a certain size, put the mixed granules into the storage hopper 311 for later use; after softening 60 parts of butter, mix and beat with 30 parts of white sugar and 30 parts of brown sugar, add 60 parts of beaten egg liquid and mix to form For the butter mixture, mix 100 parts of flour, 3 parts of baking powder, and 5 parts of soda powder into the butter mixture, add 140 parts of water, stir and mix to form a slurry, and put the slurry into the grouting hopper 331 for later use.

[0063] In summary, the baked food is rich in nutrition and meets the current nutritional needs and living needs of people. The molding process and production system for producing the food have realized large-scale mass prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com