Patents

Literature

32results about How to "Suppress abnormal sounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

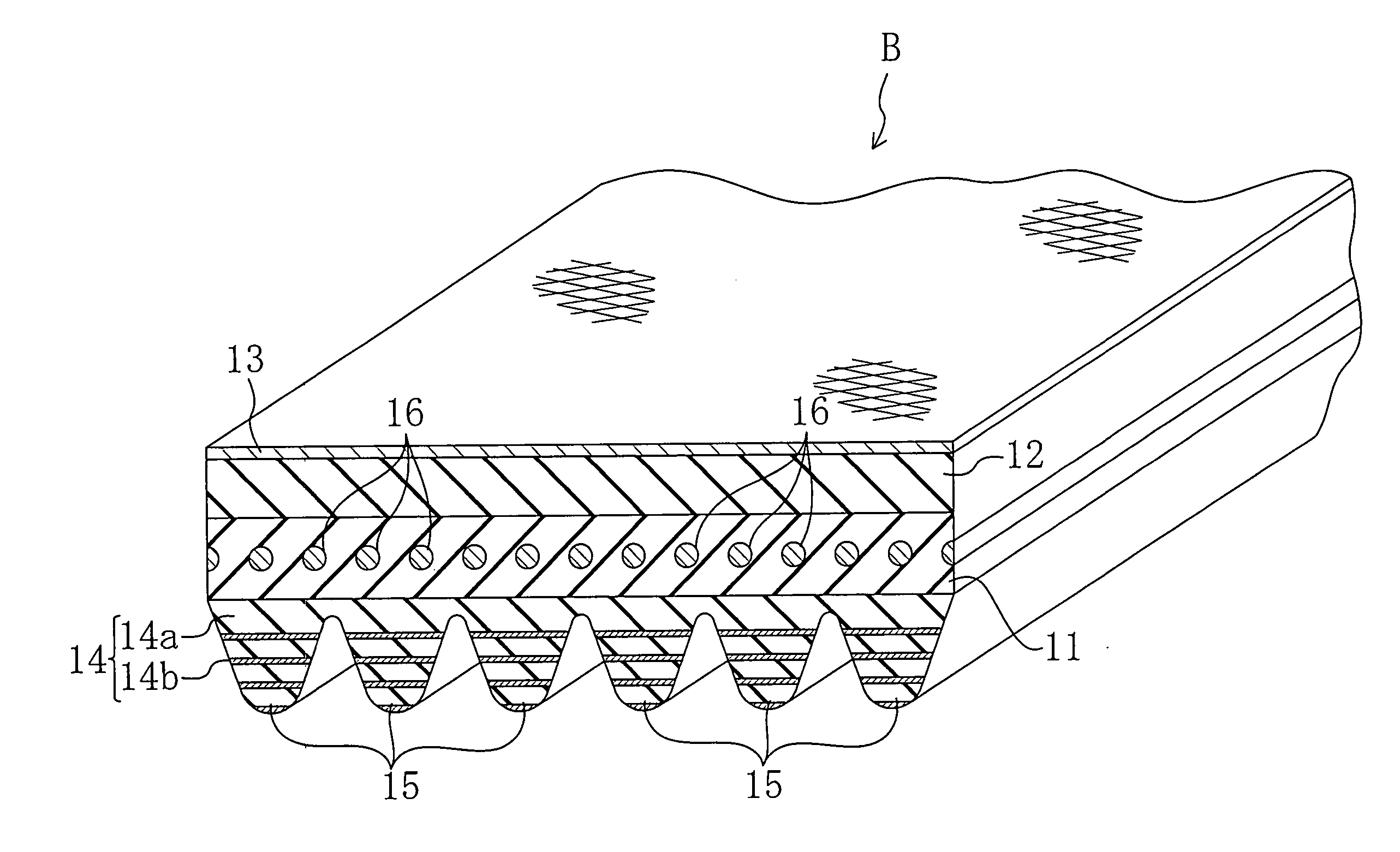

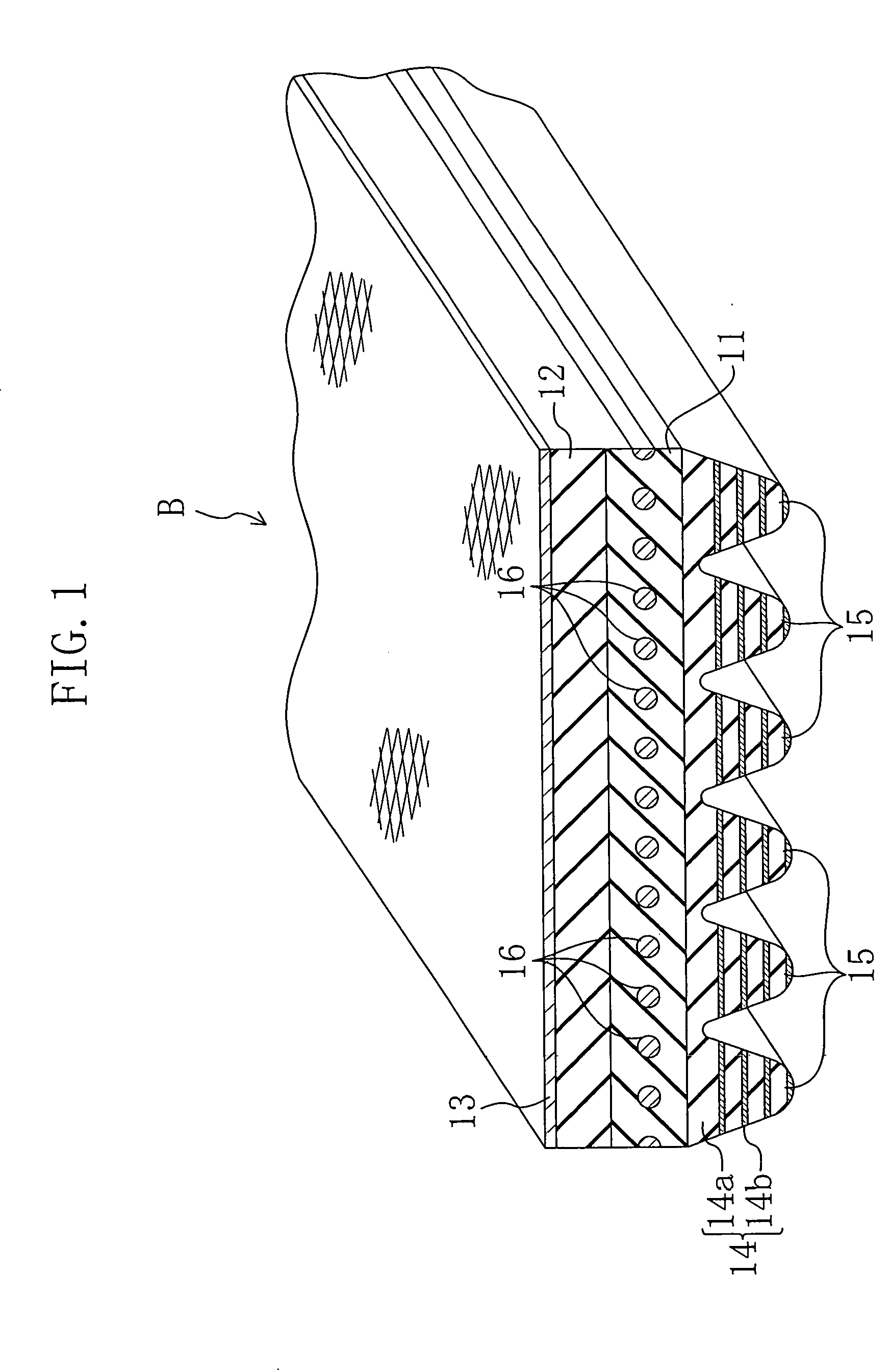

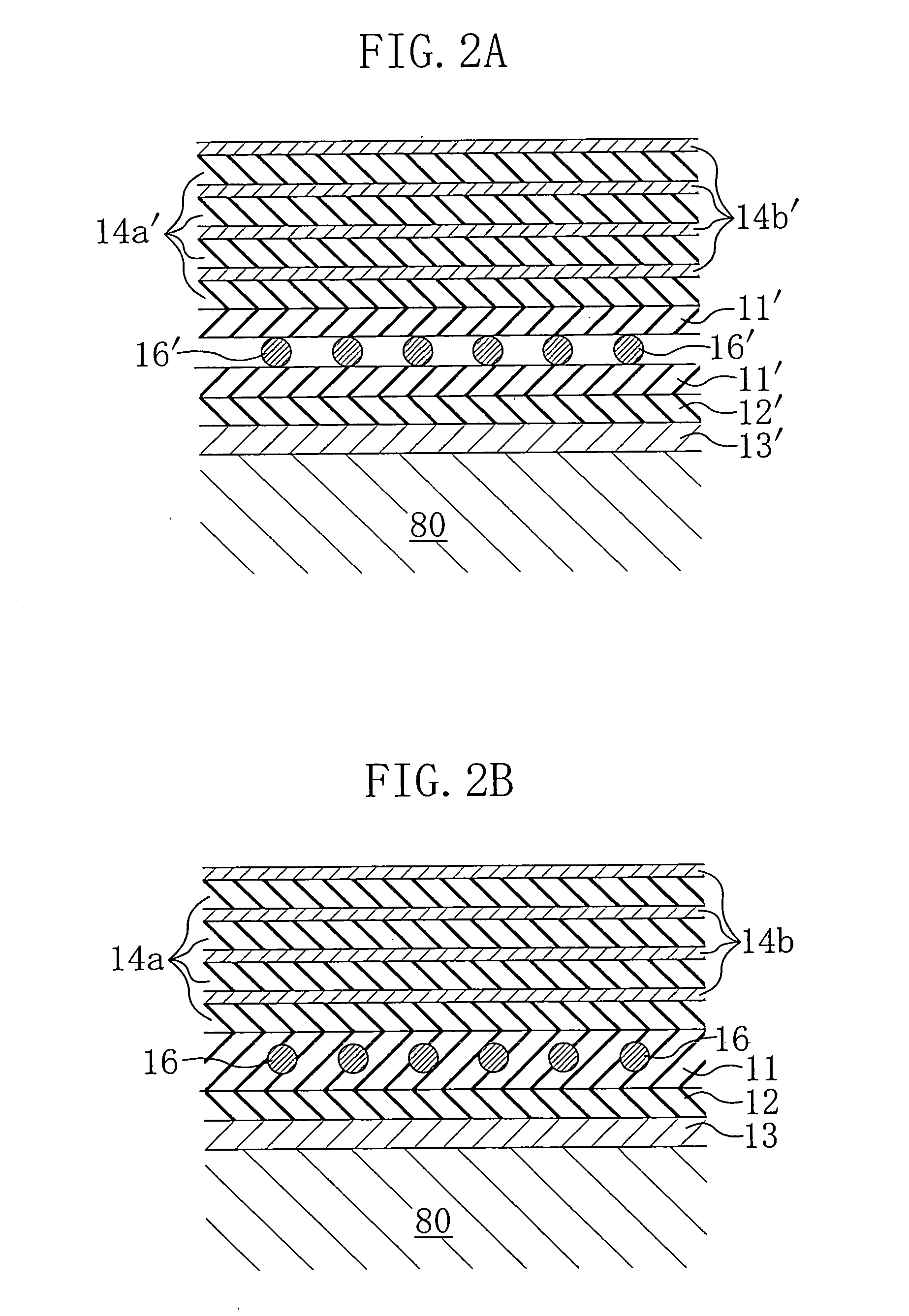

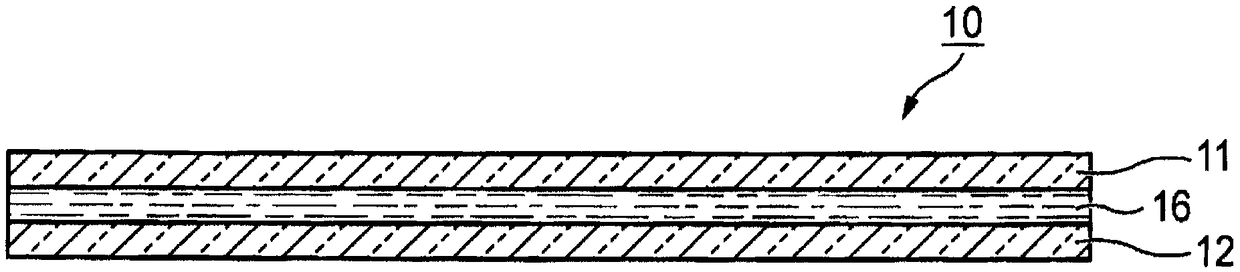

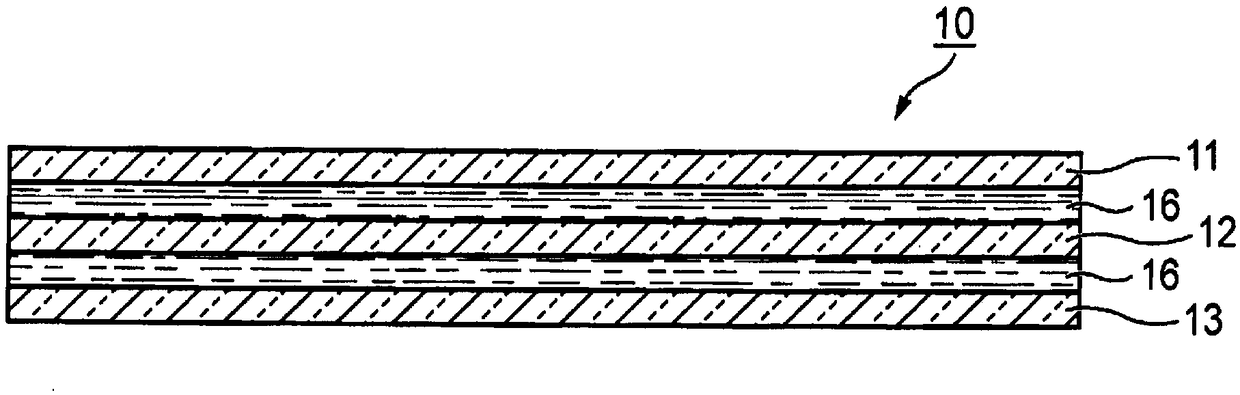

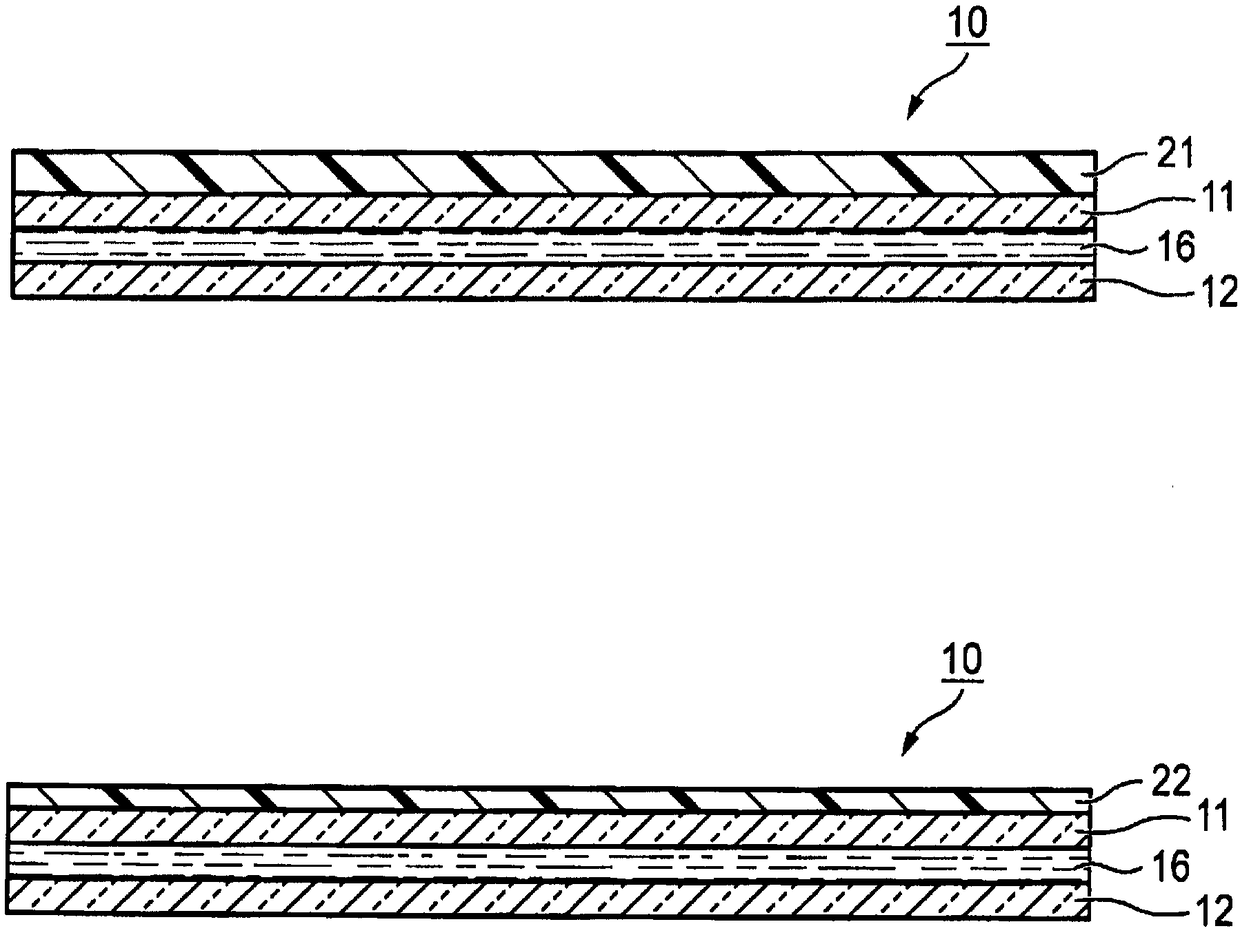

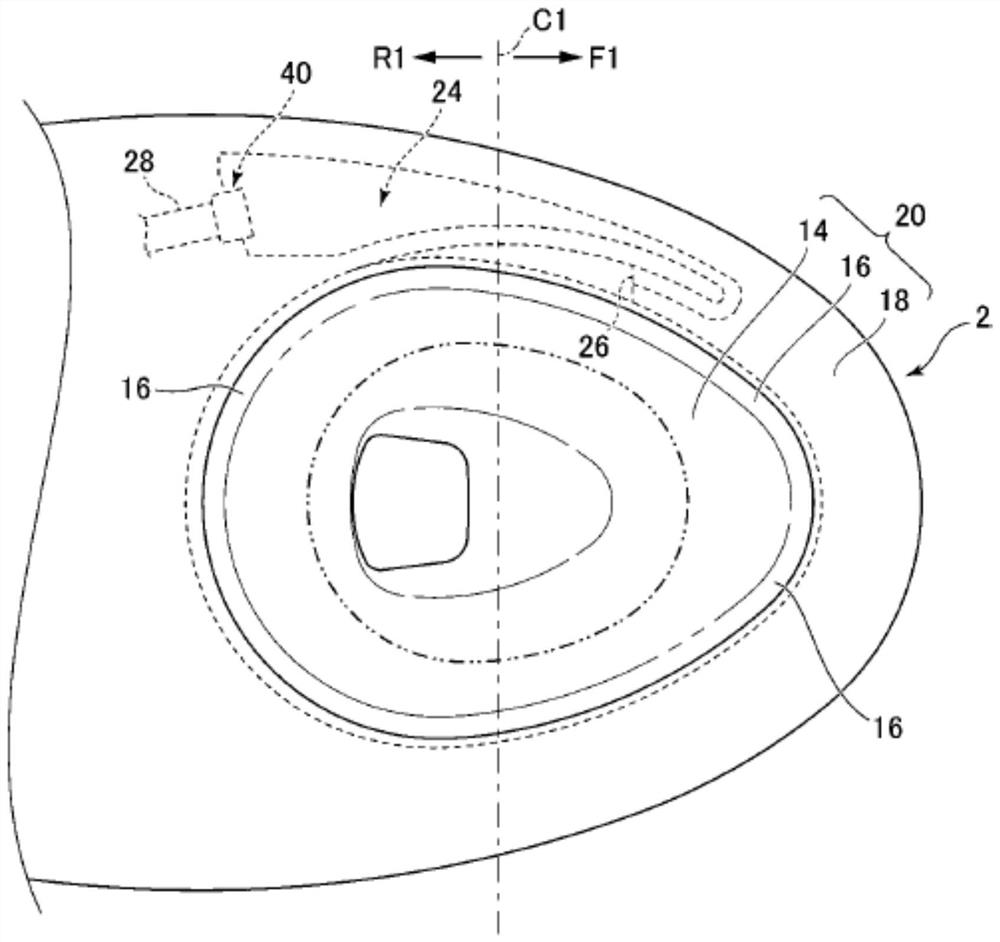

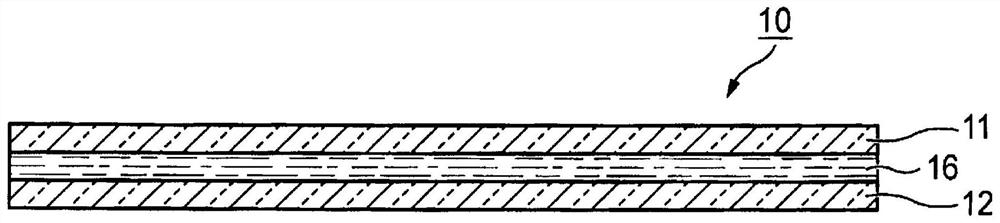

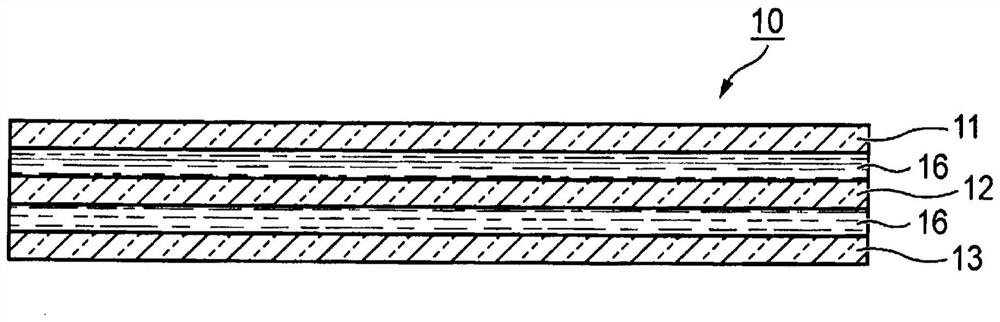

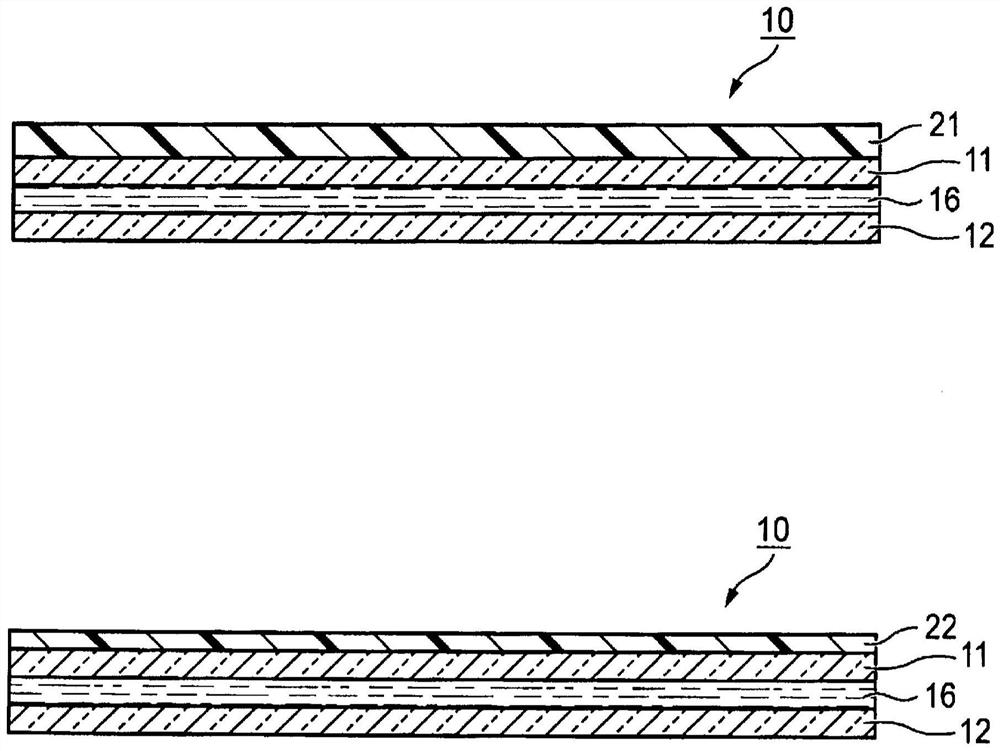

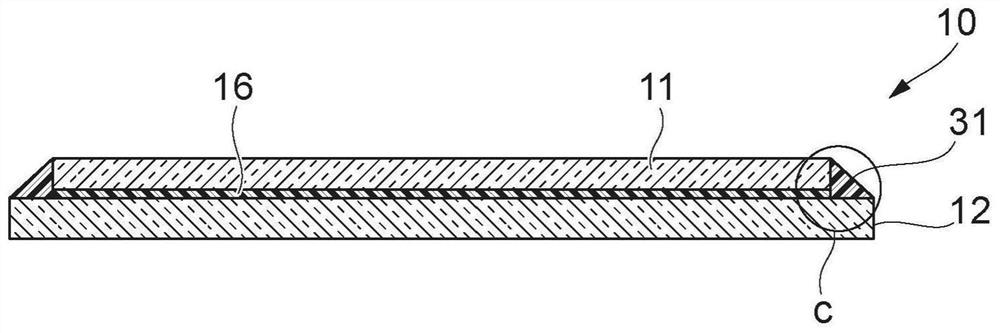

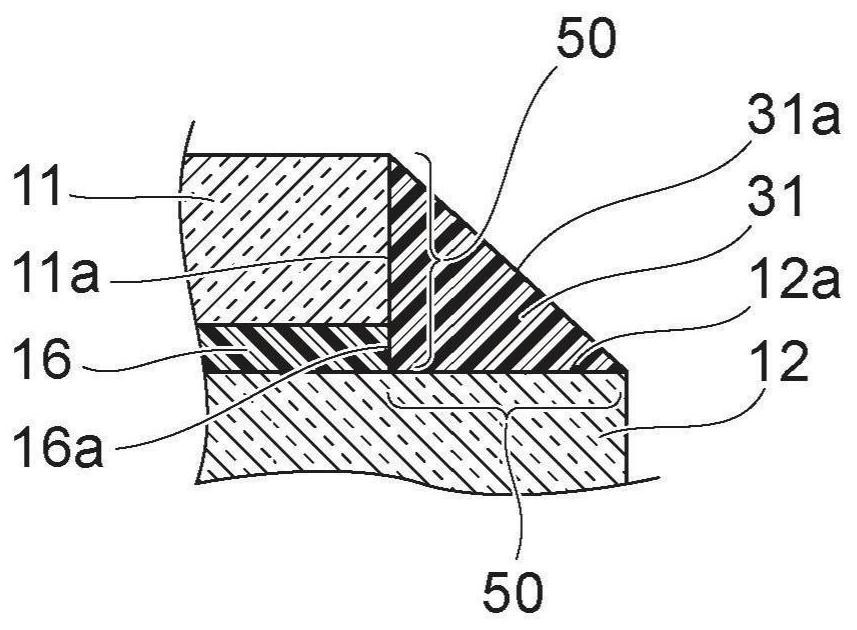

Friction drive belt and method for fabricating the same

InactiveUS20050143209A1Reduce coefficient of frictionIncrease the itineraryV-beltsRopes and cables for vehicles/pulleyTransmitted powerConveyor belt

A friction drive belt is used by being wrapped around a plurality of pulleys and transmits power by friction between its belt body and each of the pulleys. The working part of the belt body has a structure in which rubber layers and non-woven fabric layers are alternately stacked along the thickness of the belt.

Owner:BANDO CHEM IND LTD

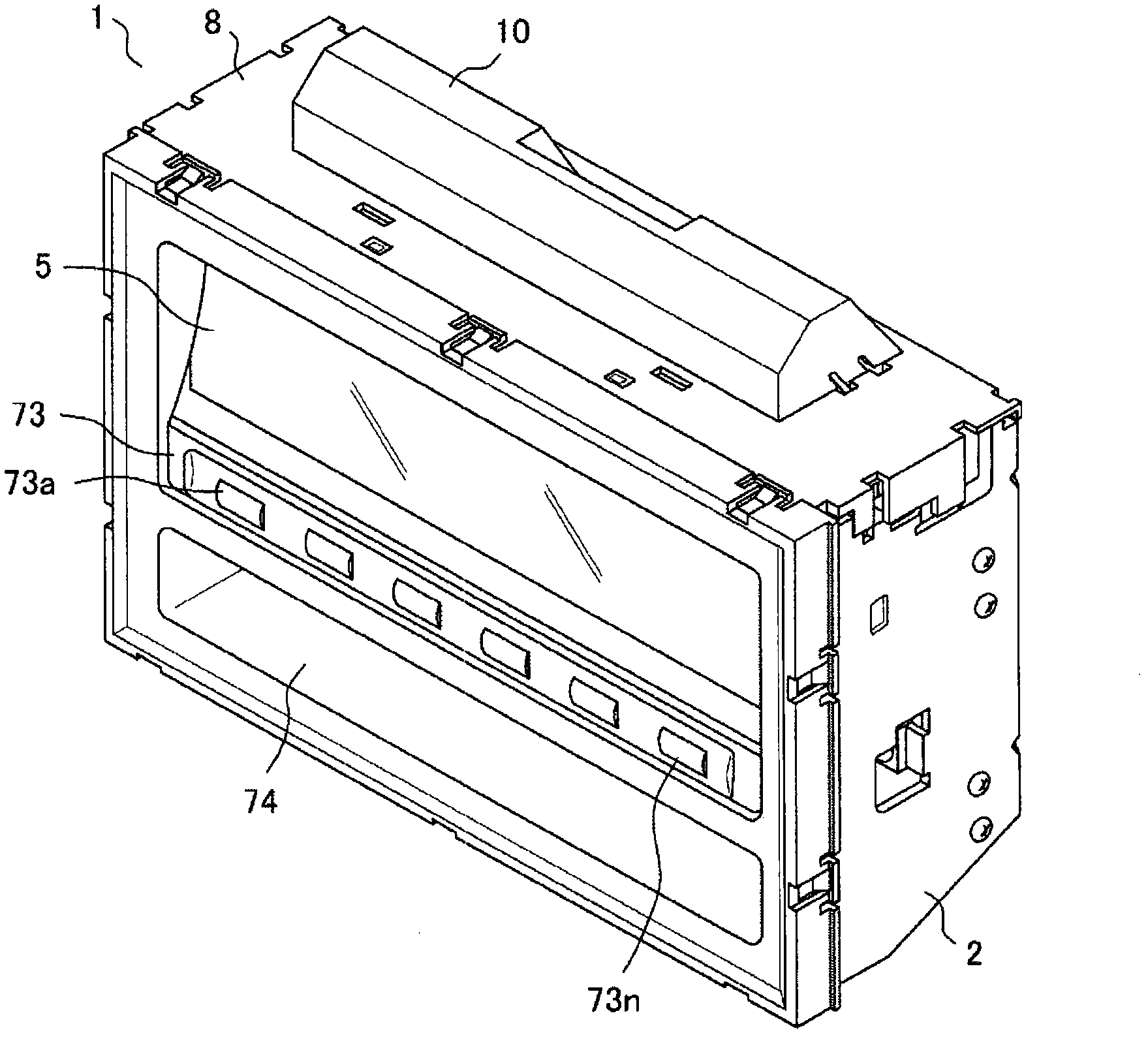

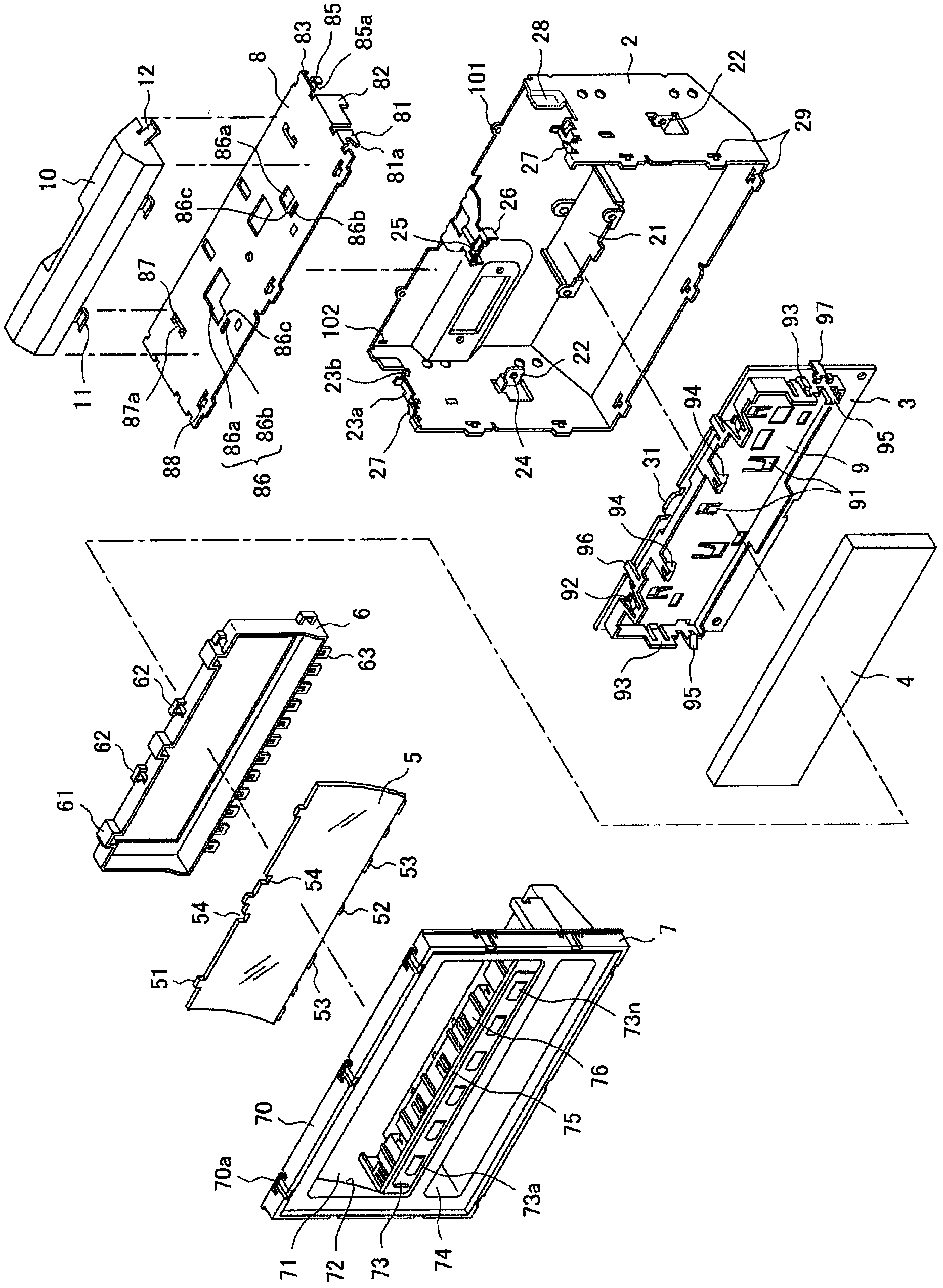

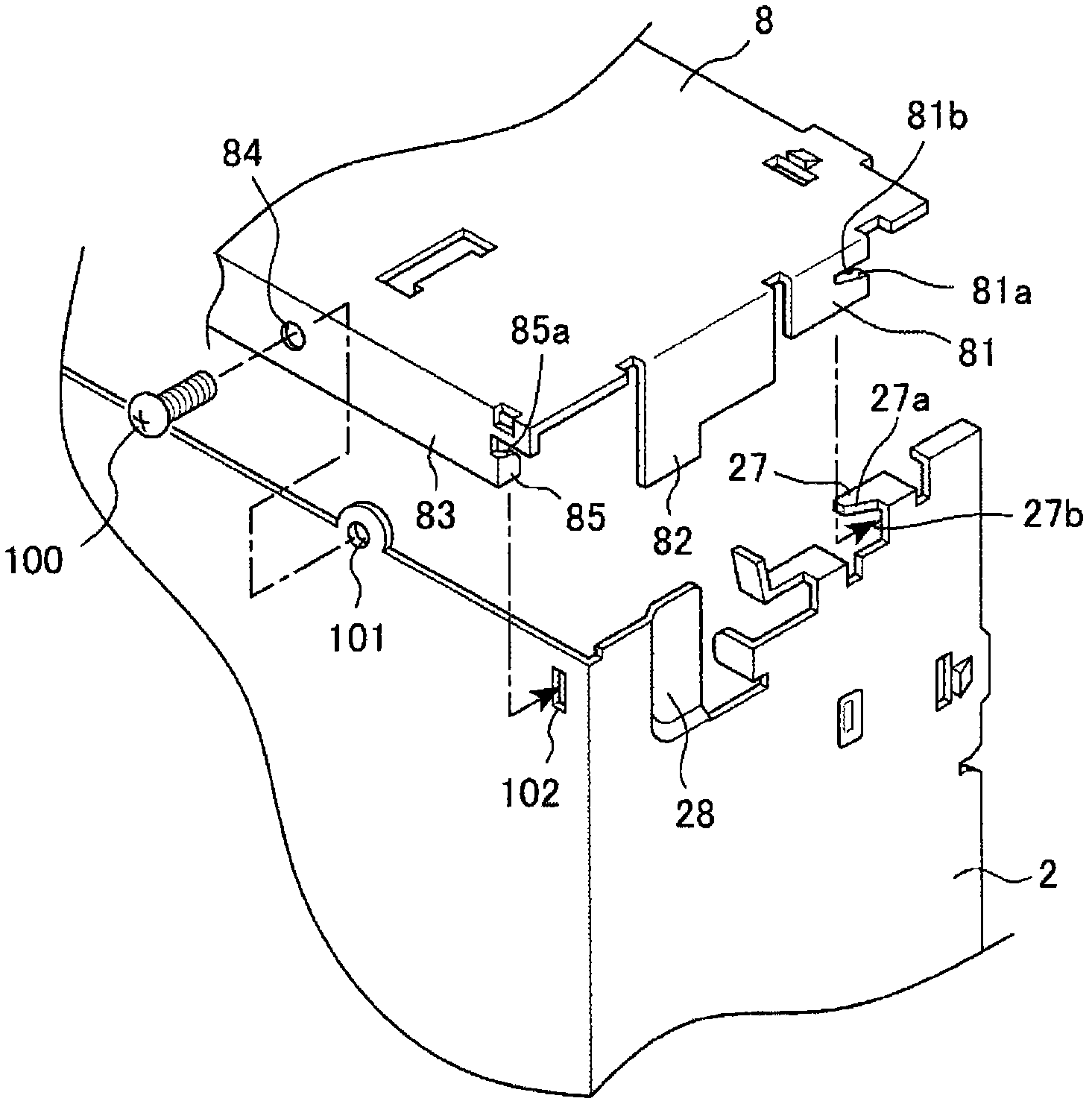

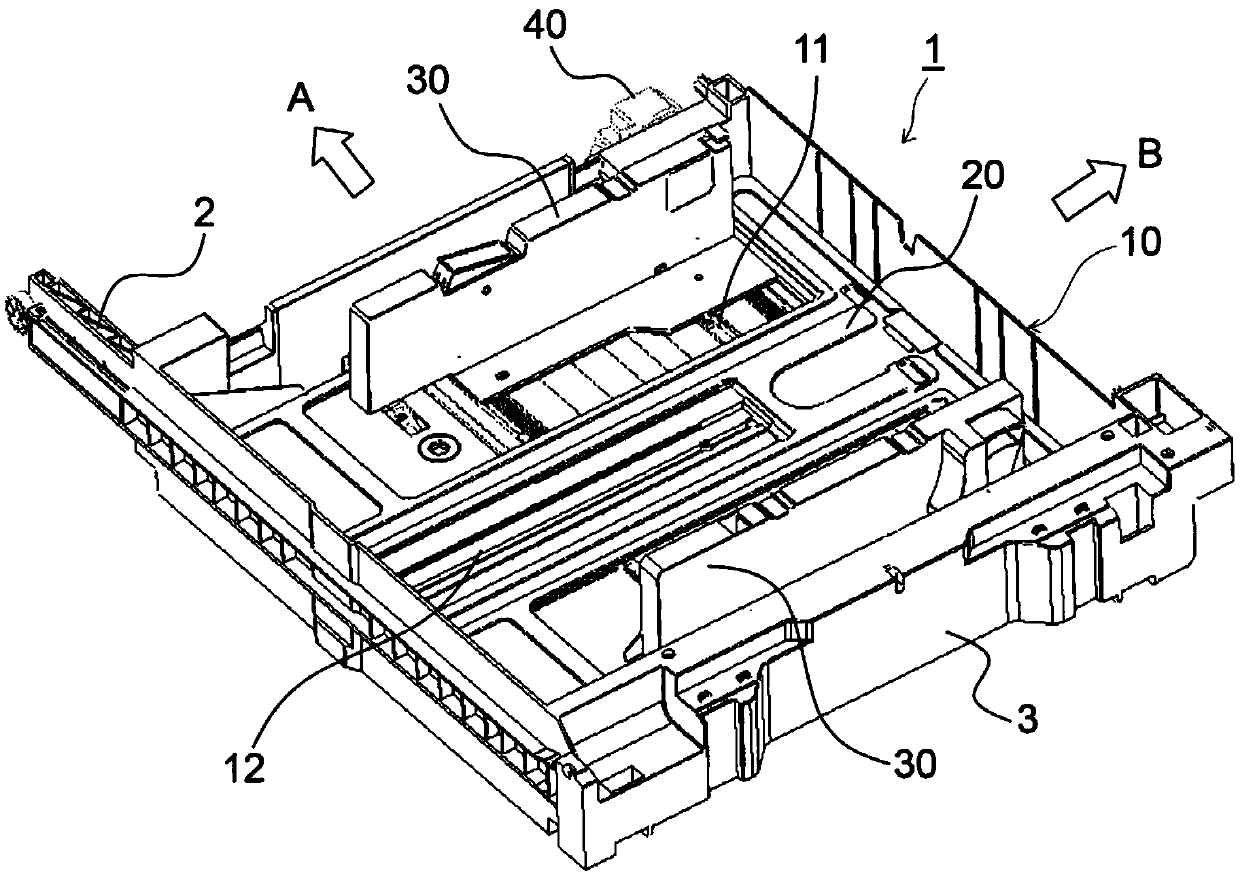

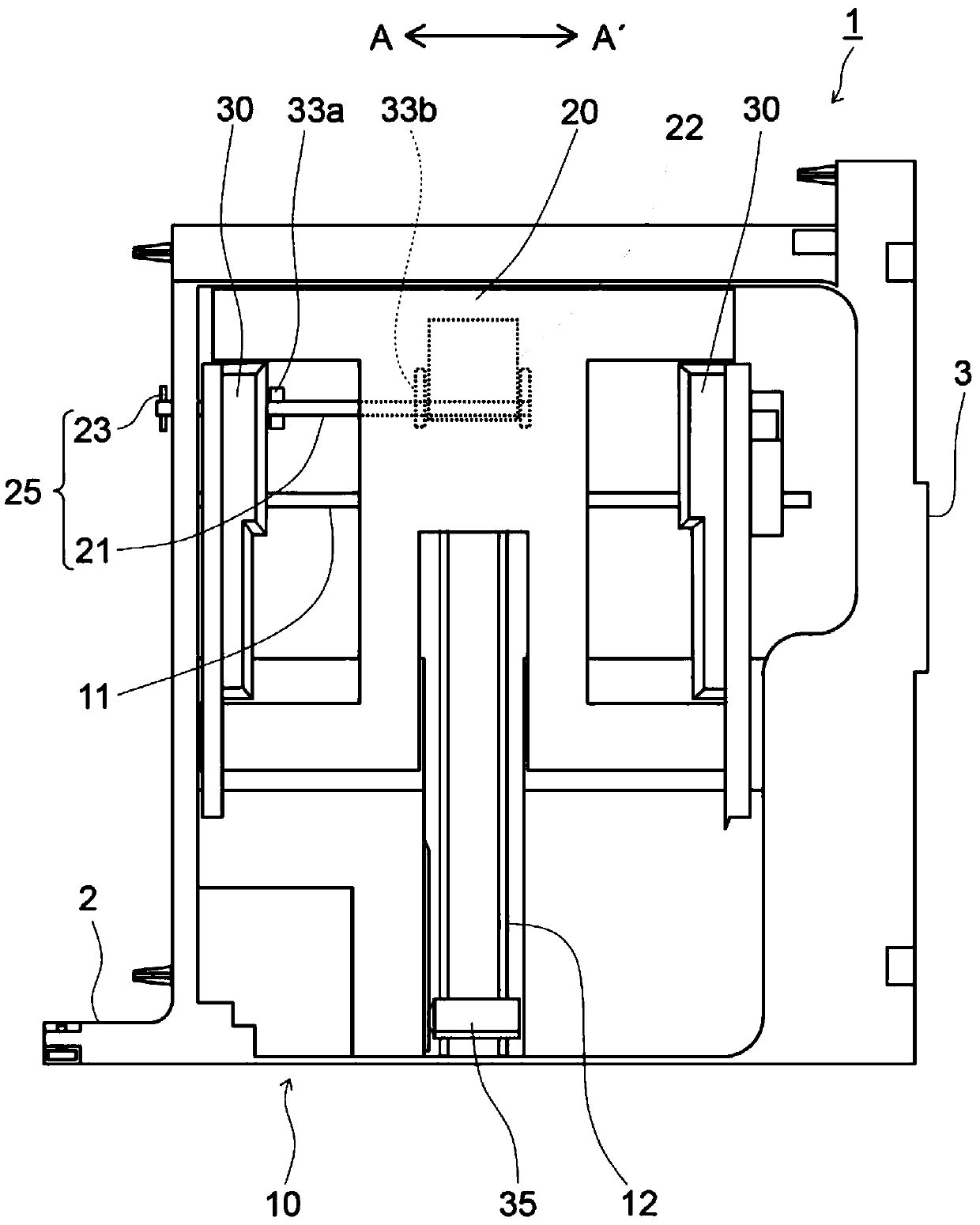

Structure for fastening metallic plate parts together

InactiveCN102342190AEasy to assembleImprove decomposition abilityClosed casingsMetal casingsHookingChassis

A chassis 2 as a first sheet-metal part has an L-shaped hooking section 27 formed at a cover mounting opening end of each side plate thereof, and an assembly guide section 28 dimpling inwardly the opening end of the chassis 2 by the thickness of a cover 8; the cover 8 as a second sheet-metal part has a hooking claw 81 extending from each side edge of the cover to the mounting side thereof and engaging with the L-shaped hooking section 27, and a guide lug 82 engaging with the assembly guide section 28, wherein an engaging claw 85 and an engaging hole 102, and a tapped hole 101 and a screw passing-through hole 84 are relatively provided on the abutment faces between the chassis 2 and the cover 8, respectively.

Owner:MITSUBISHI ELECTRIC CORP

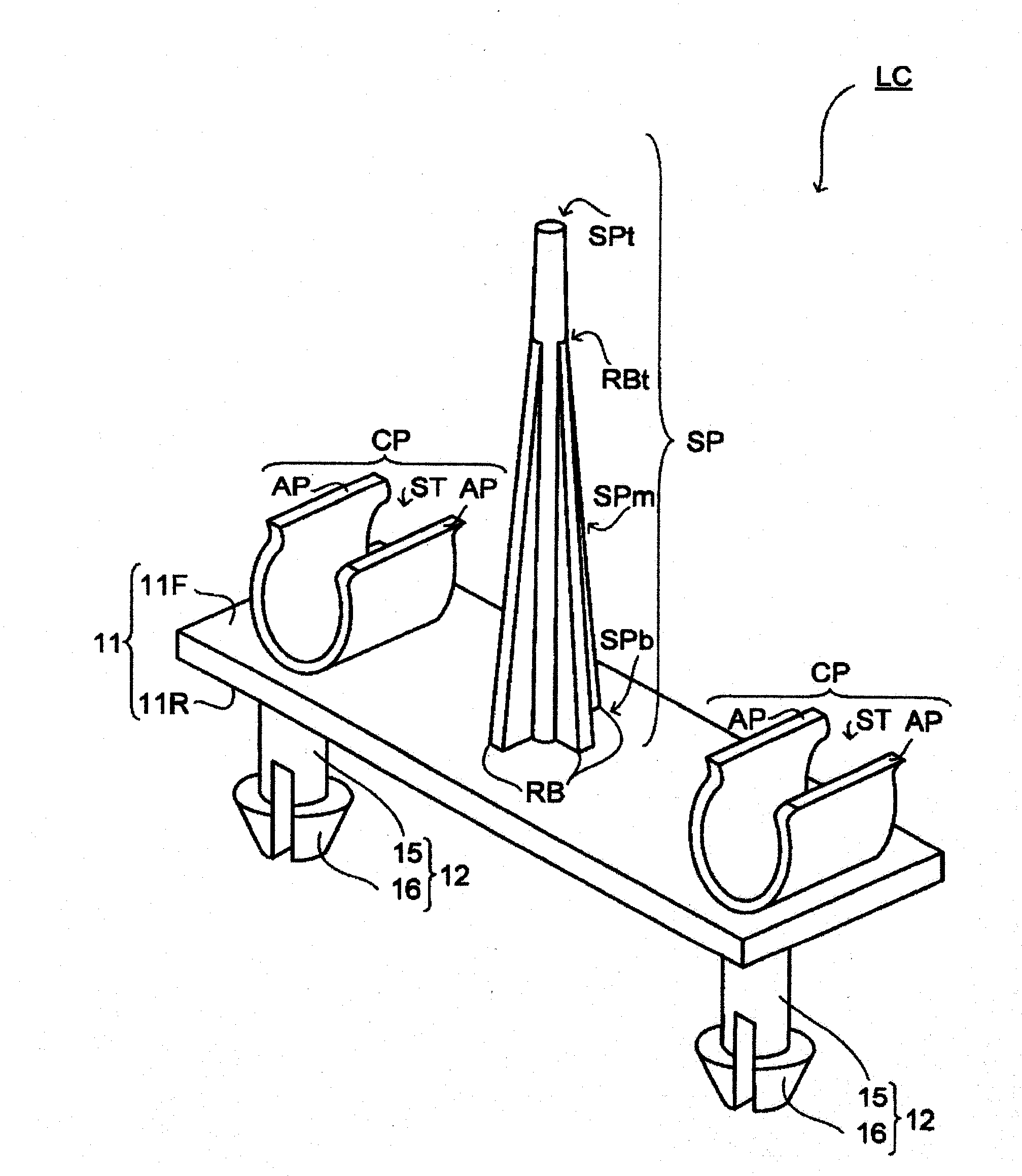

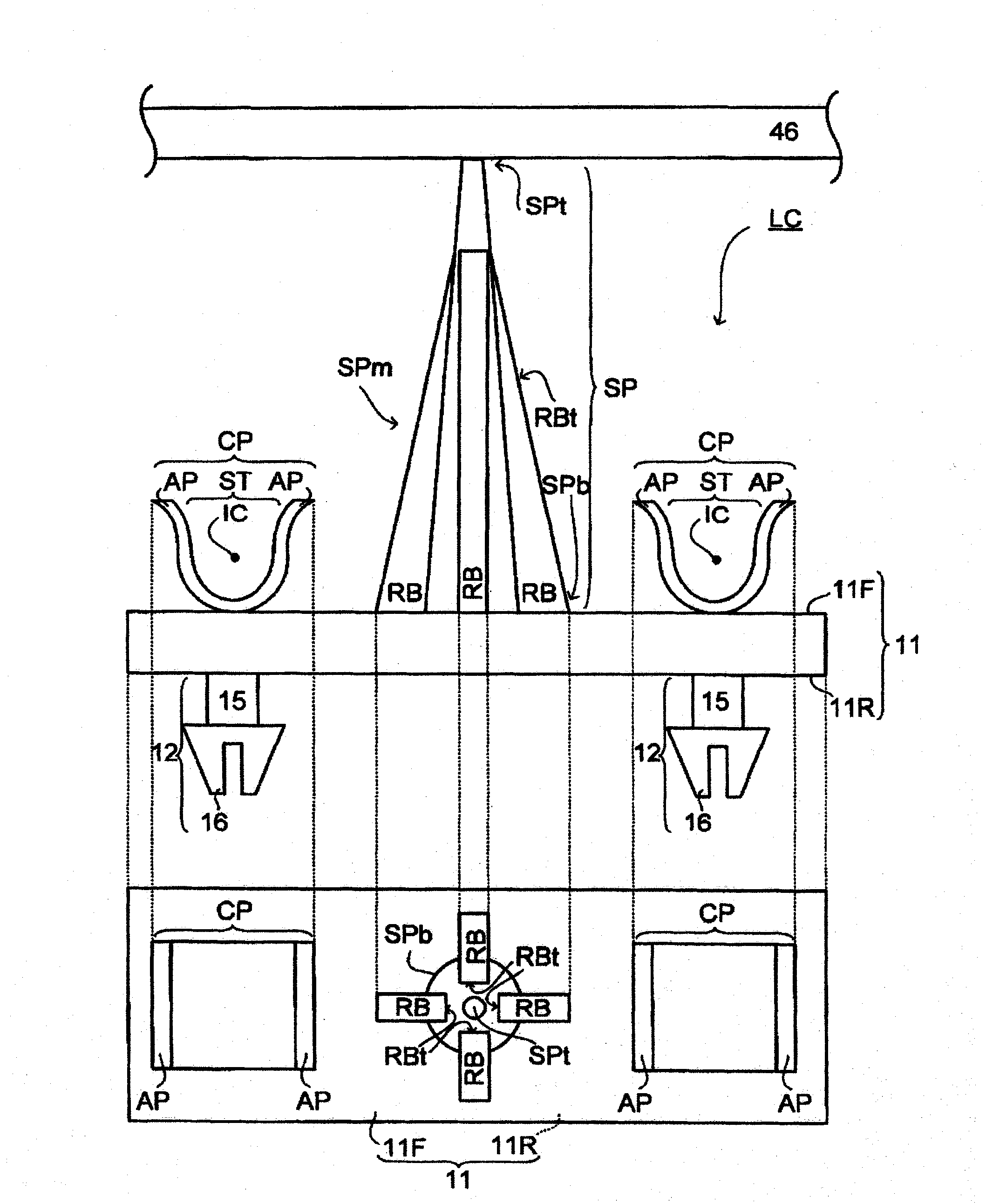

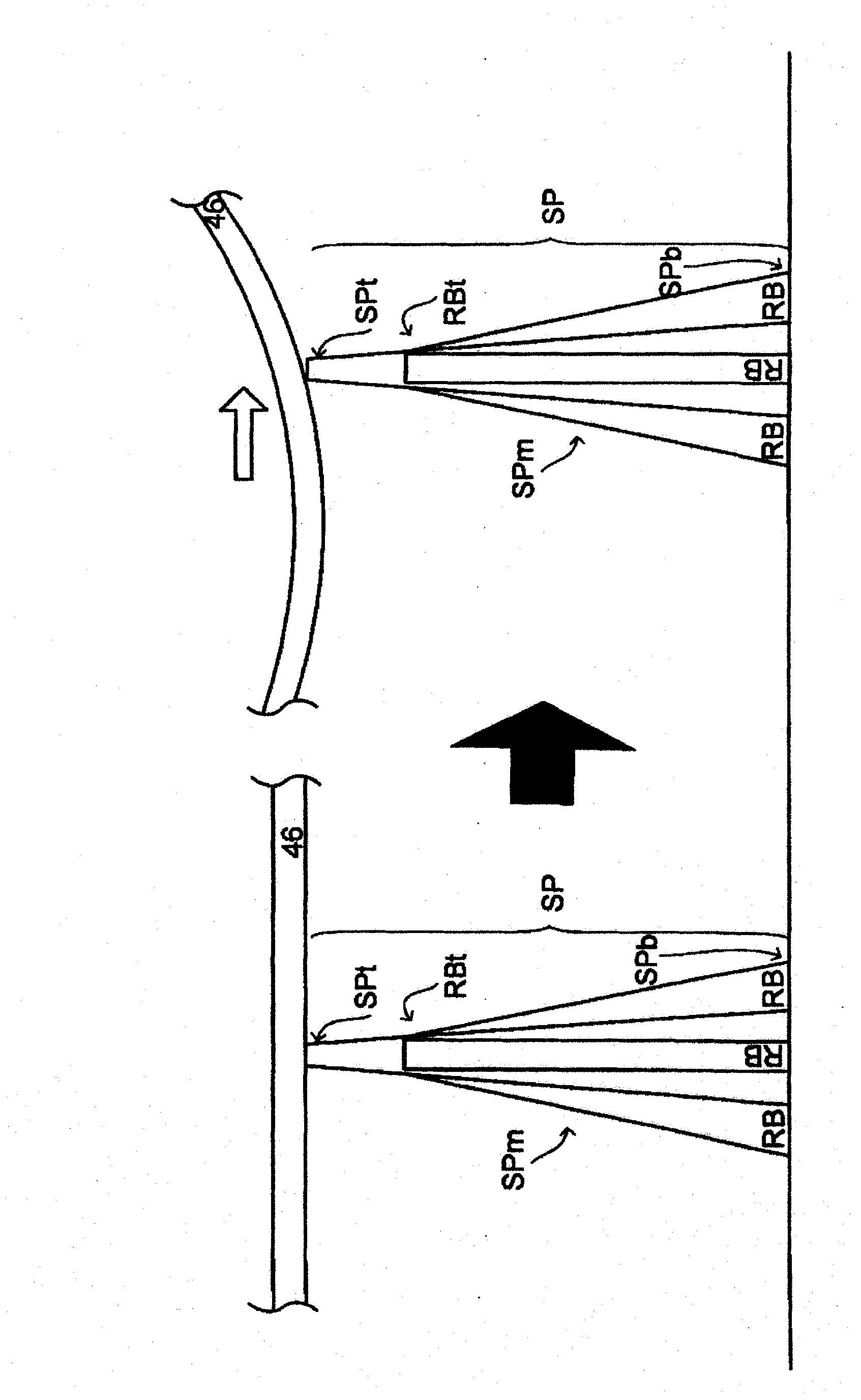

Support unit, lighting device, and display device

InactiveCN102159883AHigh strengthBending will notElongate light sourcesElectric lightingDisplay deviceEngineering

The invention provides a support unit, a lighting device and a display device. A lamp clip (LC) includes a support pin (SP) making contact with and supporting an optical sheet such as a diffusion plate (46), and also includes ribs (RB) rising from the outer periphery of the support pin (SP) and reinforcing the support pin (SP).

Owner:SHARP KK

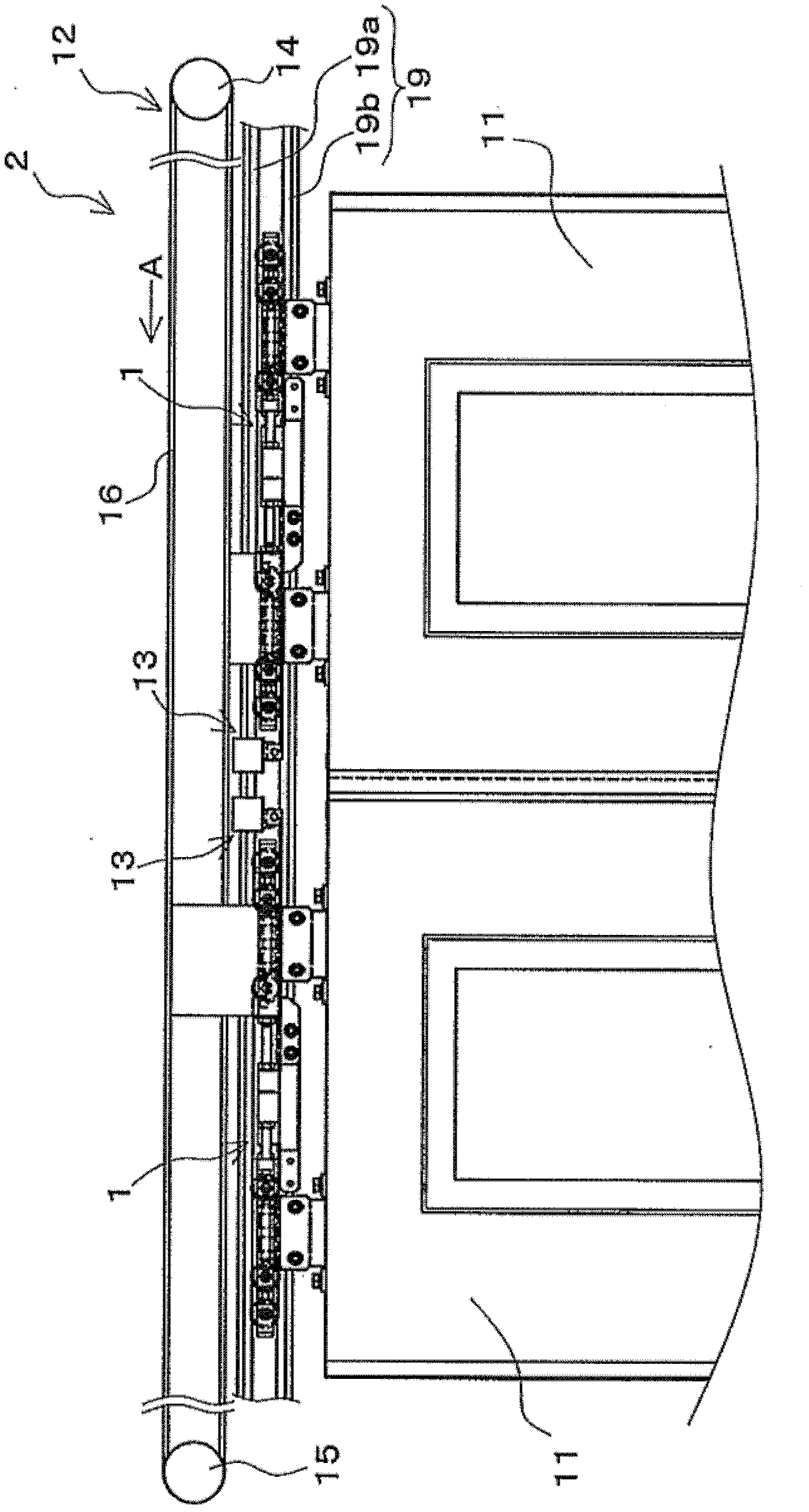

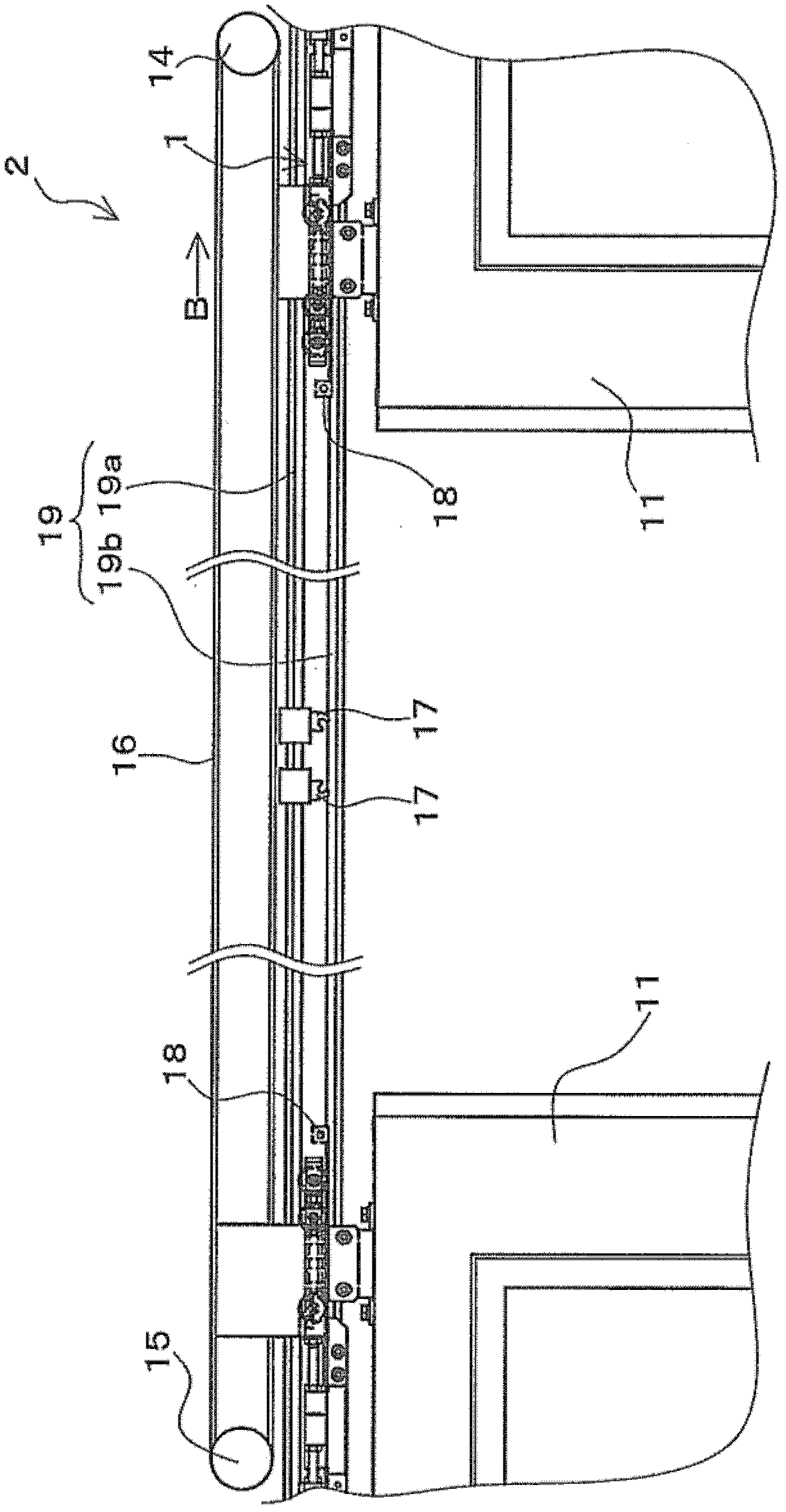

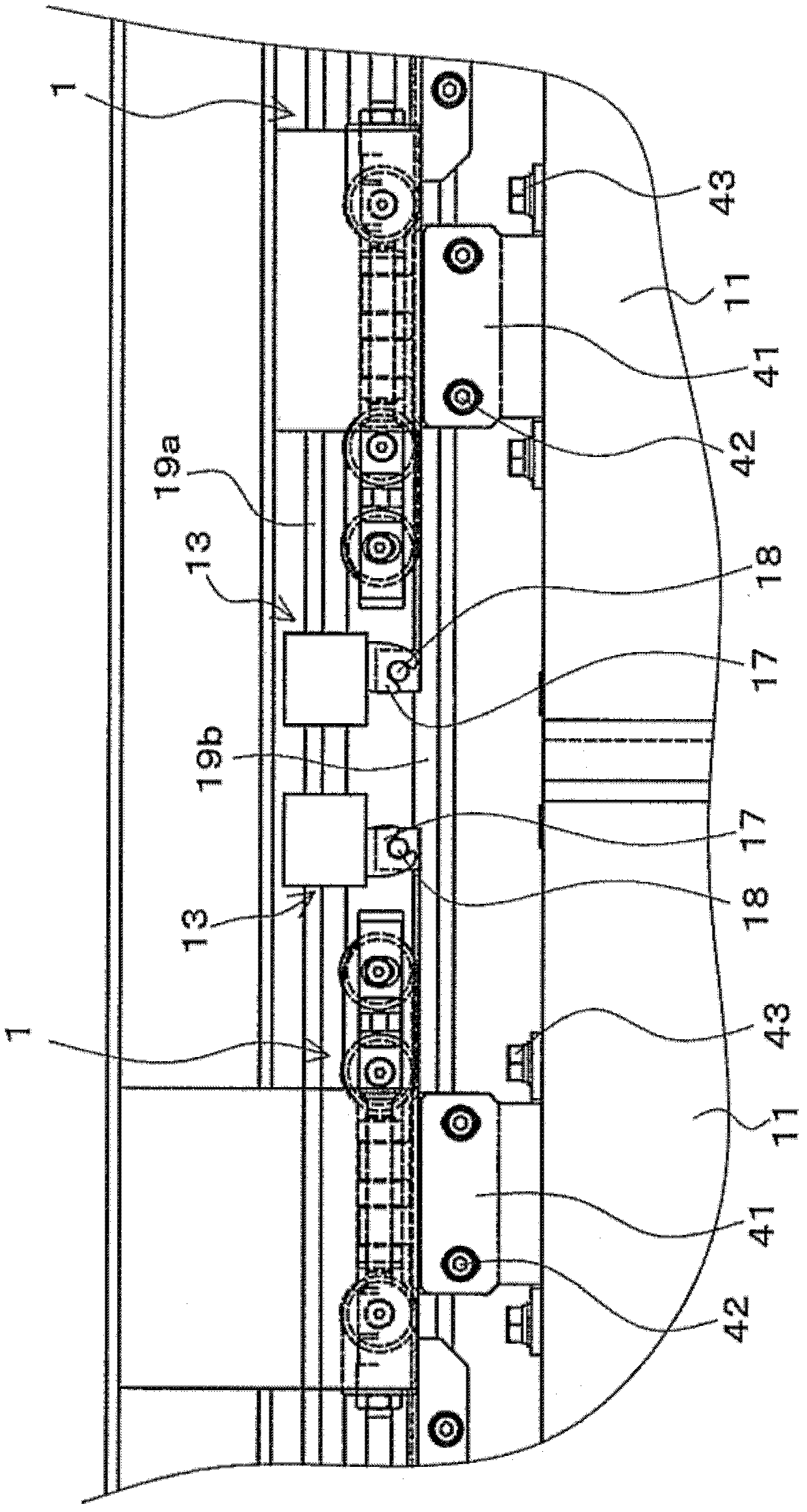

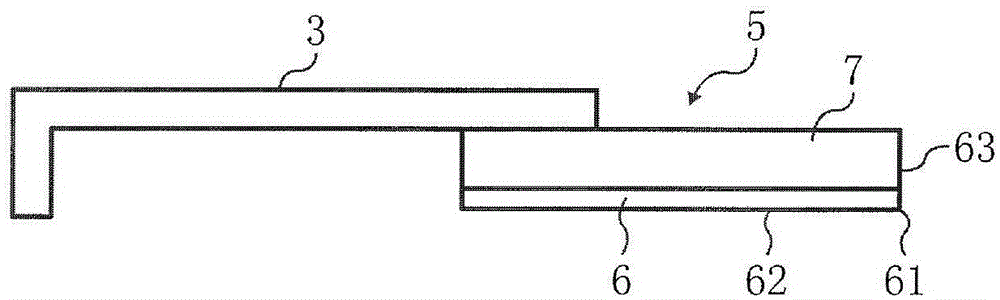

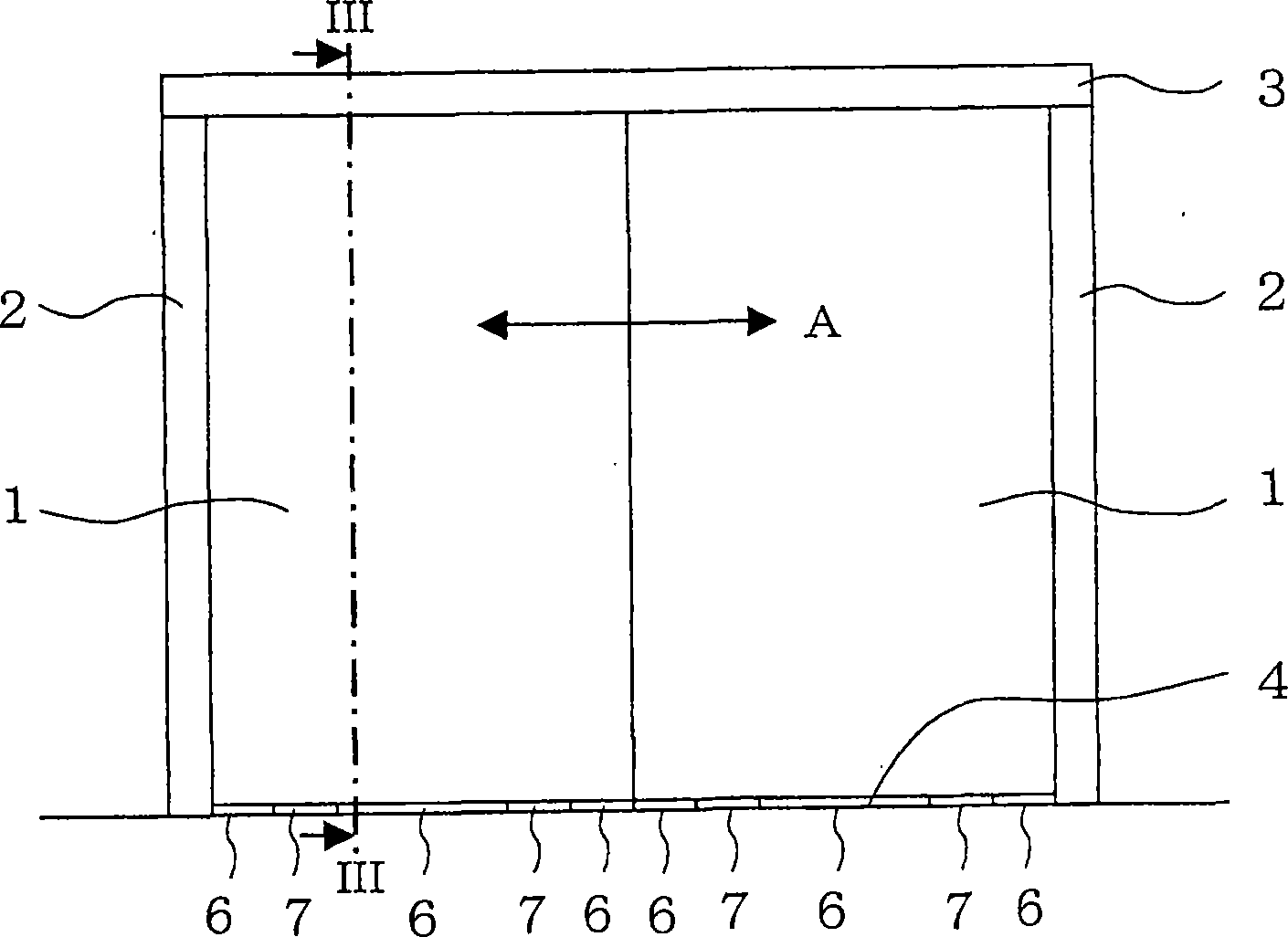

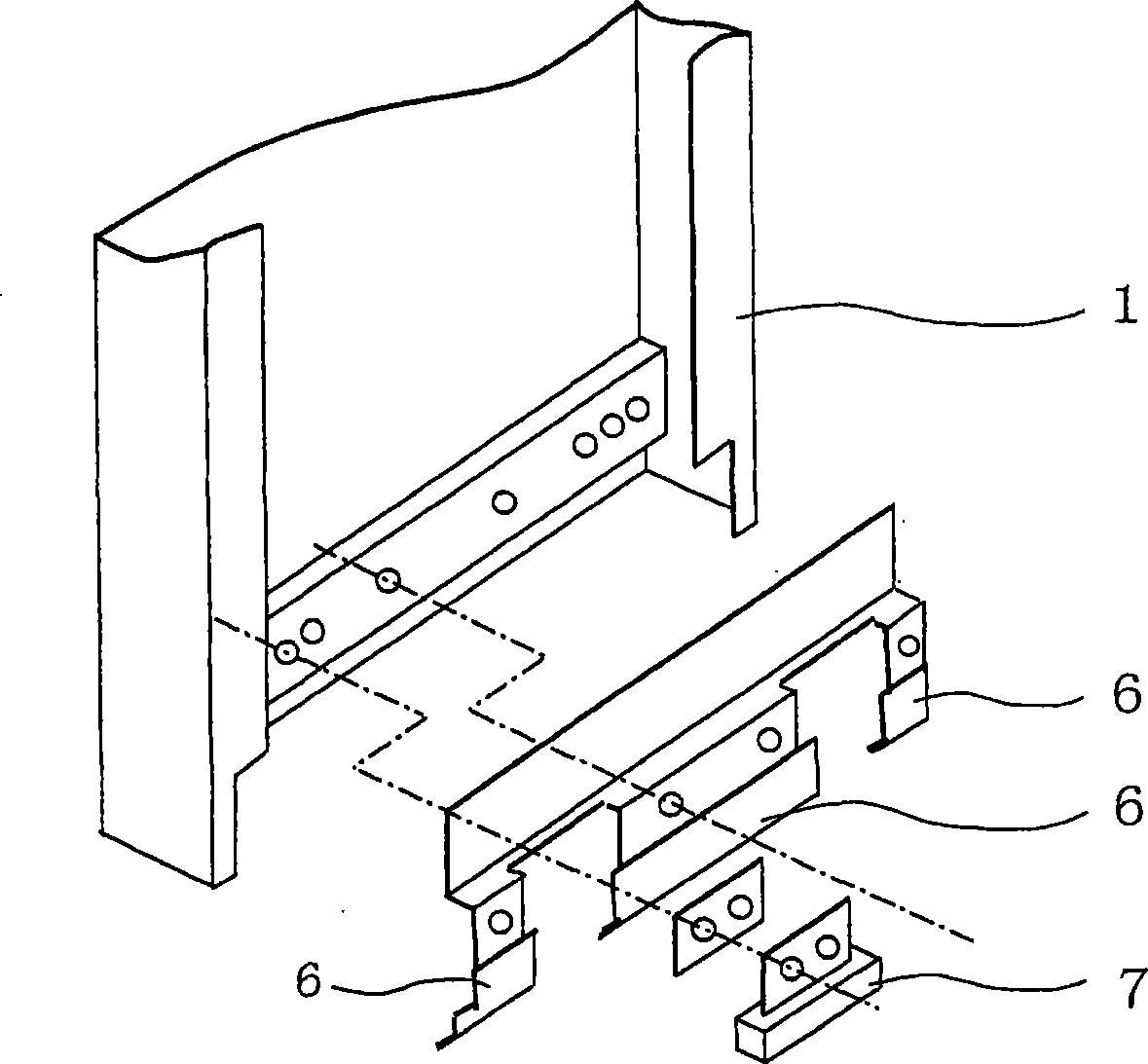

Door suspension apparatus and door apparatus equipped with the same

ActiveCN102482910ASave man hoursShorten working timeVehicle locksMan-operated mechanismEngineeringMechanical engineering

Owner:NABLESCO CORP

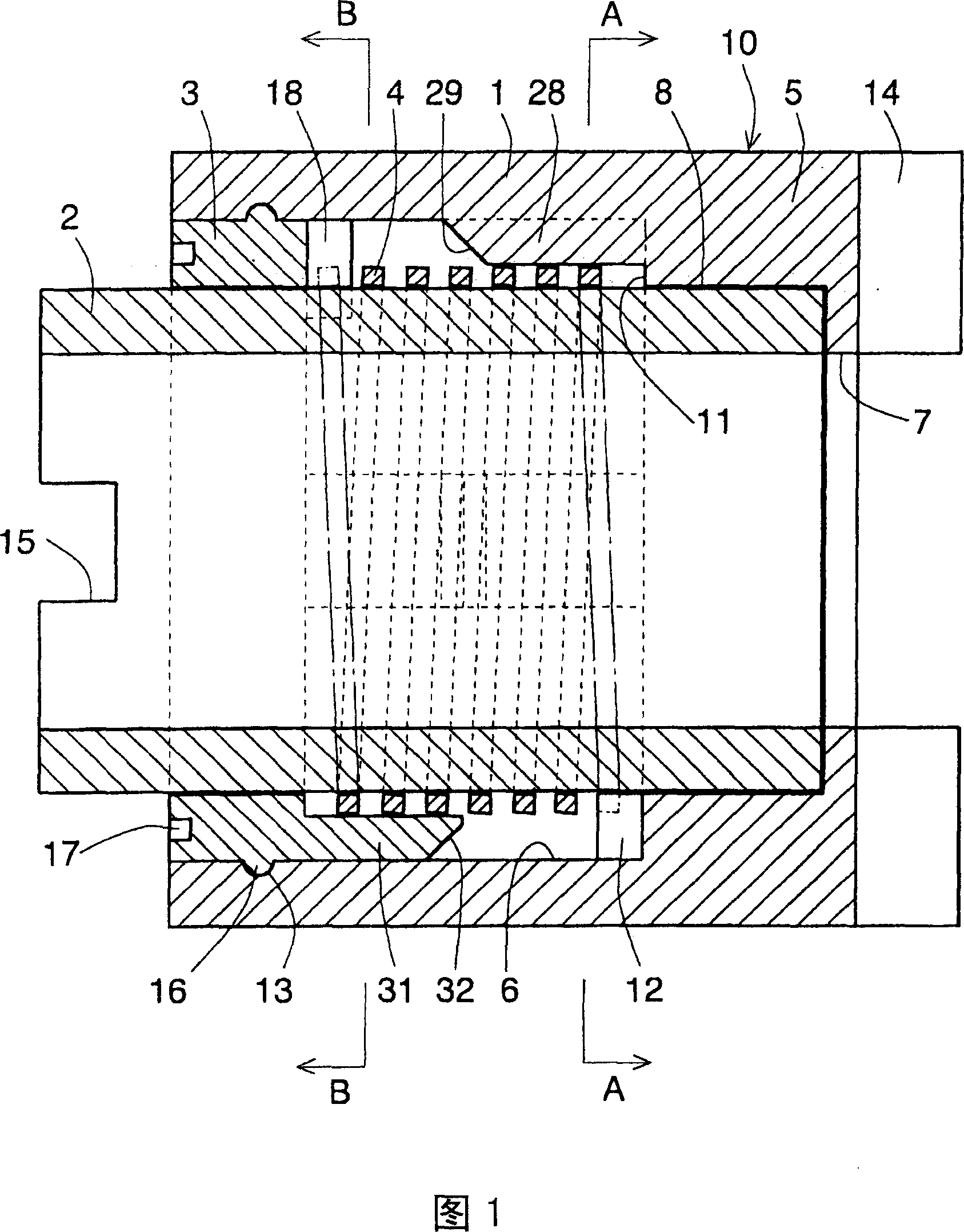

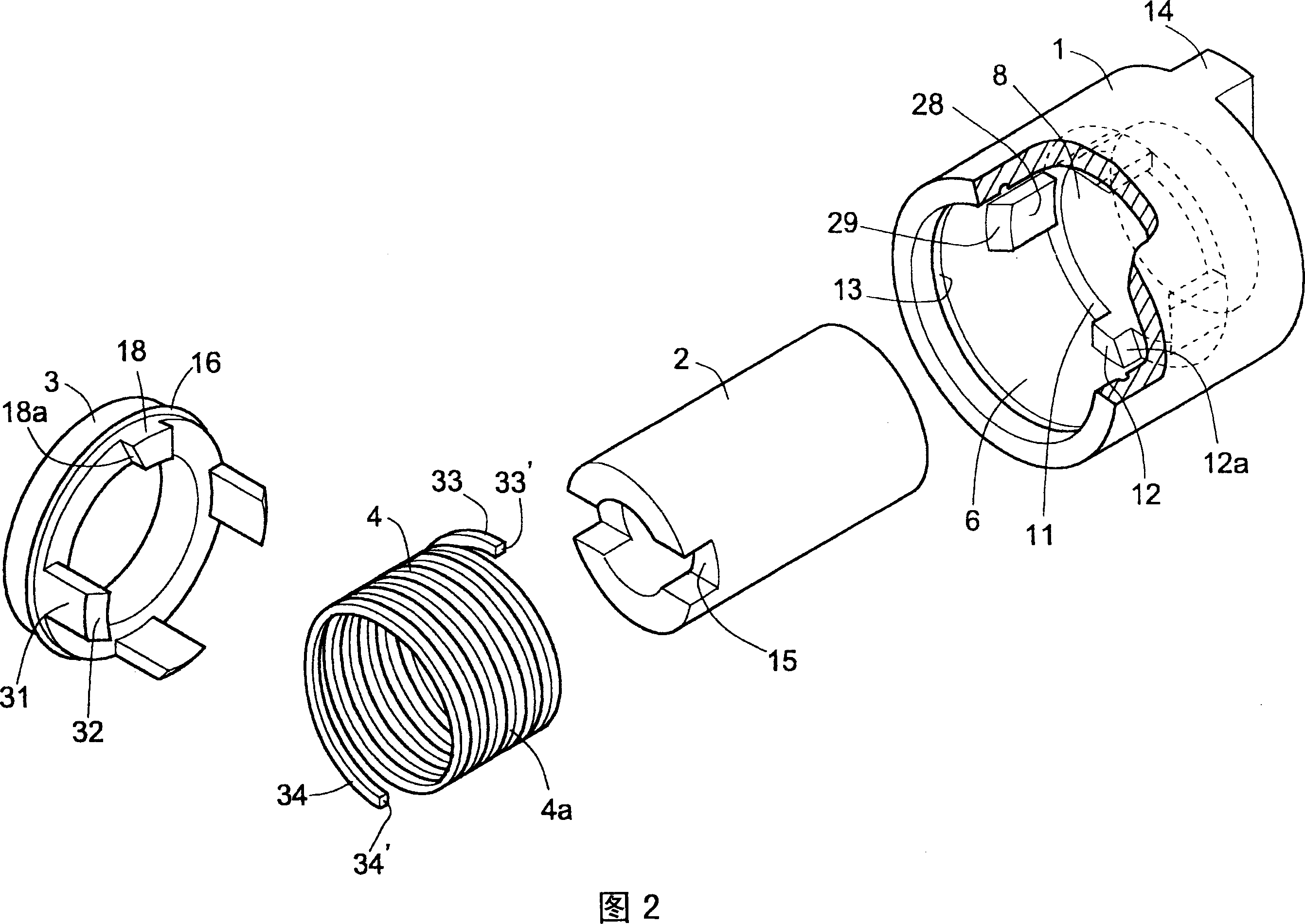

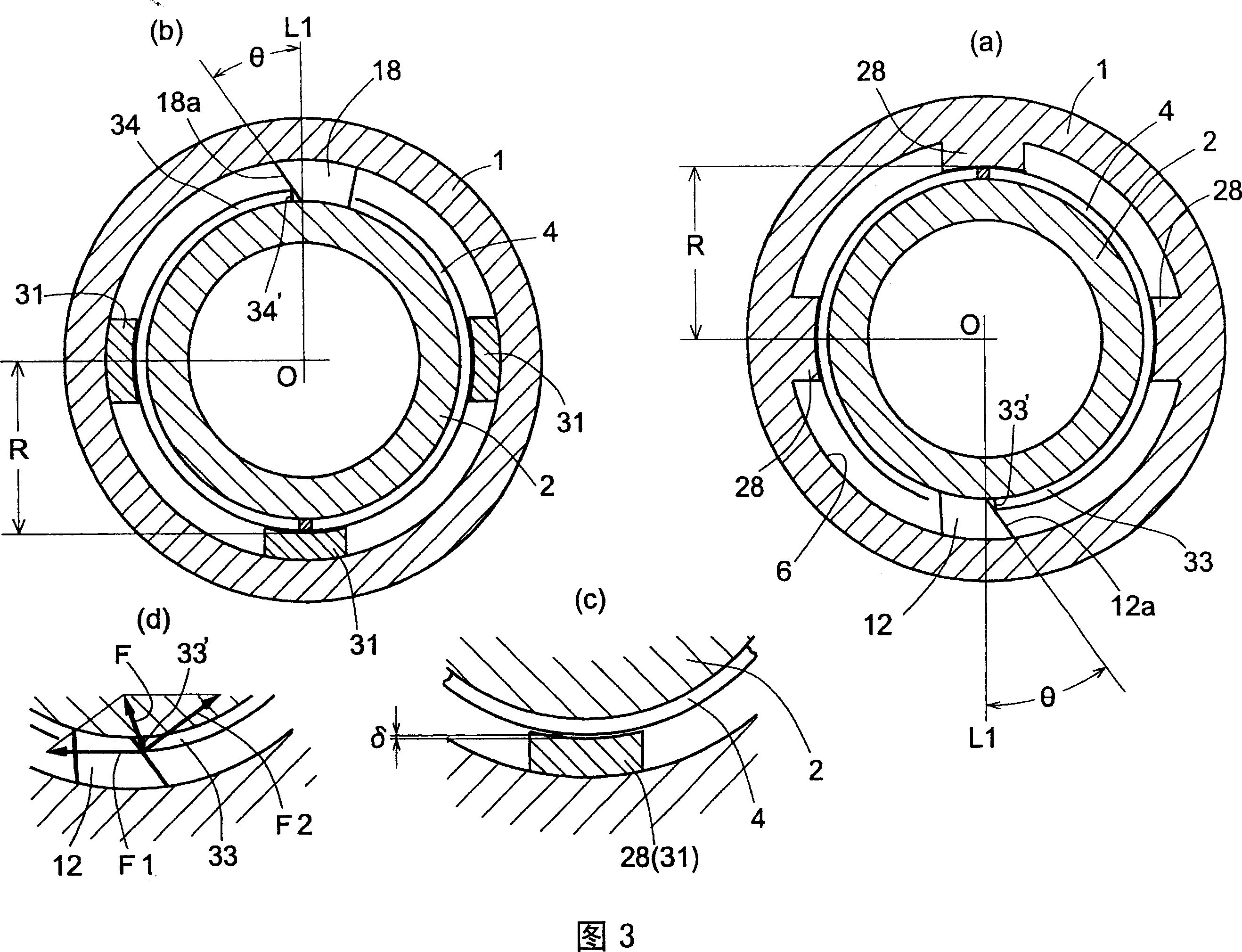

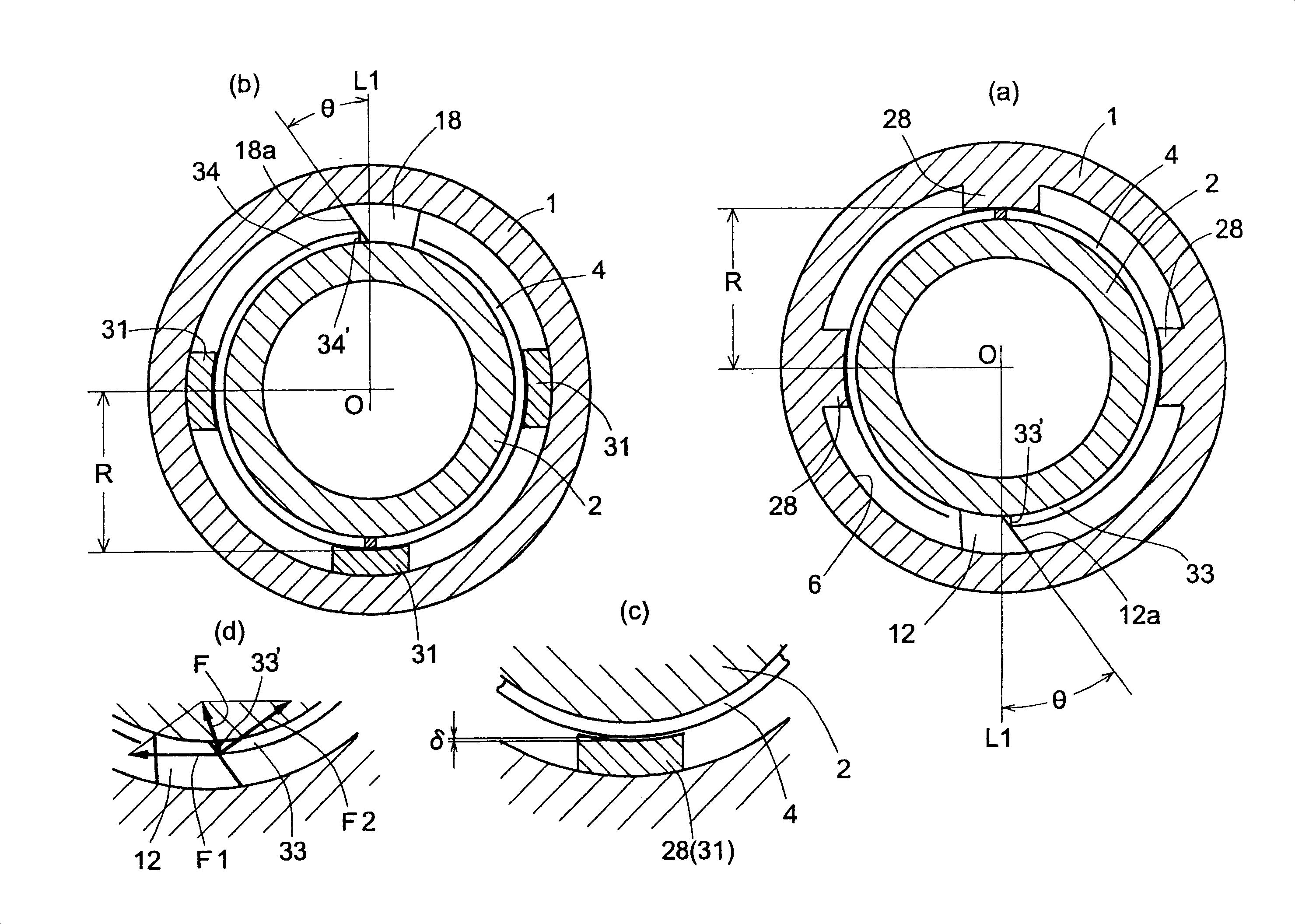

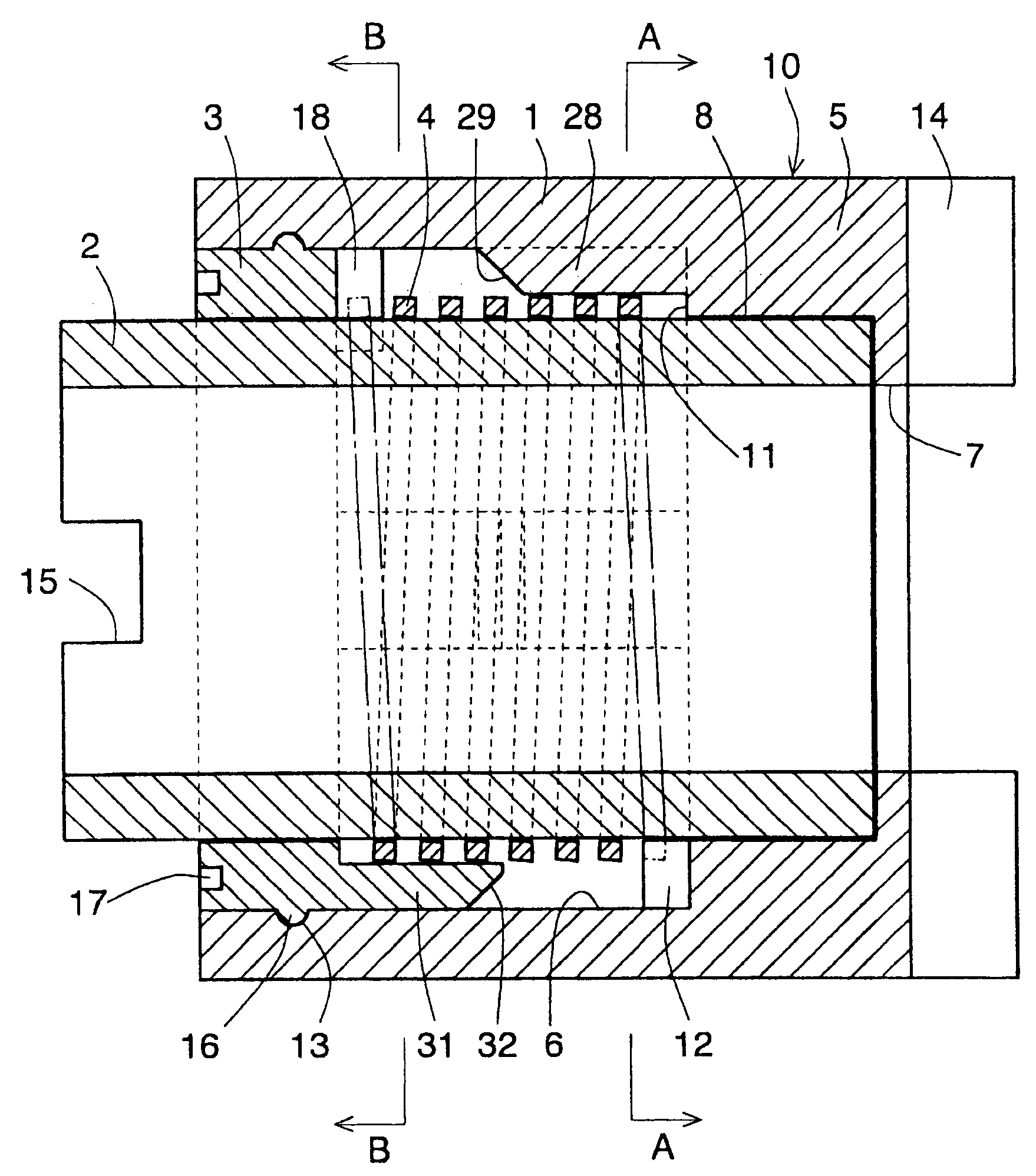

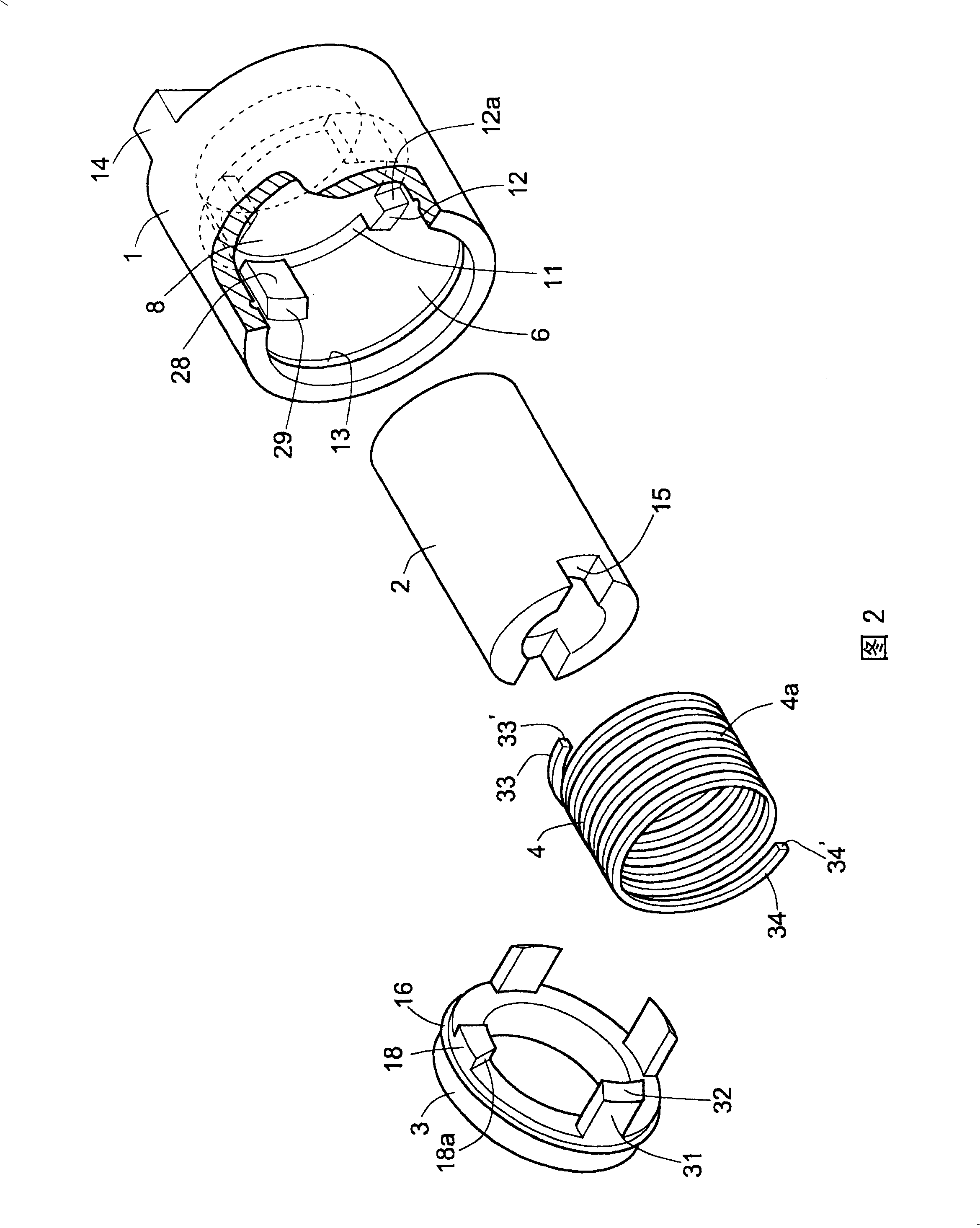

Torque restrictor

The present invention provides a spring-type torque limiter, which prevents vibration and abnormal sound during use by increasing the rigidity of both ends of a coil spring. By making the side faces of the outer ring member protrusion (12) and the cover member protrusion (18) on both ends of the coil spring (4) mounted on the outer diameter surface of the inner ring (2) have an inclination angle , the movement of the two ends in the direction of the outer diameter is restricted, thereby increasing the rigidity, and suppressing the generation of vibration and abnormal sound of the coil spring (4).

Owner:NTN CORP

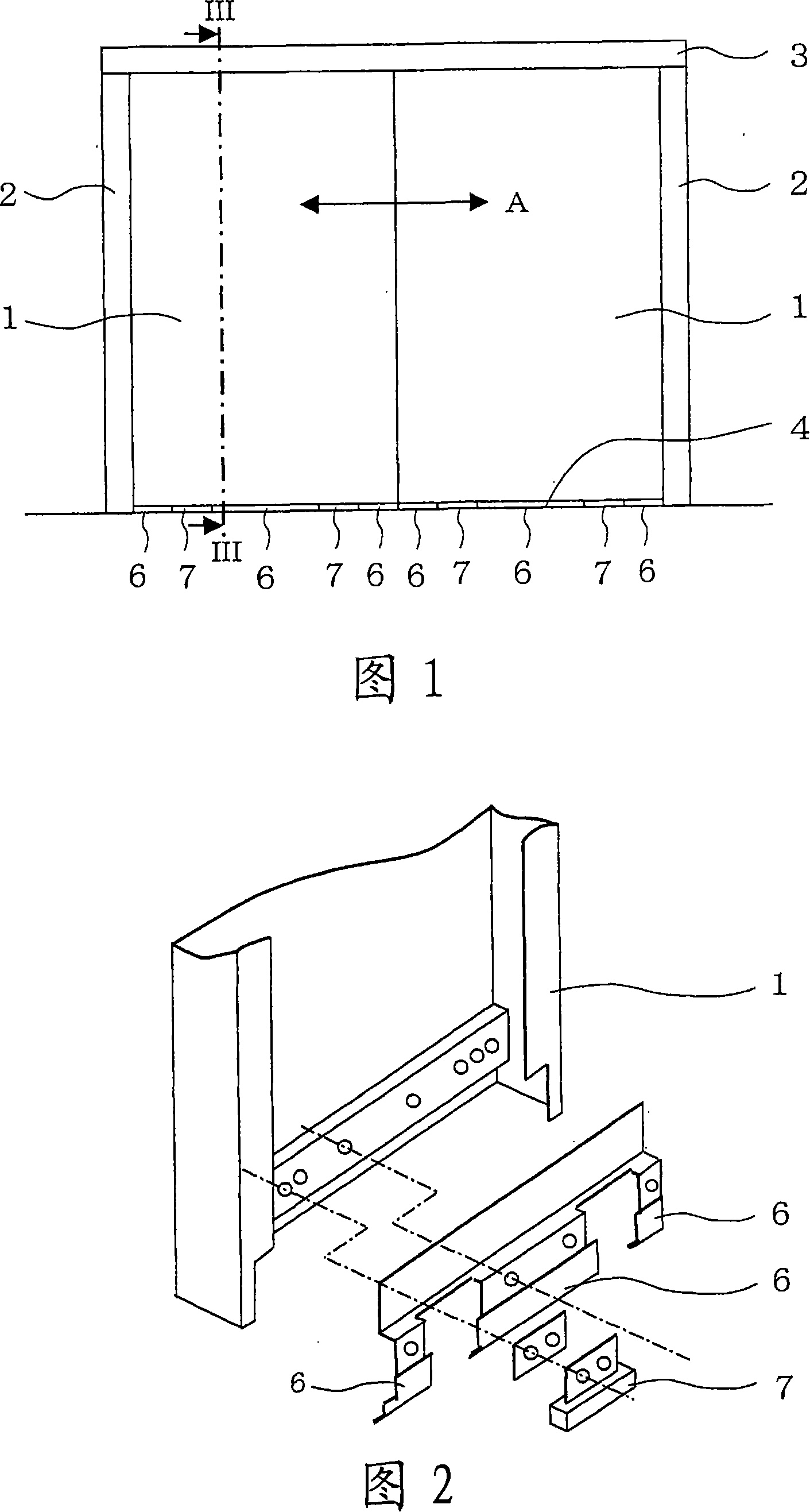

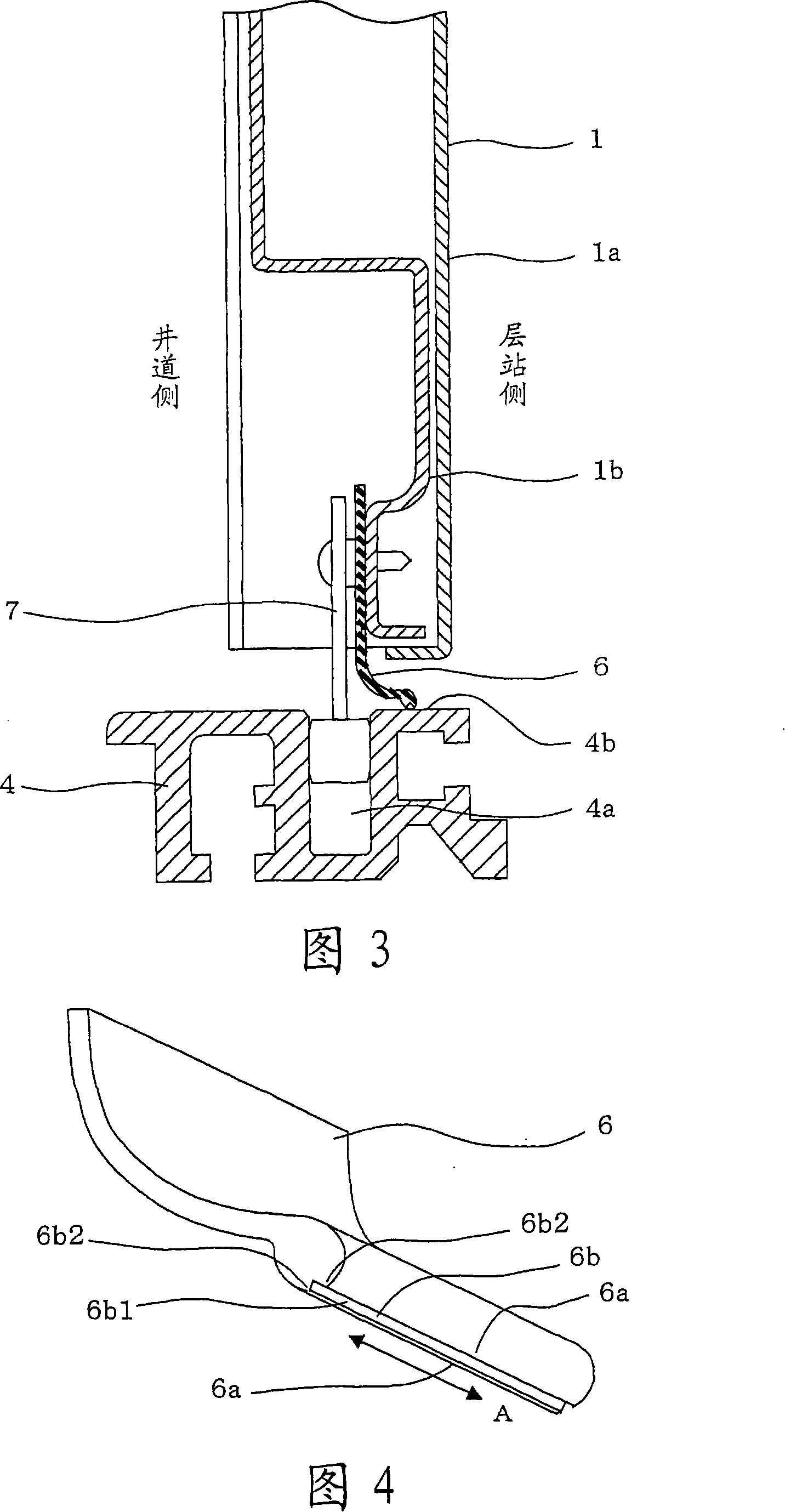

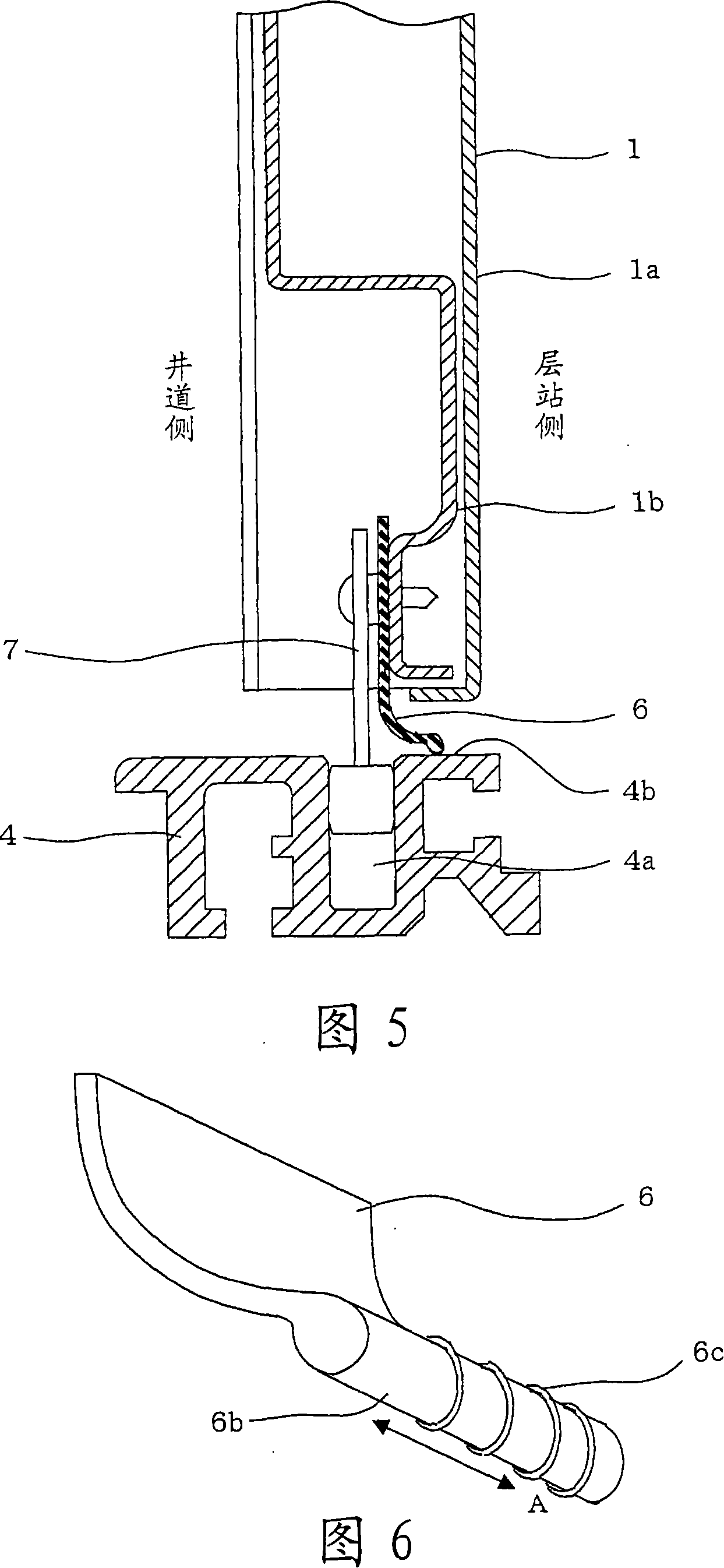

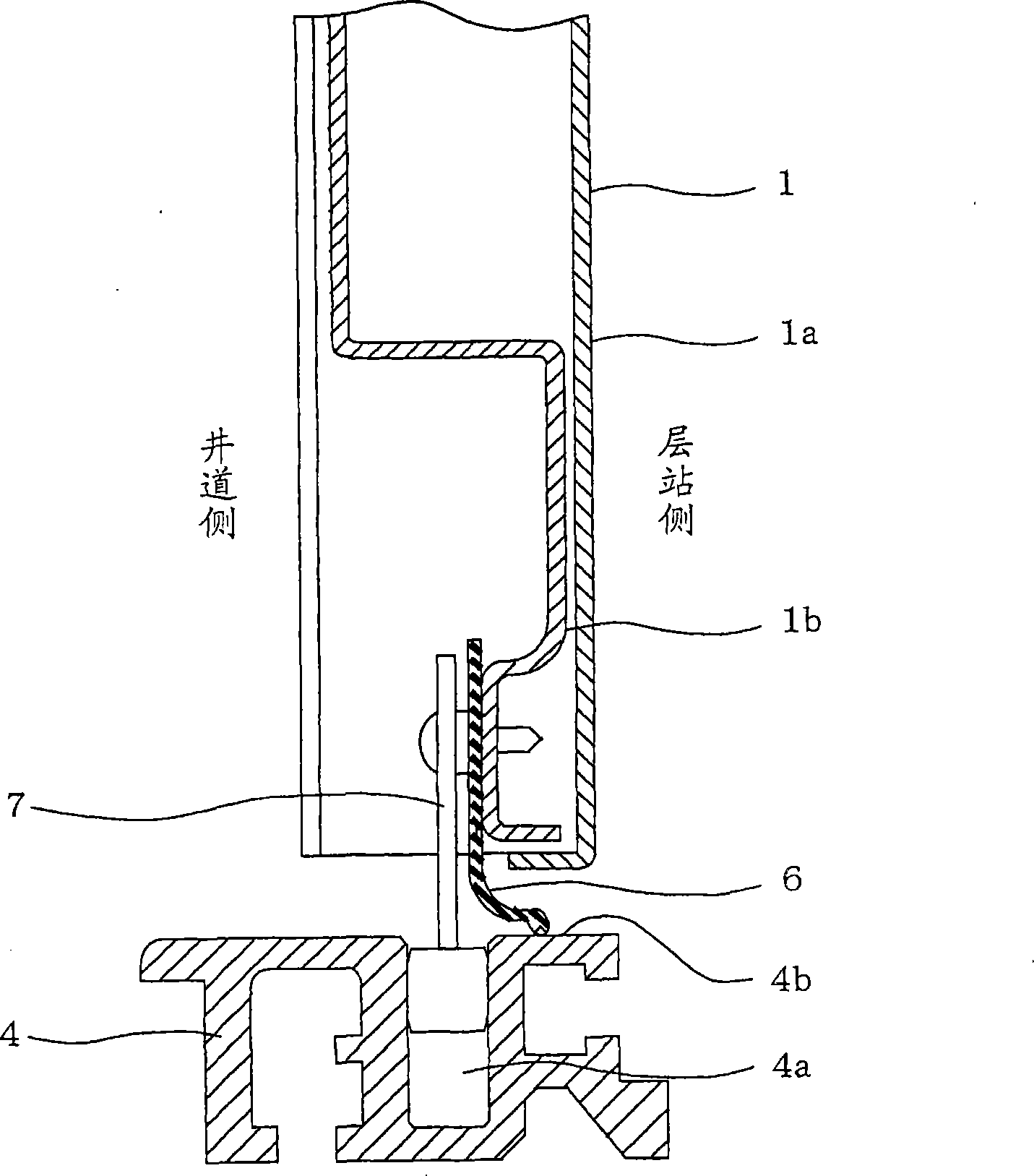

Elevator door device

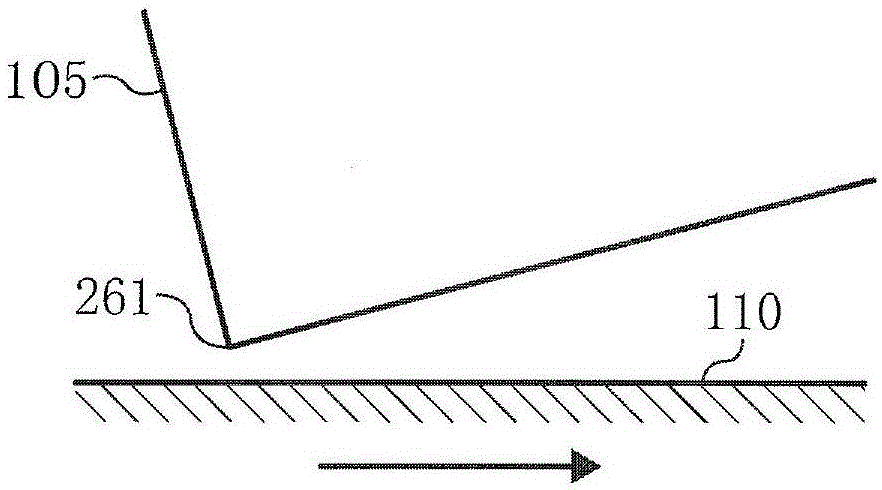

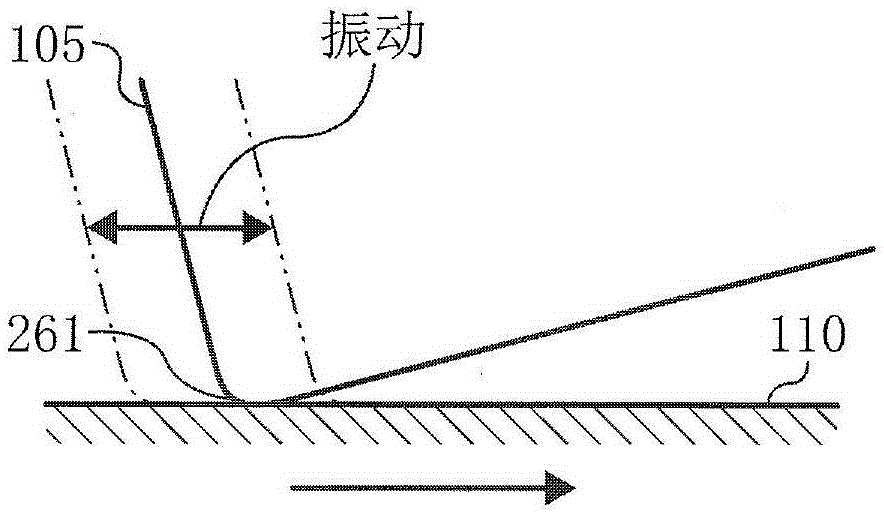

InactiveCN101132984AReduced opening and closing resistanceSuppress abnormal soundsBuilding liftsMechanical engineeringLow friction

The present invention provides a door device for an elevator, a flexible airtight member (6) extending in the opening and closing direction (A) of the door main body (1b), so as to be crimped to the surface on the ground side by virtue of its flexibility ( 4b) is attached to the door main body (1b), and the airtight member (6) is in pressure contact with the surface (4b) on the ground side, as the door (1) opens and closes, And slide on the surface (4b) of the above-mentioned ground side, in the door device of such an elevator, on the crimping surface (6a) of the above-mentioned airtight member (6) that is crimped with the surface (4b) of the above-mentioned ground side A low friction portion (6b) is formed.

Owner:MITSUBISHI ELECTRIC CORP

Glass plate constituent

ActiveCN109076288AGood reproducibilityNot easy to resonateRecord carriersBase layers for recording layersLongitudinal waveMechanical engineering

The present invention is a glass plate constituent in which the loss factor is 1*10<-2> or more and the longitudinal wave sound velocity value in the plate thickness direction is 5.5*10<3> m / s or more.

Owner:ASAHI GLASS CO LTD

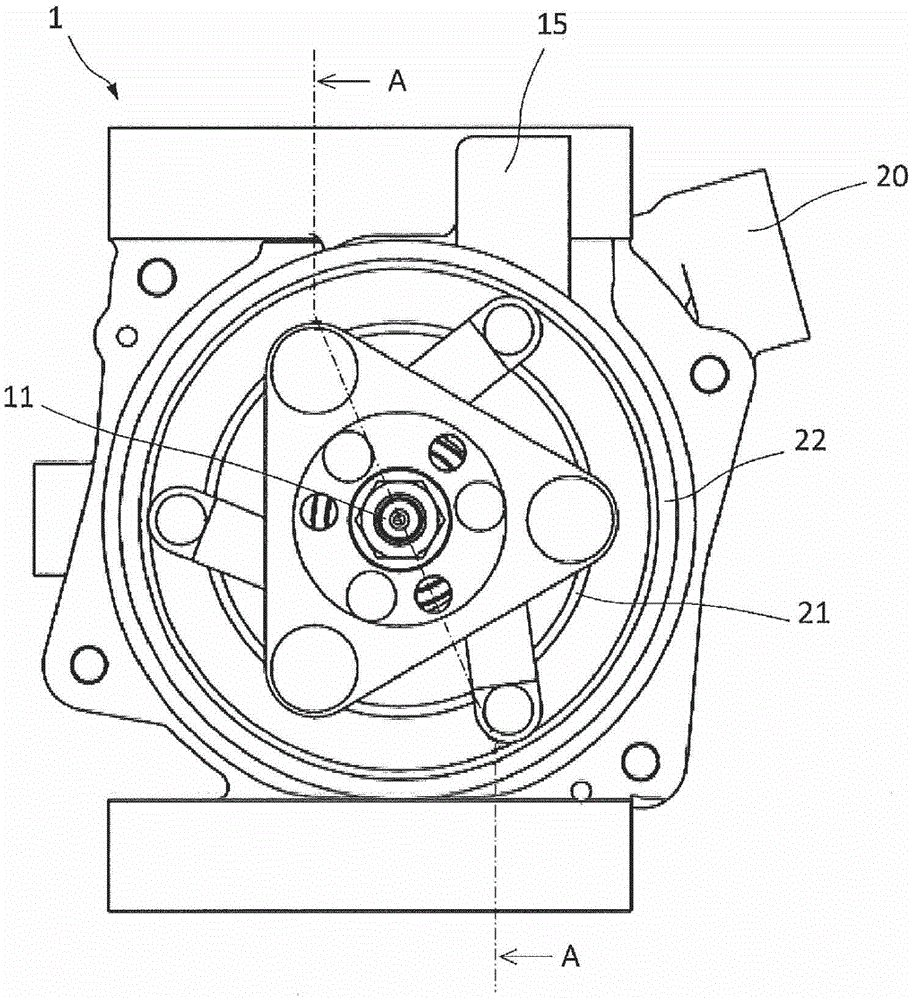

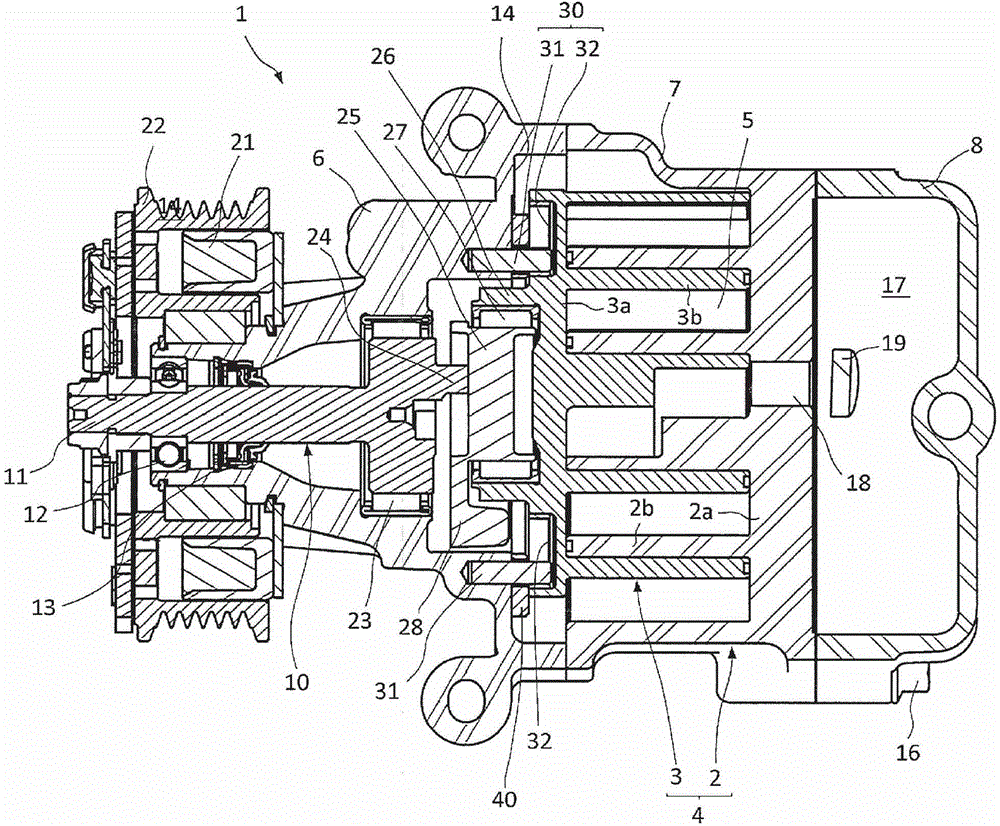

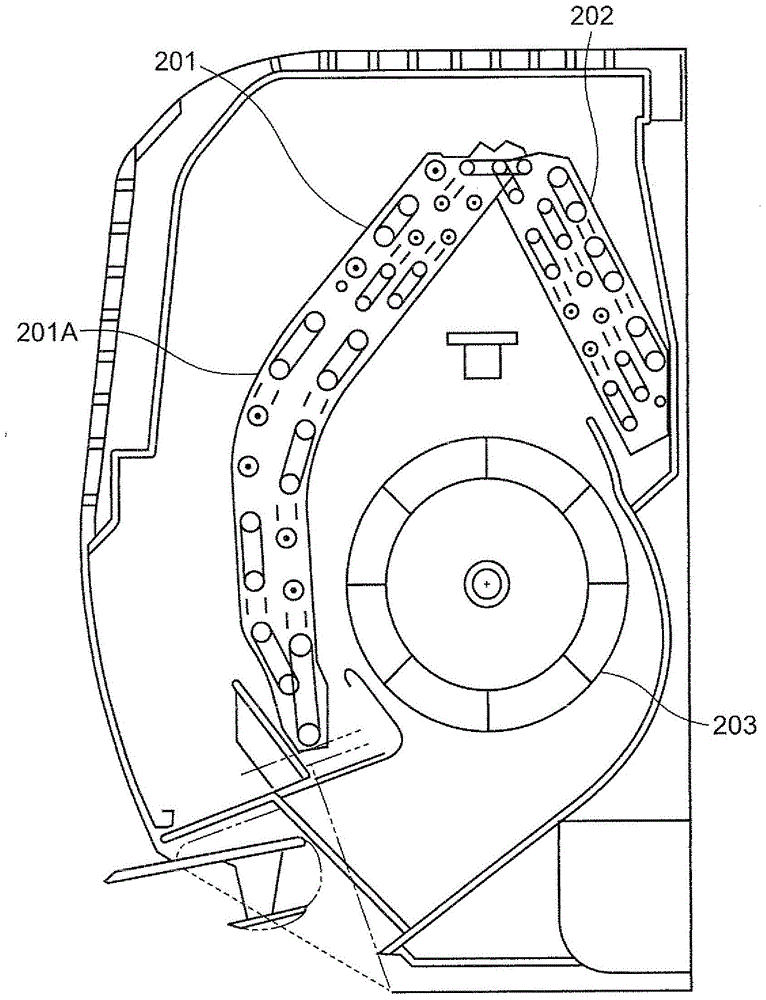

Scroll type fluid equipment

ActiveCN104976115AIncreased durabilityReliable and easy to installRotary piston pumpsRotary piston liquid enginesThrust bearingFront cover

The present invention provides scroll type fluid equipment which adopts a thrust plate installing structure, wherein, the thrust plate installing structure can reliably fix a thrust plate by absorbing a manufacturing tolerance and reduce the contact surface pressure of a fitting part of pins and the thrust plate. Four pieces of pins (31) are protruded from a thrust bearing part (1) of a front cover (6), four gap parts (41a-41d) are formed on the thrust plate (40) for fitting with the pins (31), the shapes of the four gap parts (41a-41d) are that the four gap parts extend along a radius direction of the thrust plate, and the shapes of the three gap parts (41a-41c) of the four gap parts are that the fitting gap of the gap parts and the pins (31) is minimal on the periphery of the thrust plate.

Owner:三电株式会社

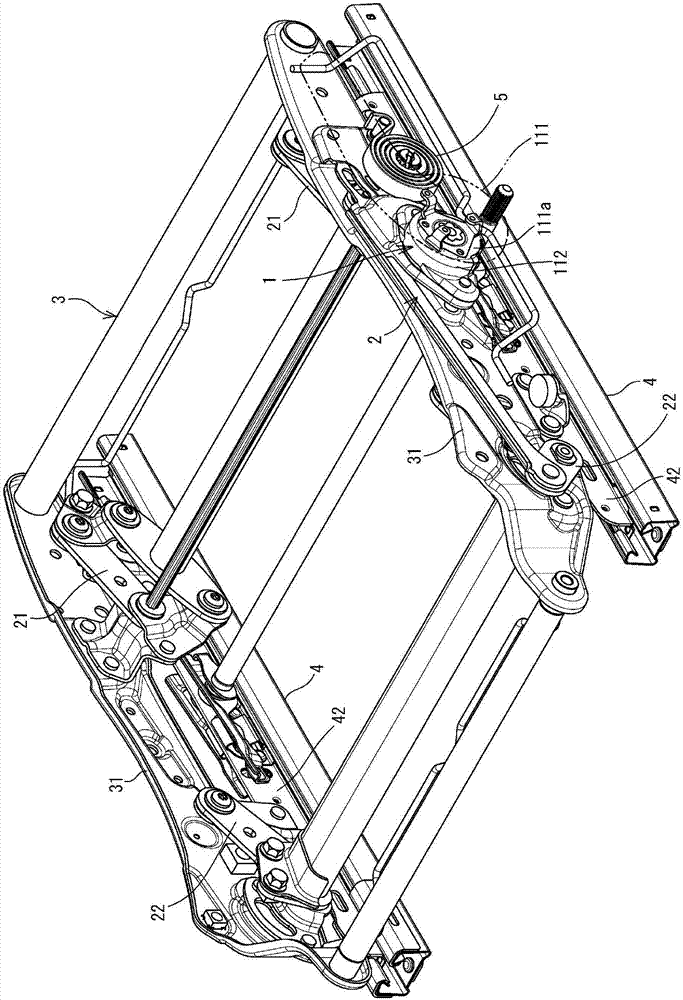

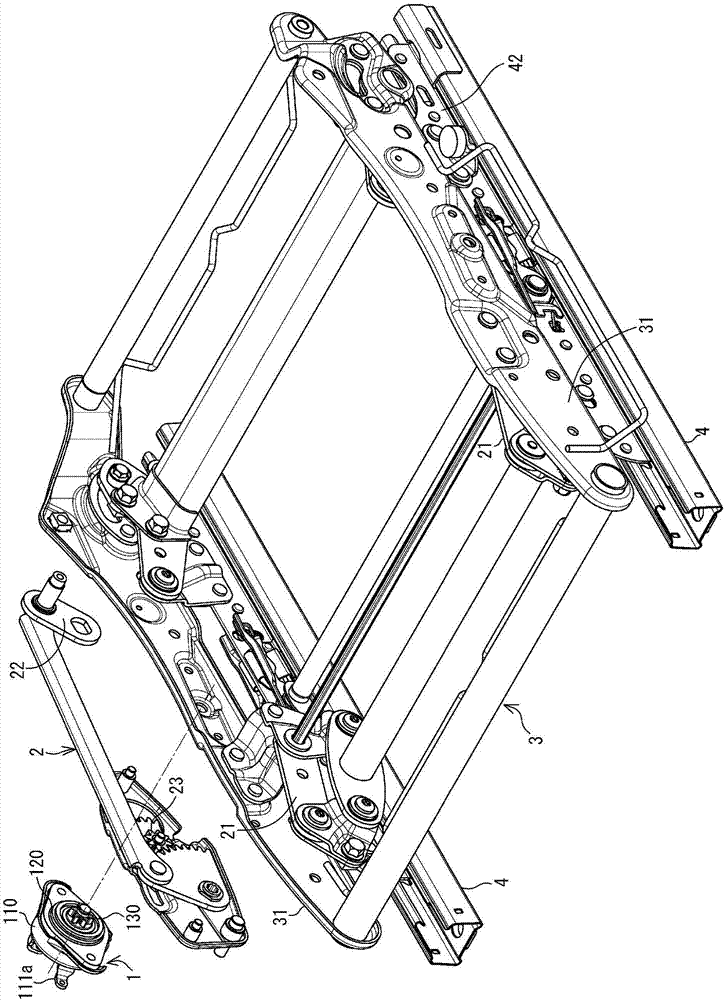

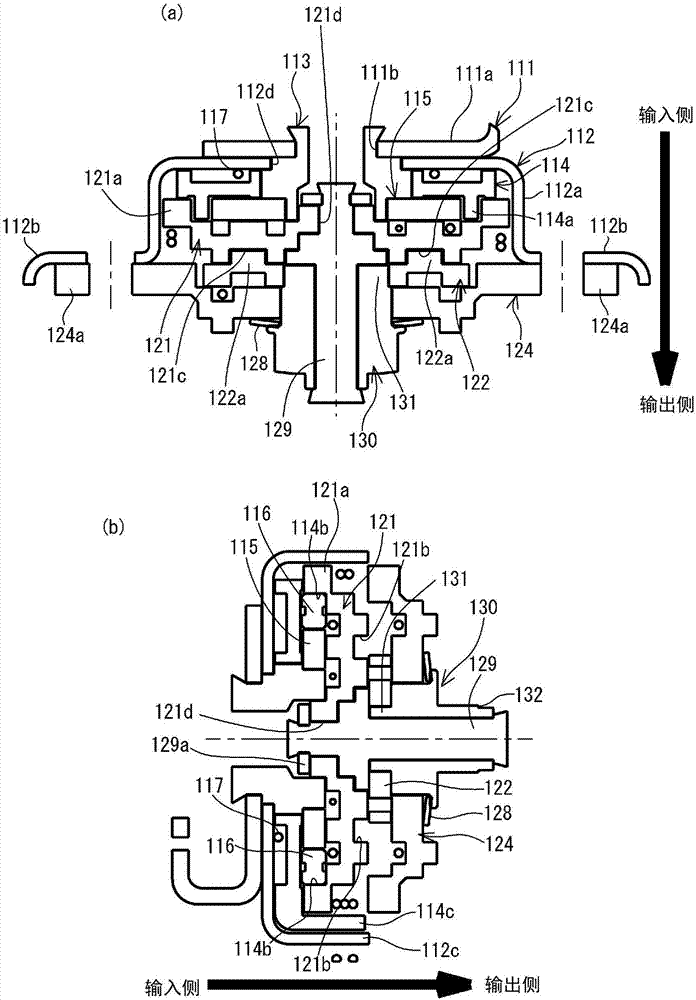

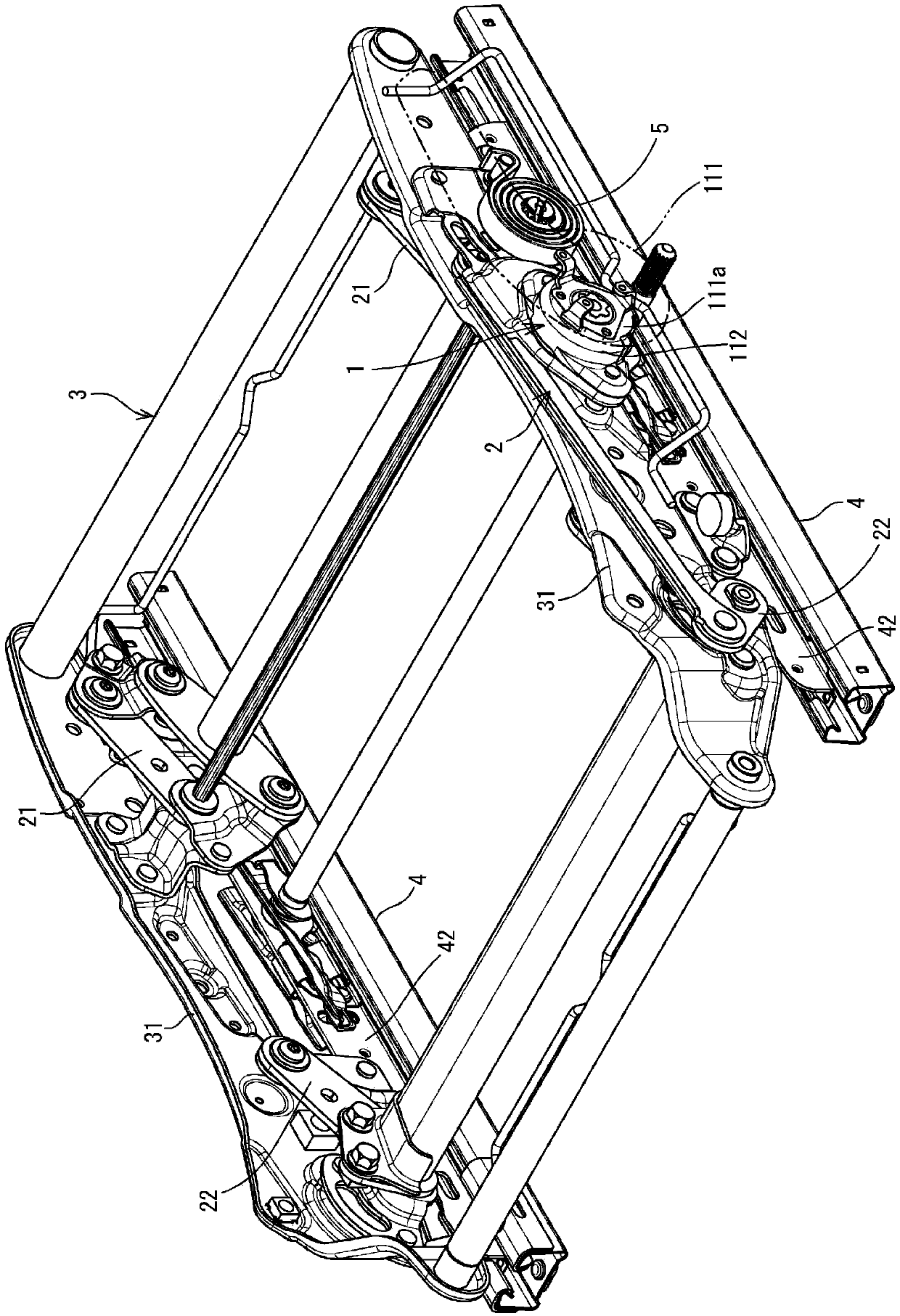

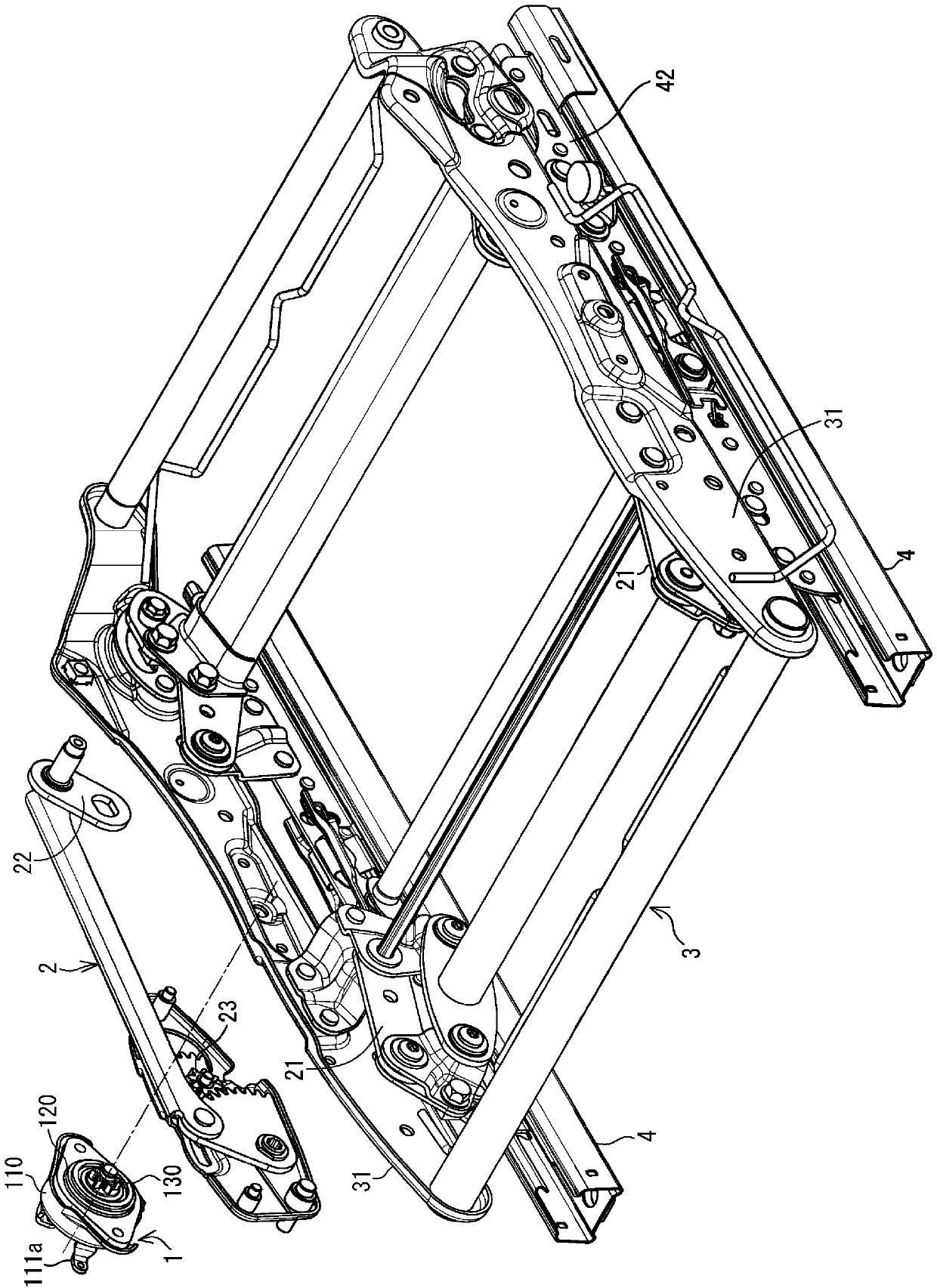

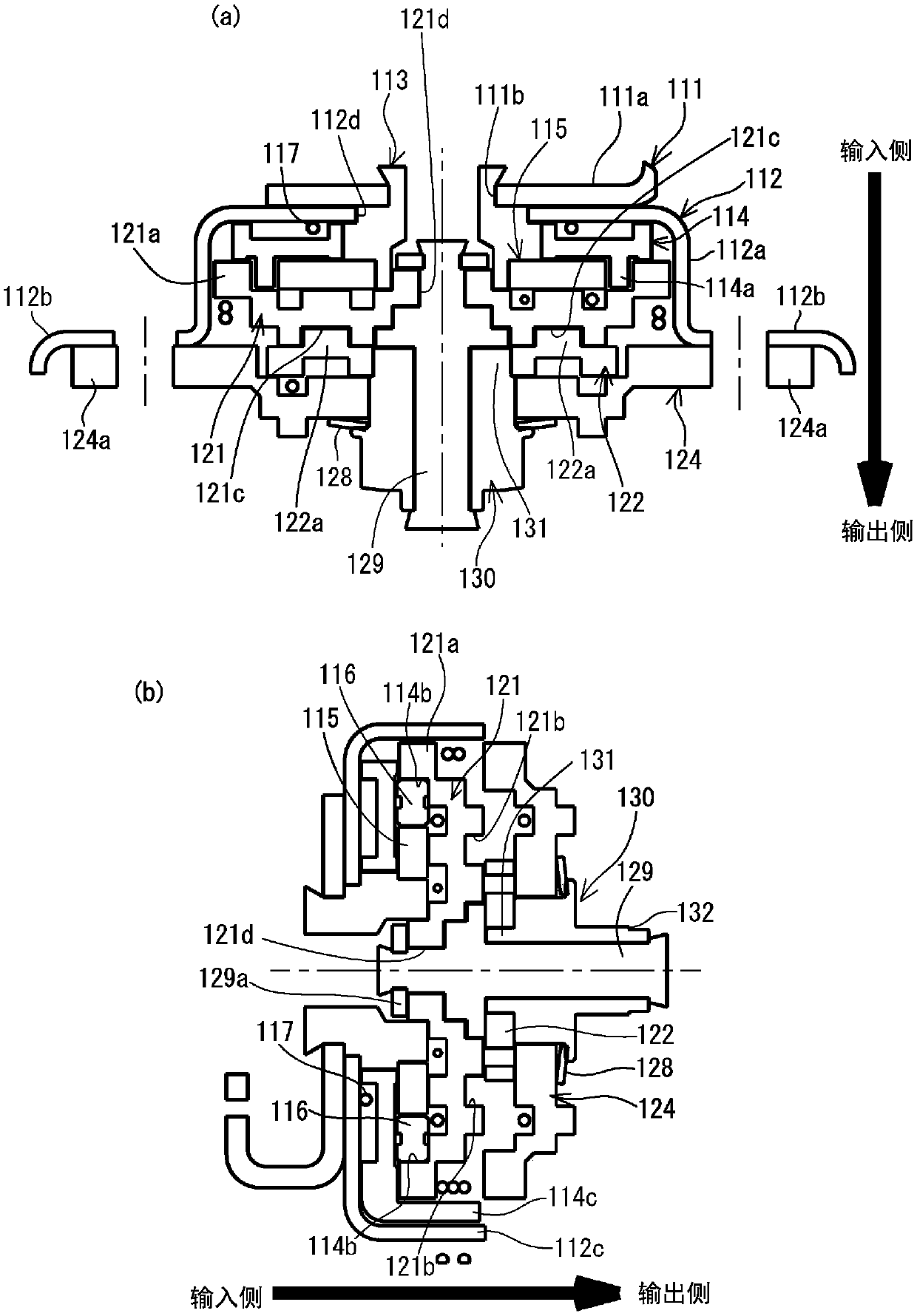

Torque transfer control mechanism and seat structure

ActiveCN107074129AAvoid displacementReduce loosenessGearingLimiting/preventing/returning movement of partsTransfer mechanismLocking plate

The present invention more reliably suppresses output-side displacement in comparison with conventional mechanisms. The present invention is provided with a rotation control part 120 which maintains a locked state when an input torque rotating the transfer mechanism 110 is not applied, and which releases the locked state when the transfer mechanism is rotated. The rotation control part 120 has an internal gear 124 and a lock plate 123 which has outer teeth that can be engaged with internal teeth of the internal gear 124. When an input torque is not applied, the inner teeth of the internal gear 124 are engaged with the outer teeth of the lock plate 123, and when the transfer mechanism 110 is rotated, the engagement of both the internal and outer teeth is released. Thus, even if torque is applied from the output side, the engagement of both the internal and outer teeth is not released by the torque.

Owner:DELTA TOOLING CO LTD

Blade and image forming apparatus incorporating same

ActiveCN105527813ASuppress abnormal soundsSuppress fatigueSynthetic resin layered productsCleaning equipmentImage formationStructural engineering

Owner:RICOH KK

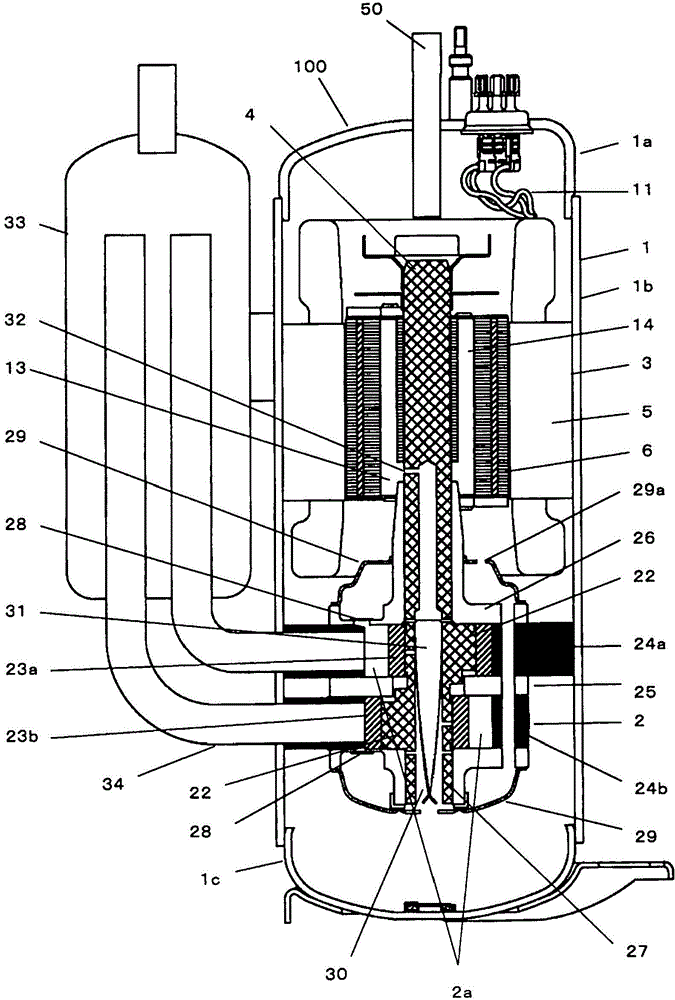

Hermetic compressor and refrigerating cycle device including the hermetic compressor

ActiveCN103362821BSuppression of pressure pulsation differenceReduce noiseRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsLow noiseEngineering

The invention provides a hermetic compressor which can inhibit abnormal sounds, low noises and low vibration generated by vertical movement of a rotor without increasing the number of parts, and a refrigeration cycle apparatus comprising the hermetic compressor. One part of a main bearing (26) of a crankshaft (4) is received inside a counter-bore part (13) of a rotor (6) of an electric element (3) which is coaxially fixed with the crankshaft (4). The rotor (6) has a vent hole (14) that is axially disposed along an upper end of the rotor (6) and is communicated with the counter-bore part (13).

Owner:MITSUBISHI ELECTRIC CORP

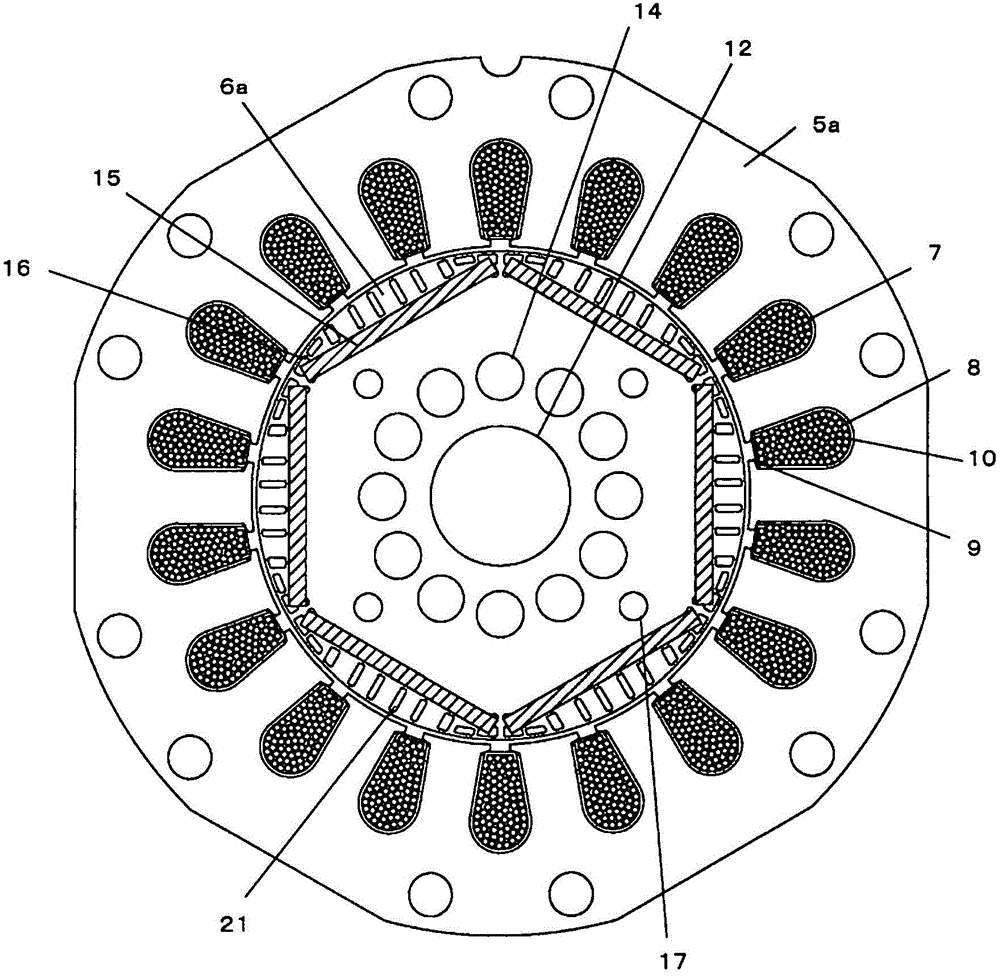

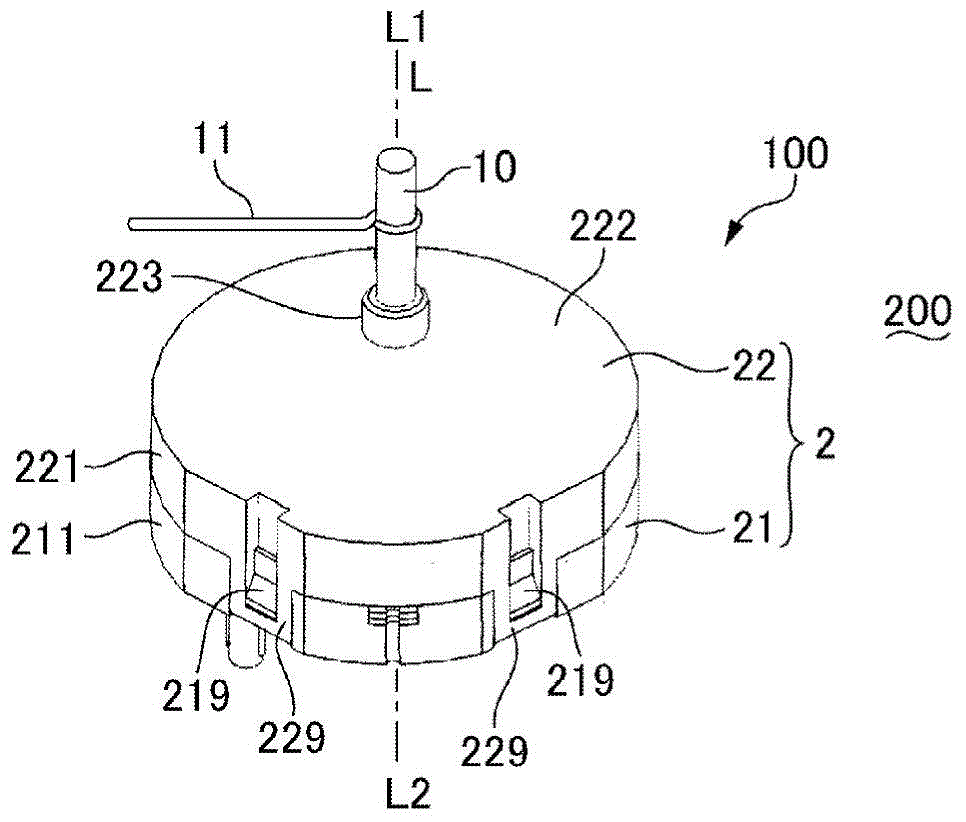

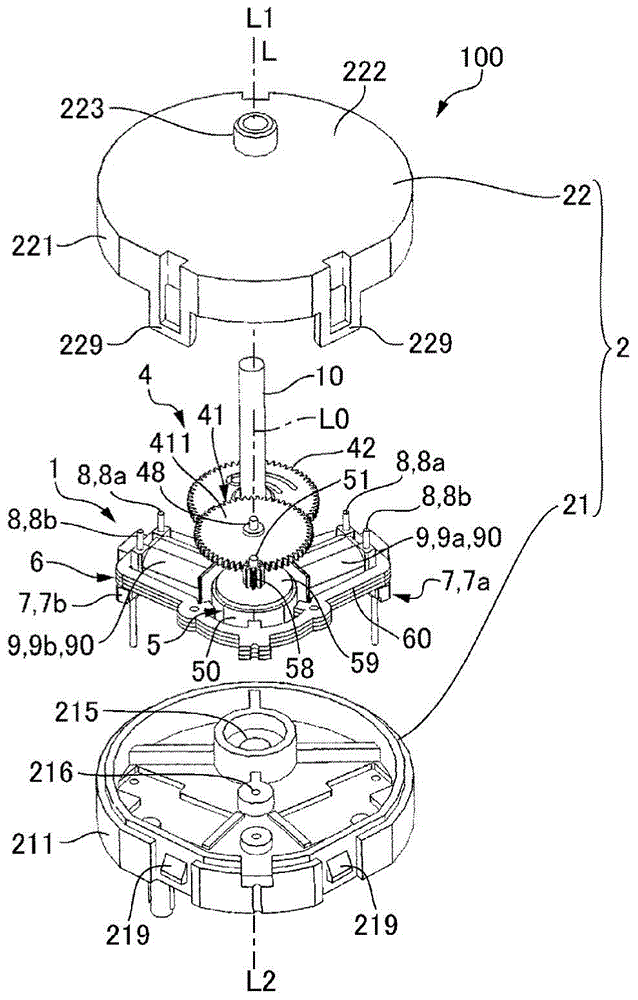

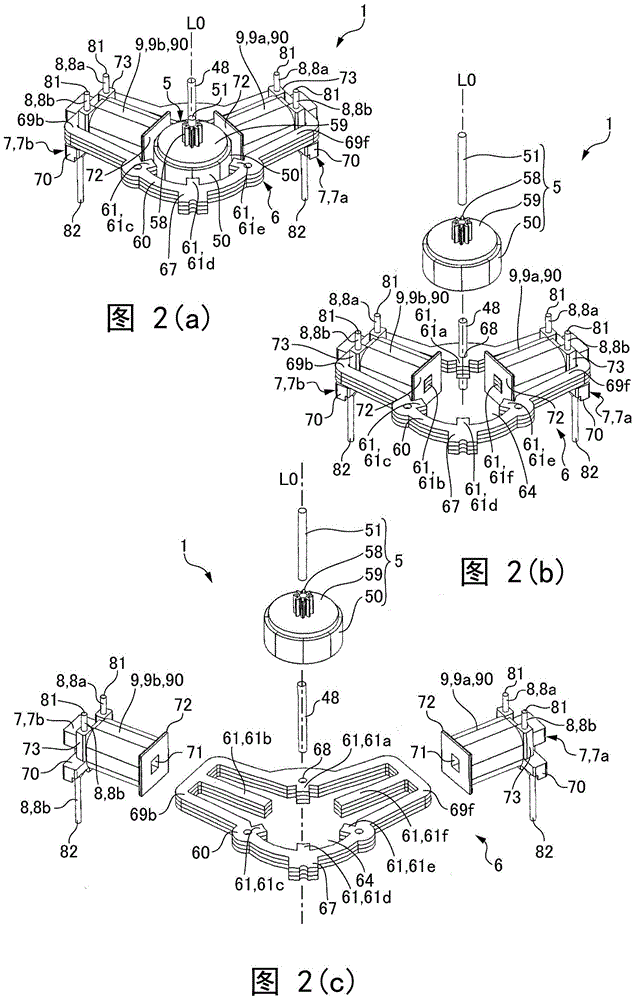

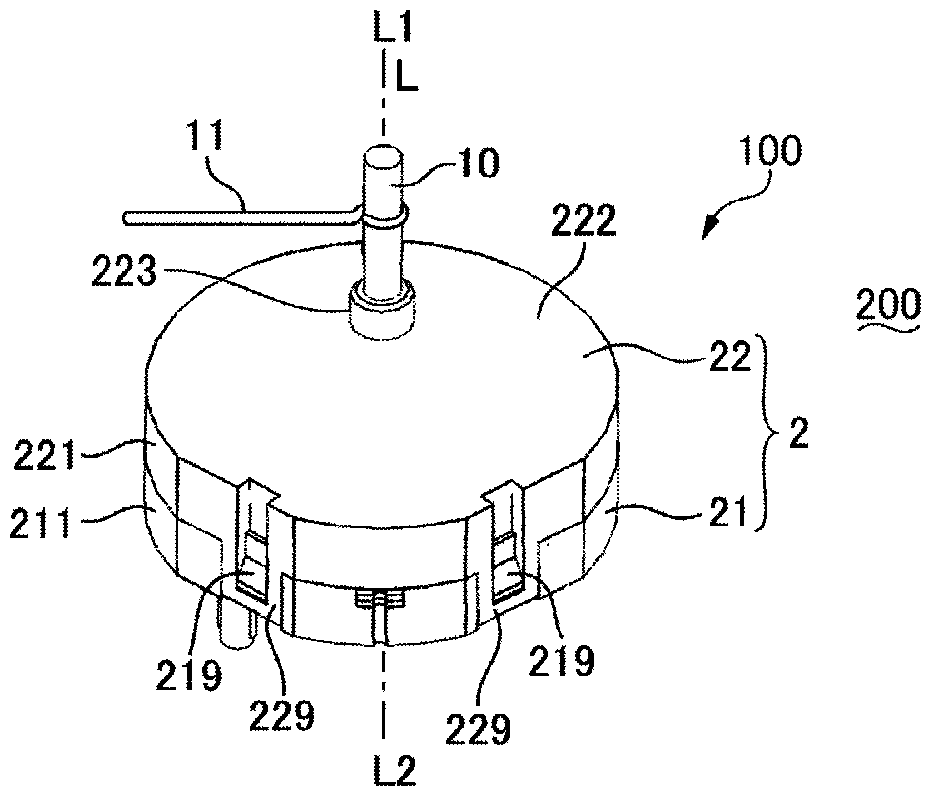

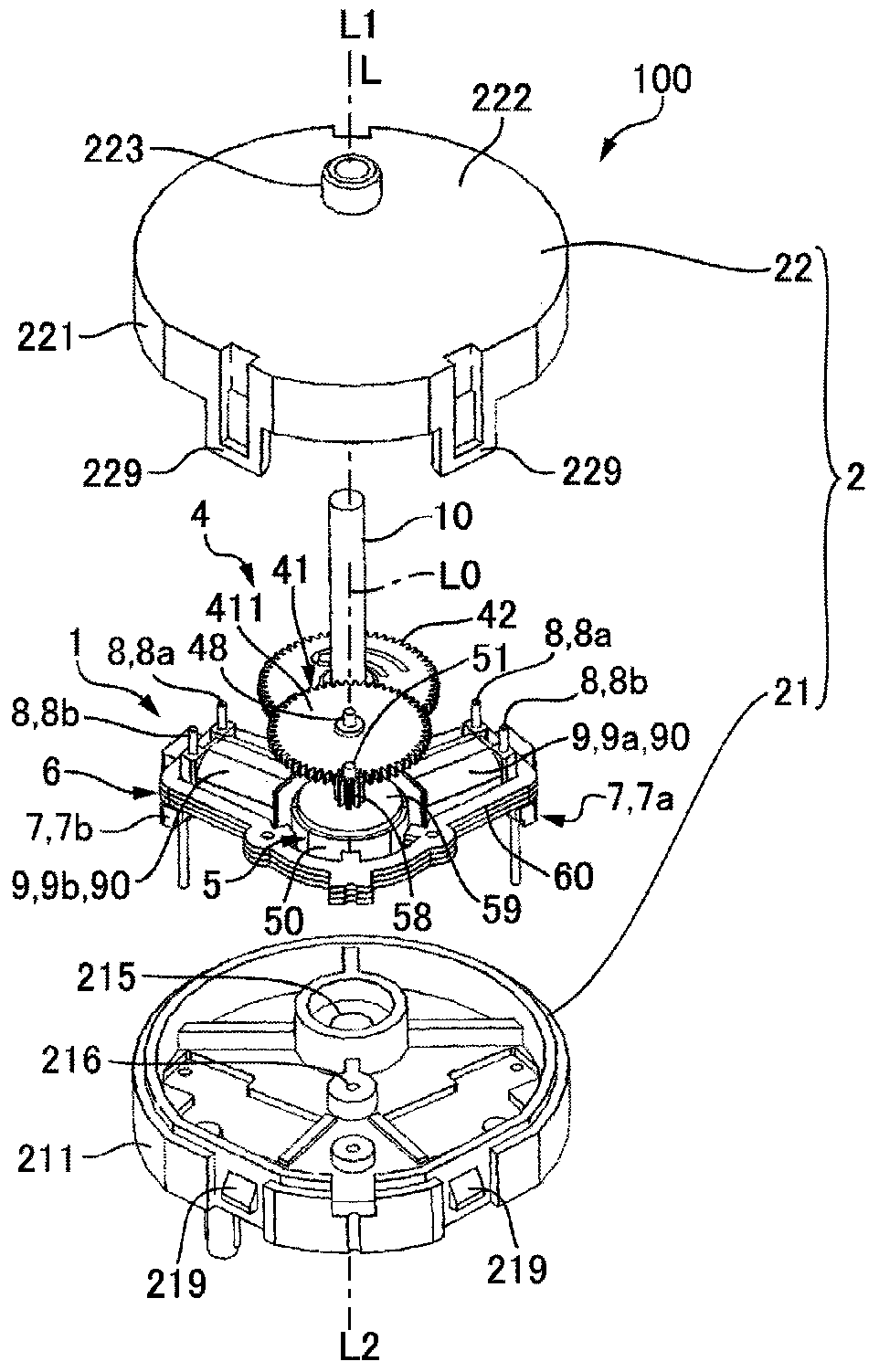

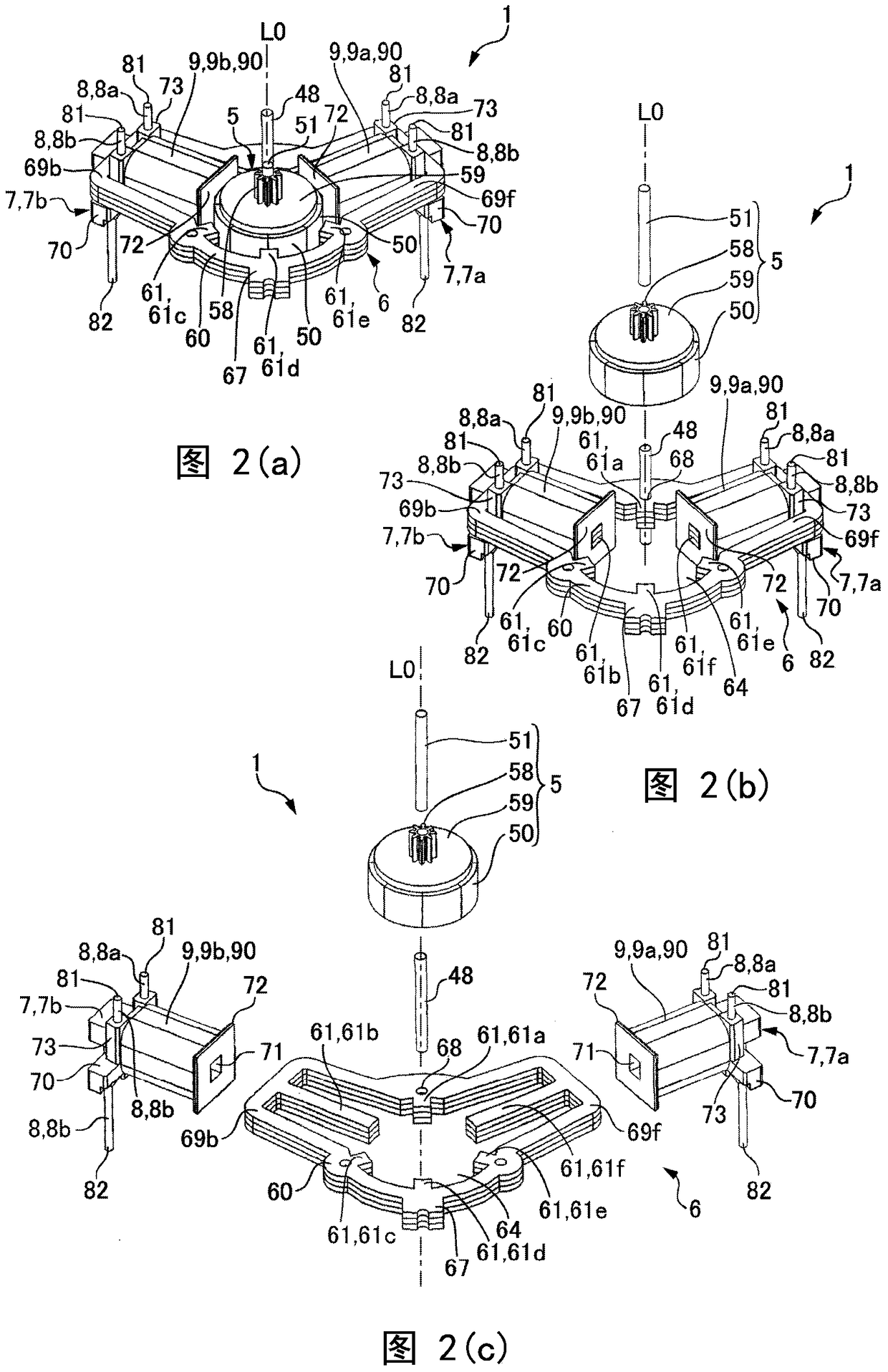

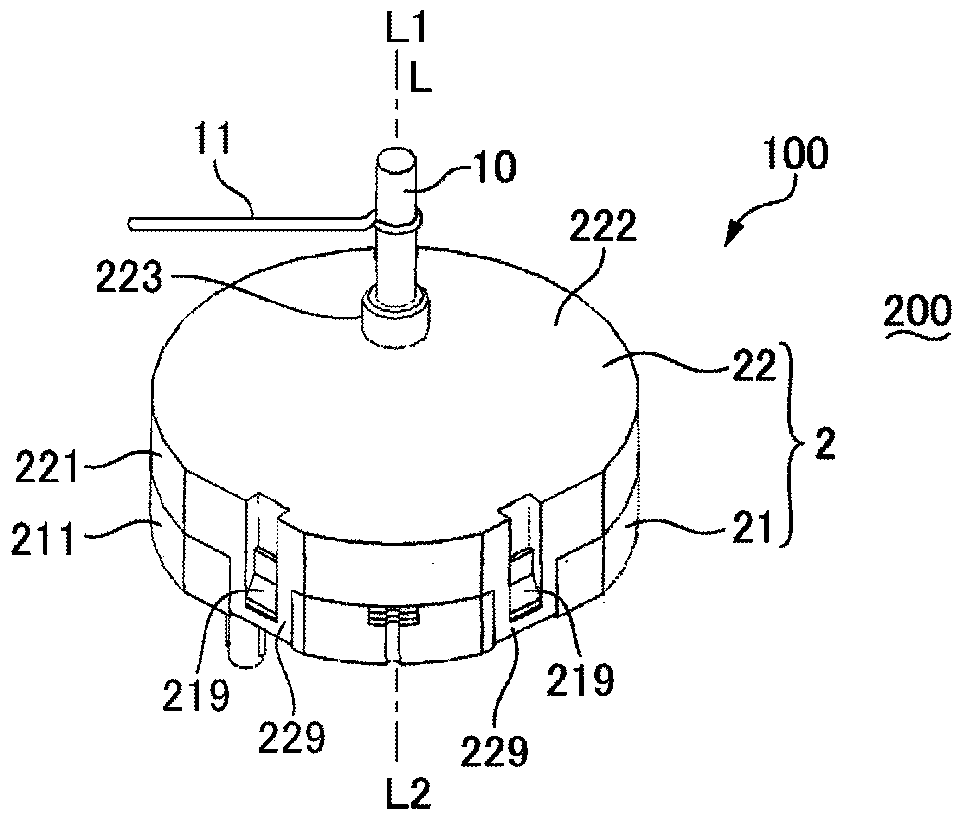

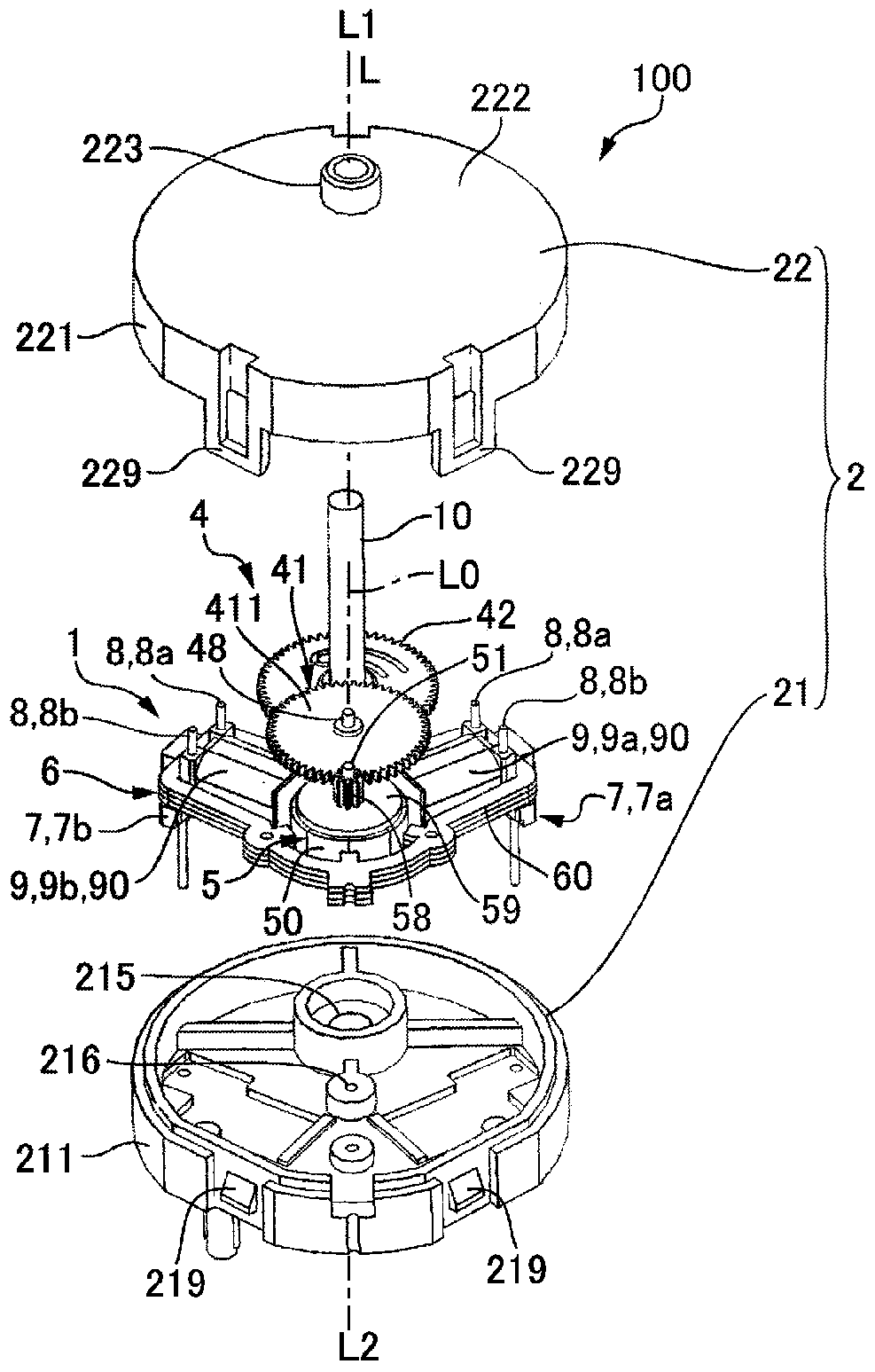

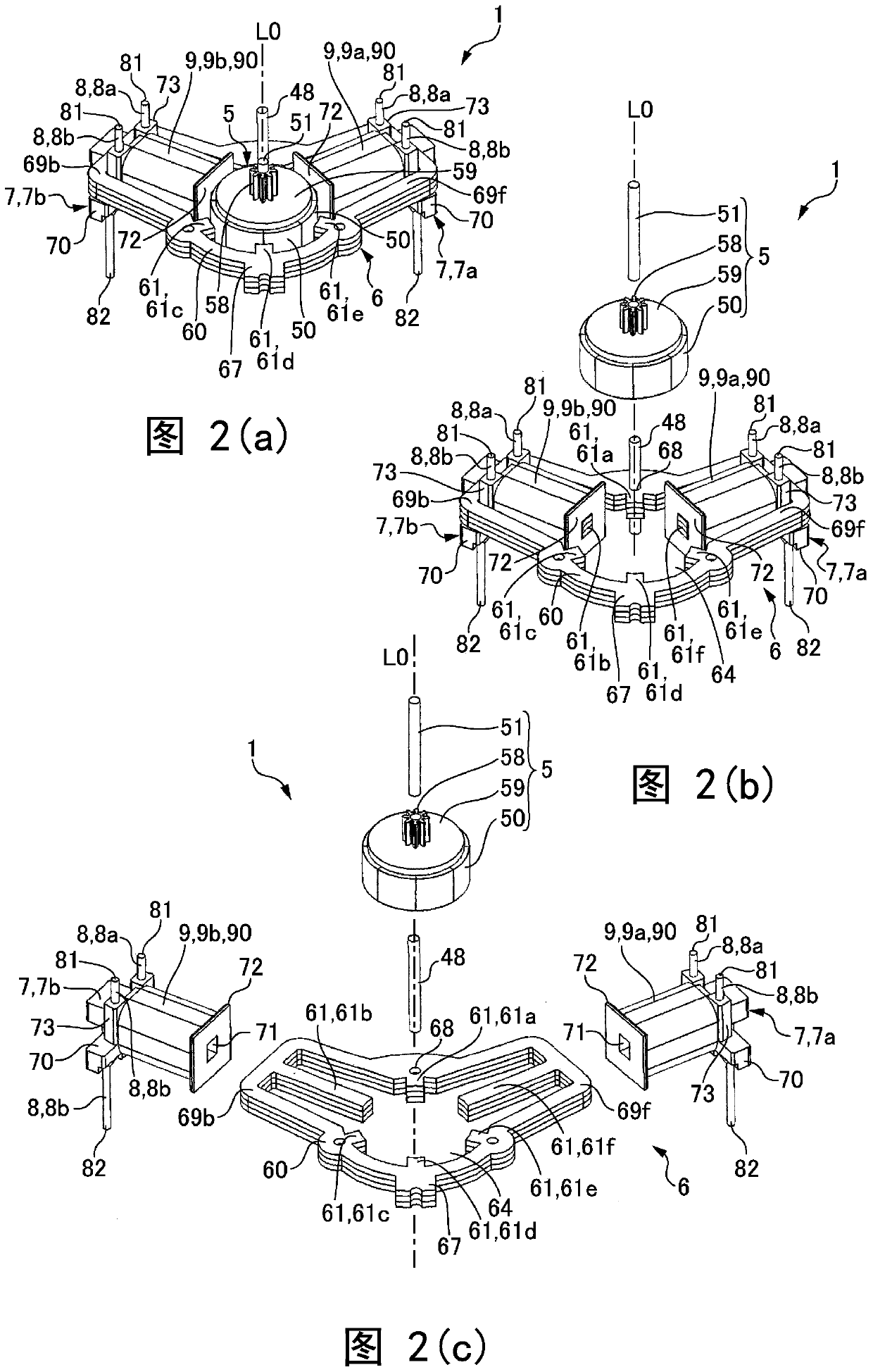

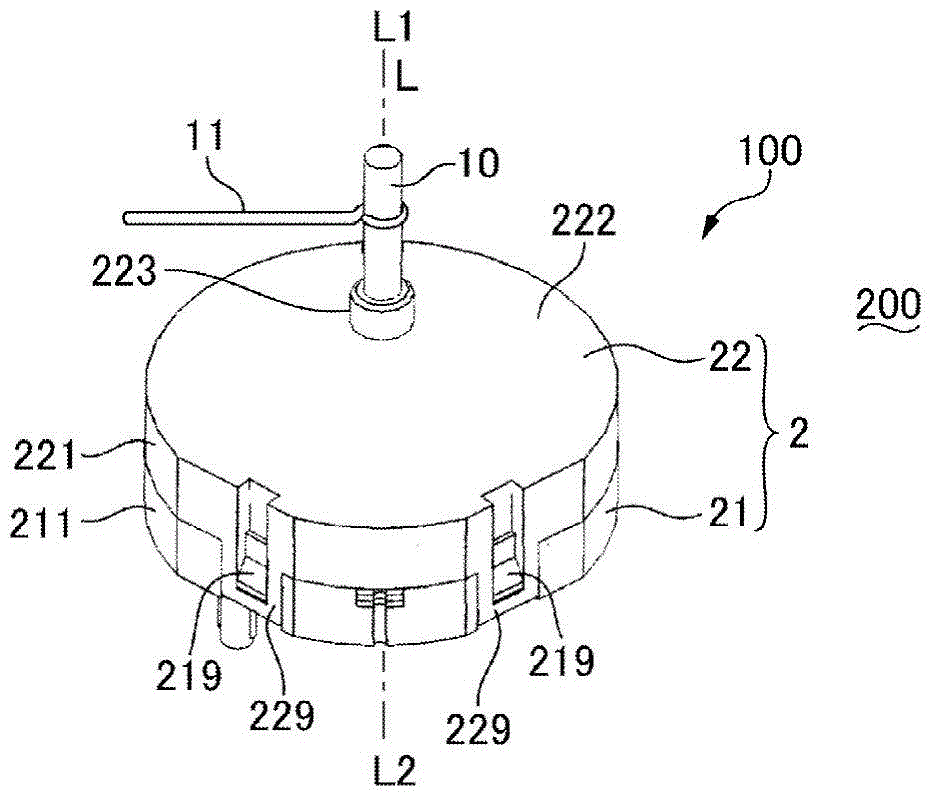

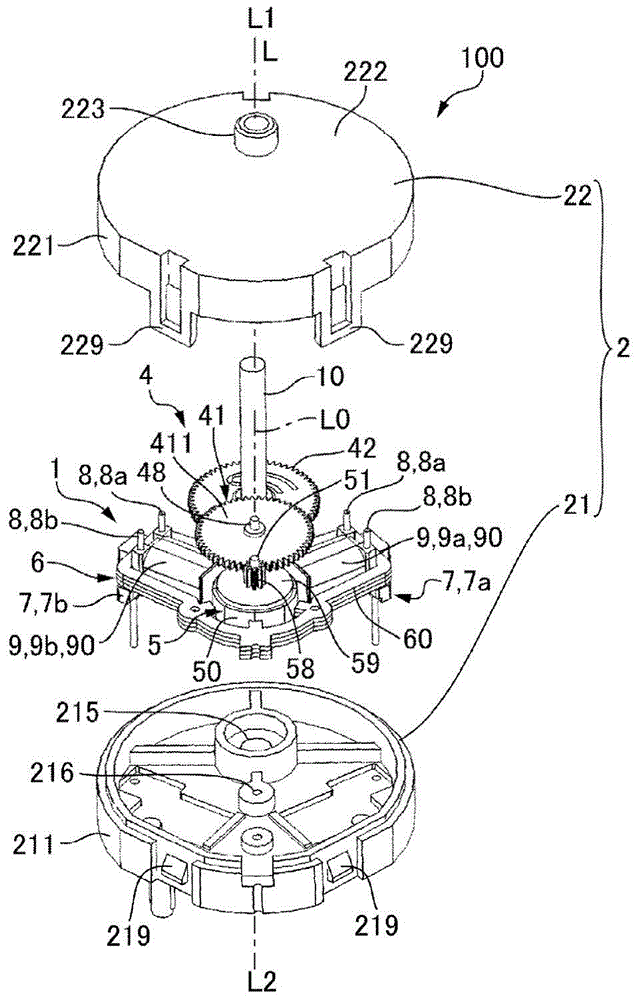

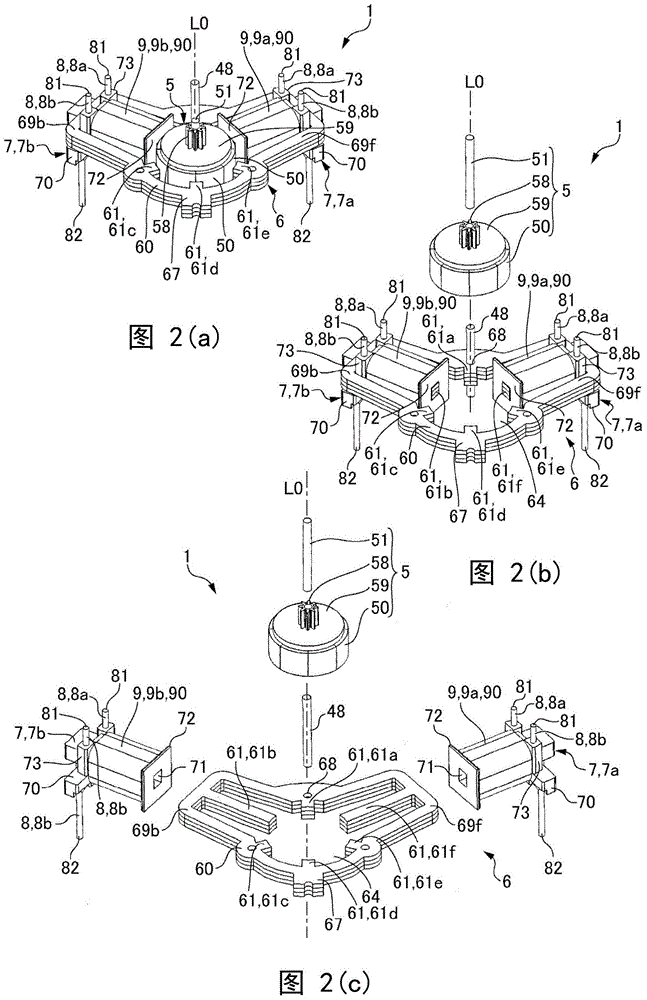

Motor, Motor device and pointer type display device

InactiveCN104901507ANot easy to vibrateSuppress abnormal soundsDynamo-electric machinesDisplay deviceMagnet

The invention provides a motor capable of restraining a rotor to radially vibrate, a motor device with the motor and a pointer type display device. In the motor, coils are configured at the periphery of two salient poles (61f, 61b) (main poles) arranged in a first angle region (theta1) less than 180 degrees among a plurality of salient poles of a stator iron core. And the salient poles (61c to 61e) in a second angle region (theta2) of 180 degrees among the plurality of salient poles are first assisting poles which are not provided with coils at the periphery. At the opposite side to the two main poles (the salient poles 61f, 61b) side, the second angle region (theta2) takes an extension line of two bisectrixes as a center. The bisectrixes divide the first angle region (theta1) into two equal parts. An interval structure between the main poles (the salient poles 61f, 61b) and a magnet is different from the internal structure between the first assisting poles (the salient poles 61c to 61e) and the magnet.

Owner:SANKYO SEIKI MFG CO LTD

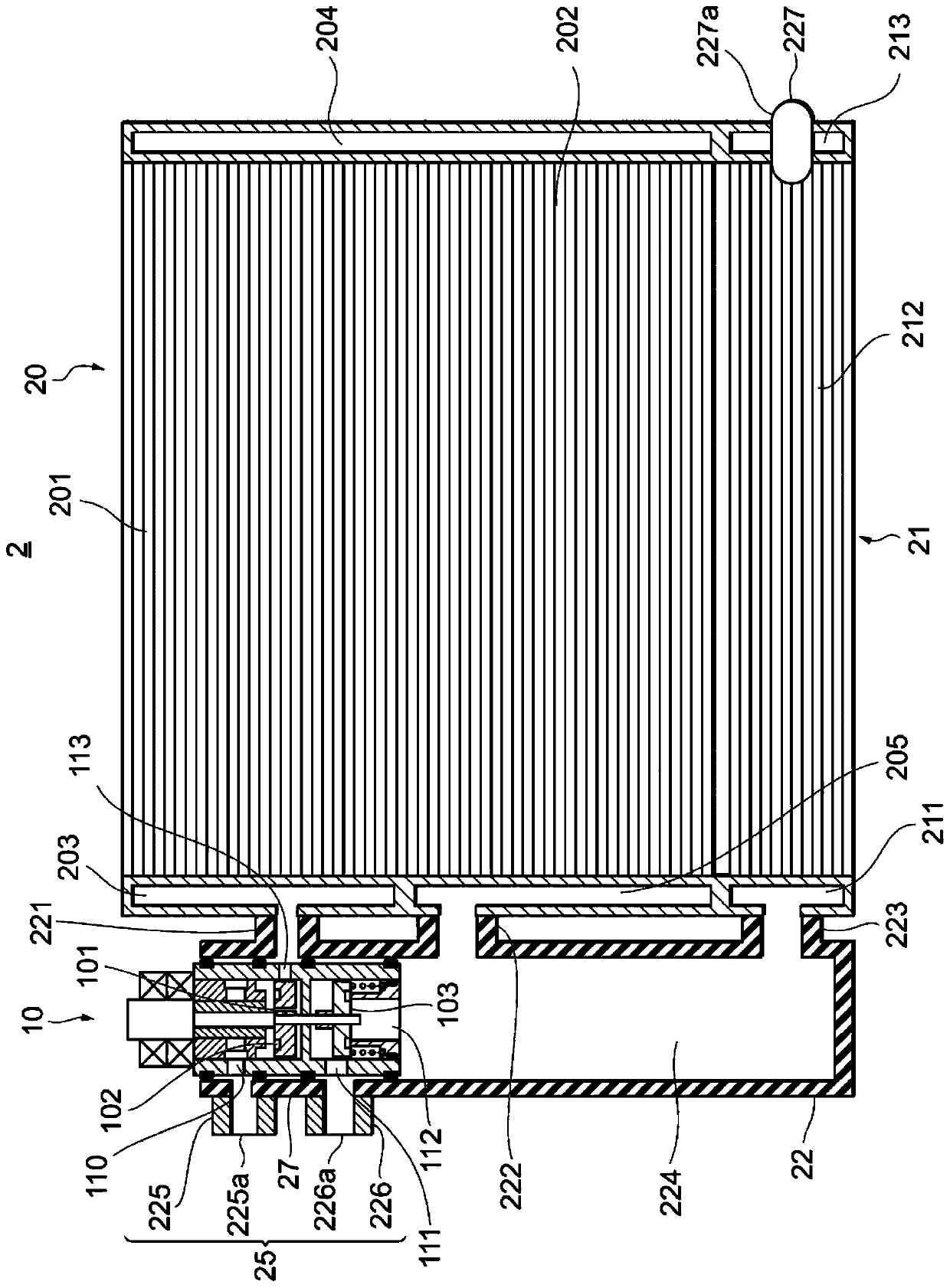

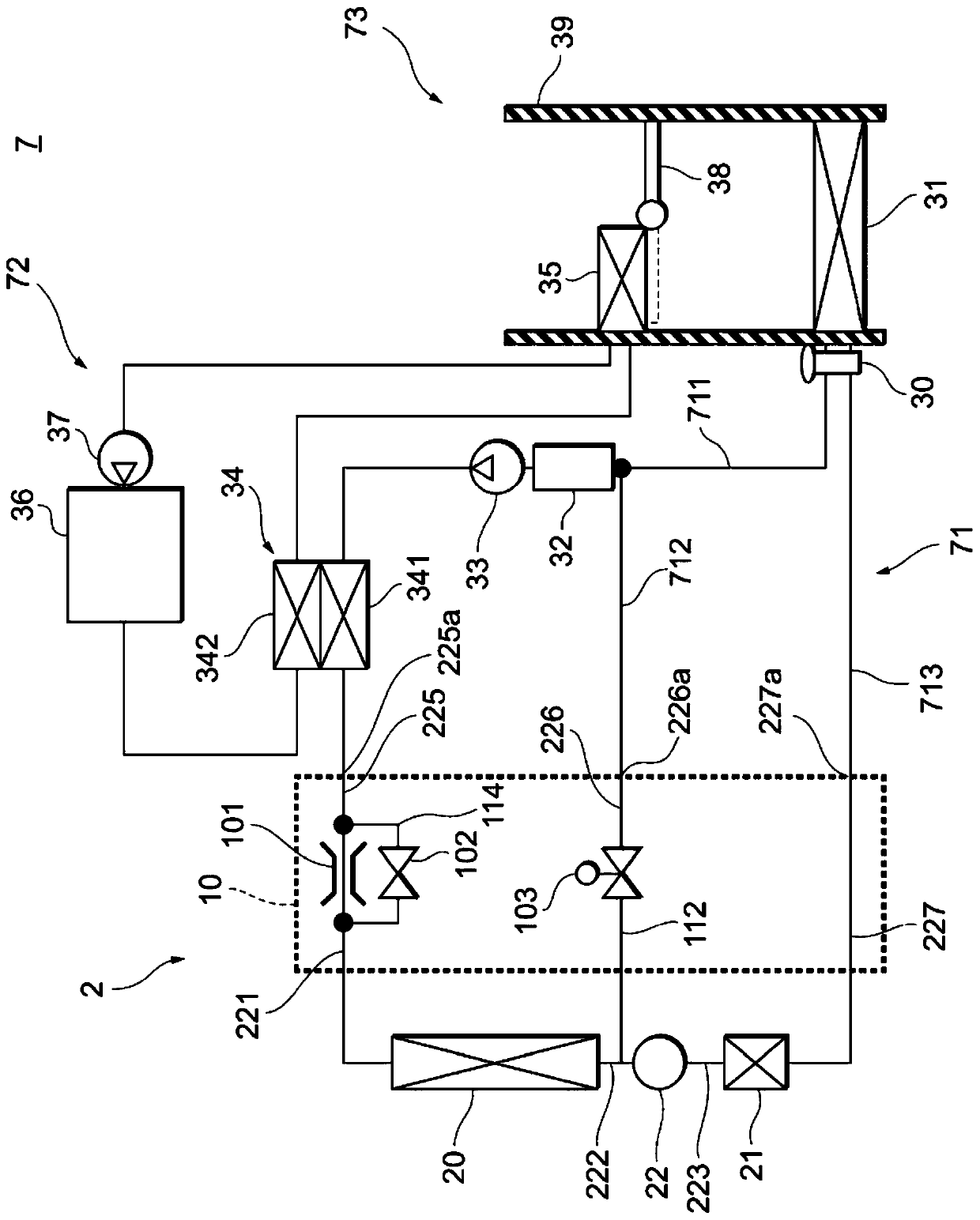

heat exchanger

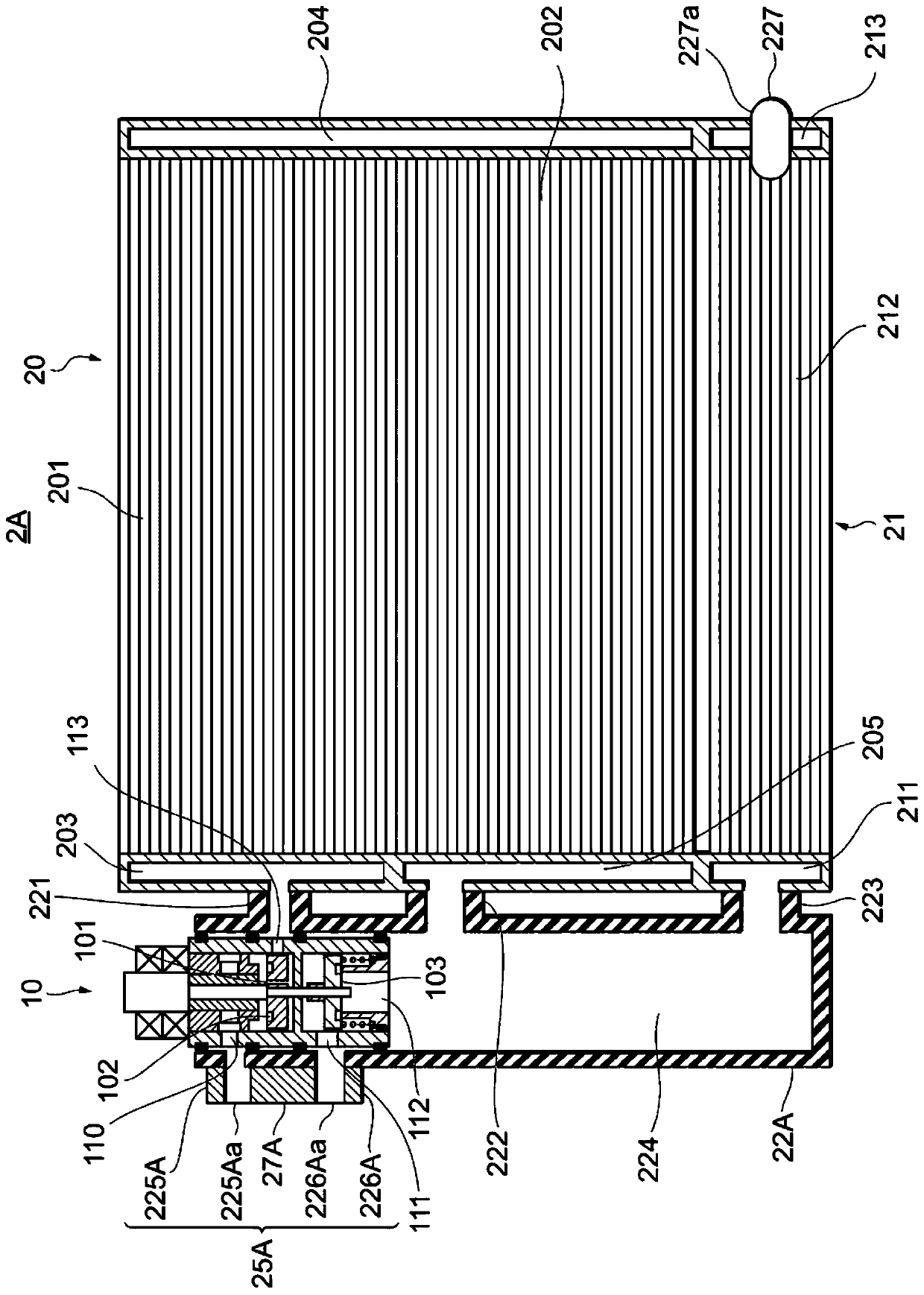

ActiveCN111213020BPrevent heat transferInhibition of power deteriorationAir-treating devicesMechanical apparatusHeat flowRefrigerant

In the heat exchanger, there are provided: an inflow port (225a) for the refrigerant to flow in; a cooling outflow port (227a) for the refrigerant to flow out during the cooling operation; and a heating outflow port (227a) for the refrigerant to flow out during the heating operation (226a), the distance between the inflow port (225a) and the heating outflow port (226a) is arranged to be shorter than the distance between the inflow port (225a) and the cooling outflow port (227a).

Owner:DENSO CORP

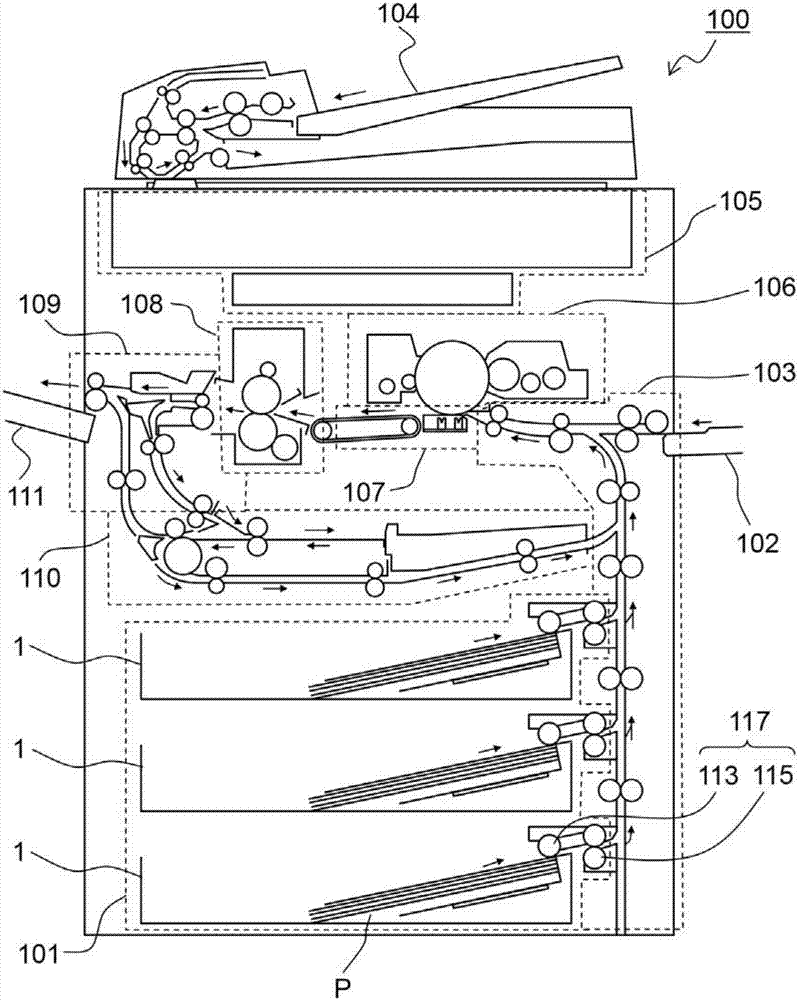

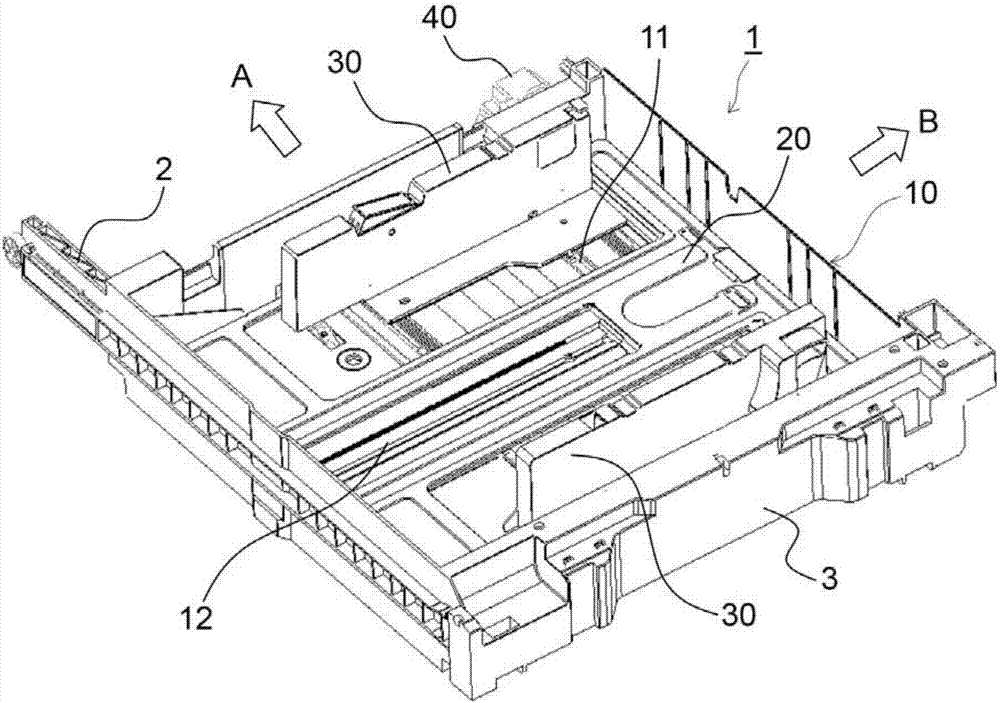

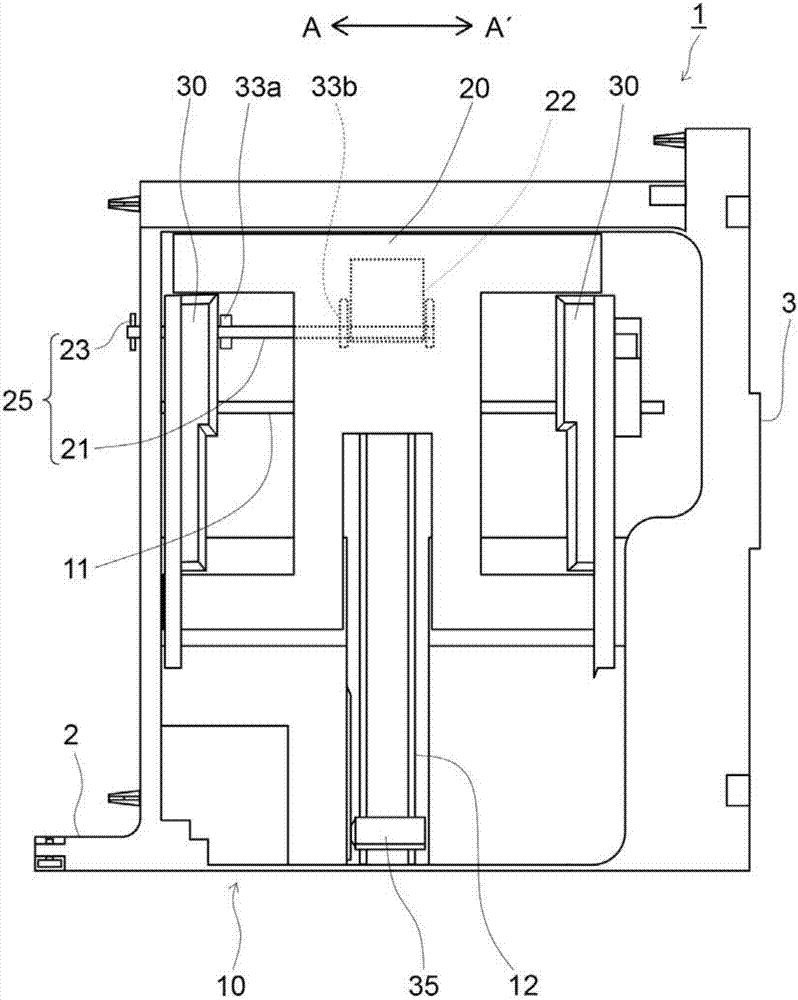

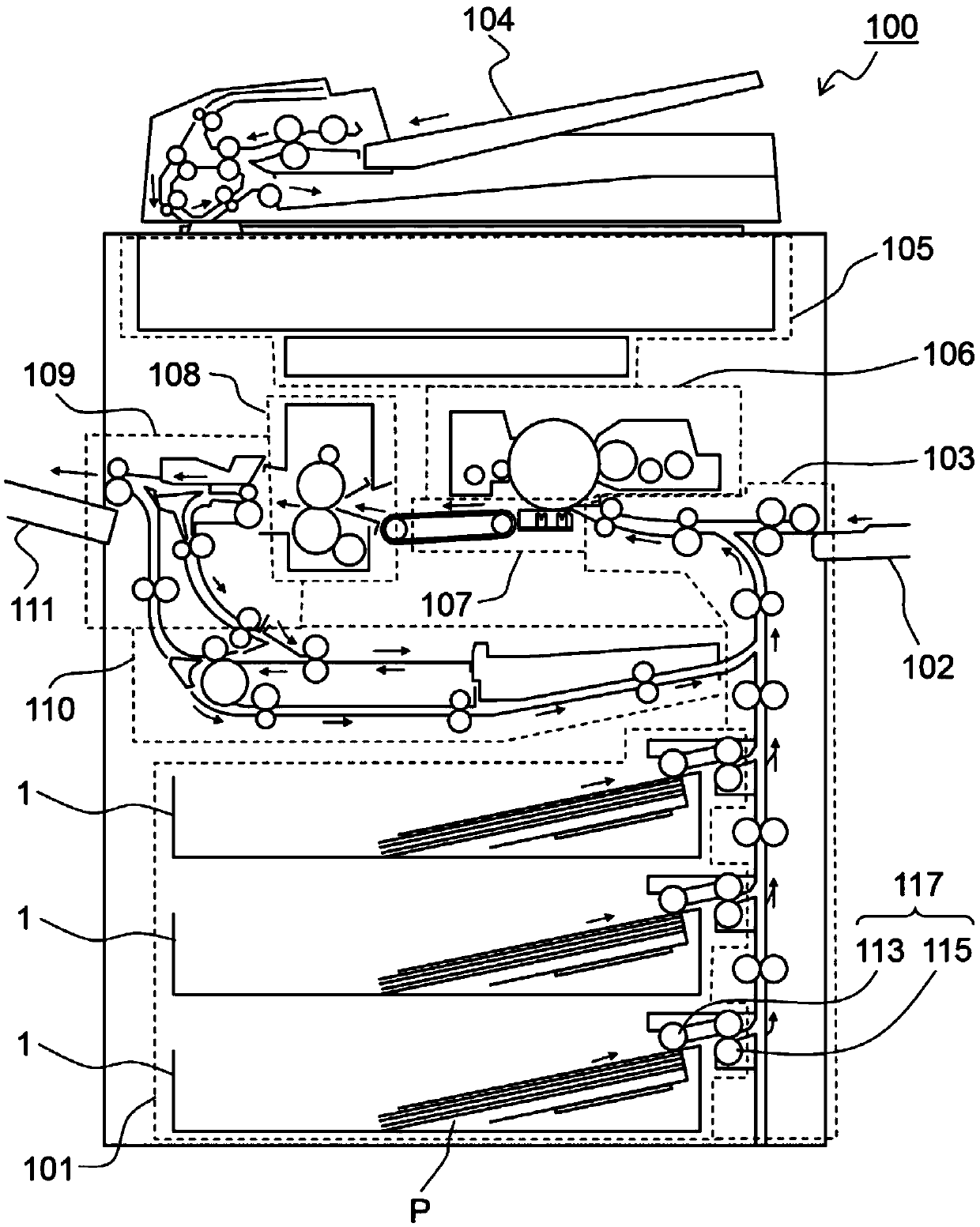

Coupling mechanism, and sheet feed device and image forming apparatus including same

ActiveCN107265148ASuppress abnormal soundsPrevent continuous exposure to loads above the specified valueCouplings for rigid shaftsElectrographic process apparatusEngineeringMechanical engineering

A coupling mechanism of the present disclosure includes a drive transmission member, a coupling member and a biasing member. The drive transmission member includes a shaft portion and an engagement pin. The coupling member includes a plurality of engagement protrusions and a holding protrusion which is smaller than the engagement protrusion. The holding protrusion makes contact with the engagement pin in a state where the engagement pin makes contact with the pressing surface. A load in a reverse rotation direction is applied from the holding protrusion to the engagement pin when the coupling member is reversely rotated.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

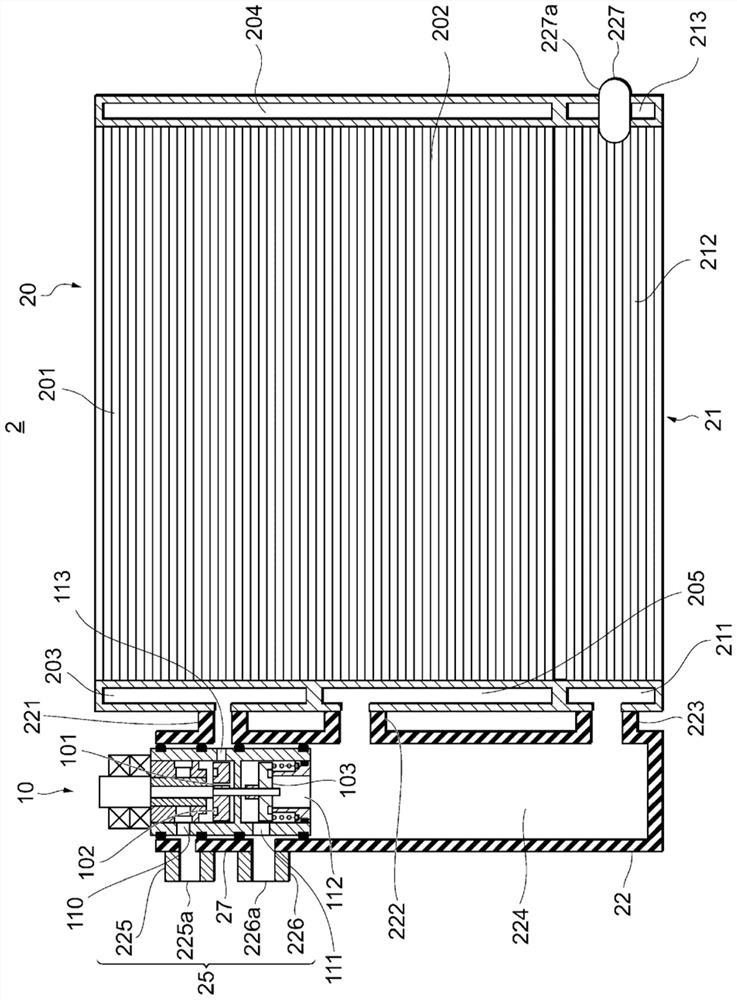

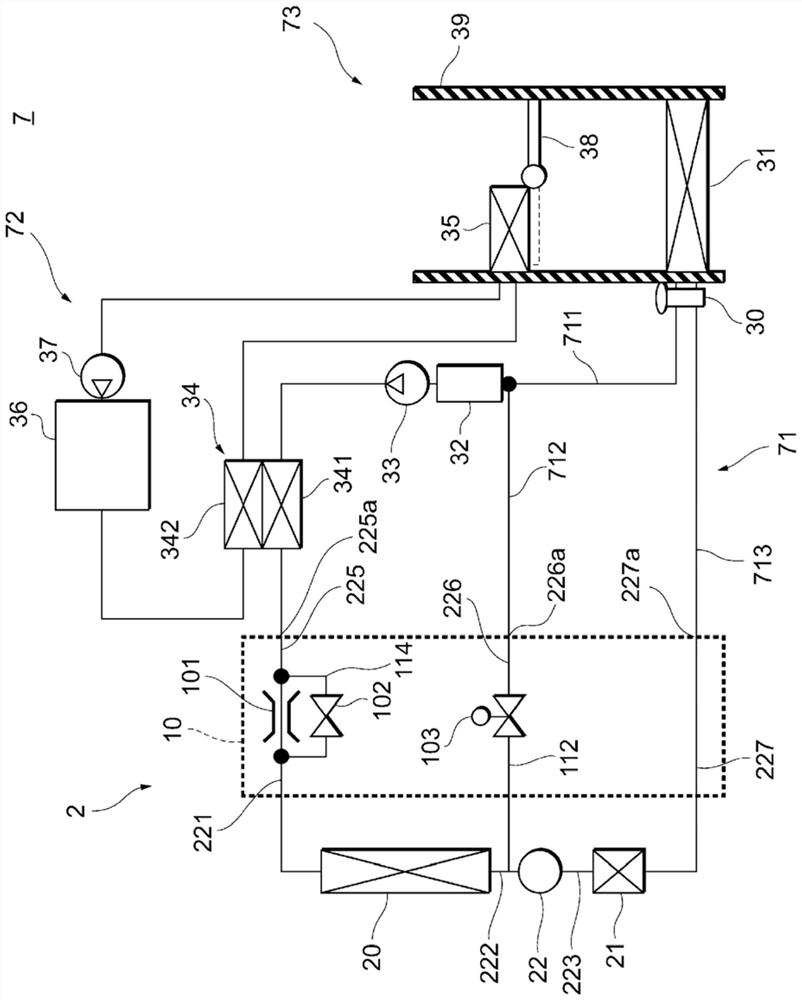

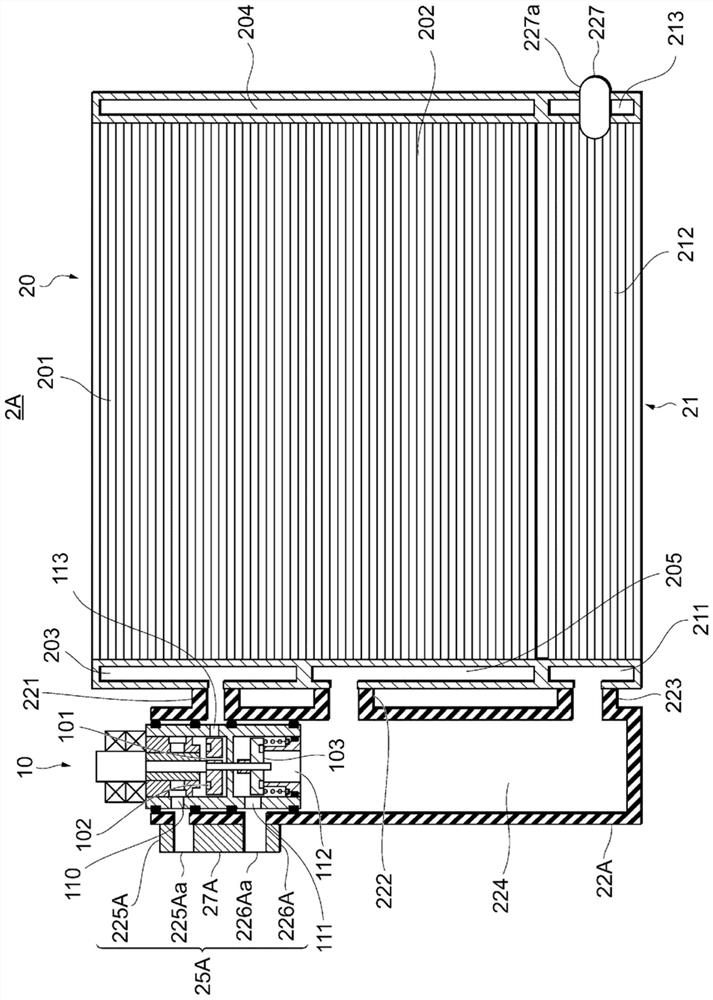

Heat exchanger

ActiveCN111213020APrevent heat transferInhibition of power deteriorationAir-treating devicesCompression machines with several condensersHeat flowEngineering

A heat exchanger is provided with: an inflow port (225a), through which a refrigerant flows in; a cooling flow outlet port (227a), through which the refrigerant flows out when cooling operations are performed; and a warming flow outlet port (226a), through which the refrigerant flows out when warming operations are performed. The ports are disposed such that the distance between the inflow port (225a) and the warming flow outlet port (226a) is shorter than the distance between the inflow port (225a) and the cooling flow outlet port (227a).

Owner:DENSO CORP

Rotary force transmission control mechanism and seat structure

ActiveCN107074129BAvoid displacementReduce loosenessGearingLimiting/preventing/returning movement of partsTransfer mechanismControl theory

The present invention more reliably suppresses output-side displacement than conventional mechanisms. The present invention is provided with a rotation control unit 120 that maintains a locked state when an input torque rotating a transfer mechanism 110 is not applied, and releases the locked state when the transfer mechanism 110 rotates. The rotation control unit 120 has an internal gear 124 and lock plates 123 that include outer teeth that can engage with inner teeth of the internal gear 124. When an input torque is not applied, the inner teeth of the internal gear 124 engage with the outer teeth of the lock plates 123, and when the transfer mechanism 110 is rotated, engagement between the inner teeth and the outer teeth is released. Thus, even when torque is applied from the output unit side, engagement between the inner teeth and the outer teeth is not released by the torque.

Owner:DELTA TOOLING CO LTD

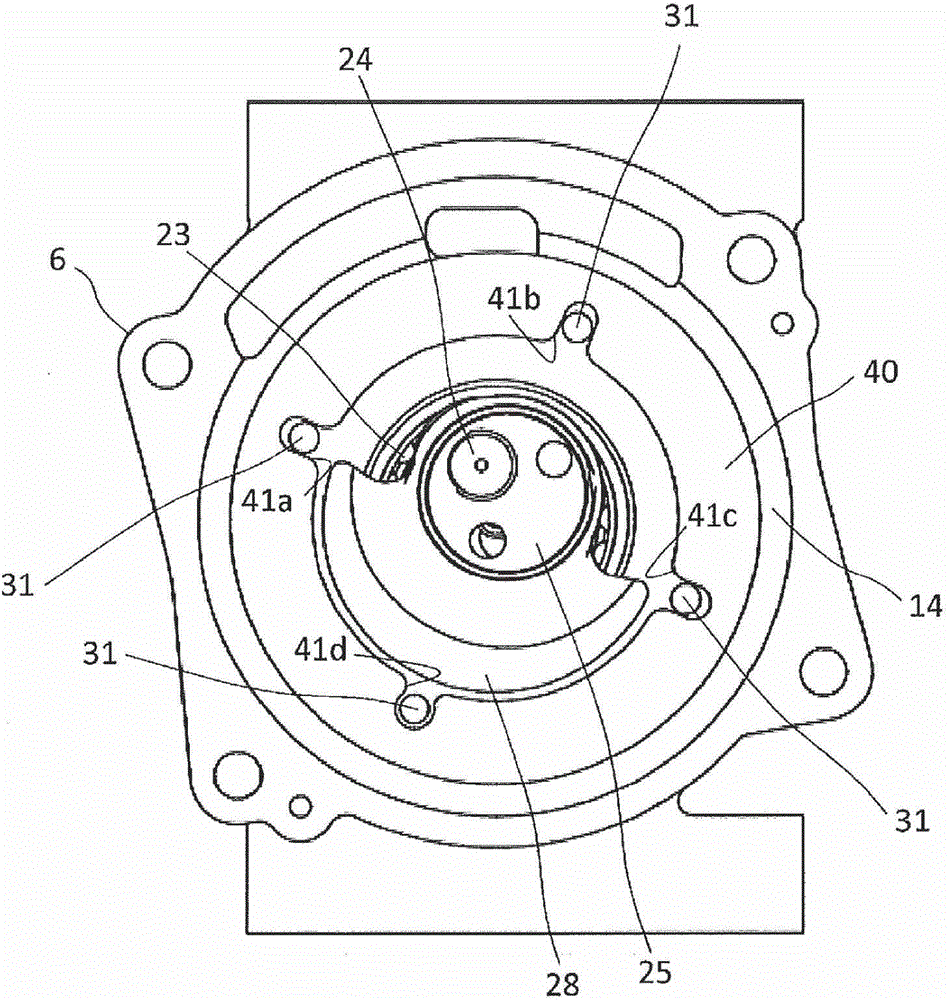

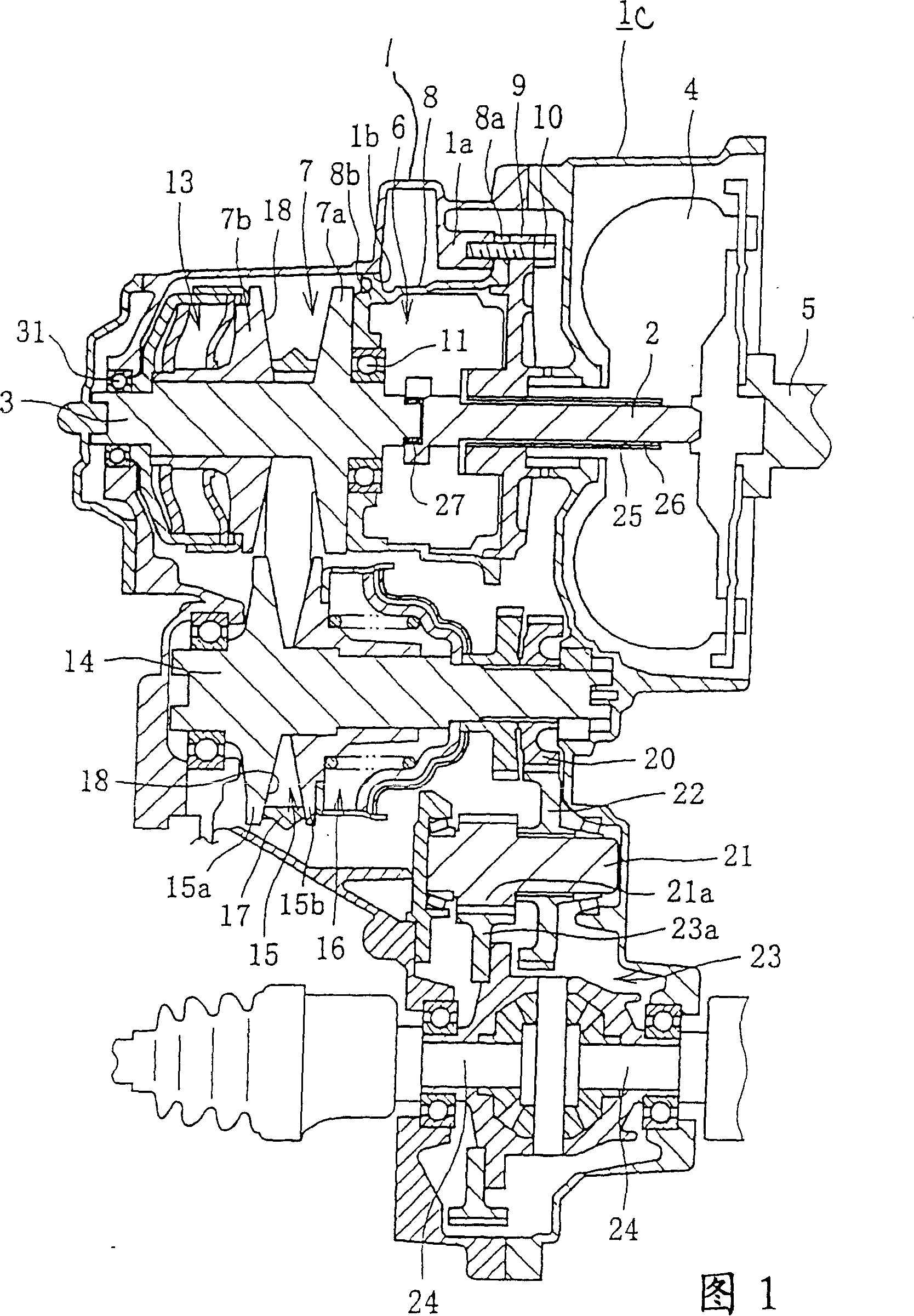

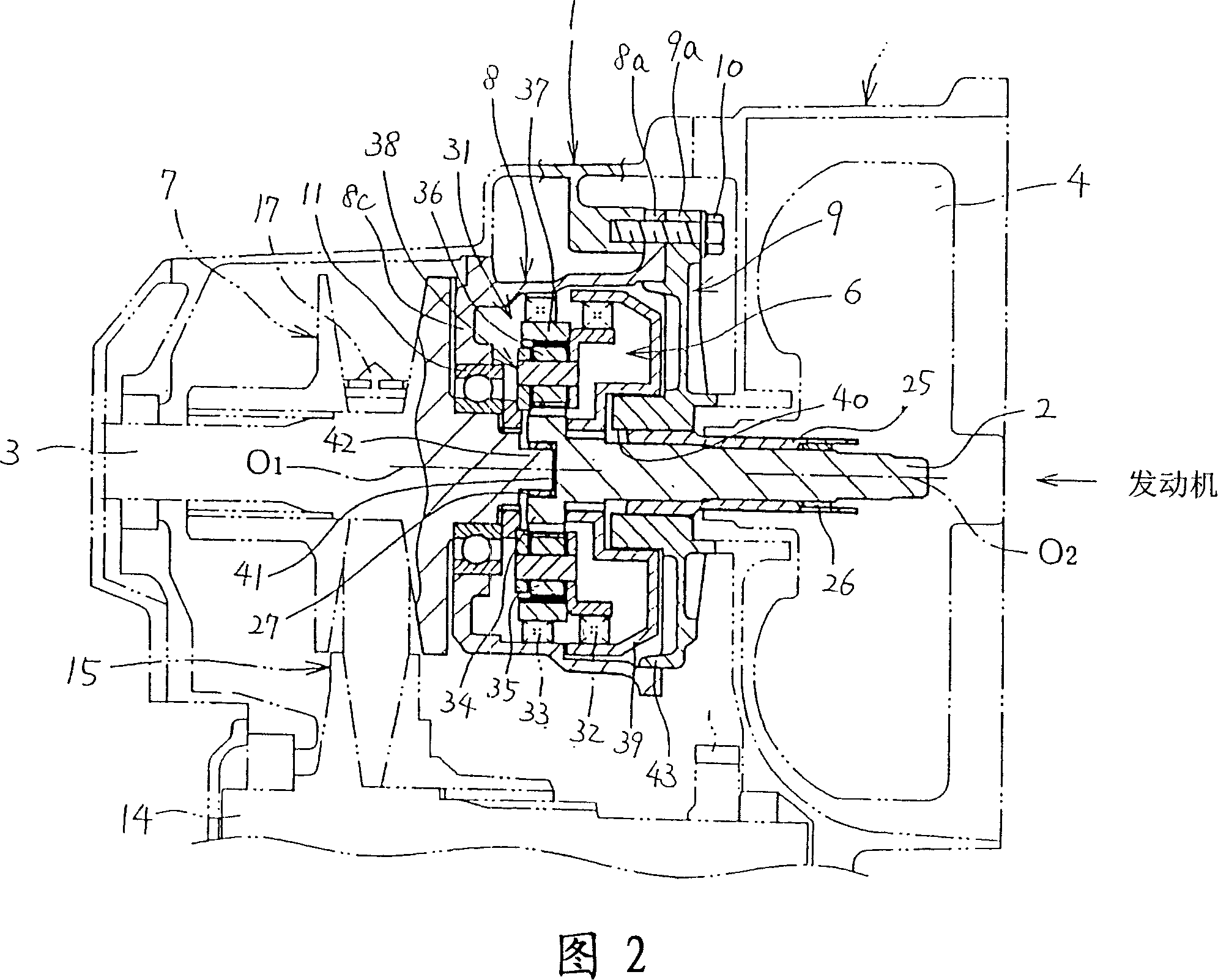

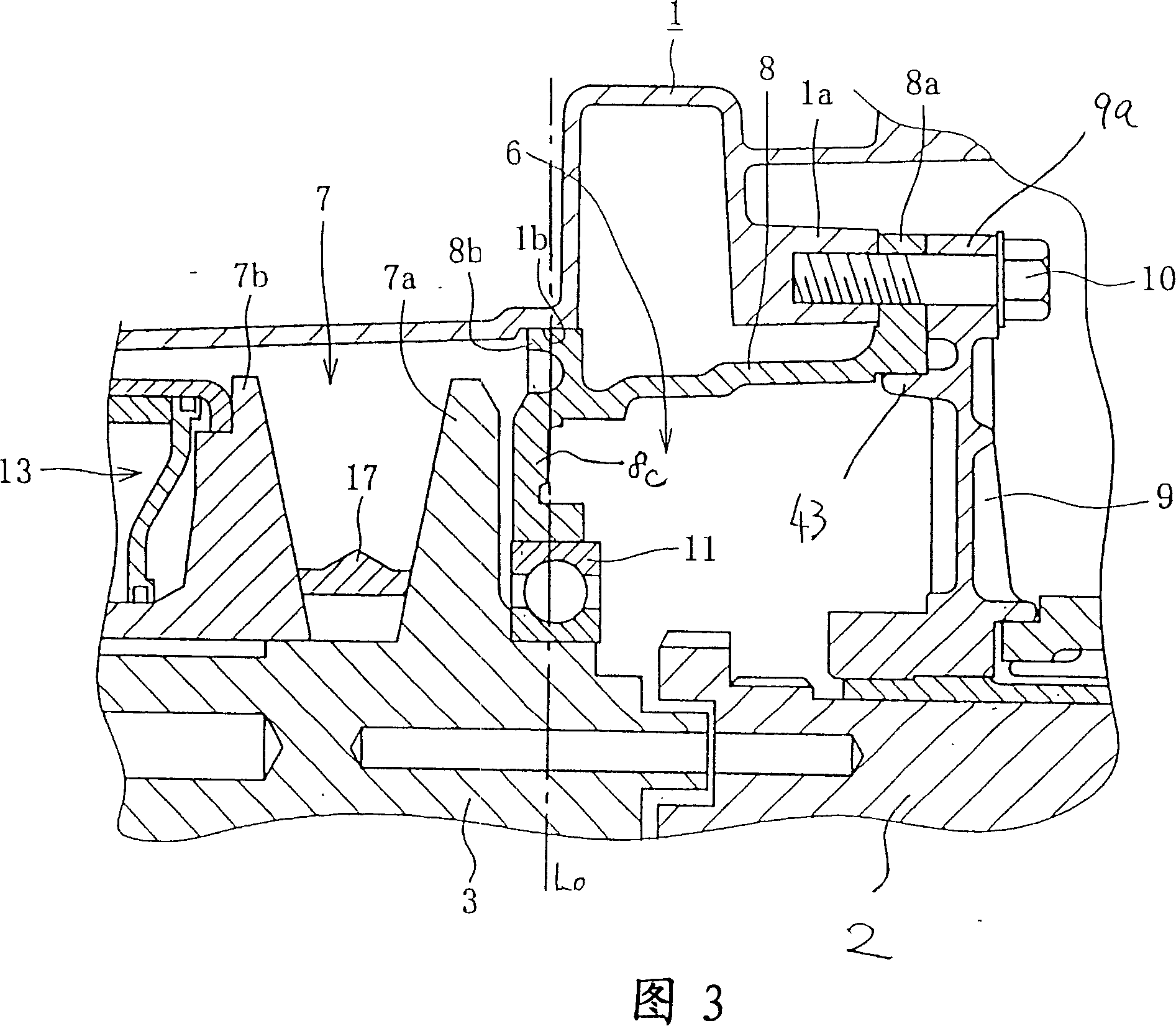

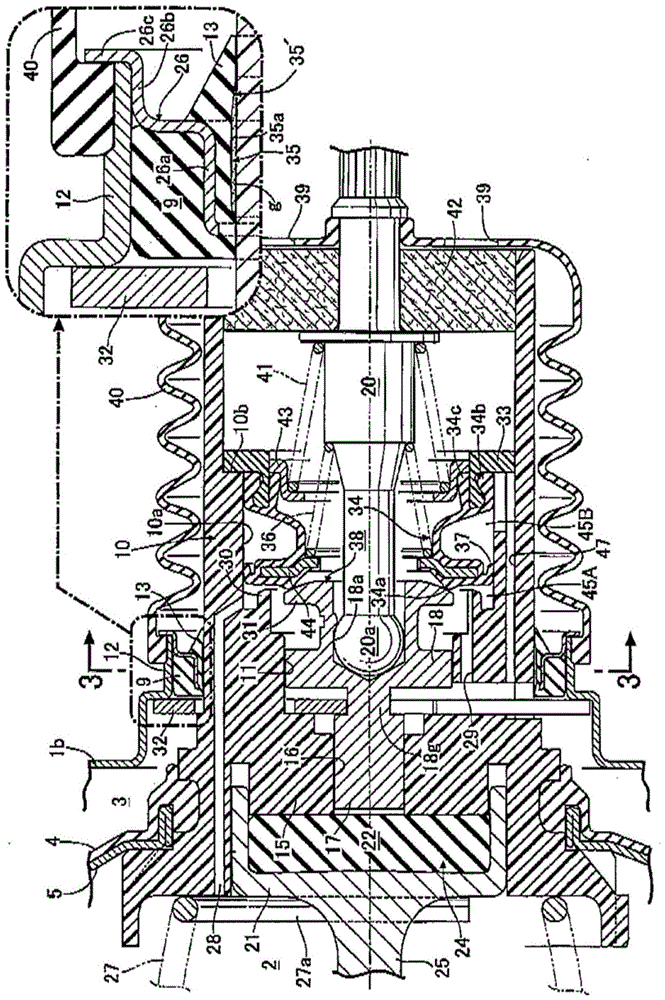

Continuously variable transmission

A forward-speed / reverse-speed changeover mechanism 6, serving as a motive-force connection / disconnection mechanism, is accommodated into a housing member 8 fixed to a casing 1. To the forward-speed / reverse-speed changeover mechanism 6 an input end of a primary shaft 3 is connected. The housing member 8 rotatably supports the primary shaft 3 via a bearing member 11. On an imaginary line intersecting the primary shaft 3 perpendicularly and passing through the bearing member 11, a load-receiving element 1b, 8b is provided between the housing member 8 and the casing 1. The tension of a belt 17 is received by the load-receiving element 1b, 8b. As a result, it is possible to provide a bearing structure of a continuously variable transmission enabling holding the bearing members of the primary and secondary shafts at their regular positions against the tension of the belt and maintaining an optimum belt-alignment, thereby enhancing the durability of the continuously variable transmission.

Owner:MITSUBISHI MOTORS CORP

Coupling mechanism, sheet supply device and image forming device

ActiveCN107265148BSuppress abnormal soundsPrevent continuous exposure to loads above the specified valueCouplings for rigid shaftsElectrographic process apparatusEngineeringMechanical engineering

A coupling mechanism of the present disclosure includes a drive transmission member, a coupling member and a biasing member. The drive transmission member includes a shaft portion and an engagement pin. The coupling member includes a plurality of engagement protrusions and a holding protrusion which is smaller than the engagement protrusion. The holding protrusion makes contact with the engagement pin in a state where the engagement pin makes contact with the pressing surface. A load in a reverse rotation direction is applied from the holding protrusion to the engagement pin when the coupling member is reversely rotated.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

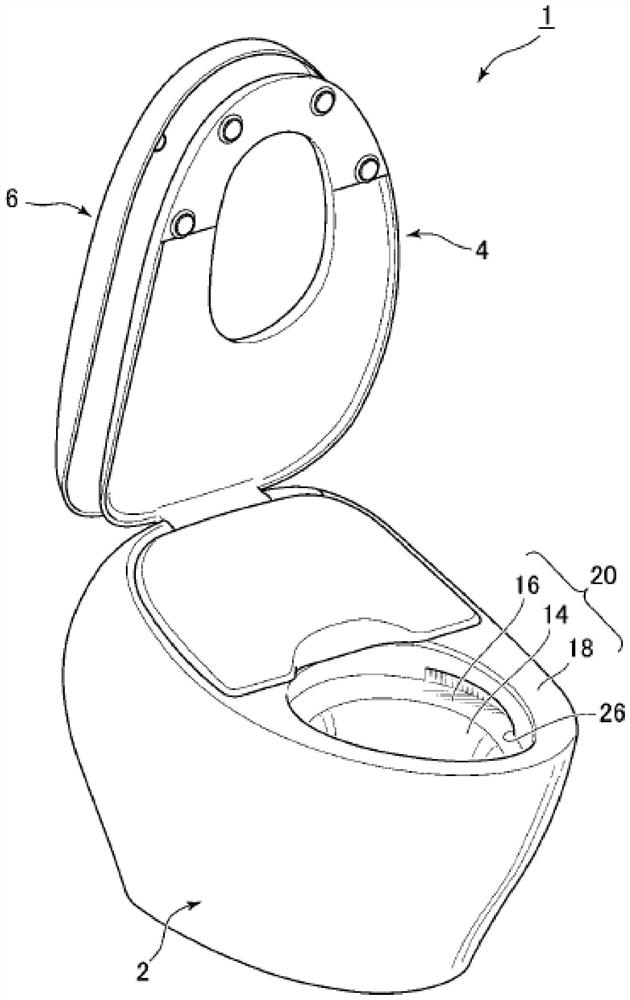

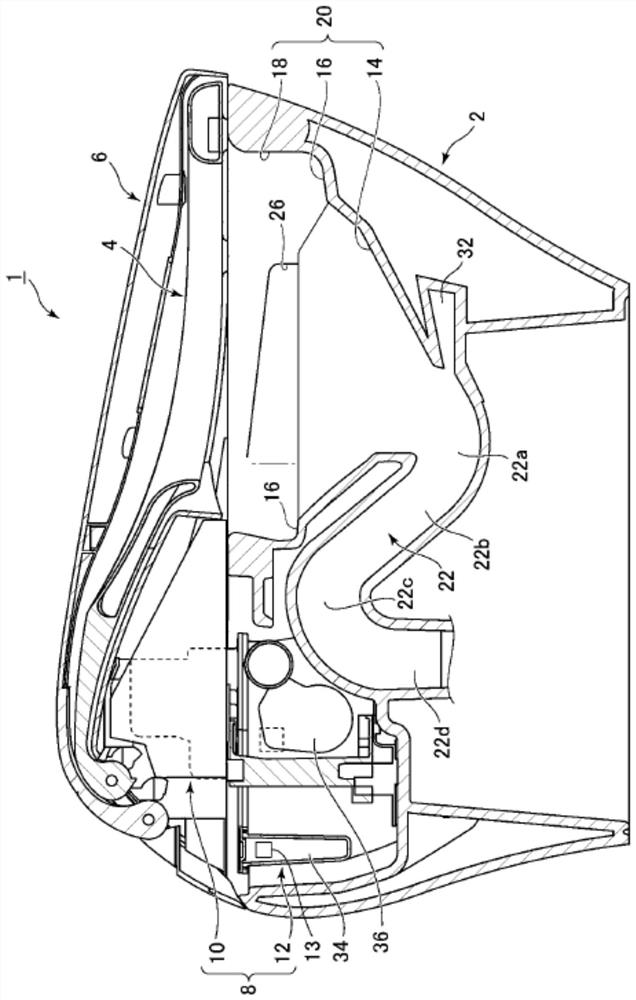

flush toilet

ActiveCN109469177BSuppress abnormal soundsImprove mute effectWater closetsEnvironmental engineeringFlush toilet

The present invention provides a flush toilet capable of suppressing generation of abnormal noise and improving quietness when discharging cleansing water from an inner edge spout together with air accumulated in the inner upper portion of an inner edge water guide. The flush toilet of the present invention comprises: a basin portion (20), a basin-shaped dirt receiving surface (14) and an inner edge portion (18) formed on the upper edge of the dirt receiving surface; an inner edge spout (26) ), spit cleaning water from the inner edge to the basin; the inner edge water guide (24), extends from the rear side area of the basin to the inner edge water spout in the inner edge; and the stirring unit (44), disturbs the inner The cleaning water in the water guide channel (24).

Owner:TOTO LTD

Glass plate structure, vibrating plate, opening member, and glass substrate for magnetic recording medium

ActiveCN109076288BGood reproducibilityNot easy to resonateRecord carriersBase layers for recording layersLongitudinal waveEngineering

A glass plate structure with a loss coefficient of 1×10 ‑2 above, and the longitudinal wave sound velocity value in the thickness direction is 5.5×10 3 m / s or more.

Owner:ASAHI GLASS CO LTD

Motors, Motor Units, and Analog Display Units

InactiveCN104901506BNot easy to vibrateSuppress abnormal soundsDynamo-electric machinesDisplay deviceMagnet

The invention provides a motor capable of restraining a rotor to radially vibrate, a motor device with the motor and a pointer type display device. In the motor, coils are configured at the respective periphery of two salient poles (61f, 61b) (main poles) arranged in a first angle region (theta1) less than 180 degrees among a plurality of salient poles (61) of a stator iron core. And the salient poles (61c to 61e) in a second angle region (theta2) of 180 degrees among the plurality of salient poles (61) are first assisting poles which are not provided with coils at the periphery. At the opposite side to the two main poles (the salient poles 61f, 61b) side, the second angle region (theta2) takes an extension line of two bisectrixes as a center. The bisectrixes divide the first angle region (theta1) into two equal parts. A first interval (g1) between the main poles (the salient poles 61f, 61b) and a magnet is narrower than a second internal (g2) between the first assisting poles (the salient poles 61c to 61e) and the magnet.

Owner:SANKYO SEIKI MFG CO LTD

glass plate structure

ActiveCN110313185BGood reproducibilityGuaranteed StrengthTransportation and packagingGlass/slag layered productsLiquid layerStructural engineering

A glass plate structure comprising at least two plates and a liquid layer held between the two plates, wherein at least one of the two plates is a glass plate. In the glass plate structure, the end faces of the two plates are shifted to form a step-like height difference in cross-sectional view, and there is also a seal provided to seal at least the liquid layer in the height difference. Material.

Owner:AGC INC

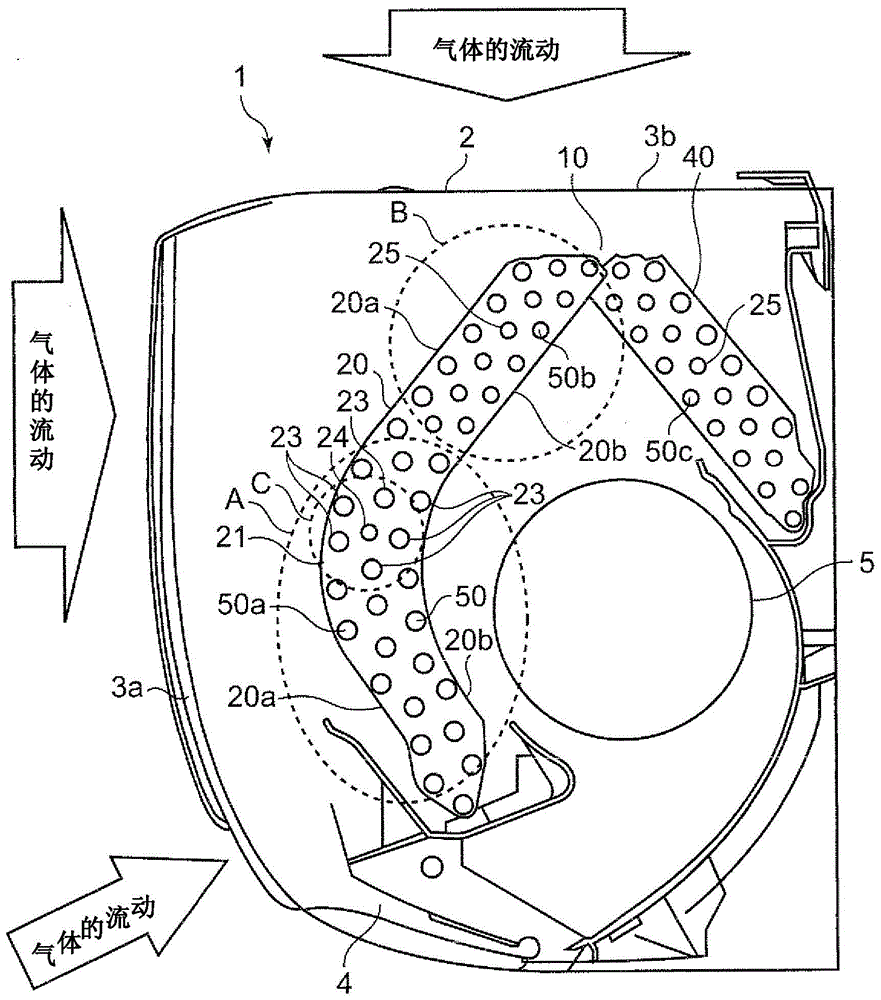

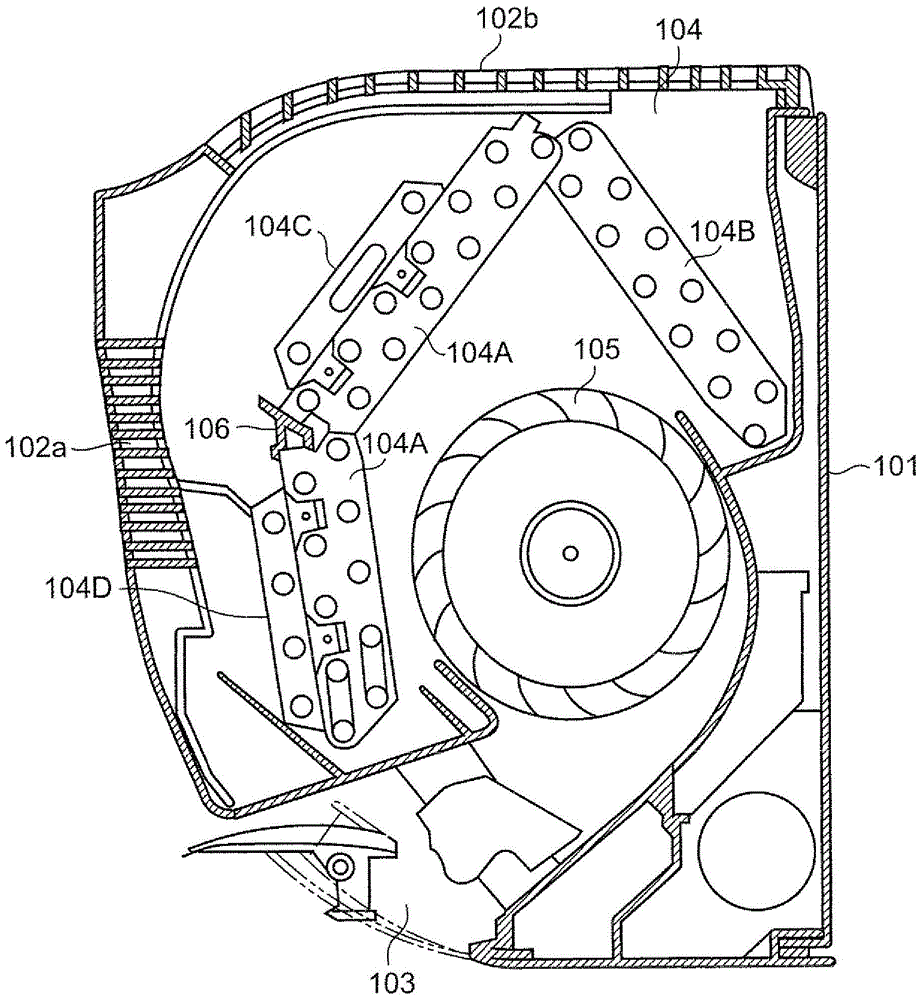

finned heat exchanger

ActiveCN103765149BUniform distribution of wind speedSuppress abnormal soundsSpace heating and ventilation detailsAir conditioning systemsEngineeringRefrigerant

The finned heat exchanger of the present invention, in order to substantially uniformize the wind speed distribution of the heat exchanger and improve heat exchange performance, includes a heat transfer tube (50) through which refrigerant flows and a plurality of first heat transfer tubes inserted into the heat transfer tubes. A stack of fins (21) of a fin collar (23), a plurality of first fin collars are arranged in a plurality of rows along a direction substantially orthogonal to the flow direction of the gas, and second fin collars that are not inserted into the heat transfer tube The fin collars (24) are arranged between the first fin collars arranged in multiple rows.

Owner:PANASONIC CORP

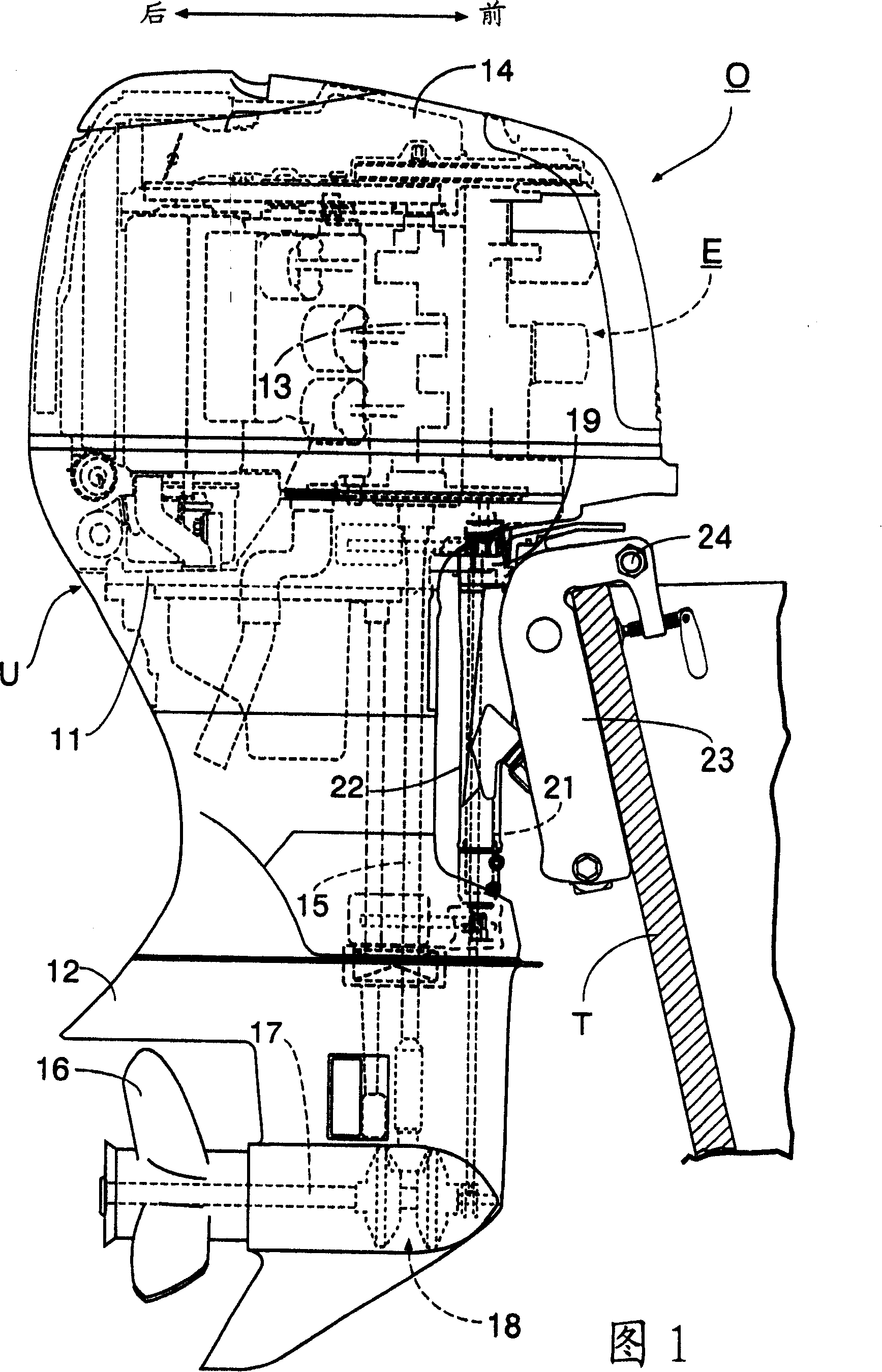

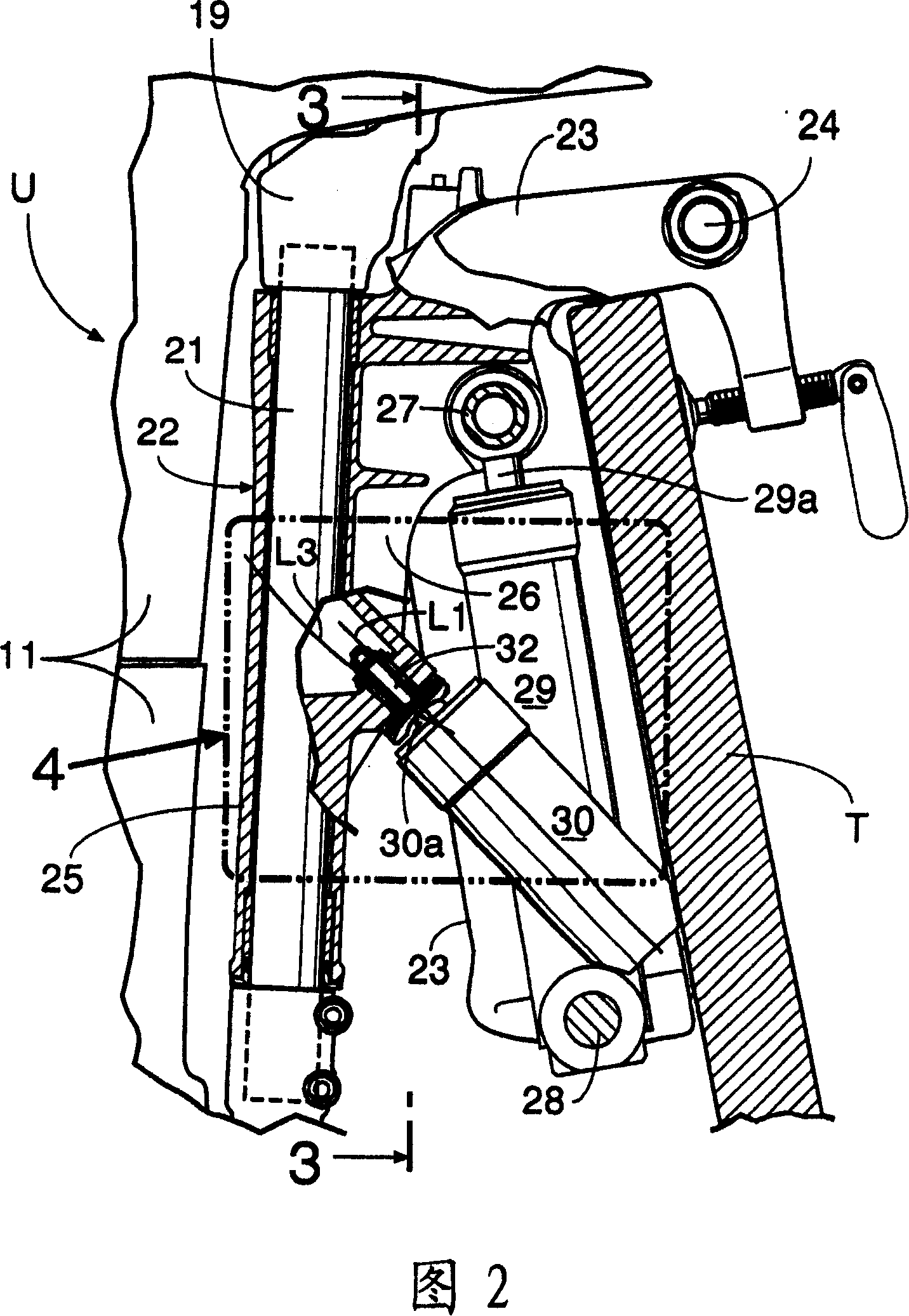

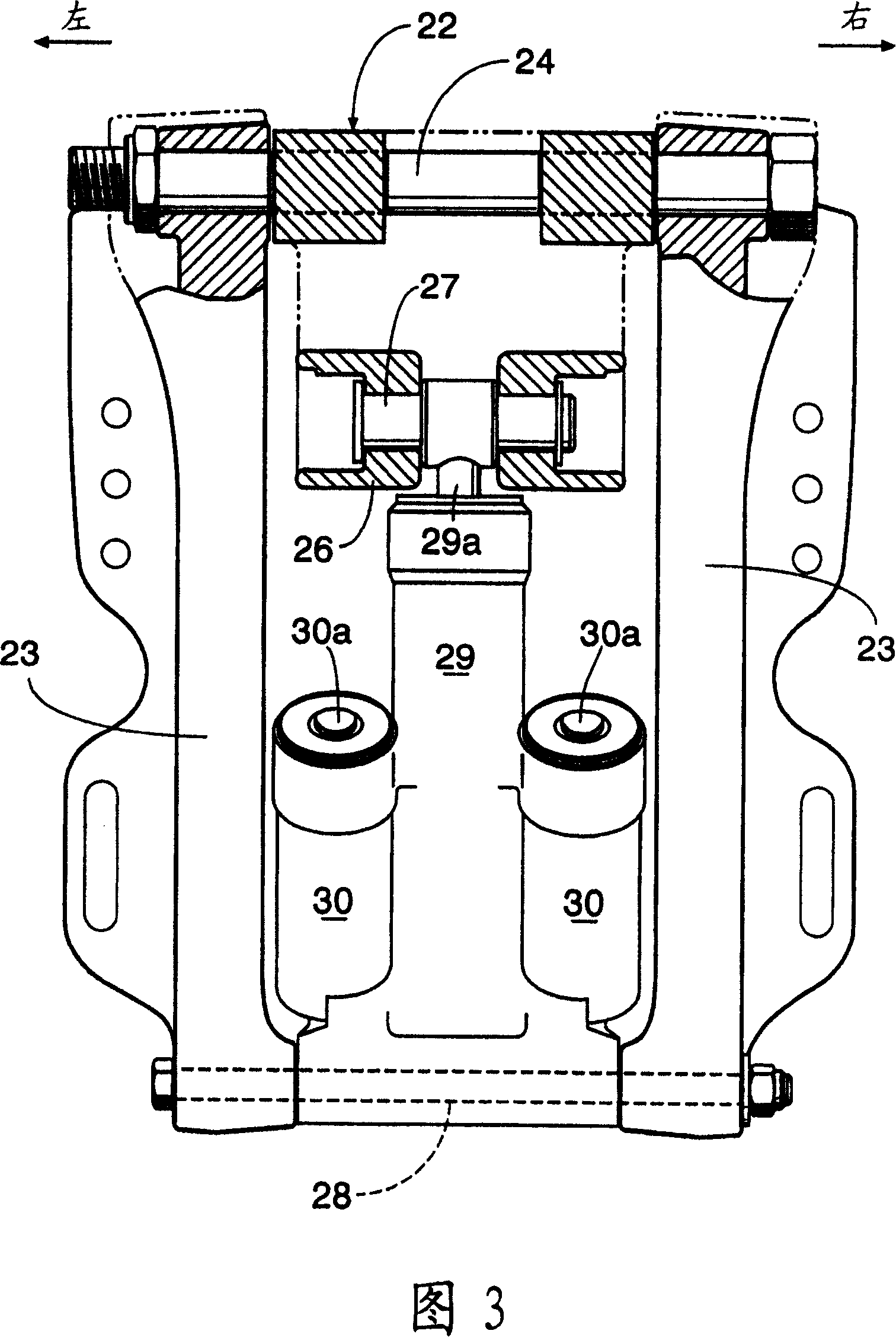

Outboard engine system

InactiveCN100374353CReduce abnormal soundTorsion MinimizationPropulsion power plantsOutboard propulsion unitsAbutmentLubricant

A thrust receiver abuts against an expandable and contractable trim rod to adjust a trim angle of a body of an outboard engine system. The thrust receiver includes a shaft portion rotatable about an axis generally parallel to an axis of the trim rod, and a pressure-receiving portion provided on the shaft portion to abut against a tip end of the trim rod. An abutment point between the trim rod and the pressure-receiving portion is displaced by a distance from an axis of the shaft portion in a lateral direction of the system body. Because the pressure-receiving portion of the thrust receiver rotates about the axis of the shaft portion accompanying the expansion and contraction of the trim rod, a twisting generated at the abutment point can be minimized to suppress generation of an abnormal sound. Moreover, the structure can be simplified to contribute to a reduction in cost, as compared with a system in which a ball is disposed at an abutment point.

Owner:HONDA MOTOR CO LTD

Elevator door device

InactiveCN101132984BReduced opening and closing resistanceSuppress abnormal soundsBuilding liftsEngineeringMechanical engineering

A door device for an elevator, in which a flexible air-tight member (6) extended in the opening / closing direction (A) of a door body (1b) is attached to the door body (1b) so as to be in pressed contact with a floor-side surface (4b) and, as the door (1) is opened and closed, the air-tight member (6) slides on the floor-side surface (4b) while being in pressed contact with the floor-side surface (4b). A low friction section (6b) is formed on that surface (6a) of the air-tight member (6) with which the floor-side surface (4b) is in pressed contact.

Owner:MITSUBISHI ELECTRIC CORP

Motor, motor device and pointer display device

InactiveCN104901507BNot easy to vibrateSuppress abnormal soundsDynamo-electric machinesDisplay deviceAuxiliary electrode

The present invention provides a motor capable of suppressing radial vibration of a rotor, a motor device having the motor, and a pointer display device. In the motor, coils are respectively arranged around two salient poles (61f, 61b) (main poles) located in a first angular range (θ1) smaller than 180° among a plurality of salient poles of the stator core. And, the salient poles (61c to 61e) located in the second angle range (θ2) of 180° among the plurality of salient poles become the first auxiliary poles without coils arranged around them. The side opposite to the side where the two main poles (61f, 61b) are located is centered on the extension of an imaginary bisector that bisects the first angle range (θ1). The structure of the air gap between the main poles (61f, 61b) and the magnet is different from the structure of the air gap between the first auxiliary poles (61c to 61e) and the magnet.

Owner:SANKYO SEIKI MFG CO LTD

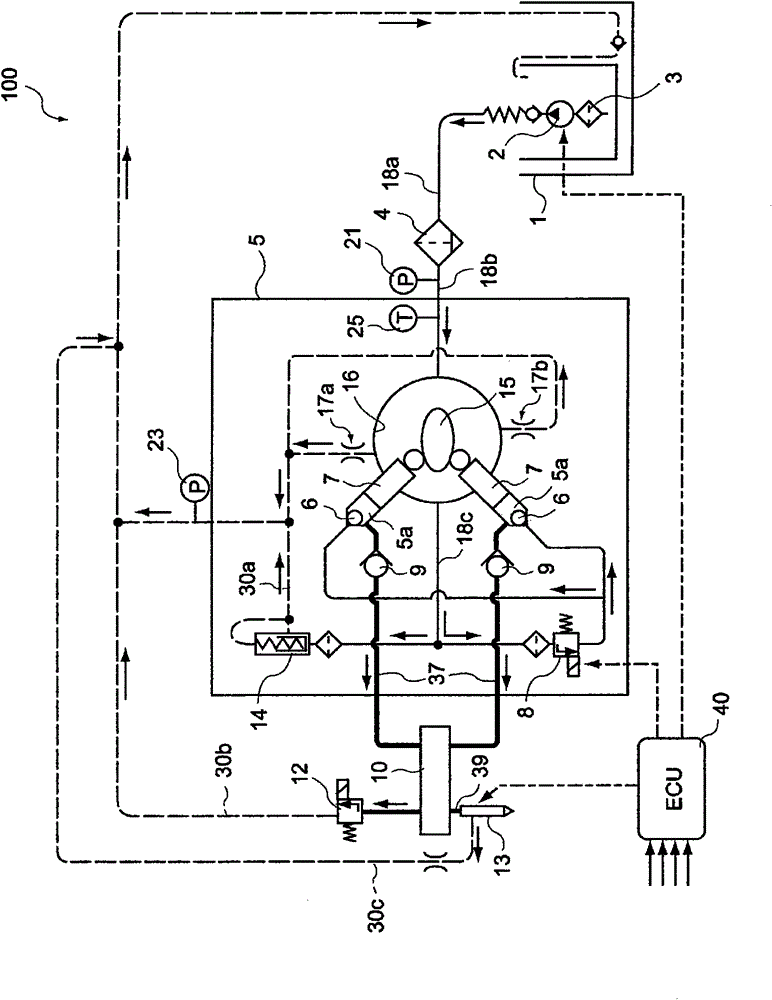

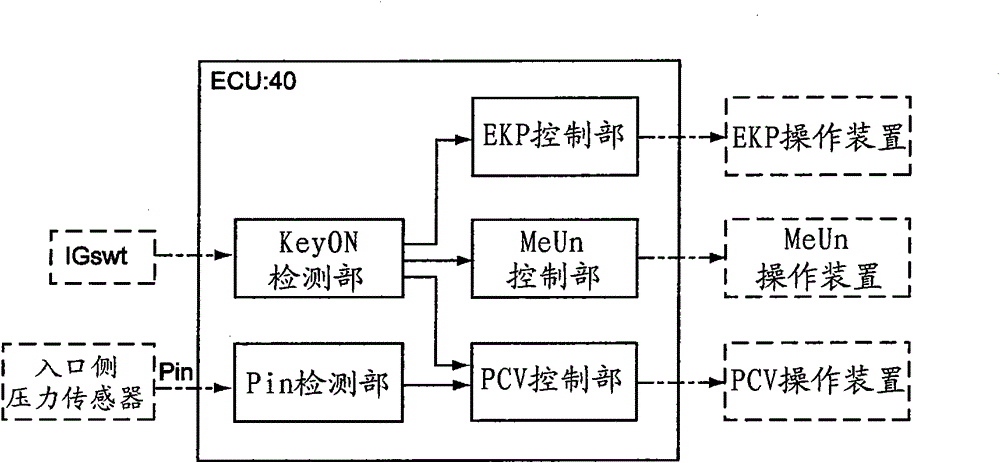

Fuel supply device for internal combustion engine and control device for fuel supply device

InactiveCN101910612BInhibitionReduce loadElectrical controlMachines/enginesExternal combustion engineInternal combustion engine

A fuel supply apparatus of an internal combustion engine is provided which can discharge air bubbles or air from within fuel supply paths while increasing pressure within a common rail up to a predetermined pressure level before a start of the internal combustion engine, can reduce a period of time of cranking from when an ignition switch is switched on and which can reduce noise that occurs when the air bubbles or air are being discharged. The fuel supply apparatus is provided with a flow rate control valve that adjusts a flow rate of fuel supplied to the common rail and a pressure control valve that reduces the pressure within the common rail. The fuel supply apparatus is further provided with: a pre-start drive control portion that performs a pre-start drive of an electromagnetic low pressure pump before the start of the internal combustion engine; a flow rate control valve control portion that maintains the flow rate control valve in an open state while the pre-start drive is being performed; and a pressure control valve control portion that maintains the pressure control valve in a closed state and performs a control that opens the pressure control valve at least once for a short time period while the pre-start drive is being performed.

Owner:BOSCH CORP

Motor, Motor device and pointer type display device

InactiveCN104901506ANot easy to vibrateSuppress abnormal soundsDynamo-electric machinesDisplay deviceMagnet

The invention provides a motor capable of restraining a rotor to radially vibrate, a motor device with the motor and a pointer type display device. In the motor, coils are configured at the respective periphery of two salient poles (61f, 61b) (main poles) arranged in a first angle region (theta1) less than 180 degrees among a plurality of salient poles (61) of a stator iron core. And the salient poles (61c to 61e) in a second angle region (theta2) of 180 degrees among the plurality of salient poles (61) are first assisting poles which are not provided with coils at the periphery. At the opposite side to the two main poles (the salient poles 61f, 61b) side, the second angle region (theta2) takes an extension line of two bisectrixes as a center. The bisectrixes divide the first angle region (theta1) into two equal parts. A first interval (g1) between the main poles (the salient poles 61f, 61b) and a magnet is narrower than a second internal (g2) between the first assisting poles (the salient poles 61c to 61e) and the magnet.

Owner:SANKYO SEIKI MFG CO LTD

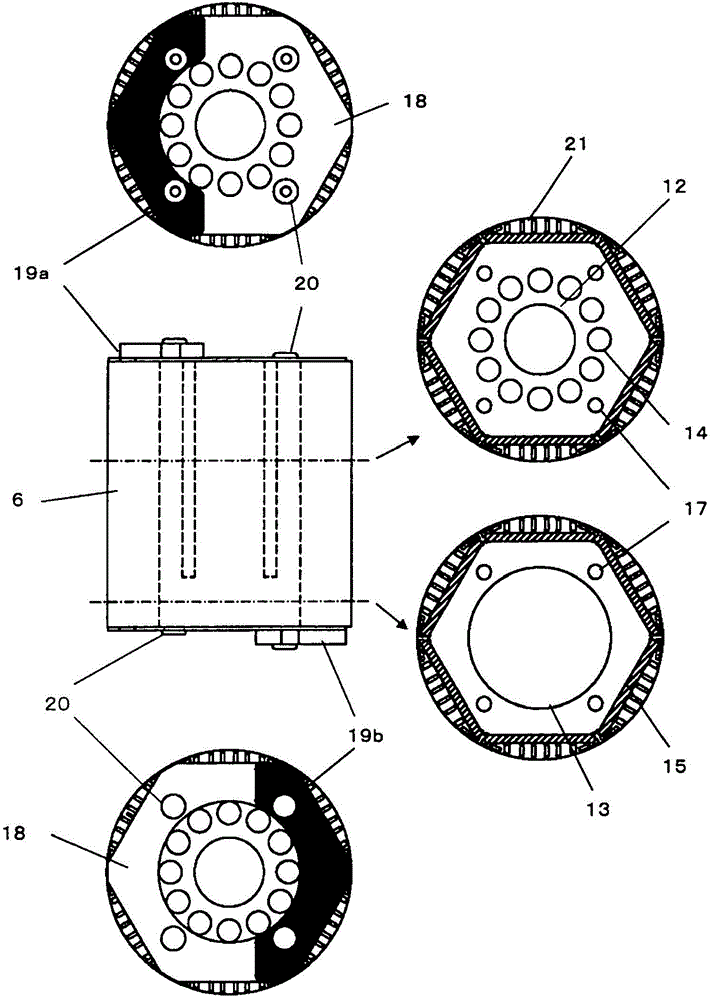

Torque restrictor

The present invention provides a spring type torque limiter capable of preventing vibration and noise when used by increasing the rigidity of both end parts of a coil spring. Inclination angles are provided on side faces of an outer ring member projecting part (12) and a cover member projecting part (18) on which the both end parts of the coil spring (4) fitted on an outer diameter face of an inner ring (2) abut, respectively, so as to restrict movement of the both end parts to the outer diameter direction. This enhances the rigidity and suppresses vibration and noise of the coil spring (4).

Owner:NTN CORP

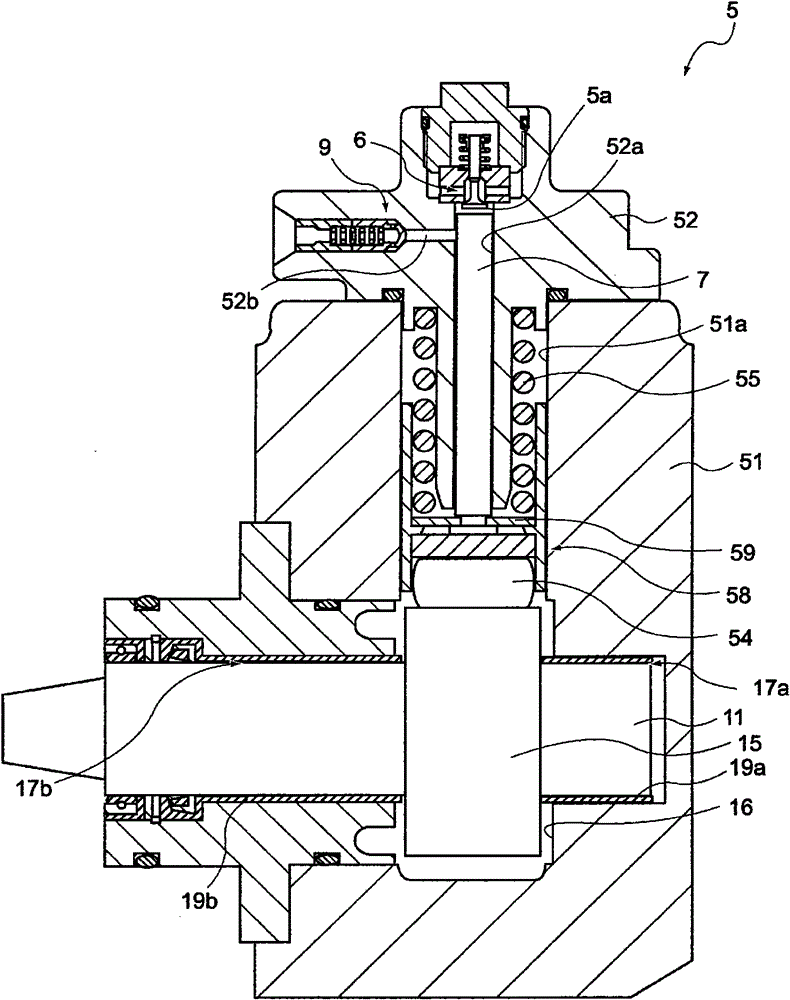

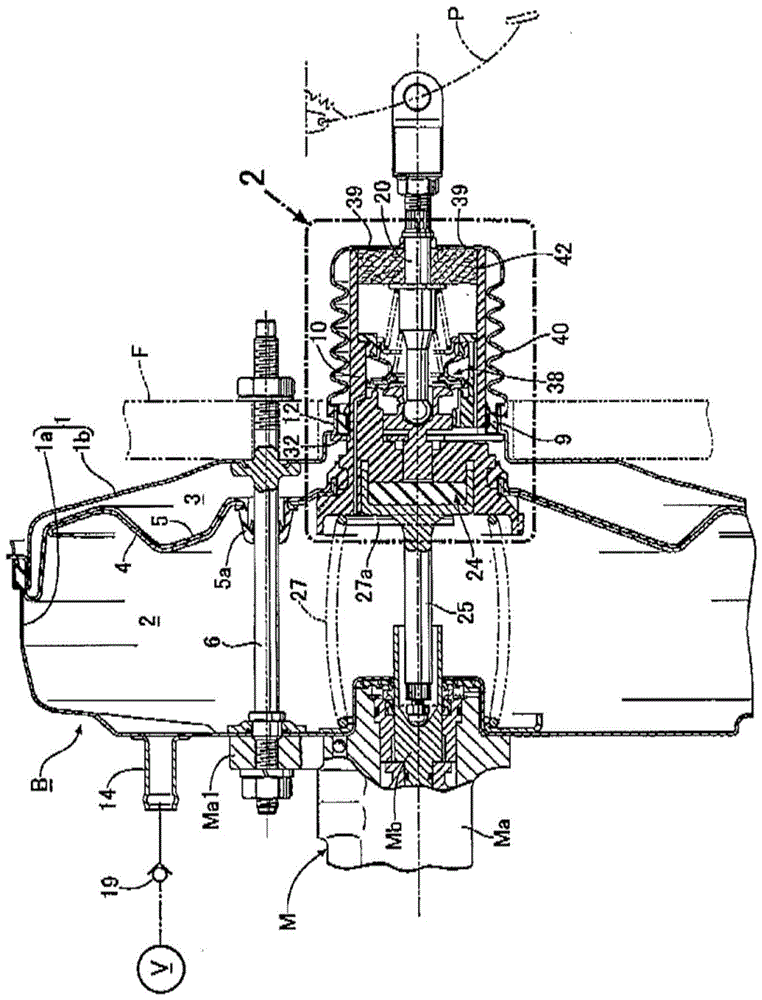

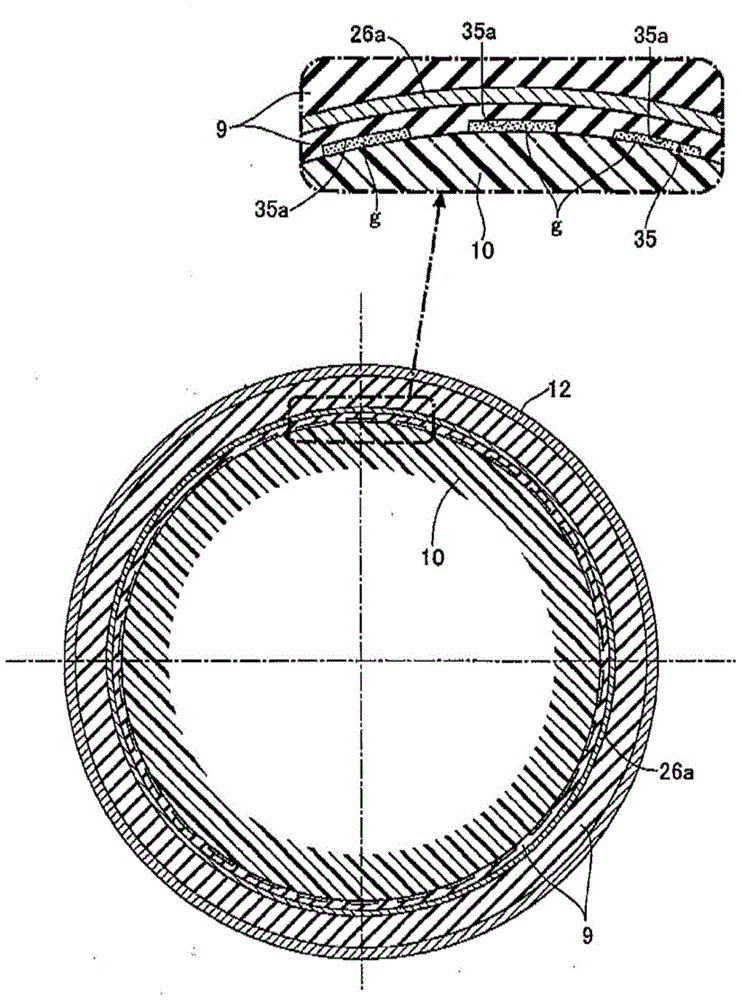

Negative pressure booster

ActiveCN103723136BPrevent stick-slipSuppress abnormal soundsEngine sealsBraking action transmissionMechanical engineeringVacuum chamber

The invention provides a negative pressure supercharger that can prevent the stick-slip phenomenon of the sealing lip, ensure the smooth sliding of the valve cylinder, and prevent the generation of abnormal sounds. The negative pressure supercharger of the present invention installs a bearing sleeve (9) made of elastic material in the bearing sleeve (12) provided on the rear wall of the supercharger housing (1), which is in contact with the supercharger piston (5) The outer circumferential surface of the connected valve cylinder (10) is slidably supported, and a grease storage tank (35) for holding grease (g) is provided on the inner circumferential surface of the bearing sleeve (9). In addition, the bearing sleeve (9) The rear end of (9) is integrally connected with a sealing lip (13) whose wall thickness is thinner than the sealing lip (13) and elastically tightly connected with the outer circumferential surface of the valve cylinder (10). The inner circumferential surface of the sealing lip (13) is provided with a sealing lip (13). There is an extended grease reservoir (35') in continuous communication with the grease reservoir (35) and holding grease (g) common to the grease reservoir (35).

Owner:AUTOLIV NISSIN BRAKE SYST JAPAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com