Power transmission device

A technology for power transmission devices and transmission components, applied in the direction of transmission devices, belts/chains/gears, couplings, etc., can solve the problems of increased breaking torque, unsuitable for belt protection, engine protection, etc., and achieve a small number of parts , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

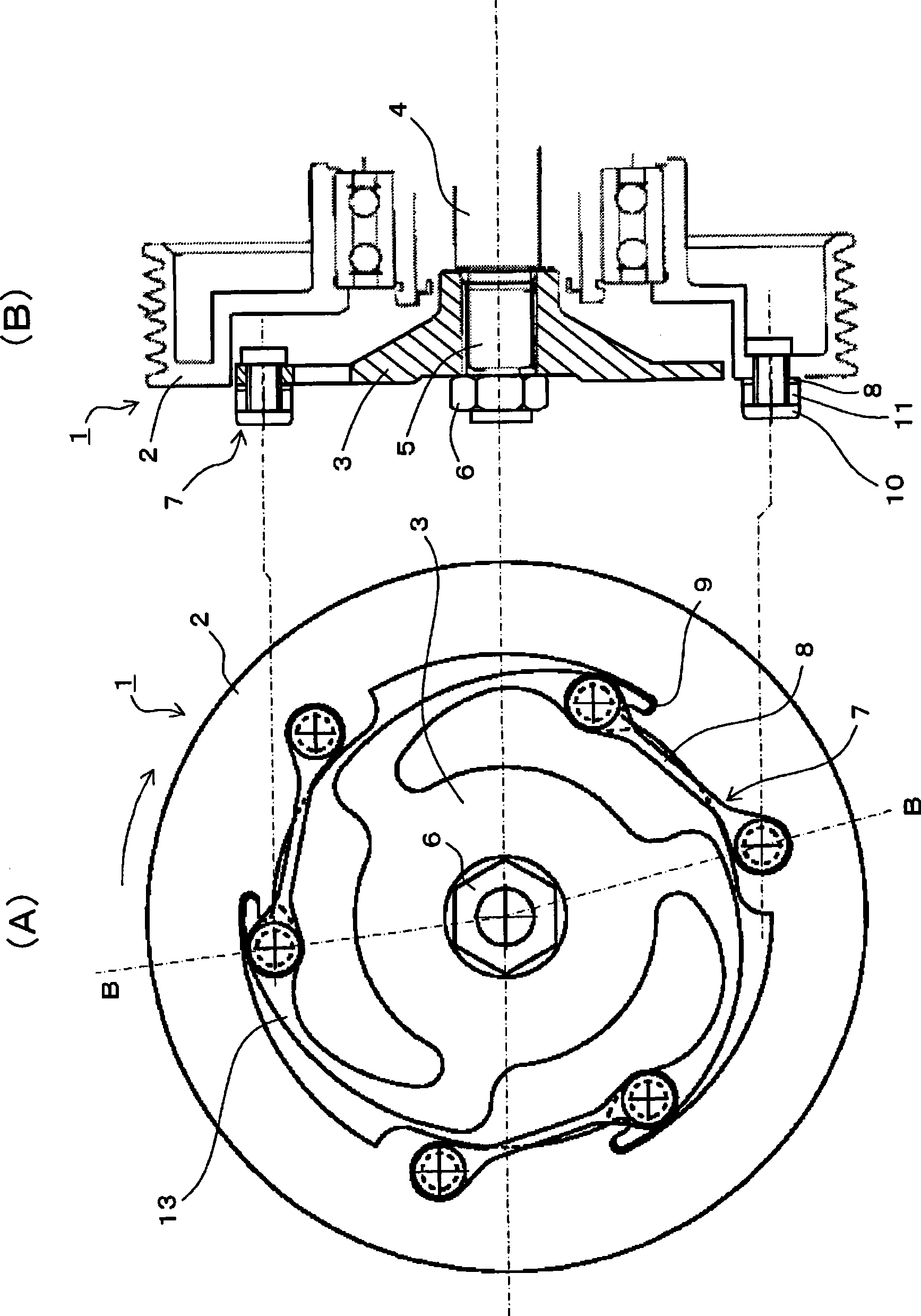

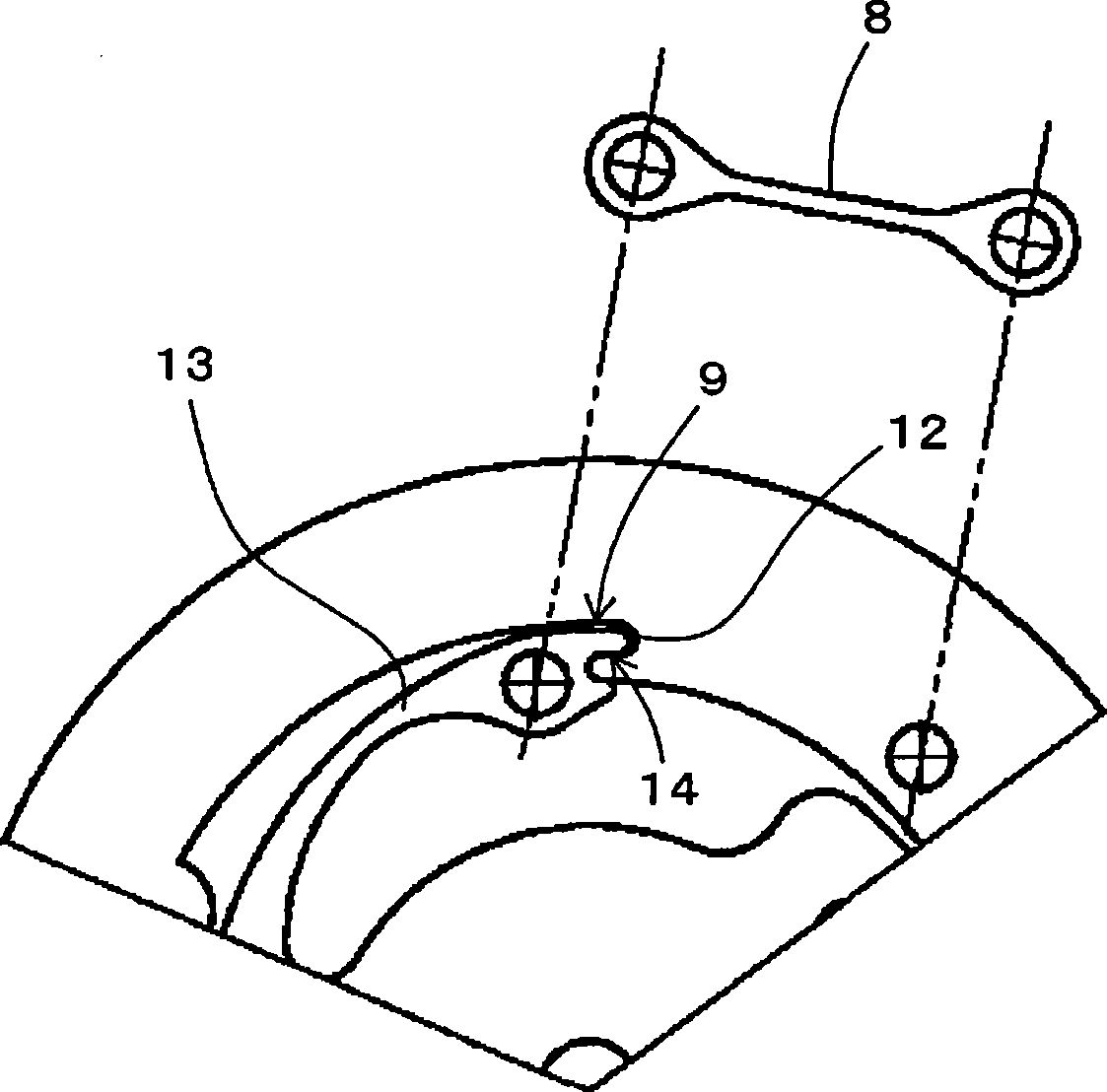

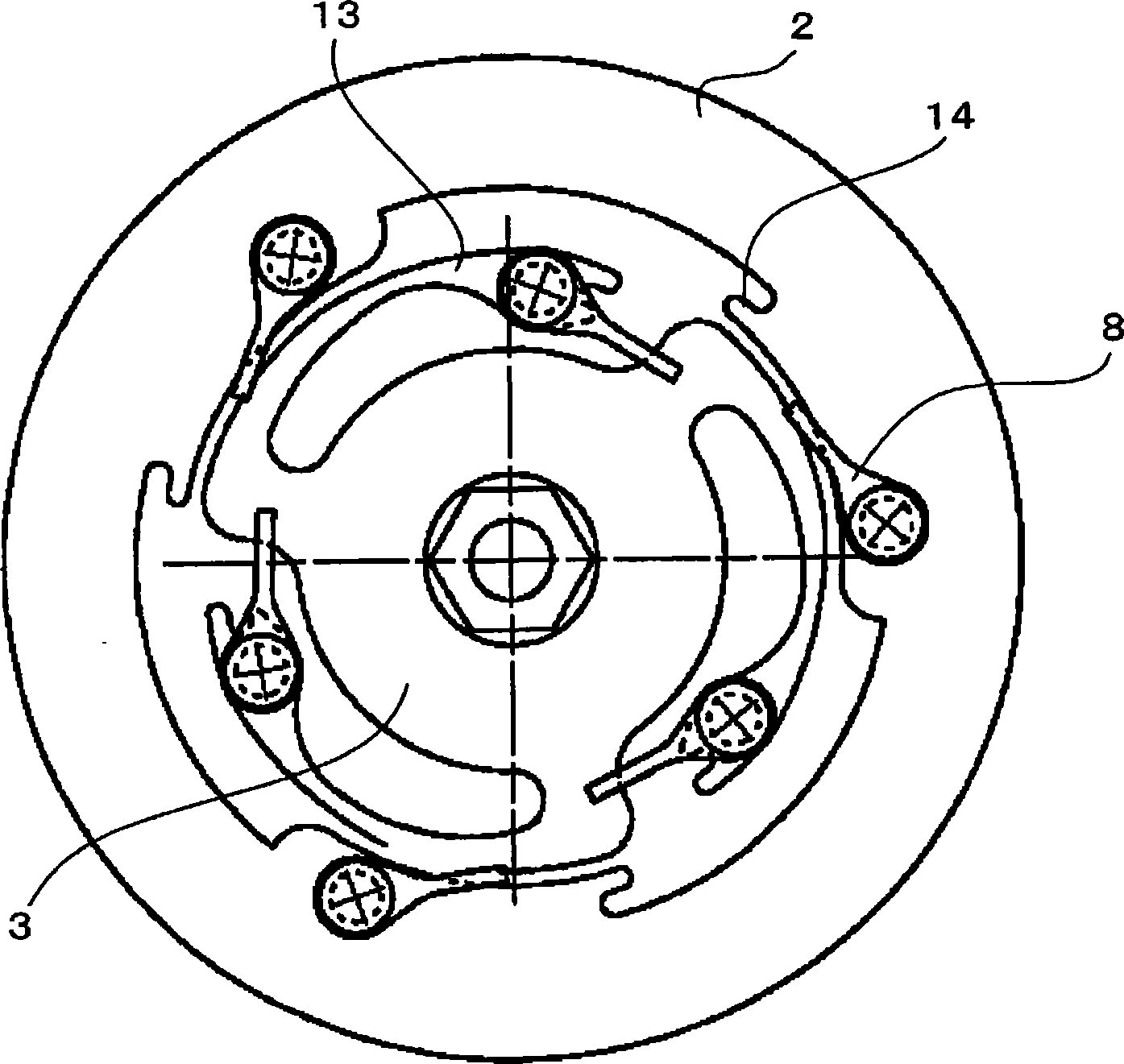

[0056] Figure 1 ~ Figure 4 A power transmission device according to Embodiment 1 of the present invention is shown. exist figure 1 Among them, the symbol 1 represents the whole power transmission device, and the power transmission device 1 includes figure 1 The two parts that rotate in the direction of the arrow in (A), that is, the pulley 2 as the driving body that receives the driving force from the engine; Hub body 3 on the end of the main shaft 4 of the compressor. These pulleys 2 and the hub body 3 are connected by the connecting portion 7, and the torque of the pulley 2 as the driving body is transmitted to the hub body 3 as the driven body, and when the driving load of the driven body exceeds a predetermined value, As will be described later, the transmission of torque is interrupted by fracture of the constituent members of the connection portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com